I once helped a client fix a major leak. They tried to connect mismatched pipes with the wrong fitting. That mistake caused a lot of water damage and stress. Now, I always explain the simple purpose of the right connector, like a threaded PVC reducer coupling.

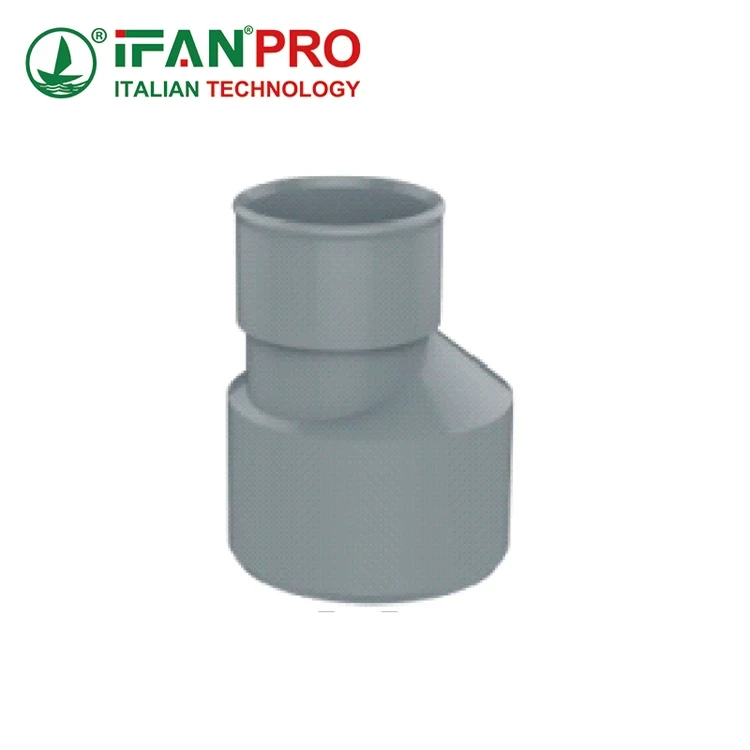

A PVC reducer coupling is a fitting that connects two pipes of different diameters. The threaded type has female threads on both ends, so you can screw it onto male-threaded pipes. People use it for low-pressure, accessible applications where they might need to take the connection apart later, like for filters or pumps.

This small fitting solves a common piping problem. Next, I will explain what it is, where to use it, and how to install it correctly.

What is a PVC Reducer Coupling and How Are Threaded Types Used?

Choosing the wrong fitting leads to leaks. Threaded PVC couplings offer a specific solution you should know about.

A threaded PVC reducer coupling is a short fitting with internal NPT threads on both ends, each a different size. It joins two male-threaded pipes of different sizes. This creates a strong connection you can take apart later without using any glue.

Understanding Its Basic Design and Function

First, let’s break down its name. “PVC” means it’s made from strong, chemical-resistant plastic. “Reducer” means it changes the pipe size from larger to smaller. “Coupling” means it joins two pipes. “Threaded” means it uses screw threads instead of glue.

This coupling has female NPT threads on the inside. You screw it onto the male-threaded ends of your pipes. This makes a tight, mechanical seal. Because you screw it together, you can also unscrew it later. This is helpful if you need to take the system apart for maintenance or changes. This feature is the main advantage over glued fittings.

Looking at Common Jobs for This Fitting

So, where do you actually use this coupling? You often find these fittings in spots where equipment needs to be installed or removed. Here are some clear examples:

- Connecting to Equipment: Attaching a PVC pipe to the threaded inlet or outlet of a pump, filter, or tank.

- Making System Changes: Adapting an old threaded pipe to a new, different-sized pipe during a repair.

- Low-Pressure Lines: Using them in irrigation systems, drain lines, or some home water supply lines where pressure is not very high.

Comparing Threaded and Glued Fittings

You need to know when to use a threaded coupling instead of a glued one. The table below makes this choice clear.

| Feature | Threaded PVC Reducer Coupling | Solvent-Weld (Glued) PVC Reducer Coupling |

|---|---|---|

| Connection Method | Screws onto threaded pipe ends. | Uses PVC cement to chemically bond to the pipe. |

| Can You Take It Apart? | Yes. You can unscrew it for maintenance. | No. It is permanent. You must cut it to remove it. |

| Best Use Case | Access points, equipment connections, areas needing future service. | Buried lines, high-pressure applications, permanent runs. |

| Pressure Rating | Generally lower. The seal depends on threads and tape. | Generally higher. It creates a single, fused piece. |

| Installation Speed | Faster, with no wait time for glue to dry. | Slower, because you must apply cement and wait for it to cure. |

In short, think about “future access” when you choose a threaded coupling. If you might ever need to open the connection, use threads. For a final, permanent connection inside a wall, a glued fitting is stronger.

Where Should You Install a Threaded PVC Reducer Coupling in Piping Systems?

Putting a fitting in the wrong place causes leaks. Knowing the correct location ensures a reliable system.

Install a threaded PVC reducer coupling in accessible, low-vibration spots where you might need to take things apart. Good locations include connection points for pumps, valves, filters, or tanks. Also use them in above-ground drain or irrigation lines you may need to service.

Following Key Rules for Placement

Two main factors guide where to put this fitting: the need for future access and the strength of a threaded joint.

First, only install threaded couplings where you can easily reach them. They are service points. If you bury one in a wall, you cannot use its main feature. Always put them in open basements, utility rooms, or valve boxes where you can use a wrench.

Second, remember that a threaded joint is not as strong as a welded one. So, avoid areas with high stress or constant vibration. For example, do not put one directly on a powerful pump that shakes a lot. The vibration could slowly loosen the threads over time.

Identifying the Best Installation Spots

Let’s look at specific, recommended places to install them:

- At Equipment Interfaces: This is the most common use. The coupling connects a fixed pipe to a piece of equipment you might replace. Think about the pipes for a pool filter or a water softener.

- In Accessible Drain Lines: For PVC drain systems, these couplings work well for clean-out adapters or connections in an accessible attic.

- For Irrigation Manifolds: In sprinkler systems, they are often used at the manifold to connect different sized valves.

- Before and After Valves: Putting a coupling on each side of an important valve lets you remove the valve later without cutting the main pipe.

Knowing Where to Avoid Using Them

You also need to know where not to use them:

- Buried or Hidden Lines: Never use a threaded coupling in a line you will bury in dirt or concrete. A future leak would mean digging it up.

- High-Pressure Mains: For main pressurized water lines, glued joints are safer and more reliable.

- Long, Unsupported Runs: Do not place one in the middle of a long pipe span with no support. The joint is a potential weak spot.

If you follow these rules, the threaded coupling will work as a convenient connection point, not a future problem.

How Do You Properly Connect and Seal a Threaded PVC Reducer Coupling?

A bad connection leads to leaks. Doing it right needs the correct technique and materials.

First, clean the pipe threads. Then, apply pipe thread sealant like Teflon tape clockwise to the male threads. Hand-tighten the coupling, then use a wrench to turn it 1-2 more turns until snug. Be careful not to over-tighten it, because you can crack the PVC.

Following the Correct Steps in Order

You must follow careful steps to get a leak-free threaded connection in PVC. PVC can crack if you force it, so be gentle.

Step 1: Check and Clean

First, look at the male threads on both pipes. They must be clean, dry, and free from old tape or dirt. Wipe them with a cloth. Also, check inside the new coupling for any debris.

Step 2: Apply the Sealant

You must use a sealant. The threads alone will not seal tightly. You have two good choices:

- PTFE Tape (Teflon Tape): This is very common for PVC. Wrap the tape clockwise around the male thread. Do 4-6 wraps. Try not to let tape hang over the first thread.

- Pipe Thread Compound (“Pipe Dope”): Use a kind made for plastic pipes. Apply a moderate, even coat over the male threads. Do not get any sealant on the first thread.

Step 3: Tighten by Hand

Start threading the coupling onto one pipe by hand. Turn it clockwise. It should spin on easily. Screw it on as far as you can with just your fingers. This makes sure the threads line up right and avoids cross-threading.

Step 4: Finish with Wrenches

Now, use two wrenches. One wrench holds the base of the male-threaded pipe so it doesn’t twist. Use the other wrench on the coupling. Turn the coupling 1 to 2 full turns past hand-tight. You will feel strong resistance. Stop right there. You want it “snug,” not “extremely tight.” Over-tightening is the top reason PVC fittings crack.

Fixing Common Sealing Problems

Sometimes problems happen even if you are careful. Here is a table of common issues and how to fix them.

| Problem | Likely Cause | Solution |

|---|---|---|

| Leak at the thread right away. | Not enough sealant or tape. | Take it apart, clean the threads well, and apply more sealant. |

| Leak after the system has pressure. | The joint was under-tightened or the tape was wrapped the wrong way. | Try tightening the joint another 1/4 to 1/2 turn with a wrench. If it still leaks, take it apart and start over. |

| Crack in the coupling during tightening. | Over-tightening. You forced it too far. | The part is broken. You must cut it out and replace the coupling and the damaged pipe. |

| Hard to thread by hand. | Threads are damaged or dirty. | Do not force it. Unscrew it, look for dirt or bent threads, and clean. If threads are damaged, replace the pipe. |

Remember, PVC threads are delicate. Patience is more important than force. A correctly made joint will be secure and leak-free for years.

What Sizes and Pressure Ratings are Available for PVC Reducer Couplings?

Picking the wrong size or pressure rating is a basic error. It makes the whole system unsafe.

Threaded PVC reducer couplings come in many sizes, usually from 1/2 inch to 6 inches. They follow standard NPT threads. Pressure ratings vary: Schedule 40 is for moderate pressure, and Schedule 80 has thicker walls for higher pressure. Always match the coupling’s schedule to your pipe and make sure its pressure rating is higher than your system’s maximum pressure.

Learning About Size Specifications

Sizing can be confusing because one fitting has two different sizes. The size always lists the two pipe sizes it connects, in order: Large x Small.

For example, a 1-1/2″ x 1″ PVC reducer coupling has a 1-1/2″ female thread on one end and a 1″ female thread on the other. You must know the exact male thread sizes of your pipes to pick the right one. These sizes are the nominal pipe diameter. They follow the National Pipe Taper (NPT) standard.

Common home sizes are between 1/2″ and 2″. Larger sizes like 3″ or 4″ are for industrial or farm use.

Understanding Pressure Ratings and Schedule

The pressure rating tells you how much pressure the fitting can handle safely. For PVC, this connects to its “Schedule” (shortened to “Sch”).

- Schedule 40: This is the standard, most common grade. It has thinner walls than Schedule 80. Its pressure rating goes down as the size goes up. For example, a 1/2″ Sch 40 fitting handles much more pressure than a 4″ Sch 40 fitting.

- Schedule 80: This has a thicker, heavier wall. Use it for higher-pressure jobs or where you need extra durability. Its color is usually darker gray than Schedule 40 white.

Using a Guide to Make the Right Choice

Choosing the right coupling means checking size and pressure. Use this table to help you start.

| Nominal Size (Inches) | Typical Schedule Available | Common Application Examples | Key Consideration |

|---|---|---|---|

| 1/2″ – 3/4″ | Sch 40, Sch 80 | Home water supply lines, connections under sinks. | For normal home water pressure, Sch 40 is enough. |

| 1″ – 2″ | Sch 40, Sch 80 | Pool pump connections, main irrigation lines. | Match the schedule to your pipe. Use Sch 80 near pumps that vibrate. |

| 3″ – 4″ | Sch 40 | Main home drain lines, low-pressure farm water. | Pressure ratings are lower here. Check your system PSI is below the rating. |

| 4″ – 6″ | Sch 40 | Low-pressure drainage, big venting systems. | These are for very low pressure or non-pressure uses only. |

The most important rule: The pressure rating of the weakest part in your line sets the safe maximum pressure for the whole system. Never use a Schedule 40 threaded coupling in a line of Schedule 80 pipe if the pressure is high. Always check the maker’s specs for the exact pressure rating at different temperatures.

Conclusion

A threaded PVC reducer coupling is a useful fitting for adaptable plumbing connections. For reliable quality in all sizes, choose IFAN‘s PVC fittings.

Recent Comments