During a project audit, I saw a corroded metal valve fail on a main supply line, causing a costly shutdown. This moment cemented why material choice in critical points is non-negotiable.

You should choose a large-diameter PVC ball valve for main lines because it provides unmatched corrosion resistance, ensures smooth and reliable flow control with minimal pressure drop, and offers significant long-term savings on both cost and maintenance compared to traditional metal valves, especially for water and chemical applications.

Let’s break down the key reasons that make PVC ball valves the superior choice for managing flow in your most important pipelines.

What Design Features Make Large-Diameter PVC Ball Valves Ideal for Main Lines?

A valve on a main line is a critical point of control. Its design must be robust and simple. From my visits to installation sites, the right design prevents most operational headaches.

Large-diameter PVC ball valves are ideal for main lines due to their full-port design, which minimizes flow restriction; their lightweight yet strong molded body; and a simple quarter-turn operation that allows for quick, reliable opening and closing even in large sizes, ensuring easy integration and control in big piping systems.

The Importance of Full-Port Design

The main job of a valve on a primary pipeline is to control flow without hindering it when open. This is where the full-port (or full-bore) design of a PVC ball valve becomes critical.

In a full-port valve, the hole through the ball is the same size as the inner diameter of the connected pipe. When you open the valve, the pathway is completely clear. This design has two major benefits for main lines:

- Minimal Pressure Drop: It creates almost no resistance to flow. This means your pumps don’t have to work harder to push fluid through the valve, saving energy.

- Prevents Clogging: The smooth, unobstructed passage is less likely to trap debris or allow for scale buildup, which is vital for maintaining consistent flow in large systems.

Construction and Ease of Operation

Next, consider the build and usability. Large metal valves can be incredibly heavy and difficult to operate.

- Lightweight Strength: PVC valves are significantly lighter than equivalent-sized iron or steel valves. This makes them much easier to handle, transport, and install on large pipelines, reducing labor and equipment costs.

- Simple Quarter-Turn Mechanism: The operation is brilliantly simple: a 90-degree turn of the handle moves the ball from fully open to fully closed. This simplicity is reliable. There are no complex gears or multiple turns required, which makes operation fast and easy, even for large-diameter valves that might be equipped with gear operators.

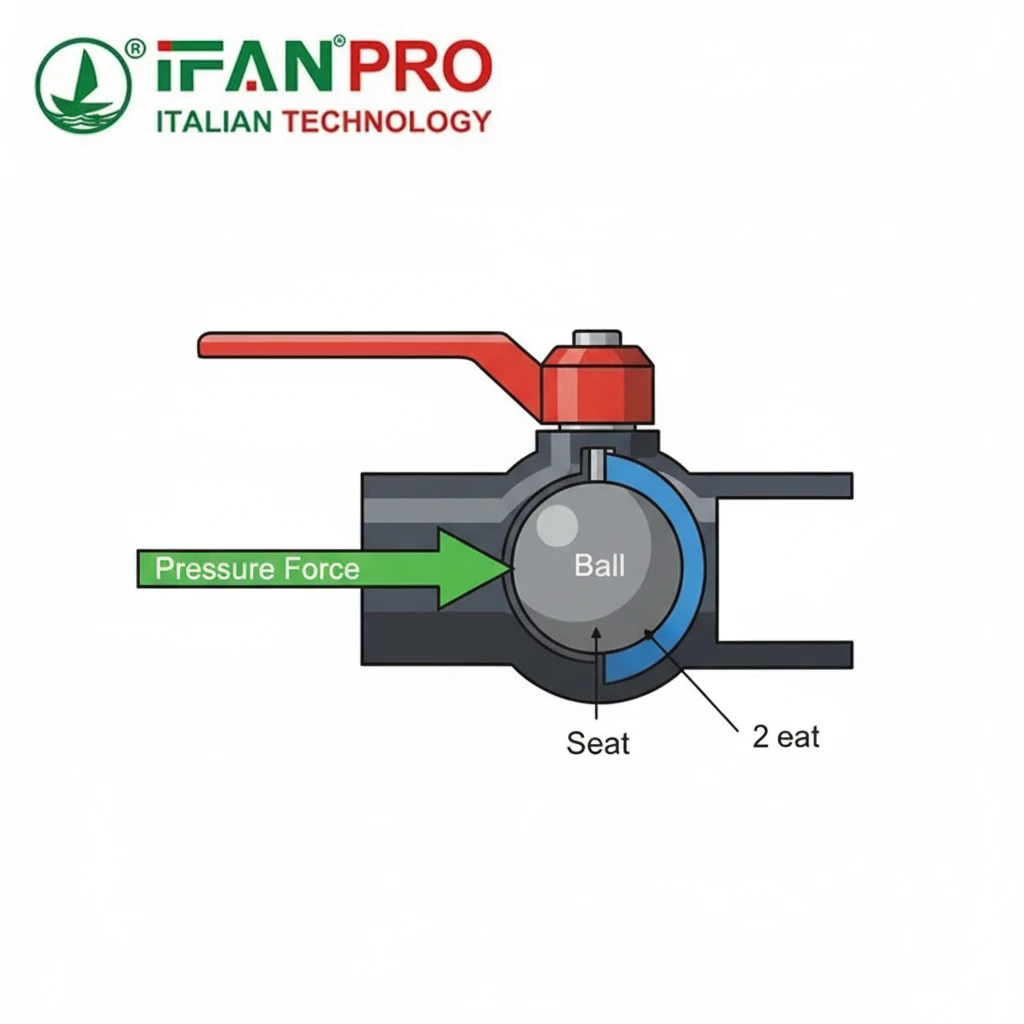

- Robust Seat Design: The valve seats, which create the seal, are typically made from resilient materials like EPDM or Viton. These materials provide a tight seal and can accommodate minor imperfections in the system.

Key Design Features at a Glance

The table below summarizes why these design elements matter for main line applications.

| Design Feature | Benefit for Main Lines | Consequence of Poor Design |

|---|---|---|

| Full-Port Ball | Eliminates flow restriction, reduces pump workload. | Increased energy costs, reduced system capacity. |

| Lightweight PVC Body | Easy and cheap installation, no heavy lifting gear. | Higher installation cost and difficulty. |

| Quarter-Turn Operation | Fast, reliable shut-off in emergencies. | Slow response time, risk of incomplete closure. |

| Molded Body Construction | No internal crevices, smooth flow path, high strength. | Potential for trap points, weak spots, or leaks. |

In summary, the design of a large PVC ball valve is a perfect match for the demands of a main line: it gets out of the way when you need flow and provides a simple, dependable barrier when you need to stop it.

How Do PVC Ball Valves Ensure Reliable Flow Control in Large Piping Systems?

Reliability in flow control means no leaks, no surprises, and precise operation. I’ve analyzed too many system failures that started with a valve that didn’t seal properly.

PVC ball valves ensure reliable flow control through a bubble-tight seal created by the pressurized ball against resilient seats, a simple mechanism with few failure points, and excellent durability that maintains consistent performance without seizing or corroding shut, even after long periods of inactivity.

The Principle of Bubble-Tight Shut-Off

The core of reliable control is the ability to shut off flow completely. PVC ball valves achieve what is known as a “bubble-tight” seal.

Here’s how it works: When the valve is closed, the solid side of the ball blocks the pipeline. System pressure acts on the back of the ball, pushing it firmly against the downstream valve seat (the soft sealing ring). This pressure-activated sealing means that the higher the line pressure, the tighter the seal becomes. The soft seat material (like EPDM) conforms perfectly to the surface of the ball, leaving no path for liquid or gas to escape. This reliability is crucial for isolating sections of a main line for maintenance or in case of a downstream leak.

Simplicity Equals Reliability

In engineering, complexity often introduces potential failure points. The ball valve mechanism is elegantly simple.

- Minimal Moving Parts: Essentially, there is just the ball, the stem, and two seats. Compare this to a gate valve with a rising stem, threads, and a wedge. Fewer parts mean fewer things that can wear out or break.

- No Internal Corrosion: In a metal valve, internal corrosion can cause the ball or gate to stick or the seats to degrade. PVC is immune to this, so the mechanism operates smoothly year after year, whether it’s used daily or only in emergencies.

- Clear Position Indication: A standard ball valve handle shows position at a glance: inline with the pipe means OPEN, perpendicular means CLOSED. This visual cue prevents dangerous operational errors on critical main lines.

Performance in Large Systems

For large-diameter systems, consistent performance is non-negotiable.

| System Demand | How PVC Ball Valve Meets It | Risk with Inferior Valves |

|---|---|---|

| Instant Shut-Off | Quarter-turn allows for rapid closure. | Slow closure can lead to water hammer or fail to contain a leak. |

| Low Pressure Drop | Full-port design offers minimal flow resistance. | Restrictive valves increase pumping costs and limit system flow. |

| Long-Term Stability | Non-corrosive material won’t fuse or seize shut. | Metal valves can corrode closed, becoming unusable in a crisis. |

| Bi-Directional Flow | Seals effectively regardless of flow direction. | Some valves (like check valves) only work in one direction. |

This combination of a pressure-energized seal, mechanical simplicity, and material integrity ensures that when you need to control the flow in your main line—whether to direct, throttle, or stop it—a PVC ball valve will perform reliably every time.

Why Is Corrosion Resistance Critical for Valves in Main Water and Chemical Lines?

Corrosion is the silent killer of piping systems. The cost of replacing a failed valve on a buried main line is astronomical, not just in parts, but in downtime.

Corrosion resistance is critical because a valve failure on a main line can cause catastrophic system shutdowns, product loss, and environmental hazards. PVC’s complete immunity to electrochemical corrosion, rust, and most chemical attacks guarantees the valve’s structural integrity and sealing function over decades, unlike metals which degrade and fail from the inside out.

The High Cost of Valve Failure

A valve is often the weakest link in a pipeline because it has moving parts and complex geometry. When corrosion attacks a metal valve on a main line, the consequences are severe:

- Leakage: Corrosion can eat through the valve body or damage the sealing surfaces, leading to leaks. In a water main, this wastes resources and can damage infrastructure. In a chemical line, it poses safety and environmental risks.

- Catastrophic Failure: The valve body can split or the internals can seize completely. You lose all control over that section of pipeline, forcing a full, urgent shutdown.

- Contamination: In water lines, rust and corrosion products from metal valves flake off and travel downstream, contaminating the water supply. This affects quality, taste, and can stain fixtures.

PVC: The Inherently Corrosion-Resistant Material

PVC stands apart because its resistance is not a coating—it’s a property of the material itself.

- No Electrochemical Reaction: Unlike iron or steel, PVC does not undergo galvanic corrosion. It can be installed in contact with other metals or in moist, electrolytic soils without degrading.

- Chemical Inertness: PVC offers excellent resistance to a wide range of acids, bases, salts, and oxidants commonly found in water treatment, irrigation, and industrial processes. This makes it perfect not just for potable water, but also for aggressive chemical service where stainless steel might be cost-prohibitive.

- No Rust, No Scaling: The smooth PVC surface will not rust or develop mineral scale build-up. This maintains the full bore diameter and smooth operation for the life of the system.

Material Selection Guide for Valve Bodies

Choosing the wrong valve material for your service fluid leads directly to the pain points of failure and high cost.

| Fluid Service | Typical Metal Valve Choice | Risk of Corrosion | PVC Valve Performance |

|---|---|---|---|

| Potable Water | Ductile Iron, Brass | Rust, dezincification, lead leaching. | Excellent. No corrosion, no contamination. |

| Wastewater/Sewage | Cast Iron | Rapid corrosion from H2S gas and microbes. | Superior. Highly resistant to biogenic sulfide corrosion. |

| Saltwater/Irrigation | Stainless Steel (316) | Pitting and crevice corrosion from chlorides. | Excellent. Immune to chloride attack. |

| Mild Chemical Lines | Stainless Steel | Can be attacked by specific acids/halogens. | Good to Excellent. Resists many chemicals that attack metals. |

In short, specifying a corrosion-resistant PVC ball valve for a main line is a proactive decision. It removes one of the biggest variables that lead to unpredictable system failure. You are not just buying a valve; you are buying long-term peace of mind and system integrity.

What Cost and Maintenance Advantages Do Large-Diameter PVC Ball Valves Provide?

Total cost dictates most procurement decisions. In my comparisons for clients, the lifetime cost of PVC valves consistently beats metals, often surprising them.

Large-diameter PVC ball valves provide major cost advantages through lower initial purchase price, drastically reduced installation costs due to light weight, and near-zero maintenance needs because they don’t corrode, scale, or seize. This results in the lowest total cost of ownership over the system’s lifespan.

Breaking Down the Initial and Installation Savings

The financial benefits start from the moment you purchase the valve.

- Lower Purchase Price: The raw material and manufacturing process for PVC valves is generally less expensive than for equivalent-sized carbon steel, ductile iron, or stainless steel valves. For large diameters, this price difference can be substantial.

- Dramatically Lower Installation Cost: This is often the most overlooked saving. A 12-inch ductile iron valve can weigh hundreds of pounds and requires heavy machinery (cranes, excavators) and a crew to lift and position it. A 12-inch PVC valve might weigh 80% less. It can often be moved and installed by two or three workers without heavy equipment. This slashes installation time and cost.

The True Savings: Minimal Lifetime Maintenance

After installation, the cost profile of PVC versus metal diverges completely. Metal valves require ongoing maintenance and eventual replacement; PVC valves largely do not.

Maintenance Requirements Comparison:

| Maintenance Activity | Metal Valve (e.g., Ductile Iron) | PVC Ball Valve |

|---|---|---|

| Preventative Cycling | Required regularly to prevent seizing. | Not required. Won’t seize. |

| External Painting/Coating | Required to protect against atmospheric corrosion. | Not required. Material is immune. |

| Internal Cleaning/Descaling | Often needed to remove rust and scale buildup. | Not required. Smooth bore stays clean. |

| Packing/Gland Adjustment | Often needed on stem seals over time. | Rarely needed. Simple seal design. |

| Lubrication | Required for gears and threads on large valves. | Not required for valve operation. |

| Expected Service Life | 15-25 years before major refurbishment or replacement. | 50+ years with no degradation. |

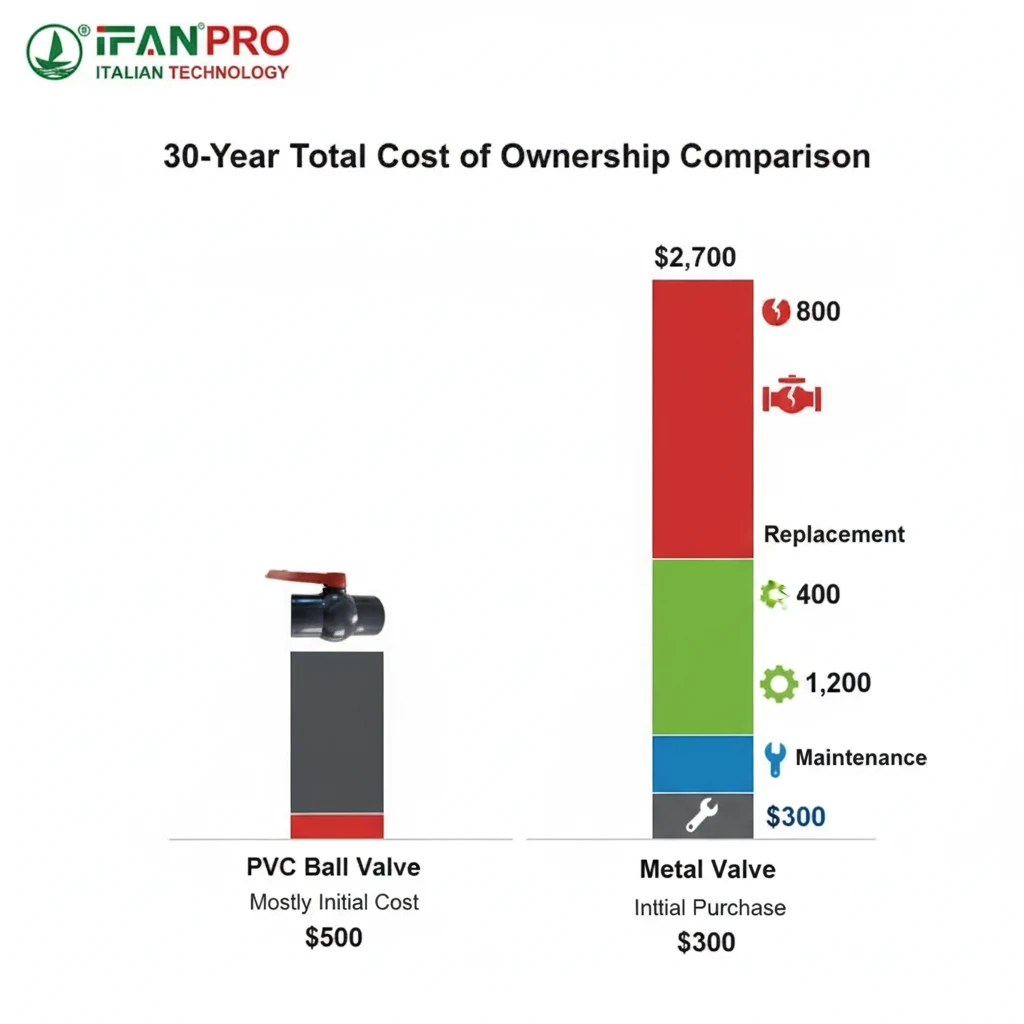

Total Cost of Ownership Analysis

Let’s quantify this with a hypothetical example for a large-diameter main line valve:

| Cost Category | 12″ Ductile Iron Valve | 12″ PVC Ball Valve | Notes |

|---|---|---|---|

| Unit Purchase Price | $2,800 | $1,500 | PVC costs ~45% less upfront. |

| Installation (Labor & Equipment) | $1,500 | $500 | PVC’s light weight cuts install cost by 66%. |

| 20-Year Maintenance Cost | $1,200 | $100 | Includes cycling, painting, minor repairs. |

| Replacement Cost at Year 25 | $4,300 | $0 | Metal likely needs full replacement. |

| Estimated Total 30-Year Cost | $9,800 | $2,100 | PVC offers 79% lower lifetime cost. |

The table makes a compelling case. The higher upfront cost of metal is just the beginning. The recurring costs of maintenance and the inevitable costly replacement project make metal valves far more expensive in the long run. PVC ball valves, with their install-and-forget reliability, provide unparalleled financial and operational efficiency for main lines.

Заключение

For main line applications, large-diameter PVC ball valves deliver unbeatable reliability, safety, and lifetime value. For your next project, specify IFAN’s high-performance PVC ball valves for a durable, cost-effective, and zero-maintenance solution.

Последние комментарии