I once saw a cheap plastic supply line burst under a sink. The flood ruined cabinets and flooring. That moment cemented my trust in a better solution: the stainless steel braided hose.

A stainless steel braided flexible hose is a crucial connection point in water supply systems, valued for its flexibility, strength, and leak resistance. It features a durable inner core wrapped in a braided stainless steel exterior, designed to handle high pressure and movement while preventing catastrophic failures common in older rubber hoses.

Now, let’s get into the details of how to work with these hoses, what makes them last, and how to choose the best ones for a safe, reliable plumbing system.

How Do You Install a Stainless Steel Braided Hose for Water Supply Connections?

A wrong installation can undo the benefits of a great hose. I guide my clients through simple, fail-safe steps to ensure a perfect fit every time.

To install a stainless steel braided hose, first shut off the water supply. Then, unscrew the old connection, wrap Teflon tape clockwise around the new hose’s threaded ends, and hand-tighten the connections. Finally, use an adjustable wrench to give each fitting a final quarter to half turn, being careful not to overtighten and damage the seals.

The Step-by-Step Installation Guide

Installing these hoses is a straightforward DIY task if you follow the right steps. The goal is to create a watertight seal without putting stress on the hose or fittings. Here is a simple guide to follow.

First, and most importantly, you must turn off the water supply. Locate the shut-off valve for the fixture you are working on, like under the sink or behind the toilet. Turn the valve clockwise until it stops. Then, open the faucet to drain any remaining water and pressure from the line. This prevents a messy spray when you disconnect the old hose.

Next, disconnect the old supply line. Use an adjustable wrench to hold the valve fitting steady, and another wrench to loosen the nut on the hose. Once loose, you can unscrew it by hand. Do the same at the connection to the faucet or toilet fill valve. Have a small bucket or towel ready to catch any leftover drips.

Preparing and Connecting the New Hose

Now, prepare your new stainless steel braided hose. Check that the washers (usually rubber or nylon) inside the hose’s nuts are present and in good condition. These washers create the seal, so they are vital. Then, apply Teflon tape to the threaded fittings you will connect to. Wrap the tape clockwise around the threads 3-4 times. This helps ensure a tight, leak-free seal.

Start by hand-tightening the hose connections. Screw the hose nut onto the water supply valve by hand first. Then, connect the other end to the faucet or toilet inlet. Hand-tightening ensures you don’t cross-thread the connections, which can cause leaks or damage.

Finally, use your wrench to secure the connections. Hold the body of the valve steady with one wrench to avoid twisting the plumbing in the wall. With the other wrench, gently tighten the hose nut. You only need to go about a quarter to half turn past hand-tight. A common mistake is to overtighten, which can crush the sealing washer or crack the fitting. The table below summarizes the key tools and actions.

Installation Tools and Key Actions

| Step | Tool Needed | Key Action & Tip |

|---|---|---|

| 1. Shut Off Water | None (use your hand) | Turn the shut-off valve clockwise until fully closed. |

| 2. Disconnect Old Hose | Adjustable Wrench | Hold the valve steady while loosening the hose nut to prevent damage. |

| 3. Prepare New Hose | Teflon Tape | Wrap tape clockwise 3-4 times on the male threads only. |

| 4. Hand-Tighten | Your hands | Screw nuts on by hand to avoid cross-threading. |

| 5. Final Tighten | Adjustable Wrench | Give each nut a final 1/4 to 1/2 turn. Do not overtighten. |

Once both ends are secure, slowly turn the water supply back on. Check both connections carefully for any signs of dripping. It’s normal to see a few drops at first from the faucet aerator as the lines refill, but the hose connections themselves should be completely dry. If you see a leak, turn the water off again and check if the connection needs a slight additional tighten or if the washer is seated correctly.

What Makes Stainless Steel Braided Hoses Durable for Water Supply Systems?

Clients ask why these hoses don’t fail like rubber ones. The answer is in their layered construction, which is designed to withstand daily stress.

Stainless steel braided hoses are durable because of their multi-layer construction. A flexible polymer inner tube carries the water, a braided stainless steel mesh overlay provides immense tensile strength and burst resistance, and durable end fittings are crimped in place, creating a unit that resists pressure, vibration, corrosion, and physical damage.

The Power of Layered Construction

The durability comes from a smart combination of materials, each serving a specific purpose. Unlike a single-material hose, this design tackles multiple failure points at once. Let’s break down each layer.

The inner core is usually made from EPDM (Ethylene Propylene Diene Monomer) rubber or a similar flexible polymer. This material is chosen because it is non-toxic and safe for potable water. It remains flexible across a wide temperature range and resists the degrading effects of chlorine commonly found in water supplies. This layer is smooth to ensure good water flow.

The Braided Steel Armor

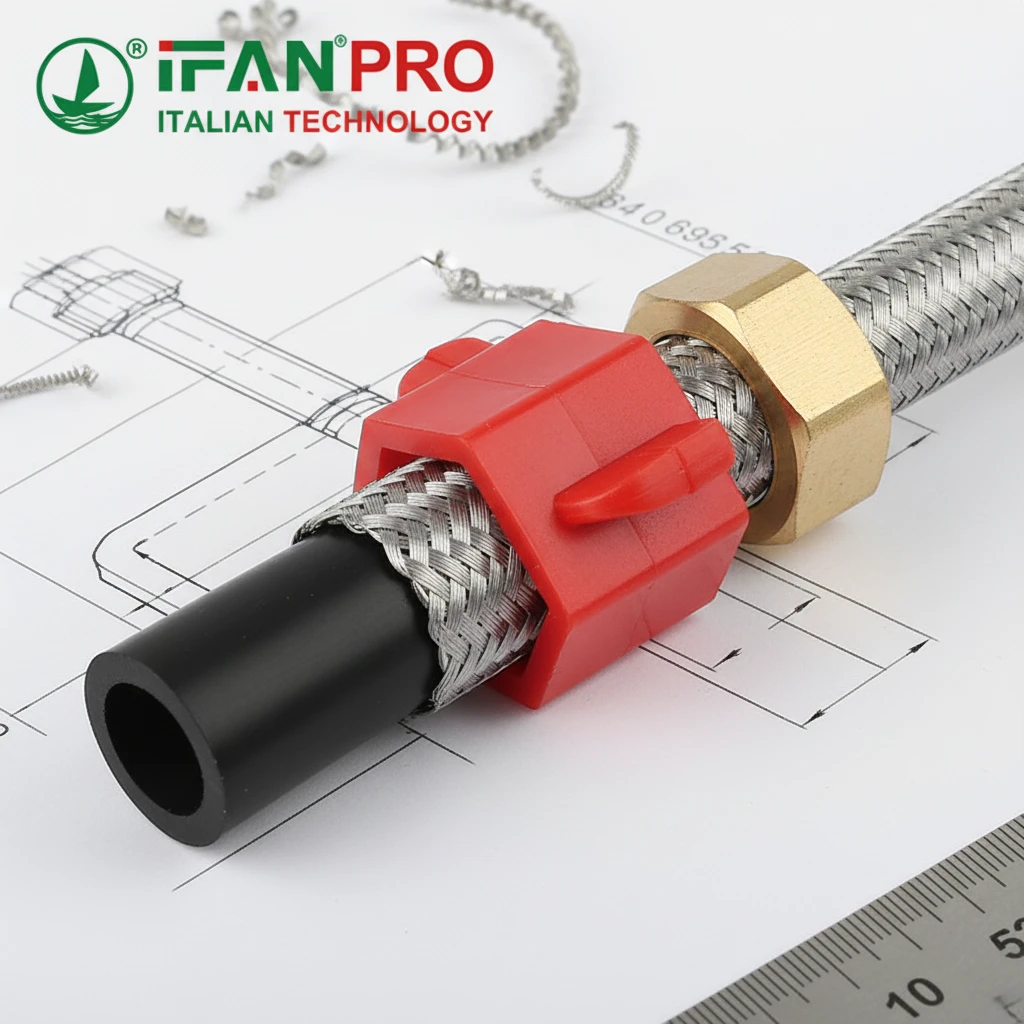

The most visible feature is the braided stainless steel sheath that wraps around the inner core. This is not just for looks. This mesh acts like a super-strong cage. When water pressure builds inside the hose, it tries to expand the inner tube. The steel braiding confines this expansion, giving the hose an extremely high burst pressure rating. It also provides excellent abrasion resistance, protecting the soft inner tube from getting nicked or cut if it rubs against a sharp cabinet edge.

Furthermore, the stainless steel provides crucial protection from external elements. It will not rust or corrode in the damp environment under sinks or behind toilets. This is a major advantage over plain rubber hoses or even exposed metal parts that can corrode over time.

Fitting and Failure Point Security

The ends are critical failure points. In quality hoses, the stainless steel braiding is integrated into a solid brass fitting using a precision crimping process. This creates a permanent, mechanical bond that is far stronger than an adhesive or a simple collar. This crimped fitting can handle the twisting force during installation and the constant vibration from water flow without coming loose.

To illustrate how this construction outperforms older types, consider this comparison:

Hose Type Durability Comparison

| Hose Type | Core Material | Outer Layer | Common Failure Points | Relative Lifespan |

|---|---|---|---|---|

| Plain Rubber Hose | Rubber | None | Bulging, cracking, burst from pressure. | Short (3-5 years) |

| Plastic (PVC) Hose | PVC Plastic | None | Becoming brittle, cracking at fittings. | Short to Medium |

| Stainless Steel Braided | EPDM Rubber | Braided Steel Mesh | Rare; usually only if washer fails or severely overtightened. | Long (8-10+ years) |

This robust construction directly addresses common client pain points like sudden bursts, leaks at the fittings, and degradation from moisture. The result is a hose you can install and forget about, providing peace of mind for years.

How Can You Identify a High-Quality Stainless Steel Braided Water Supply Hose?

Not all braided hoses are equal. Through years of sourcing, I’ve learned to spot the markers of quality that prevent callbacks and complaints.

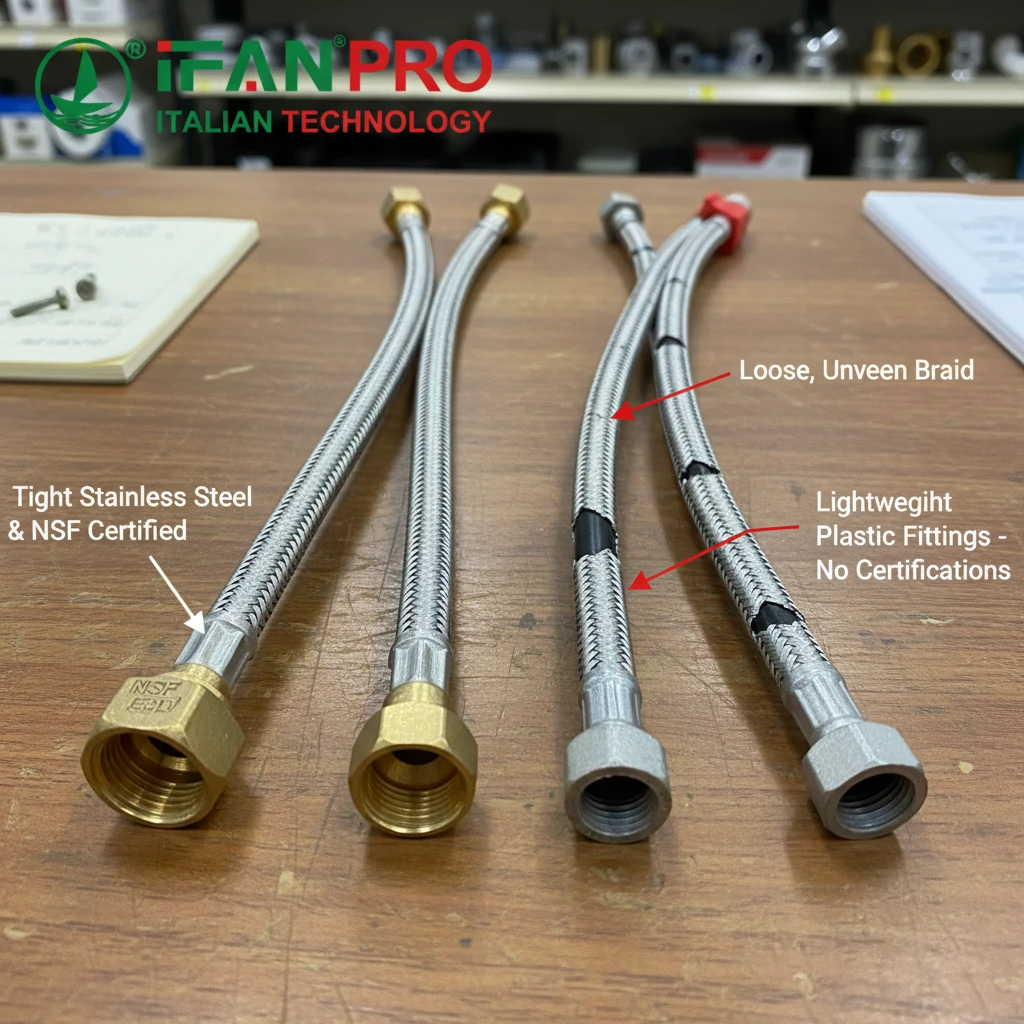

You can identify a high-quality hose by checking four things: a thick, tightly woven stainless steel braid; solid, heavy brass fittings (not plastic); a clear marking for compliance with safe water standards like NSF/ANSI 372; and a firm, kink-resistant feel. Avoid hoses with loose braiding, lightweight fittings, or no certification markings.

Inspecting the Physical Build

Knowing what to look for can save you from buying a substandard product that looks good but performs poorly. Start with a simple visual and tactile inspection.

First, examine the stainless steel braiding. The weave should be very tight and consistent. Run your fingers along it; it should feel smooth and dense. A loose, gappy, or uneven weave is a sign of poor craftsmanship and offers less burst protection. The braid should also have a consistent, polished look without discolored or rusty strands.

Next, feel the end fittings. They should be made of solid, substantial brass. Brass is preferred because it is strong, corrosion-resistant, and threads cleanly. Pick up the hose; the fittings should feel heavy, not light and cheap. Be wary of fittings that are partially or fully made of plastic or thin, plated metal. These can crack during installation or corrode over time. Look at the crimp where the braid meets the fitting—it should be neat, even, and secure.

Checking for Certifications and Markings

A quality hose meant for drinking water will have its credentials stamped or printed right on it. This is non-negotiable.

Look for a marking that says “NSF/ANSI 372” or “NSF/ANSI 61.” This means the materials are certified to be lead-free and safe for contact with drinking water. In many regions, this is a legal requirement for potable water plumbing. The absence of such a marking is a major red flag. Also, check for a pressure rating (like 150 PSI or 1000 kPa) and a manufacturer’s name or brand. Reputable companies stand behind their products.

Performance and Feel

Finally, give the hose a gentle flex. A high-quality hose with a good inner tube will be flexible but will resist kinking. If it kinks easily and holds the kink, the inner core might be of lower quality, which can restrict water flow and create a weak point. The hose should feel like a robust, integrated unit, not like a loose braid sliding over a separate inner tube.

Quick Quality Checklist

Use this table as a guide when selecting hoses:

| Feature to Check | High-Quality Sign | Low-Quality Warning Sign |

|---|---|---|

| Stainless Braid | Tight, dense, uniform weave. | Loose, gappy, or uneven weave. |

| End Fittings | Heavy, solid brass. | Lightweight, plastic components, or thin plated metal. |

| Certifications | Clearly marked “NSF/ANSI 372/61”. | No safety certification markings. |

| Crimp | Neat, even, and secure. | Sloppy, uneven, or looks weak. |

| Flexibility | Flexible but springs back, resists kinks. | Kinks easily and holds the kink. |

Choosing a hose that passes all these checks might cost a little more upfront, but it is the most cost-effective decision in the long run, avoiding the high cost and hassle of a water leak.

What Are the Safety Standards for Stainless Steel Braided Hoses in Plumbing?

Safety standards exist for a reason. In our audits, we insist on certified hoses because they are the proven defense against water damage and contamination.

Key safety standards for stainless steel braided hoses include NSF/ANSI 372 for lead-free content, NSF/ANSI 61 for overall safety in contact with drinking water, and pressure rating standards (like ASTM or EN codes) that verify the hose can withstand rated pressures without bursting. These certifications ensure the product is safe for health and reliably strong.

Health Safety: Keeping Water Clean

The most critical standards protect your health by ensuring the materials in the hose do not leach harmful substances into your drinking water. This is where you should be most vigilant.

The NSF/ANSI 372 standard is specifically for lead content. It certifies that the product contains less than 0.25% lead in its wetted surfaces. Given the severe health risks of lead, this is a fundamental requirement. The broader NSF/ANSI 61 standard covers all aspects of drinking water system component health effects. It tests for the potential leaching of a wide range of contaminants into the water. A hose compliant with NSF/ANSI 61 has been rigorously tested to be safe.

Performance Safety: Preventing Bursts and Leaks

A hose that contaminates water is dangerous, but so is a hose that bursts and floods your home. Performance standards ensure physical reliability.

Hoses should be manufactured and tested to meet specific pressure ratings. These are often based on standards set by organizations like ASTM (American Society for Testing and Materials) or similar bodies in other regions. A hose rated for 150 PSI (pounds per square inch) has been tested to withstand that pressure continuously and at higher pressures for short bursts. Using a hose without a verifiable pressure rating is a gamble.

Another important aspect is temperature rating. The hose should be clearly labeled for the maximum water temperature it can handle (e.g., 100°C / 212°F). Using a hose not rated for hot water on a hot water line can cause the inner core to degrade rapidly.

How to Verify Compliance

Responsible manufacturers make this easy. They will clearly mark the hose jacket or its packaging with the relevant certification logos and text. Sometimes, they will list a certification number you can look up. You should never accept a hose from a supplier who cannot provide proof of these certifications.

Overview of Key Safety Standards

This table explains what the main standards mean for you:

| Standard | Focus Area | What It Means for Your Home |

|---|---|---|

| NSF/ANSI 372 | Material Composition | Guarantees the hose is lead-free, protecting against lead contamination in water. |

| NSF/ANSI 61 | Health Effects | Ensures the hose does not leach any harmful levels of chemicals or metals into drinking water. |

| Pressure Rating (e.g., 150 PSI) | Performance & Strength | Certifies the hose has been tested to safely handle normal and surge water pressures without bursting. |

| Marking of Max Temperature | Performance & Suitability | Prevents hose failure by ensuring it is used only within its safe operating temperature range. |

Insisting on products that meet these standards is not just about following rules; it’s about making a smart choice for your property and your family’s well-being. It’s the simplest way to filter out substandard, risky products from the market.

Conclusion

Choosing the right stainless steel braided hose ensures a safe, durable, and leak-free connection. For hoses that meet the highest standards of quality and safety, trust IFAN‘s certified stainless steel braided water supply lines.

Recent Comments