Ten years ago, a client asked me about “green” pipes, and most saw it as a cost. Today, they demand it—and for good reason.

Sustainability is becoming key in pipe manufacturing because it directly addresses urgent environmental regulations, reduces long-term project costs, mitigates climate risks, and meets the growing market demand from both consumers and investors for responsible, future-proof building materials. It is no longer just an option but a business imperative for staying competitive and compliant.

The shift is real and accelerating. Let’s explore the concrete factors driving this change and the tangible benefits for your next project.

How Do Regulations and Green Building Standards Drive Sustainable Material Use?

I recall a project nearly failing inspection because the pipes didn’t meet a new local green code. Regulations have moved from suggestion to strict requirement.

Government regulations and green building standards like LEED, BREEAM, and local codes drive sustainable material use by mandating reductions in embodied carbon, restricting harmful chemicals, and rewarding the use of recycled content. Manufacturers must adapt their formulas and processes to earn certifications that are now essential for entering major construction tenders and projects.

The Force of Law and Market Access

You can think of regulations and standards as the primary engine for change. They create a non-negotiable framework that dictates what materials are acceptable. This isn’t just about being “green”; it’s about legal compliance and market access.

First, consider building codes. Cities and countries worldwide are updating their codes to mandate higher environmental performance. For pipes, this often means:

- Low Embodied Carbon: Requirements to calculate and reduce the total greenhouse gas emissions from producing the material.

- Material Health: Restrictions on volatile organic compounds (VOCs), heavy metals, and plasticizers that can leach into water or air.

- Durability and Waste: Standards that favor long-life products to minimize future waste.

Second, voluntary green building standards have become de facto mandates for high-value projects. LEED (Leadership in Energy and Environmental Design) is the most well-known. Specifying pipes with recycled content, low VOC emissions, and from manufacturers with environmental management systems (like ISO 14001) earns crucial points for the entire building’s certification.

The Direct Impact on Material Choice

This regulatory push forces a shift away from traditional, resource-intensive materials. For example, producing PVC from virgin materials has a higher carbon footprint than producing polypropylene. Standards that reward recycled content push manufacturers to develop advanced recycling streams for their production waste and post-consumer material.

The table below shows how common standards directly influence pipe manufacturing specs:

| Standard/Code | Key Requirement for Pipes | Manufacturer’s Response |

|---|---|---|

| LEED v4.1 | Credits for recycled content, material ingredient reporting, and low-emitting materials. | Use post-industrial/post-consumer recyclate, provide HPDs (Health Product Declarations), eliminate harmful additives. |

| BREEAM | Focus on life cycle assessment (LCA) and responsible sourcing. | Conduct and publish LCA studies, source raw materials from suppliers with ESG policies. |

| International Green Construction Code (IgCC) | Sets baseline for material sustainability and waste reduction. | Design for durability, reduce packaging waste, optimize production energy use. |

| Local Plumbing Codes (e.g., in EU/US cities) | Increasingly ban certain substances (e.g., lead) and mandate water efficiency. | Develop “green” compound formulas and ensure full material traceability. |

For a project manager or specifier, choosing a pipe without these certifications now carries tangible risk: the risk of failing inspection, losing a contract, or devaluing the building asset. Sustainable material use is, therefore, a direct response to these market signals. It transforms compliance from a cost center into a competitive advantage.

What Are the Lifecycle Assessment Benefits of Durable, Recyclable Piping?

We once replaced a 20-year-old galvanized system. The waste was staggering. Modern LCA shows the true cost of that “cheap” initial choice.

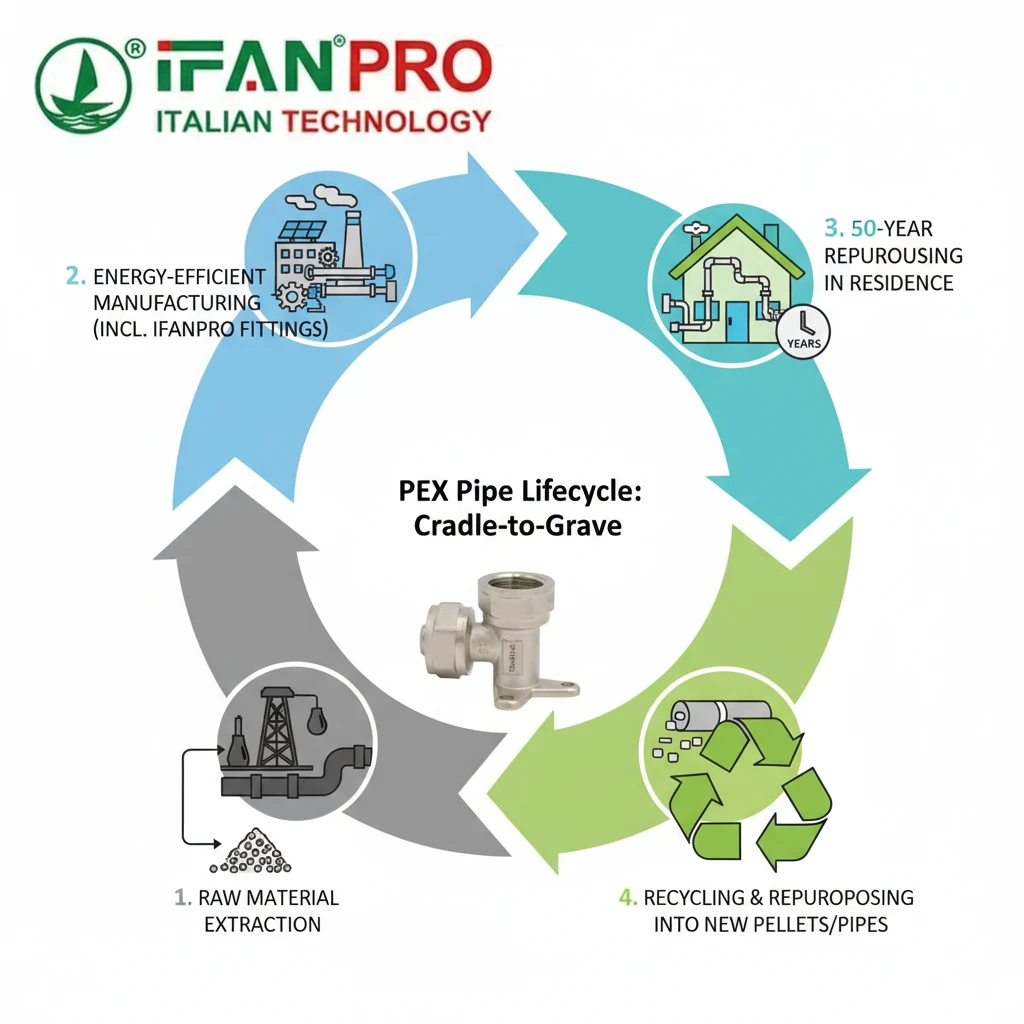

The lifecycle assessment (LCA) benefits of durable, recyclable piping are profound: they drastically lower the total environmental impact across decades. Durable pipes avoid frequent replacements, saving raw materials and energy. Recyclable pipes keep material in a circular loop at end-of-life, reducing landfill waste and the need for virgin resource extraction.

Looking Beyond the Purchase Price

Lifecycle Assessment is a method that measures the environmental impact of a product from “cradle to grave”—from raw material extraction to manufacturing, transport, use, and final disposal. For pipes, the “use” phase is where durable products shine, and the “end-of-life” is where recyclability matters.

Let’s break down the LCA benefits stage by stage:

1. Production & Installation (The First Cost): This stage includes the environmental impact of making the pipe. While recycled materials can lower this impact, the key is to view this cost in context. A slightly higher impact here can be justified if it saves massive impacts later.

2. Use Phase (The Long Haul): This is the most impactful phase for durable products. A PP-R pipe system that lasts 50+ years without leaks, corrosion, or loss of performance has an incredibly low annual environmental impact. It avoids the repeated manufacturing, transportation, and installation impacts of replacing inferior pipes every 20 years. It also minimizes water damage and associated repair waste.

3. End-of-Life (Closing the Loop): At the end of its long service life, a recyclable pipe becomes a valuable resource, not waste. Thermo-plastics like PP-R can be cleaned, shredded, and re-pelletized to make new pipes or other products. This closed-loop recycling drastically cuts down on landfill use, ocean pollution, and the environmental damage of mining or drilling for new plastic or metal.

Quantifying the Savings with LCA

An LCA study might compare two piping systems over a 50-year building lifespan. The results consistently show that the long-life, recyclable option wins.

| Impact Category | Traditional Pipe (e.g., Short-life PVC/Metal) | Durable & Recyclable Pipe (e.g., PP-R) | Why the Difference? |

|---|---|---|---|

| Global Warming Potential | Higher | Lower | Avoids the carbon emissions from manufacturing 2-3 replacement systems. |

| Resource Depletion | Higher | Lower | Uses less virgin material over time; recycled content further reduces demand. |

| Waste Generation | Higher | Lower | One installation vs. multiple replacements; material is recycled, not landfilled. |

| Water Pollution Risk | Higher | Lower | No corrosion or leaching over its lifespan; no replacement excavation disturbing soil. |

For your project, this means specifying durable, recyclable piping is one of the most effective decisions you can make to reduce the building’s long-term environmental footprint. It turns the piping system from a liability into a legacy of resource efficiency.

How Do Energy-Efficient Production Processes Reduce the Total Carbon Footprint?

Touring our partner factories, I saw old machines humming and new ones purring. The energy meter told the whole story: modernization cuts carbon.

Energy-efficient production processes reduce the total carbon footprint by consuming less electricity and fossil fuels during the most energy-intensive phase: manufacturing. This includes using advanced, low-energy extruders, recovering and reusing process heat, powering plants with renewable energy, and optimizing material flow to minimize waste that would need re-processing.

The Manufacturing Hotspot

For any product, the manufacturing stage is often a major contributor to its carbon footprint. For plastic pipes, the two most energy-intensive steps are:

- Raw Material Production: Creating the plastic resin.

- Pipe Extrusion: Melting and forming the resin into pipes.

Therefore, focusing on the efficiency of the extrusion process and the energy source of the factory yields significant carbon reductions.

Key Strategies in Efficient Manufacturing

Modern, sustainable pipe manufacturers employ several key strategies:

1. High-Efficiency Extrusion Lines: Newer extruder designs use advanced screw technology and better insulation to melt plastic using significantly less electrical energy per kilogram of output. Some can recover the rotational inertia of the motors to feed energy back into the grid.

2. Heat Recovery Systems: The extrusion process generates a lot of waste heat. Advanced factories capture this heat from cooling tanks and machine barrels. They then reuse it to pre-heat incoming raw materials or to heat office spaces, reducing reliance on external heating fuels.

3. On-Site Renewable Energy: The most forward-thinking manufacturers install solar panels on factory roofs or purchase wind power. This directly decarbonizes the electricity used in production. When you buy a pipe made in a solar-powered plant, its embedded carbon from manufacturing is much lower.

4. Process Optimization and Lean Manufacturing: This reduces carbon in a less obvious way. By perfecting production schedules, minimizing start-up/shut-down cycles, and reducing material waste (off-cuts, startup purges), the factory produces more usable pipe with the same energy input. Less waste means less material to recycle or discard, avoiding those secondary carbon costs.

The Carbon Math: A Practical Example

Consider two factories making the same PP-R pipe.

- Factory A uses older equipment and grid electricity (largely from coal).

- Factory B uses modern extruders with heat recovery and runs on 50% solar power.

The carbon footprint of the pipe from Factory B can be 30-50% lower just from these operational choices. For a large project using thousands of meters of pipe, this difference translates into tons of CO2 saved, which can contribute directly to the project’s overall carbon reduction goals.

Specifying pipes from manufacturers who prioritize production efficiency is a direct lever you can pull to lower the embodied carbon of your building.

Why Does Sustainable Sourcing Future-Proof Your Projects and Brand?

A client’s brand was once targeted for using pipes from a polluting supplier. Their “cheap” source became a costly reputation disaster.

Sustainable sourcing future-proofs your projects and brand by mitigating four key risks: 1) Regulatory bans on irresponsibly sourced materials, 2) Supply chain disruptions from climate or social unrest, 3) Reputational damage from association with polluting or unethical suppliers, and 4) Cost volatility from resource scarcity. It builds resilience and aligns with inevitable market trends.

Building Resilience Against Future Shocks

Future-proofing is about managing risk. Traditional sourcing often seeks the lowest upfront cost, ignoring hidden vulnerabilities. Sustainable sourcing looks at the entire supply chain for stability and ethics.

Let’s examine the key risks it mitigates:

1. Regulatory and Legal Risk: Governments are increasingly passing “due diligence” laws. These laws require companies to ensure their supply chains are free from environmental harm and human rights abuses. If your pipe supplier is dumping waste illegally or has poor labor practices, your project could face legal liability, fines, or be barred from future public tenders. Sustainable sourcing with verified audits removes this risk.

2. Physical Supply Chain Risk: Climate change causes extreme weather that disrupts ports, roads, and factories. Sourcing from suppliers who manage their water, energy, and waste responsibly makes them more resilient to these shocks. A supplier with water recycling is less likely to shut down during a drought. This means more reliable deliveries for your project timeline.

3. Reputational and Market Risk: End-consumers, investors, and tenants are increasingly making choices based on sustainability. If your project is exposed for using materials linked to deforestation or pollution, it can damage the brand of the developer, builder, and owner. Sustainable sourcing is a powerful marketing story that protects and enhances brand value.

4. Economic Risk: Virgin resources are becoming scarcer and more expensive. A supply chain dependent on them is exposed to price spikes. Suppliers using recycled content or sustainably managed biopolymers are less tied to volatile commodity markets, offering more stable long-term pricing.

The Practical Path to Future-Proof Sourcing

How do you implement this? It starts with asking the right questions to your pipe supplier, like IFAN:

- Origin of Raw Materials: Can they provide traceability for their polymer?

- Supplier Code of Conduct: Do their sub-suppliers adhere to environmental and social standards?

- Circularity Plan: What is their process for taking back and recycling installation scrap or end-of-life pipes?

- Certifications: Do they have independent audits like ISO 14001 (Environmental Management) or participate in product stewardship schemes?

Choosing a partner committed to these principles is no longer a niche choice. It is the strategic choice for anyone building assets meant to last—and retain value—in the 21st century.

Заключение

Sustainable pipe manufacturing is essential for compliance, cost savings, and risk reduction. For your next project, choose IFAN’s green-certified PP-R piping systems, designed for durability, recyclability, and low-carbon production.

Последние комментарии