I recently saw a major restaurant renovation halted because of a chronic drain clog. The problem? A standard tee fitting that trapped debris. This common issue shows why smart fitting choice matters.

A sweep tee is ideal for waste systems because its curved, smooth interior design guides waste and water around corners with minimal flow disruption. This reduces turbulence, prevents solids from catching on sharp edges, and significantly lowers the risk of clogs and backups, ensuring reliable drainage.

Let’s look closer at how this simple design change makes a big difference in performance and reliability.

How Does a Sweep Tee Improve Drainage Efficiency in Waste Piping Systems?

Slow drains frustrate everyone. In commercial kitchens I’ve worked with, poor drainage can even shut down operations.

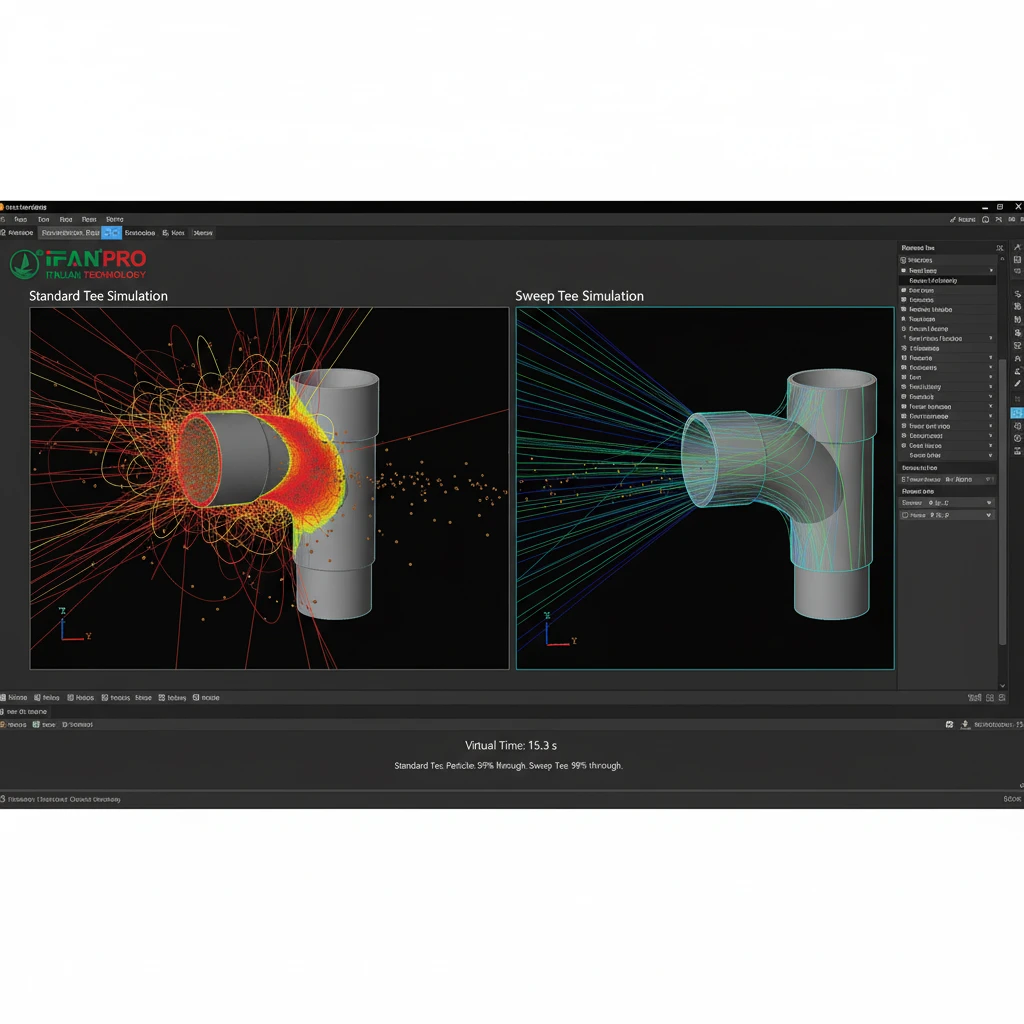

A sweep tee improves drainage efficiency by providing a smooth, gradual path for waste to flow. Unlike a standard tee with a sharp 90-degree turn, the sweep tee’s curved radius reduces resistance and turbulence. This allows water and solids to maintain more speed and momentum, leading to faster and more complete waste removal from the system.

The Problem with Sharp Turns

To understand efficiency, we need to talk about flow dynamics. In any pipe system, changes in direction create resistance. Think of it like driving a car. Taking a sharp turn at high speed is difficult and slow. Taking a gentle, curved turn is smooth and fast. The same principle applies to wastewater.

A standard sanitary tee forces water and solids to make an abrupt 90-degree turn. This sudden change has several negative effects:

- Turbulence: The flow becomes chaotic and “bumpy” inside the fitting.

- Velocity Loss: The water and waste slam into the opposite wall of the fitting, losing speed and momentum.

- Solids Separation: Heavier solid particles can’t make the sharp turn easily. They fall out of the water stream and settle in the fitting’s heel.

How the Sweep Design Creates Better Flow

A sweep tee solves these problems with its curved inner radius. This design offers a guided pathway.

- Reduced Resistance: The curve presents less sudden obstruction to the flow.

- Laminar Flow: Water and waste are encouraged to move in smoother, more parallel layers (laminar flow) instead of chaotic turbulence.

- Maintained Momentum: Because the turn is gradual, the flow maintains more of its speed and energy. This higher velocity helps carry solids through the fitting and further down the drain line.

The result is a system that clears itself more effectively with each flush. Less water is needed to move the same amount of waste, and the risk of solids building up at the junction is much lower.

Flow Efficiency Comparison

| Flow Characteristic | Standard Sanitary Tee | Sweep Tee (Long Radius) |

|---|---|---|

| Turn Angle | 90 degrees | 90 degrees (gradual) |

| Internal Design | Sharp, squared-off heel | Smooth, curved radius |

| Flow Type | Highly turbulent | More laminar (smooth) |

| Velocity Loss | High | Low to Moderate |

| Solid Carrying Ability | Poor; solids tend to drop | Good; solids stay suspended |

For anyone managing a property, this efficiency means fewer complaints about slow drains and a system that works reliably under normal use.

Why Does the Curved Design of a Sweep Tee Prevent Clogs and Backups?

Clogs mean emergency plumber calls and unhappy tenants. I’ve traced many backups directly to standard tees filled with accumulated gunk.

The curved design of a sweep tee prevents clogs by eliminating the sharp, flat “heel” inside a standard tee where debris collects. Waste materials like grease, hair, and paper slide along the smooth curve instead of catching and building up. This self-cleaning action stops blockages from forming in the first place.

The Clog-Prone Zone in Standard Fittings

The primary weakness of a standard sanitary tee is its internal geometry. The corner where the branch meets the main run creates a flat, sheltered shelf. This area is called the “heel.”

In a drain line, everything is moving with the water flow. When that flow hits the sharp turn of a standard tee, it loses energy. Grease cools and sticks to the flat surface. Hair and fibrous materials snag on the sharp edge. Food particles and other solids settle in this quiet zone. Over time, these materials combine and build up, slowly narrowing the pipe’s opening until a full clog occurs.

The Self-Cleaning Action of a Sweep

A sweep tee has no flat shelf or sharp edge to catch debris. Its continuous, curved wall acts like a slide.

- No Snag Points: Hair and threads cannot easily catch on a smooth, curved surface.

- Reduced Grease Adhesion: The curved surface offers less ideal conditions for grease to cool and stick compared to a flat shelf.

- Scouring Effect: The maintained water velocity in a sweep tee helps “scour” or clean the inside of the fitting with each use. The flow pushes potential buildup around the bend and down the line.

Think of the difference between sliding down a smooth playground slide versus getting stuck in a corner. The sweep tee is the smooth slide for your waste.

Common Clog Materials and How They Behave

| Clog Material | Behavior in Standard Tee | Behavior in Sweep Tee |

|---|---|---|

| Grease & Fats | Cools and sticks to the flat heel, building up in layers. | More likely to be carried around the curve before fully cooling. |

| Hair & Strings | Snag on the sharp edge at the branch entrance. | Slide along the smooth curve without catching. |

| Food Particles | Settle in the low-velocity zone of the heel. | Stay suspended in the faster, smoother flow. |

| Paper Products | Can get lodged against the sharp corner. | Guided smoothly around the bend. |

By preventing the initial accumulation, the sweep tee breaks the clog cycle. This is especially critical in high-use areas like apartment building stacks, commercial restrooms, and kitchen drain lines where clogs are most common and costly to fix.

What Are the Installation Advantages of Using a Sweep Tee in Drain Lines?

Installation headaches cause project delays. I recall a project where using sweep tees from the start saved days of labor and future access panel planning.

The main installation advantage of a sweep tee is its flexibility in aligning pipes. It can accommodate slight pipe misalignments due to its curved shape, making connections easier. While it requires more space than a standard tee, its use often eliminates the need for additional fittings and reduces future access points for cleaning, simplifying the overall system layout.

Space Requirements vs. System Simplicity

It is true that a sweep tee has a larger footprint than a compact sanitary tee. This is often the first concern for installers working in tight spaces like wall cavities. However, this perspective only looks at the single fitting.

In practice, using a sweep tee can lead to a simpler overall installation. Here’s why:

- Fewer Fittings Needed: With a standard tee, if you need to change the flow direction more gently, you might have to use two 45-degree elbows to create a sweep. This means three glued joints instead of one. A single sweep tee accomplishes the same gentle turn with one joint, reducing potential leak points.

- Easier Alignment: The curved body of a sweep tee can absorb minor measurement errors or pipe misalignments. A rigid, compact standard tee offers no such flexibility, sometimes forcing installers to cut and re-fit pipes.

Long-Term Maintenance Access

This is a critical advantage often overlooked during installation. A standard tee, being a primary clog point, frequently needs to be accessed with a drain snake or inspection camera.

If a standard tee is buried inside a wall, you must cut an access panel to reach it. Good planning puts this access panel in a convenient spot. Poor planning leads to cutting open finished walls later.

Because a sweep tee is far less likely to clog, it dramatically reduces the need for future access. This allows builders and plumbers to install cleaner, more permanent walls and ceilings without sacrificing serviceability. You are essentially building a more reliable system that won’t need to be opened up.

Installation Factor Comparison

| Installation Factor | Standard Sanitary Tee | Sweep Tee |

|---|---|---|

| Fitting Size (Footprint) | Compact | Larger, requires more space |

| Alignment Flexibility | Low; requires precise alignment | Moderate; can absorb small misalignments |

| Typical Joint Count for a Gentle Turn | 3 (Tee + two elbows) | 1 (Single fitting) |

| Future Maintenance Probability | High; often requires an access panel | Low; can often be buried permanently |

| Best Use Case | Tight spaces where space is absolute priority | Where long-term reliability and flow are key |

Therefore, while the installer must plan for the space, the trade-off is a faster, simpler glue-up and a system that will likely never need to be opened for a clog at that junction.

How Does a Sweep Tee Compare to a Standard Tee for Waste System Performance?

Clients often ask if the extra cost for sweep tees is worth it. After seeing both types in service for years, the performance difference is clear.

A sweep tee outperforms a standard tee in every key area of waste system performance: it provides superior flow efficiency, excellent clog prevention, and lower long-term maintenance. While a standard tee is smaller and cheaper initially, it creates flow resistance, collects debris, and is the most common point for blockages, leading to higher lifetime costs.

Head-to-Head Performance Analysis

Let’s break down the comparison into specific performance categories. This shows why building codes increasingly require sweep tees for horizontal-to-horizontal drain connections.

1. Hydraulic Performance (Flow):

This is about moving water and waste effectively. The standard tee is a major obstruction in the pipe. It creates significant “head loss,” which is a technical term for pressure or energy loss in the system. This loss must be overcome by pipe slope or water volume. The sweep tee, with its smooth radius, creates much less head loss. This means the system works better with the natural flow of gravity.

2. Reliability (Clog Prevention):

This is the most practical difference. A standard tee is a designed-in trouble spot. Its geometry guarantees that over time, it will collect materials. It’s not a matter of “if” but “when” it will need attention. A sweep tee, by avoiding the debris-catching shelf, turns a chronic problem point into a reliable section of pipe. This reliability is invaluable in multi-story buildings or systems where a clog can affect multiple units.

3. Maintenance and Operational Cost:

The initial fitting cost is only a tiny part of the equation. Consider the full cost:

- Standard Tee: Lower material cost, but higher risk of clogging. This leads to costs for: emergency plumbing service, potential water damage from backups, labor to open access panels, and tenant inconvenience or business interruption.

- Sweep Tee: Slightly higher material cost, but near-zero risk of clogging at that joint. This eliminates all the potential costs listed above.

Side-by-Side Comparison Table

| Performance Metric | Standard Sanitary Tee | Sweep Tee (Long Radius) | Winner |

|---|---|---|---|

| Initial Material Cost | Lower | Slightly Higher | Standard Tee |

| Flow Efficiency | Poor; high turbulence | Excellent; smooth flow | Sweep Tee |

| Clog Potential | Very High | Very Low | Sweep Tee |

| Long-Term Maintenance | High (Frequent cleaning) | Very Low | Sweep Tee |

| System Longevity | Can be compromised by clogs | Promotes clear pipes | Sweep Tee |

| Code Compliance for Horizontal Drains | Often not allowed | Typically required | Sweep Tee |

| Total Lifetime Cost | Higher | Lower | Sweep Tee |

In summary, the standard tee has one advantage: compact size for tight spaces. The sweep tee wins in every category that affects how well the system works day after day, year after year. For any application where reliable drainage is important—which is almost every application—the sweep tee is the superior performance choice.

Conclusion

For a waste system that flows smoothly and stays clog-free, the sweep tee is the clear winner. Choose reliable performance with IFAN’s certified sweep tees for your next drainage project.

Recent Comments