Pipeline systems form the backbone of countless industries worldwide. From oil and gas transportation to water distribution networks, these systems require precise flow control mechanisms. Valves serve as the critical control points that regulate, direct, and stop fluid flow within pipeline infrastructure.

Understanding Pipeline Valve Fundamentals

Pipeline valves control fluid movement through strategic positioning along transmission lines. These mechanical devices open, close, or partially obstruct passageways to manage flow rates and pressure levels. Modern pipeline operations depend entirely on reliable valve performance.

Different valve types serve specific functions. Gate valves provide complete shut-off capabilities. Ball valves offer quick operation with minimal pressure drop. Butterfly valves excel in large-diameter applications where space constraints matter.

Critical Valve Types for Pipeline Applications

Gate Valves dominate pipeline applications requiring full bore flow. Their wedge-shaped disc slides perpendicular to flow direction. This design minimizes pressure loss when fully open. Gate valves handle high-pressure, high-temperature conditions effectively.

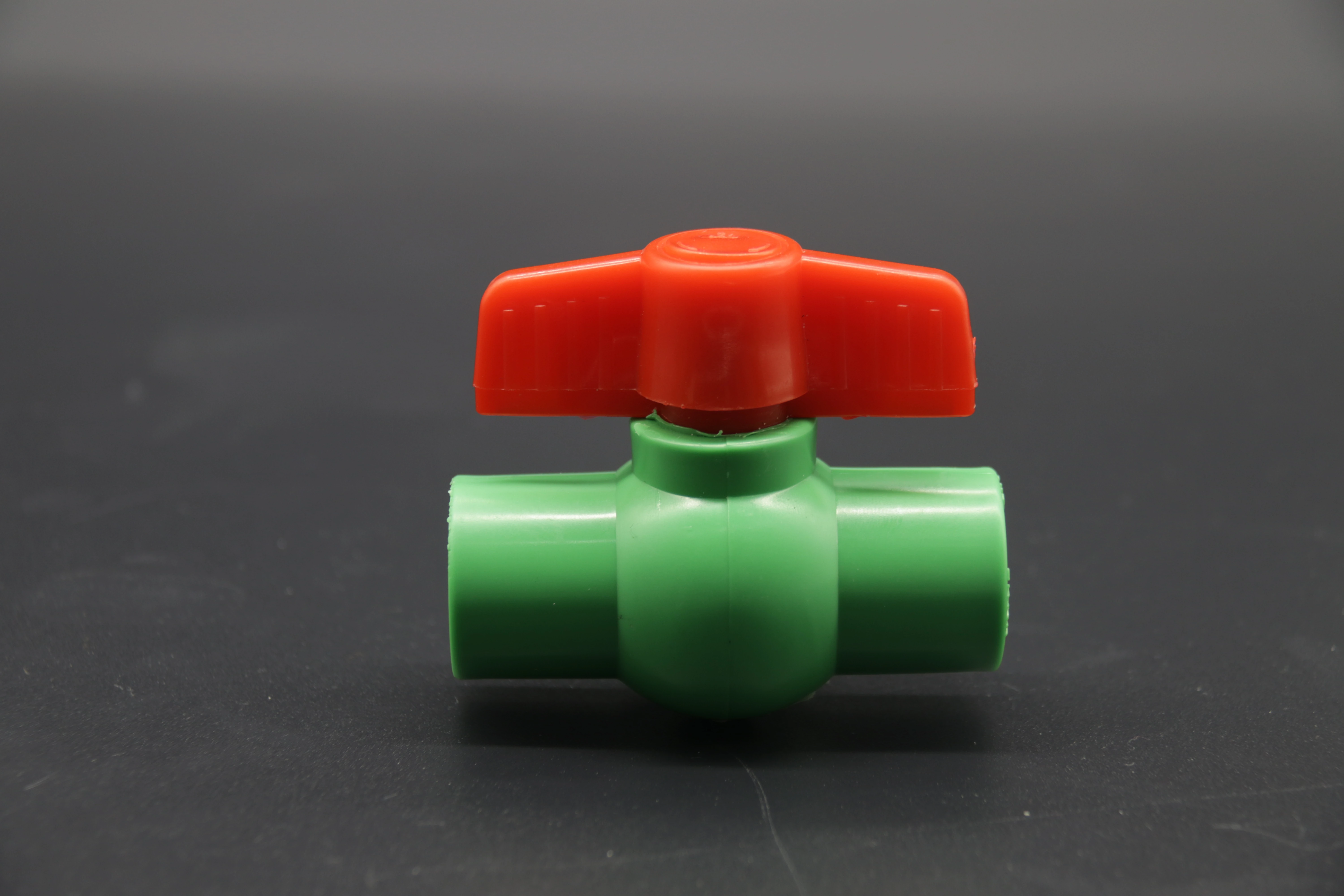

Ball Valves feature spherical closure elements with cylindrical holes. Quarter-turn operation makes them ideal for automated systems. Their tight sealing capability prevents leakage in critical applications. Ball valves resist corrosion better than many alternatives.

Butterfly Valves use rotating discs to control flow. Their compact design suits large-diameter pipelines where installation space is limited. These valves cost less than gate or ball alternatives. However, they create some pressure drop even when fully open.

Check Valves prevent reverse flow automatically. They protect pumps and other equipment from damage. Spring-loaded designs ensure reliable closure under low-flow conditions. These valves require no external power source.

Material Selection Considerations

Carbon steel valves handle standard hydrocarbon pipelines effectively. Their strength withstands high pressures while maintaining cost efficiency. Stainless steel options resist corrosion in aggressive environments. These materials suit chemical processing applications.

Specialized alloys serve extreme conditions. Duplex stainless steel combines strength with corrosion resistance. Exotic materials like Hastelloy handle highly corrosive fluids. Material selection directly impacts valve longevity and maintenance costs.

Seat materials require careful consideration. Soft seats provide tight sealing but limit temperature ranges. Metal seats handle extreme temperatures but may leak slightly. PTFE seats offer chemical resistance with good sealing properties.

Sizing and Pressure Ratings

Proper valve sizing ensures optimal system performance. Undersized valves create excessive pressure drops. Oversized valves increase costs unnecessarily while potentially causing control problems.

Pressure ratings must exceed maximum system pressures. Class 150 valves suit low-pressure applications. Class 600 and higher ratings handle high-pressure transmission lines. Temperature affects pressure ratings significantly.

Flow coefficients (Cv values) quantify valve flow capacity. Higher Cv values indicate better flow characteristics. These specifications help engineers select appropriate valve sizes for specific applications.

Installation and Maintenance Best Practices

Proper installation determines valve service life. Support heavy valves adequately to prevent pipe stress. Allow sufficient clearance for operation and maintenance access. Follow manufacturer torque specifications during installation.

Regular maintenance prevents costly failures. Inspect valve exteriors for leakage signs. Test operation periodically to ensure smooth function. Replace worn components before complete failure occurs.

Automated valve systems require additional considerations. Control signals must reach valves reliably. Backup power systems ensure operation during emergencies. Position feedback confirms valve status accurately.

Industry-Specific Applications

Oil and Gas Pipelines transport crude oil and natural gas across continents. These systems require valves capable of handling flammable, high-pressure fluids. Emergency shutdown valves provide safety protection. Pig launcher and receiver valves enable pipeline cleaning operations.

Water Distribution Systems deliver potable water to communities. These networks use lower pressures but require corrosion-resistant materials. Gate valves control main line flow. Pressure reducing valves maintain safe distribution pressures.

Chemical Processing involves aggressive fluids requiring specialized valve materials. Double block and bleed configurations provide additional safety. Lined valves protect against corrosion while maintaining structural integrity.

Emerging Technologies and Trends

Smart valve technology integrates sensors and communication capabilities. These systems provide real-time performance data. Predictive maintenance algorithms identify potential problems before failures occur. Remote monitoring reduces inspection costs significantly.

3D printing enables rapid prototyping of custom valve components. This technology accelerates development cycles for specialized applications. Advanced materials expand operating envelopes for extreme conditions.

Digital twin technology creates virtual valve models. These simulations optimize performance before physical installation. Engineers can test different scenarios without risking actual equipment.

Economic Considerations

Initial valve costs represent only part of total ownership expenses. Installation, maintenance, and energy costs accumulate over valve lifecycles. Higher-quality valves often provide better long-term value despite increased upfront investment.

Valve failures create significant economic impacts. Unplanned shutdowns cost thousands per hour in lost production. Proper selection and maintenance minimize these risks effectively.

Standardization reduces inventory costs while simplifying maintenance procedures. Common valve types across facilities enable bulk purchasing advantages. Training costs decrease when technicians work with familiar equipment.

Conclusion

Pipeline valve selection requires balancing multiple factors including application requirements, material compatibility, and economic considerations. Understanding these fundamentals enables informed decisions that optimize system performance while controlling costs. Proper installation and maintenance practices ensure reliable long-term operation.

Whether handling crude oil transmission or municipal water distribution, the right valve choice makes the difference between efficient operation and costly problems. Work with experienced manufacturers like those at ifanultra.com who understand these critical applications and can provide customized solutions for specific pipeline requirements.

Recent Comments