When selecting pipes for your plumbing system, understanding the differences between PPR and PPRC pipes is crucial. Both materials offer excellent performance, but they serve different applications and have distinct characteristics.

What Are PPR Pipes?

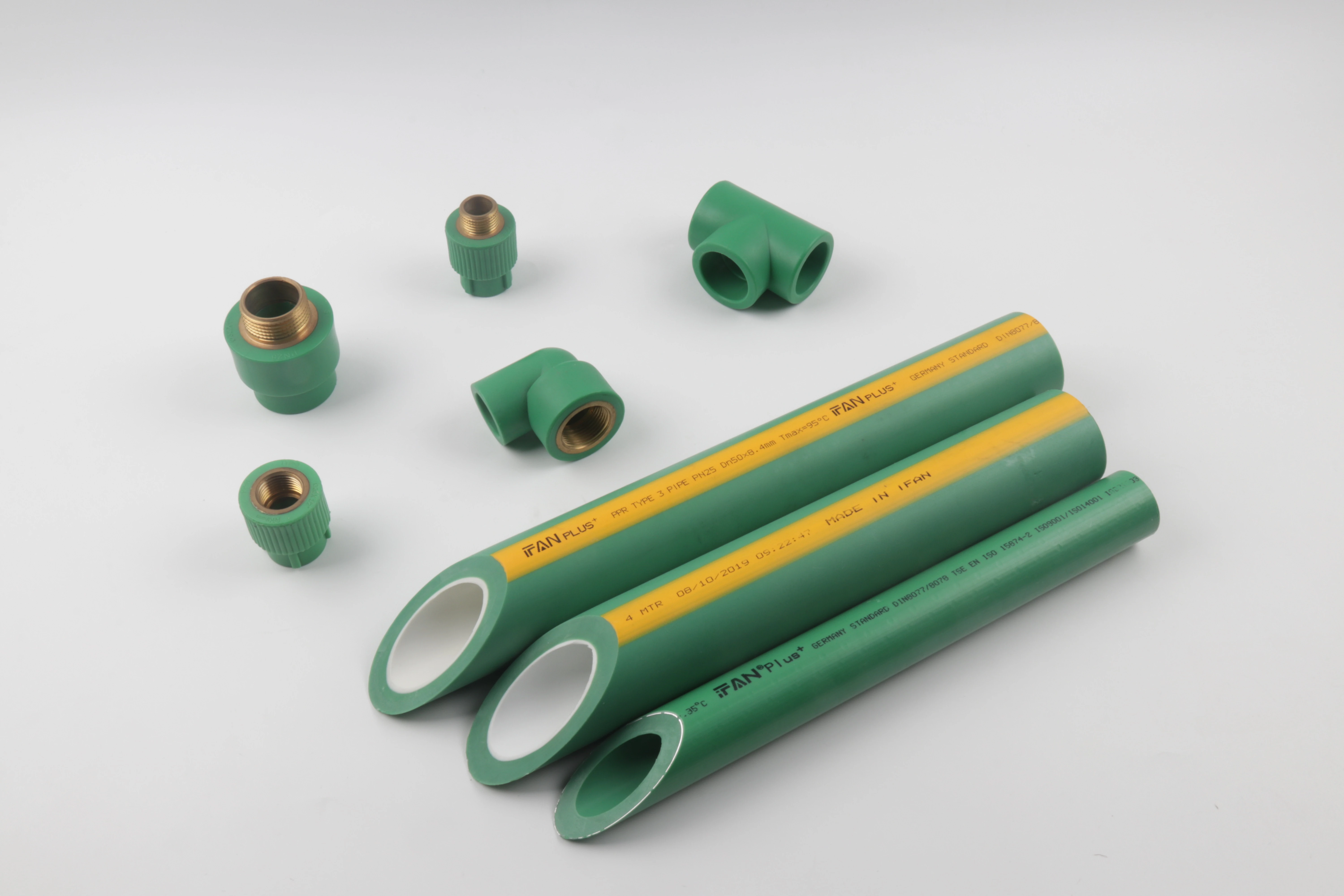

PPR (Polypropylene Random Copolymer) pipes are thermoplastic pipes made from polypropylene random copolymer material. These pipes have gained popularity in residential and commercial plumbing due to their durability and cost-effectiveness.

PPR pipes feature excellent chemical resistance. They withstand most acids, alkalis, and salts without degradation. The material maintains its structural integrity even when exposed to aggressive chemicals commonly found in water systems.

Temperature tolerance is another key strength. PPR pipes operate effectively in temperatures ranging from -10°C to 95°C. This wide temperature range makes them suitable for both hot and cold water applications.

Understanding PPRC Pipes

PPRC (Polypropylene Random Copolymer Compound) pipes represent an enhanced version of standard PPR pipes. Manufacturers add specific compounds to improve certain properties and performance characteristics.

The compound additives in PPRC pipes enhance UV resistance. Standard PPR pipes can degrade when exposed to direct sunlight, but PPRC pipes maintain their properties even with prolonged UV exposure.

PPRC pipes also demonstrate improved impact resistance. The compound formulation makes these pipes less likely to crack or break under mechanical stress compared to regular PPR pipes.

Key Differences Between PPR and PPRC Pipes

Material Composition

PPR pipes consist of pure polypropylene random copolymer. PPRC pipes contain the same base material plus additional compounds that enhance specific properties.

UV Resistance

Standard PPR pipes require protection from direct sunlight to prevent degradation. PPRC pipes can withstand UV exposure without significant property loss.

Impact Strength

PPRC pipes offer superior impact resistance compared to PPR pipes. This makes PPRC more suitable for applications where mechanical stress is a concern.

Cost Considerations

PPR pipes typically cost less than PPRC pipes. The additional compounds in PPRC pipes increase manufacturing costs, reflected in the final price.

Temperature Performance

Both pipe types handle similar temperature ranges. However, PPRC pipes maintain their properties more consistently across temperature variations.

Applications and Use Cases

PPR Pipe Applications

PPR pipes excel in indoor plumbing systems. They work well for:

- Hot and cold water supply lines

- Heating systems

- Industrial process piping

- Chemical transport applications

The chemical resistance of PPR pipes makes them ideal for transporting various fluids in industrial settings.

PPRC Pipe Applications

PPRC pipes suit both indoor and outdoor applications. Common uses include:

- Outdoor water supply systems

- Agricultural irrigation

- Swimming pool plumbing

- Exposed piping installations

The enhanced UV resistance of PPRC pipes makes them perfect for applications with sun exposure.

Installation Considerations

Both PPR and PPRC pipes use similar installation methods. Heat fusion welding creates strong, leak-proof joints. The fusion process melts the pipe material, creating a homogeneous connection.

Proper installation requires trained technicians. Incorrect fusion temperatures or timing can compromise joint integrity. Professional installation ensures optimal system performance and longevity.

Durability and Lifespan

PPR pipes typically last 50+ years in indoor applications. Their excellent chemical resistance and stable material properties contribute to this longevity.

PPRC pipes offer similar lifespans but perform better in challenging environments. The compound additives help maintain properties under stress conditions that might affect standard PPR pipes.

Maintenance Requirements

Both pipe types require minimal maintenance. Regular system inspections help identify potential issues early. Proper support and protection from mechanical damage extend system life.

Cleaning is straightforward for both materials. Standard cleaning agents won’t damage the pipe surfaces or affect their properties.

Environmental Impact

Both PPR and PPRC pipes are recyclable. The thermoplastic nature allows for reprocessing into new products at the end of their service life.

Manufacturing both pipe types requires less energy compared to metal alternatives. This contributes to a lower overall environmental footprint.

Making the Right Choice

Consider your specific application requirements when choosing between PPR and PPRC pipes. Indoor installations typically work well with standard PPR pipes, offering cost savings without compromising performance.

Outdoor or exposed applications benefit from PPRC pipes. The enhanced UV resistance and improved impact strength justify the additional cost in these scenarios.

System longevity, installation environment, and budget constraints all influence the optimal choice. Professional consultation helps determine the best solution for your specific needs.

Quality Standards and Certifications

Reputable manufacturers produce both PPR and PPRC pipes according to international standards. Look for certifications like ISO 15874 for PPR pipes and relevant standards for PPRC pipes.

Quality certification ensures consistent performance and reliability. Certified pipes undergo rigorous testing for pressure resistance, temperature tolerance, and chemical compatibility.

Conclusion

PPR and PPRC pipes both offer excellent performance for plumbing applications. PPR pipes provide cost-effective solutions for indoor use, while PPRC pipes excel in challenging outdoor environments.

Understanding these differences helps you select the right pipe material for your project. Consider application requirements, environmental conditions, and budget constraints when making your decision.

For custom pipe solutions and expert guidance, professional manufacturers can help optimize your system design and material selection.

Recent Comments