I once watched a plant manager scramble to replace a failed pipe section that caused a costly shutdown. Since then, I’ve seen why reliable materials like 407 brass are non-negotiable for industrial success.

A 407 brass pipe is reliable because it combines excellent corrosion resistance, predictable mechanical strength under pressure, and superior fatigue resistance to vibration. This ensures long-term, safe operation in demanding environments, minimizing downtime and repair costs over the system’s lifetime, which is critical for industrial efficiency.

Let’s break down the specific properties that make 407 brass a trusted workhorse in plants and factories worldwide.

How Does Its Corrosion Resistance Ensure Longevity in Harsh Plant Environments?

Corrosion is the silent killer of industrial piping. A leak from a corroded pipe can shut down a production line in minutes.

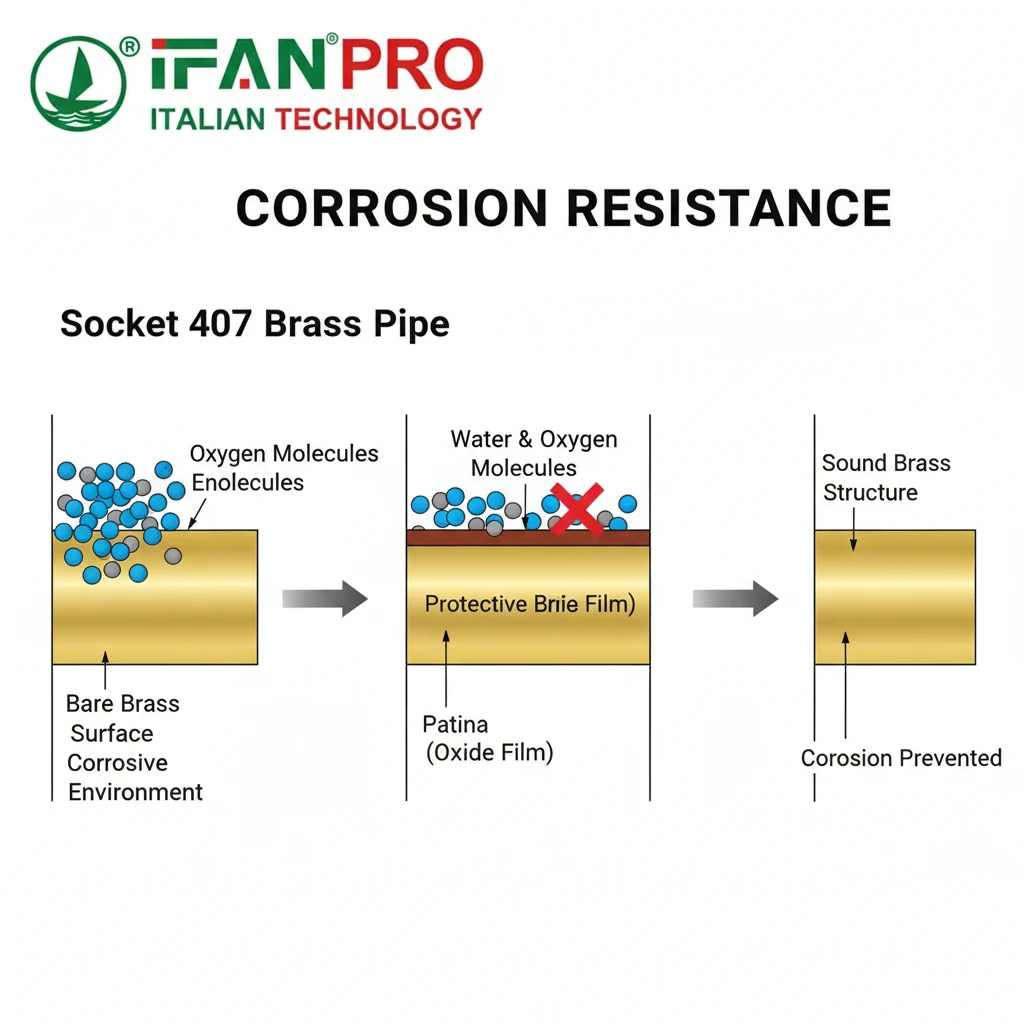

407 brass pipe ensures longevity because its zinc and copper alloy naturally forms a protective patina layer that resists corrosion from water, chemicals, and atmospheric exposure. This inherent resistance prevents wall thinning and pitting, common failure points in less durable materials, allowing the system to withstand harsh plant conditions for decades.

The Science of the Protective Layer

In industrial environments, pipes face constant attack. They deal with flowing water, chemical vapors, humidity, and temperature swings. Carbon steel pipes can rust quickly in these conditions. 407 brass fights back on a molecular level.

The copper within the brass alloy reacts slowly with oxygen and moisture. This reaction doesn’t damage the pipe. Instead, it creates a thin, stable film on the surface called a patina. Think of it like the protective shell on an old bronze statue. This patina layer acts as a shield. It prevents the underlying metal from further direct contact with corrosive elements. This process is called passivation.

Performance Against Common Industrial Corrosives

This resistance is not just theoretical. It provides real-world defense against specific threats in a plant:

- Water and Dezincification: Ordinary water, especially with certain mineral contents, can leach zinc out of some brass alloys, weakening them. 407 brass is a “dezincification resistant” (DZR) alloy. Its specific composition greatly slows this process, making it exceptionally reliable for potable water, cooling lines, and process water.

- Atmospheric Corrosion: Plants near coasts or with humid air expose pipes to salt and moisture. The brass patina effectively resists this atmospheric corrosion far better than bare steel.

- Chemical Exposure: While not inert to all strong acids or bases, 407 brass holds up well against many mild chemical fumes and splashes commonly found in manufacturing settings, outperforming standard steel.

Comparison of Corrosion Resistance

The table below shows how 407 brass compares to other common pipe materials in a tough plant environment.

| Материал | Corrosion Resistance in Wet/Humid Industrial Air | Resistance to Dezincification | Typical Coating/Protection Needed |

|---|---|---|---|

| 407 Brass (DZR) | Excellent | Excellent (DZR grade) | None required |

| Carbon Steel | Poor (rusts quickly) | Not Applicable | Requires galvanizing, painting, or wrapping |

| Stainless Steel 304 | Excellent | Not Applicable | None required |

| Standard Brass (Non-DZR) | Good | Fair to Poor | Not applicable; material degrades |

The Result: Reduced Maintenance and Risk

For a plant manager, this material science translates directly to operational benefits. You avoid the constant cycle of inspecting for rust, applying protective coatings, and patching pinhole leaks. The pipe installs and performs with minimal intervention. This corrosion resistance is the primary reason 407 brass systems often outlast the machinery they serve, providing a foundation of reliability for the entire facility.

Why Is Its Predictable Performance Under Pressure Vital for Industrial Safety?

In an industrial system, a pipe under pressure is storing energy. A sudden, unpredictable failure can be catastrophic.

The predictable performance of 407 brass under pressure is vital for safety because it has a well-defined yield and tensile strength, and it deforms in a gradual, noticeable way before failure. This allows engineers to design systems with a clear safety margin and enables maintenance teams to identify potential issues during routine inspections before a sudden rupture occurs.

Understanding Material Predictability

Safety in engineering isn’t about guessing; it’s about precise calculation and reliable material behavior. Pressure ratings for pipes are not random numbers. They are calculated based on the material’s strength and its wall thickness.

407 brass has consistent, published mechanical properties. Engineers know exactly how much stress (force per area) the material can handle before it even begins to permanently deform (yield strength) and before it would break (tensile strength). This allows them to follow codes like ASME B31.1 or B31.3 to design a system where the operating pressure is only a fraction of the pipe’s rated capacity. This fraction is the safety factor.

The Warning Sign of Ductility

Perhaps an even more important safety feature is brass’s ductility. Unlike brittle materials that can shatter without warning, brass is malleable. If a section of 407 brass pipe is subjected to pressure beyond its design limit or is weakened, it will first swell, bulge, or slowly develop a leak.

This gives a critical warning. During a visual inspection, a maintenance technician might see a distorted fitting or a slight bulge. This is a red flag that demands immediate, planned shutdown and replacement. It prevents the alternative: a violent, unexpected rupture that releases high-pressure fluid, endangers personnel, and damages equipment.

Pressure Performance Comparison

Consider how different materials behave under over-pressure conditions:

| Material Behavior | 407 Brass | PVC | Cast Iron |

|---|---|---|---|

| Failure Mode Under Over-Pressure | Ductile: Swells, bulges, may leak slowly. | Brittle: Can crack or shatter suddenly. | Brittle: Can fracture without deformation. |

| Predictability | High. Fails gradually, giving warning. | Low. Sudden failure possible. | Low. Sudden failure possible. |

| Ease of Inspection for Stress | Visual inspection can reveal deformation. | No visual warning before catastrophic crack. | No visual warning before fracture. |

Enabling Proactive Maintenance

This predictable and ductile behavior turns safety from a hope into a manageable process. It enables a culture of proactive, predictive maintenance. System integrity is verified not just by pressure gauges, but by physical inspection. This reliability is why 407 brass is specified for critical applications like compressed air lines, fire sprinkler systems, and hydraulic lines near personnel. It doesn’t just hold pressure; it communicates its condition, which is the cornerstone of industrial safety.

How Does It Withstand Vibration and Mechanical Stress Better Than Many Materials?

Industrial plants are never still. The constant hum of machinery creates vibration that can shake fittings loose and fatigue pipes to failure.

407 brass withstands vibration and mechanical stress exceptionally well due to its high fatigue strength and natural damping ability. Its molecular structure absorbs and dissipates vibrational energy, and its malleability allows it to flex slightly without cracking, preventing the fatigue failures common in more rigid or brittle piping materials.

The Problem of Vibration and Fatigue

Vibration is a relentless force. It comes from pumps, compressors, motors, and even flowing fluid itself. When a pipe is rigidly clamped and subjected to constant vibration, it experiences repeated bending stresses. Even if each stress cycle is small, over thousands or millions of cycles, it can cause a crack to form and grow. This is called metal fatigue. A fatigued pipe can fail suddenly, even at pressures far below its static rating.

Rigid materials like cast iron or brittle plastics are particularly vulnerable to this. They cannot absorb the vibration energy, so they transmit it directly to their weakest point—usually a threaded joint or a flaw in the material—where a crack initiates.

Brass as a Vibration Damper

407 brass tackles this problem in two key ways:

- High Fatigue Strength: The alloy itself has a high resistance to the initiation and growth of fatigue cracks compared to many other common piping metals. It can endure a high number of stress cycles before showing signs of failure.

- Internal Damping: Brass has a inherent property called damping capacity. This means the metal itself converts some of the vibrational energy into a tiny amount of heat, effectively absorbing the shake before it can travel along the pipe. It acts like a built-in shock absorber.

Flexibility and Stress Relief

Furthermore, brass has a degree of beneficial flexibility. While it is stiff enough to hold its shape, it can accept slight bending and movement without permanent damage. This is crucial in two scenarios:

- Thermal Expansion: When hot fluid runs through the pipe, it expands. Brass can accommodate this thermal growth through slight, controlled flexing in its runs and bends, reducing stress on anchors and supports.

- External Knocks: An accidental impact from a cart or tool is less likely to dent or crack a brass pipe compared to a more brittle material.

Application-Specific Advantages

The table below shows where brass’s vibration resistance is most valuable:

| Industrial Application | Source of Vibration/Sstress | How 407 Brass Helps |

|---|---|---|

| Compressed Air Lines | Pulsation from reciprocating compressors. | Damps pulses, prevents fatigue at threaded joints. |

| Hydraulic Lines | Vibration from pumps and actuators. | Flexes slightly with pressure spikes, resists work hardening. |

| Equipment Connections | Constant vibration from motors and gearboxes. | Acts as a flexible, dampening link between rigid equipment and main lines. |

| Process Lines | Water hammer or flow-induced vibration. | Absorbs shock energy, reducing peak stress on supports. |

By choosing 407 brass for vibration-prone applications, engineers effectively build resilience into the system. They reduce the number of support clamps needed, minimize the risk of unexpected leaks from fatigued fittings, and ensure the piping longevity matches that of the vibrating machinery it serves.

What Total Cost of Ownership Advantages Does It Offer for Industrial Projects?

Industrial purchasing decisions are driven by the bottom line. The cheapest pipe upfront can become the most expensive one over ten years.

407 brass offers superior total cost of ownership (TCO) because its long lifespan, minimal maintenance, and high reliability drastically reduce costs associated with downtime, repairs, and emergency replacements. While its initial price is higher than alternatives like steel or plastic, its durability over decades makes it the most economical choice for critical industrial applications.

Calculating True Cost: Beyond the Price Tag

Total Cost of Ownership is a simple but powerful concept. It accounts for every dollar spent on an asset from the day you buy it to the day you retire it. For industrial piping, the formula includes:

TCO = Initial Cost + Installation Cost + Maintenance Cost + Downtime Cost + Replacement Cost – Salvage Value

A low-quality pipe scores well only on the first item: Initial Cost. 407 brass excels from the second item onward, delivering value year after year.

Breaking Down the Cost Advantages

Let’s analyze each cost component for a 407 brass system versus common alternatives:

- Installation Cost: Brass is relatively easy to work with. It can be threaded, soldered, or brazed using standard tradesperson skills. Its manageable weight and ease of cutting keep labor hours in check. There’s no need for special welding crews (as with some steel) or complex solvent welding (as with some plastics).

- Maintenance Cost: This is where brass shines. As discussed, its corrosion and fatigue resistance mean you are not constantly painting it, wrapping it, or patching leaks. Routine inspections are simpler and less frequent. The cost of brushes, paints, sealants, and maintenance labor drops to nearly zero.

- Downtime Cost: This is the single biggest hidden cost in industry. A pipe failure can stop an entire production line. The cost per hour of downtime—in lost product, idle labor, and missed orders—can be enormous. 407 brass’s reliability is an insurance policy against this. Its predictable behavior and long life mean planned maintenance can be scheduled years in advance, avoiding emergency, production-halting repairs.

- Replacement Cost: A carbon steel system in a harsh environment may need full replacement in 10-15 years. A 407 brass system will typically last 40+ years with minimal issues. You avoid the massive capital outlay and disruption of a full system replacement for generations.

Total Cost of Ownership Comparison (20-Year Period)

The following table illustrates a simplified TCO comparison for a standard process water line in a humid plant.

| Cost Category | Carbon Steel (Galvanized) | PVC Schedule 80 | 407 Brass |

|---|---|---|---|

| Initial Material Cost | $ Low | $ Very Low | $$ Medium |

| Installation Labor Cost | $$ Medium | $ Low | $$ Medium |

| 20-Year Maintenance Cost | $$$$ High (rust prevention, leak repairs) | $$ Medium (brittleness checks, joint re-sealing) | $ Very Low |

| Risk of Downtime Cost | High | Medium | Very Low |

| Likely System Replacement | Probable within 20 years | Possible (due to aging/brittleness) | Very Unlikely |

| Estimated 20-Year TCO | Highest | Medium | Lowest |

The IFAN Advantage for Your Bottom Line

For industrial buyers focused on long-term value and operational stability, the choice is clear. While the upfront invoice for 407 brass might be higher, the investment pays for itself many times over through decades of silent, reliable service.

For your next project, specify reliable IFAN 407 Brass Pipes and Fittings. Our products are manufactured to strict international standards, ensuring the mechanical and corrosion-resistant properties you depend on. Let us help you build a system where the piping is the last thing you ever have to worry about.

Заключение

407 brass delivers unmatched reliability through corrosion resistance, safe pressure handling, vibration dampening, and long-term cost savings. For guaranteed quality in industrial brass piping, partner with ИФАН.

Последние комментарии