I have seen valves fail quickly in harsh chemical environments. This firsthand experience proves that material choice is critical, and PVC valves consistently offer a smart solution for modern plants.

PVC valves are essential in water treatment because they provide unmatched corrosion resistance against chemicals like chlorine and acids at a lower cost than metal alternatives. Their smooth operation and ease of installation ensure reliable, long-term flow control in demanding filtration and dosing processes, minimizing downtime and maintenance costs.

Now, let’s break down the specific reasons that make PVC valves a cornerstone of efficient and reliable water treatment infrastructure.

What Makes PVC Valves Highly Resistant to Water Treatment Chemicals?

Chemical attack is the top killer of valves in treatment plants. I’ve replaced many corroded metal valves, but PVC stands strong where others fail.

PVC valves are highly resistant because the polyvinyl chloride material is inert to a wide range of corrosive chemicals used in treatment, such as chlorine, ferric chloride, sulfuric acid, and sodium hypochlorite. Unlike metals, PVC does not oxidize or rust, ensuring the valve body and seals do not degrade and contaminate the process or fail prematurely.

The Science Behind the Resistance

Water treatment uses aggressive chemicals to purify water. These chemicals can destroy unsuitable materials quickly. The molecular structure of PVC makes it naturally non-reactive. This means it does not easily participate in chemical reactions with acids, bases, oxidizers, and salts commonly found in treatment plants.

For example, chlorine is a universal disinfectant. It rapidly corrodes many metals, leading to valve seat damage and leaks. PVC, however, is not affected by chlorine at the concentrations used in water treatment. This same resistance applies to coagulants like alum and ferric chloride, as well as acids and alkalis used for pH adjustment.

A Practical Comparison of Materials

Let’s compare how different valve materials handle common treatment chemicals. This table shows why PVC is often the best choice.

| Valve Material | Resistance to Chlorine | Resistance to Acids | Resistance to Alkalis | Risk of Contamination |

|---|---|---|---|---|

| PVC | Excellent | Excellent | Excellent | Very Low |

| Stainless Steel 316 | Good (but can pit) | Fair to Good | Good | Low (but can leach metals) |

| Cast Iron | Poor (rusts quickly) | Poor | Fair | High (rust particles) |

| Bronze | Poor | Poor | Fair | Medium (can leach copper) |

As you can see, PVC provides consistently high performance across all major chemical types. This uniformity is a major advantage. You don’t need to specify a different valve material for different points in the plant. PVC works reliably from the inlet to the final disinfection stage.

Long-Term Reliability in Harsh Environments

This chemical inertness translates directly to longer service life and system safety. A corroded metal valve can fail in two ways: first, it can leak, causing process inefficiency or safety hazards. Second, corrosion products like rust or metal ions can flake off into the water stream. This is unacceptable in potable water treatment. PVC valves eliminate both problems. They maintain their structural integrity and do not add any contaminants to the water. For plant managers, this means fewer emergency shutdowns, lower risk of regulatory non-compliance, and consistent water quality output.

Why Are PVC Valves a Cost-Effective Choice for Large Water Treatment Systems?

Budget constraints are a constant reality. For large-scale projects, the cost savings from choosing PVC valves can be massive, freeing up capital for other critical areas.

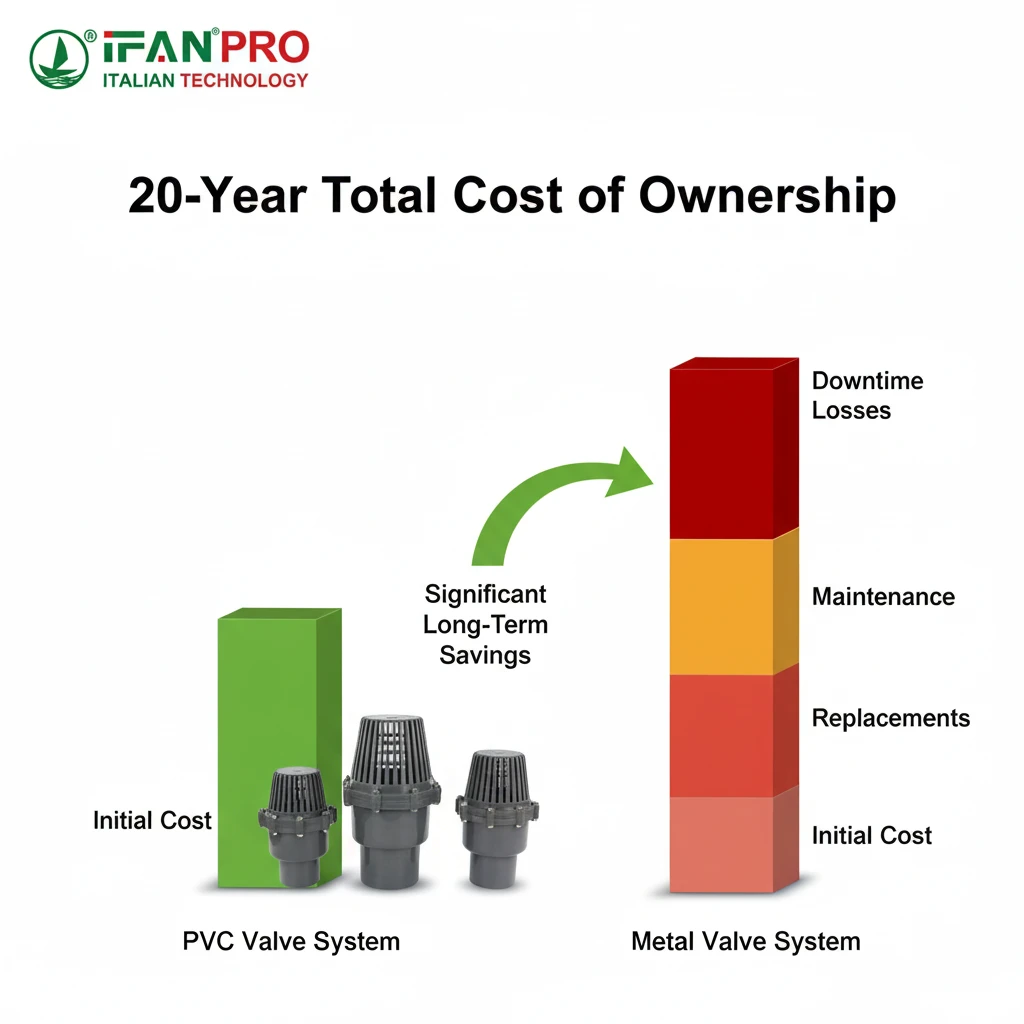

PVC valves are cost-effective because they have a significantly lower initial purchase price than equivalent metal valves. When you multiply this by hundreds or thousands of valves in a large plant, the savings are substantial. Furthermore, their minimal maintenance needs, light weight (reducing support costs), and long lifespan deliver the lowest total cost of ownership over decades of operation.

Analyzing the Initial Investment

The first cost advantage is clear. A 2-inch PVC ball valve costs a fraction of a 2-inch stainless steel ball valve. In a large treatment facility requiring thousands of valves, this difference in material cost can amount to hundreds of thousands of dollars. This direct saving allows engineers to stay within budget or allocate funds to more advanced filtration technology or automation systems.

However, the savings go far beyond the initial invoice. The lightweight nature of PVC creates a chain of further cost reductions. PVC valves are much easier and safer to handle, requiring less manpower for installation. They also do not need heavy support structures. Metal valves, especially in larger sizes, require sturdy metal supports and sometimes even lifting equipment to install, adding significant material and labor costs.

The Lifecycle Cost Advantage

The real financial power of PVC is revealed when you look at the total cost over 20 or 30 years. Let’s examine the key factors:

- Minimal Maintenance: As established, PVC does not corrode. This means you avoid the constant costs associated with repacking glands, replacing corroded stems or seats, and painting metal bodies to prevent rust. Maintenance becomes predictive rather than reactive.

- Energy Efficiency: The smooth bore of PVC valves and fittings offers less flow resistance compared to corroded or scaled metal pipes. This reduces pumping energy costs over time.

- Long Service Life: A properly specified and installed PVC valve can last as long as the piping system itself in a water treatment environment, often exceeding 20-30 years without replacement.

Total Cost of Ownership Comparison

This table illustrates the cost difference for a hypothetical installation of 100 valves in a treatment plant.

| Cost Factor | PVC Valves | Stainless Steel Valves |

|---|---|---|

| Initial Valve Cost | $5,000 | $25,000 |

| Installation Support/Labor | $2,000 | $8,000 |

| Estimated Maintenance (20 years) | $1,000 | $10,000 |

| Potential Replacements | $0 | $12,500 |

| Total 20-Year Cost | $8,000 | $55,500 |

The numbers speak for themselves. The lower upfront cost of PVC is just the beginning. The dramatic reduction in maintenance and replacement expenses makes PVC valves the most economical choice for large-scale, long-term projects.

How Do PVC Valves Ensure Reliable Flow Control in Filtration and Dosing?

Precise control is the heart of effective treatment. Unreliable valves disrupt the entire process, but PVC valves provide the consistency needed for critical operations.

PVC valves ensure reliable flow control through their tight shut-off capabilities and smooth operation. Whether used for isolating filter beds, regulating backwash cycles, or accurately dosing chemicals, their design prevents sticking and provides consistent performance. This reliability is crucial for maintaining process parameters and ensuring treated water meets quality standards.

Applications in Key Treatment Processes

Water treatment is a series of controlled processes. Valves are the instruments that direct, start, and stop these flows. PVC valves excel in several critical applications due to their design and material properties.

In filtration, PVC valves are used to direct water to different filter beds and to control the backwash sequence. A delayed or leaking valve during backwash can lead to poorly cleaned media, reducing filtration efficiency. PVC valves, particularly ball valves and diaphragm valves, offer quick, quarter-turn operation or reliable linear control, ensuring sequences happen exactly on time.

For chemical dosing, accuracy is everything. Adding too much or too little coagulant or disinfectant compromises water safety. PVC needle valves or precision ball valves allow for fine, incremental adjustment of chemical flow. Their non-sticking properties mean the setting you make today will be the same tomorrow, unlike metal valves that can seize or corrode in place.

Valve Types and Their Specific Roles

Different PVC valve types are suited for different control functions. Understanding this helps in selecting the right valve for the job.

| Valve Type | Best For | Reason for Reliability |

|---|---|---|

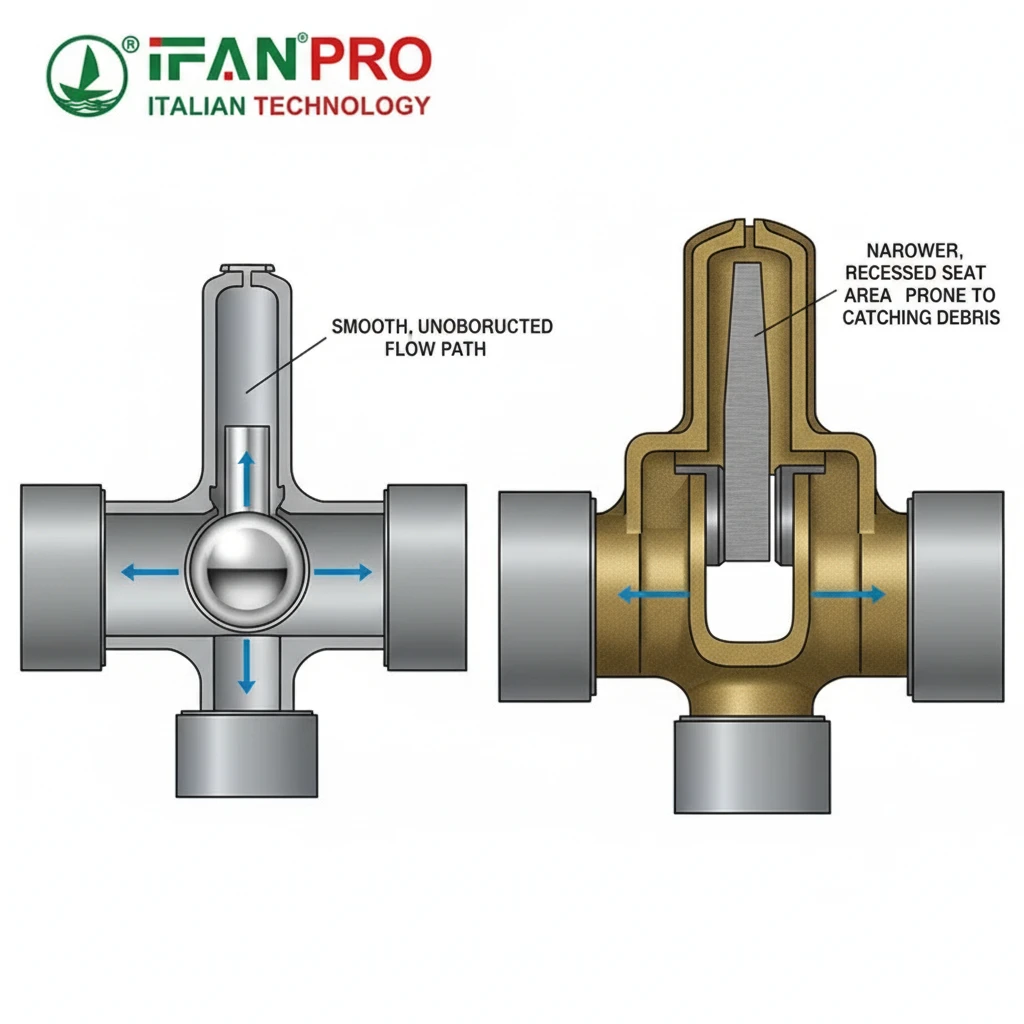

| PVC Ball Valve | On/Off isolation, backwash control. | Simple 90-degree operation, full port design for minimal pressure drop, excellent seal. |

| PVC Diaphragm Valve | Throttling/Regulating flow, abrasive slurries. | Diaphragm isolates the working parts from the flow, preventing clogging and corrosion. |

| PVC Check Valve | Preventing backflow in pump discharge lines. | Simple spring or swing mechanism ensures flow goes only one direction, protecting pumps. |

| PVC Butterfly Valve | On/Off or modulating control in large pipes. | Compact, lightweight design for large diameters, easy to automate for process control. |

Ensuring Consistent Operation

Reliability also comes from consistent performance over time. The smooth interior of PVC prevents scaling and buildup that can obstruct valve mechanisms or disrupt flow profiles. In metal valves, mineral deposits can cause discs to stick or prevent gates from closing fully. PVC’s chemical resistance also ensures that the valve seals—often made of EPDM or Viton—are not attacked and degraded by the process media, maintaining a leak-tight seal for years.

For plant operators, this translates to predictable process control. Automated systems can rely on PVC valves to open and close as commanded. Manual valves remain easy to operate. This reliability is fundamental to running an efficient, automated, and safe water treatment plant.

What Are the Installation and Maintenance Advantages of Using PVC Valves?

Time spent on installation and upkeep is money lost. PVC valves turn complex, lengthy procedures into simple, fast tasks that any technician can handle.

PVC valves offer major installation and maintenance advantages because they are lightweight, easy to cut and join with solvent cement, and require no welding, threading, or heavy equipment. Their corrosion-free nature means maintenance is largely limited to occasional cleaning and seal inspection, avoiding the frequent repairs needed for metal valves in corrosive environments.

Streamlining the Installation Process

Installing a PVC valve is a straightforward process that drastically reduces labor time and complexity. The valve is simply fitted between two sections of PVC pipe. The connection is made using PVC solvent cement, which creates a permanent, leak-proof bond in minutes. This eliminates several time-consuming and skill-intensive steps required for metal valves.

Compare this to a metal valve installation: Pipes must be precisely threaded or prepared for welding. Welding requires certified welders, hot work permits, fire watches, and post-weld inspection. Threading requires heavy machinery and creates potential leak points at every joint. PVC installation is cleaner, safer, and faster, allowing construction crews to move quickly.

A Step-by-Step Advantage

The table below highlights the key differences in the installation workflow.

| Installation Step | PVC Valve Process | Metal Valve Process |

|---|---|---|

| 1. Preparation | Dry-fit and mark pipes. | Measure, cut, and deburr pipe. |

| 2. Joint Preparation | Clean pipe/valve ends with primer. | For threading: Set up threading machine. For welding: Bevel pipe end, clean. |

| 3. Joining | Apply solvent cement and assemble. Hold for 30 seconds. | Weld (with arc/gas) or thread pipe and screw valve on. |

| 4. Completion | Allow 15 minutes for cure before pressure test. | Allow weld to cool; inspect threads; possibly apply sealant. |

Simplifying Long-Term Maintenance

The maintenance benefits are even more significant over the plant’s lifespan. The core principle is simple: if it doesn’t corrode, it doesn’t need fixing. A PVC valve’s primary maintenance task is visual inspection and occasionally exercising the valve (turning it) to keep it moving freely.

Consider the alternative. A metal valve in a wet, chemical-laden environment requires regular attention:

- Stem Packing: Glands need to be repacked regularly to prevent leaks around the stem.

- Corrosion Removal: Exterior rust must be removed and the valve repainted.

- Seat Replacement: Corroded or worn valve seats must be machined or replaced.

- Frozen Mechanisms: Stems can seize due to corrosion, requiring forceful operation or complete valve replacement.

PVC valves avoid all these issues. If a seal does eventually wear out after many years, many PVC valves have replaceable seats or diaphragms, making refurbishment quick and cheap compared to replacing the entire valve. This ease of maintenance minimizes plant downtime and keeps operational costs predictable and low.

Заключение

PVC valves deliver unbeatable chemical resistance, cost savings, reliable control, and easy installation for water treatment. For high-quality, certified PVC valves that meet these demands, choose ИФАН for your plant’s critical infrastructure.

Последние комментарии