A client once asked me this exact question after a valve failure halted their project. It taught me that knowing the real pressure limits is crucial for system safety and longevity.

The pressure an HDPE female threaded valve can handle primarily depends on its Pressure Nominal (PN) rating, such as PN10 or PN16, which indicates its maximum working pressure in bars at 20°C. However, this capacity is significantly influenced by temperature, the specific HDPE material grade, and the correct installation of the threaded connection.

Let’s break down the key factors that determine the true pressure capability of your HDPE valves.

What is the Standard Pressure Rating (PN) for HDPE Female Threaded Valves?

Choosing the wrong PN rating is a common and costly mistake. I’ve seen systems over-specified and under-specified, both leading to problems.

The standard pressure ratings for HDPE female threaded valves are typically PN10 (10 bar) and PN16 (16 bar). PN signifies the maximum allowable working pressure in bars at a reference temperature of 20°C (68°F) for water. It is a standardized classification that helps users select the correct valve strength for their application’s operating pressure.

Understanding the PN System

The PN (Pressure Nominal) system is a fundamental way to classify the strength of valves and pipes. For HDPE female threaded valves, PN10 and PN16 are the most common ratings you will find. A PN10 valve is designed for a maximum continuous working pressure of 10 bar (approximately 145 psi) when the fluid inside is water at 20°C. A PN16 valve is rated for 16 bar (approximately 232 psi) under the same conditions.

This rating is not a random number. Manufacturers determine it through extensive pressure testing. The valve must withstand its PN pressure for a very long time, often with a significant safety factor built-in. It’s crucial to understand that this rating is for cold water. If your fluid is different or the temperature is higher, the valve’s actual pressure capacity changes.

Why Threaded Connections Matter for Pressure

The “female threaded” part of the valve is a critical point for pressure integrity. Unlike a fused HDPE joint, a threaded connection is a mechanical joint. Its ability to hold pressure depends on several factors:

- Thread Quality: The threads must be clean, sharp, and free of defects.

- Sealing Method: Often, a sealant tape or compound is used on the threads to prevent leaks. The right type must be used for HDPE.

- Installation Torque: Over-tightening can stress and crack the HDPE valve body. Under-tightening can lead to leaks. Using a torque wrench is the best practice.

Common Pressure Ratings Table

This table summarizes the standard PN ratings and their typical uses.

| PN Rating | Max Working Pressure (at 20°C) | Common Applications |

|---|---|---|

| PN6 | 6 bar (87 psi) | Low-pressure irrigation, low-rise building supply. |

| PN10 | 10 bar (145 psi) | Most common. Municipal water mains, standard industrial plumbing, mining. |

| PN16 | 16 bar (232 psi) | Higher-pressure mains, pump discharge lines, industrial processes. |

| PN20+ | 20+ bar (290+ psi) | Specialized high-pressure applications (less common for threaded valves). |

When selecting a valve, your system’s maximum operating pressure should be at or below the valve’s PN rating. Always include a safety margin. For example, if your system operates at 8 bar, choosing a PN10 valve is appropriate. Choosing a PN6 valve would be a risk.

How Does Temperature Variation Affect the Pressure Capacity of HDPE Valves?

Ignoring temperature is the number one error in pressure specification. I recall a project where summer heat caused a perfectly sized system to weaken at the valves.

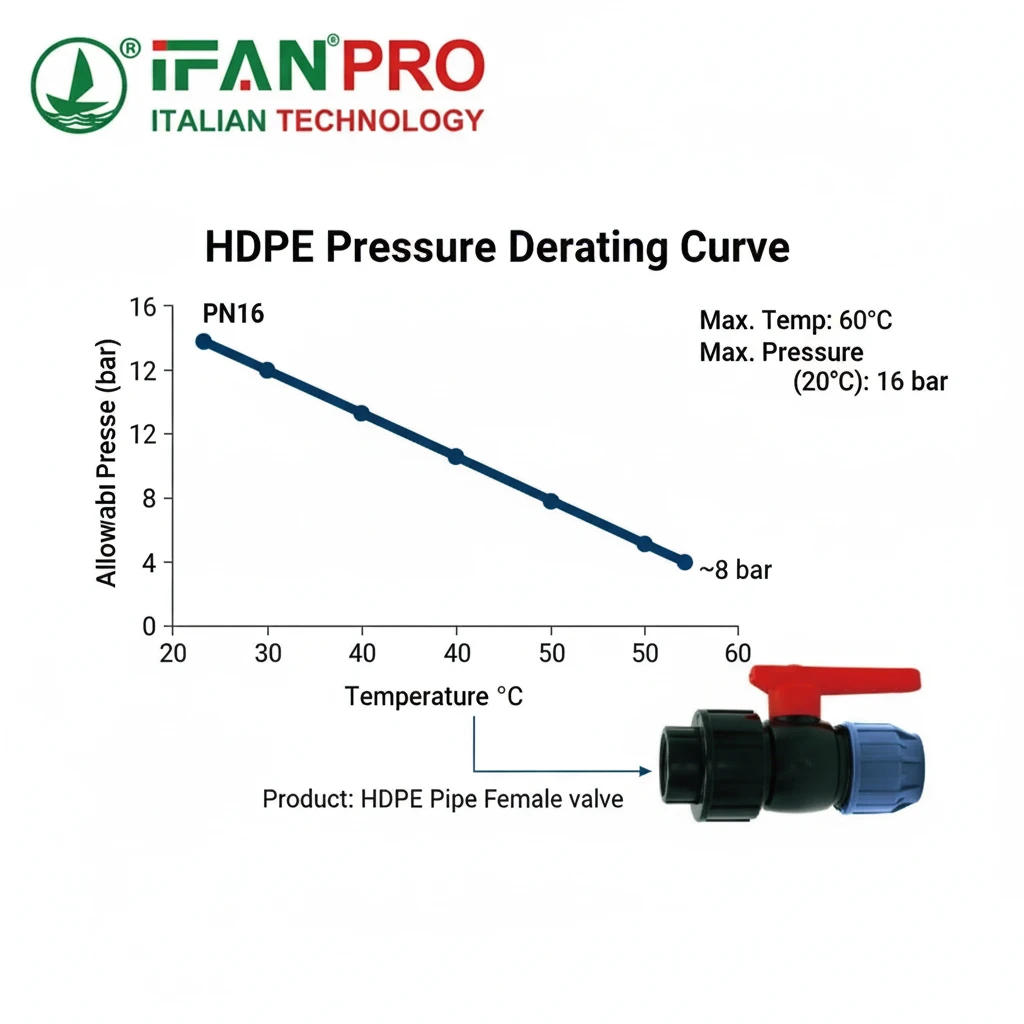

Temperature variation significantly affects HDPE valve pressure capacity because HDPE material softens as temperature increases. As the operating temperature rises above the standard 20°C (68°F) reference, the maximum allowable pressure for the valve must be reduced. Conversely, at lower temperatures, the pressure capacity increases slightly.

The Science Behind Temperature and Pressure

HDPE is a thermoplastic, which means its physical properties change with temperature. As the temperature increases, the polymer chains gain energy and move more easily, making the material more flexible and less rigid. This reduced rigidity means it cannot withstand the same internal pressures as it can at cooler temperatures.

The industry uses Pressure Reduction Factors (PRFs) or Service Factors to account for this. These are multipliers (less than 1.0) that you apply to the valve’s PN rating to find its safe working pressure at a higher temperature.

Practical Application of Reduction Factors

For example, an HDPE valve with a PN16 rating is good for 16 bar at 20°C. If the fluid inside is at 40°C, you must apply a reduction factor. A typical reduction factor for HDPE at 40°C might be 0.8. This means the safe working pressure at 40°C is now 16 bar x 0.8 = 12.8 bar.

If you fail to apply this correction and run the valve at 16 bar with 40°C fluid, you are over-stressing the material. This can lead to creep, which is the slow, permanent deformation of the valve body over time, and ultimately to failure.

Temperature Derating Table for HDPE Valves

This general guide shows how temperature affects the rated pressure. Always consult the specific manufacturer’s data for your valve.

| Fluid Temperature | Approximate Pressure Reduction Factor | Effective Pressure for a PN16 Valve |

|---|---|---|

| 20°C (68°F) | 1.00 | 16.0 bar |

| 30°C (86°F) | 0.90 | 14.4 bar |

| 40°C (104°F) | 0.80 | 12.8 bar |

| 50°C (122°F) | 0.65 | 10.4 bar |

| 60°C (140°F) | 0.50 | 8.0 bar |

Ключевые соображения

- Fluid vs. Ambient Temperature: The critical temperature is the fluid temperature inside the valve, not necessarily the air temperature outside. A buried pipe in cold ground carrying hot fluid is governed by the hot fluid’s temperature.

- Short-Term Peaks: The ratings are for continuous operation. Short-term pressure surges (water hammer) above the derated pressure can still cause damage.

- Material Grade: Different HDPE resin grades (PE80, PE100) have different temperature behaviors. PE100 generally has better long-term pressure resistance at higher temperatures than PE80.

Always design your system based on the highest expected fluid temperature, not the average. This conservative approach prevents unexpected failures.

What Safety Factors Should Be Considered When Specifying Valve Pressure Ratings?

Relying solely on the PN rating is like driving at the exact speed limit without margin for error. Safety factors provide that essential buffer.

Key safety factors to consider include: accounting for temperature derating, planning for pressure surges (water hammer), considering the chemical compatibility of the fluid, ensuring proper installation, and adding an engineering design safety margin (often 1.5 to 2 times the operating pressure) to ensure long-term reliability and account for unknowns.

Designing for Real-World Conditions

A pressure specification sheet gives you ideal lab conditions. Your job is to adapt that to the messy real world. Safety factors are not about being overly cautious; they are about being professionally responsible. They bridge the gap between theory and practice, ensuring the valve performs reliably over its entire 50+ year design life.

Here are the critical safety factors to integrate into your specification:

1. Pressure Surge (Water Hammer) Factor

This is often the most overlooked factor. When a valve closes quickly or a pump starts/stops, it creates a shockwave of pressure that can be 2 to 4 times higher than the normal operating pressure. If your system runs at 8 bar, a surge could briefly hit 16-24 bar.

- Action: You must know if your system has quick-closing valves or pumps. Specify valves with a PN rating high enough to withstand the maximum possible surge pressure, not just the working pressure. Installing surge arrestors is also a smart move.

2. Chemical and Environmental Factor

The PN rating is typically for water. Different fluids can affect HDPE.

- Chemical Resistance: Some chemicals can stress-crack HDPE or weaken it over time. Always check chemical compatibility charts.

- UV Exposure: If the valve is installed above ground and exposed to sunlight, UV degradation can weaken it. Use black HDPE (with carbon black UV stabilizer) or protect it from sunlight.

3. Installation and Operational Factor

Human error and wear are real risks.

- Installation Damage: Over-tightening, cross-threading, or using incompatible sealants can create weak points.

- Cyclic Fatigue: Systems with frequent pressure cycles (on/off) fatigue materials faster than systems with constant pressure.

4. The Overall Design Safety Factor

Engineers apply a global safety factor (SF). It’s a simple formula:

Valve PN Rating ≥ (Maximum Operating Pressure) x (Safety Factor)

A common safety factor for HDPE systems is 1.5 to 2.0.

Safety Factor Calculation Example

Let’s see how this works together for a real system:

| Design Parameter | Value | Note |

|---|---|---|

| Normal Operating Pressure | 7 bar | Your system’s usual pressure. |

| Max Fluid Temperature | 45°C | The highest expected temperature. |

| Derating Factor at 45°C | 0.75 | From manufacturer’s chart. |

| Required Pressure at 20°C | 7 bar / 0.75 = 9.33 bar | Pressure rating needed to account for heat. |

| Estimated Surge Pressure | 9.33 bar x 1.8 = 16.8 bar | Assuming an 80% surge. |

| Apply Design Safety Factor (1.5) | 16.8 bar x 1.5 = 25.2 bar | Final design pressure requirement. |

| Recommended Valve Selection | PN25 or higher | Choose a valve with a rating meeting/exceeding 25.2 bar. |

This example shows why a system operating at just 7 bar might need a valve rated for PN25. Skipping these steps and picking a PN10 valve would likely lead to premature failure.

Which International Standards Define Pressure Tests for HDPE Valves?

Standards are the common language of quality. They give buyers and suppliers a clear benchmark, preventing misunderstandings about what “pressure-rated” truly means.

Key international standards that define pressure tests for HDPE valves include ISO 4427 (for HDPE piping systems and components), ASTM F2164 (for polyethylene pressure pipes), and various regional standards like EN 12201. These standards specify test methods for long-term hydrostatic strength (LTHS), burst pressure, and leak-tightness to ensure valves meet their claimed PN ratings.

Why Standards Matter for Pressure Testing

Without standards, every manufacturer could test their valves differently, making comparisons impossible. International standards provide a rigorous, scientific, and repeatable set of tests. When a valve is certified to a standard, it means an independent body has verified that it passes these tests. This is your best assurance of quality and performance.

Breakdown of Key Standards and Tests

Let’s look at what the main standards require:

1. ISO 4427: Plastics piping systems – Polyethylene (PE) pipes and fittings

This is a globally recognized standard. For valves, it references test methods to verify:

- Hydrostatic Pressure Test: Valves are subjected to pressures significantly higher than their PN rating for a set time (e.g., 1 hour) at different temperatures to check for leaks or rupture.

- Long-Term Hydrostatic Strength (LTHS): This is the core test for establishing the PN rating. Pipes and representative samples are held under constant pressure and temperature for thousands of hours. The data is used to extrapolate a 50-year strength at 20°C. The PN rating is derived from this 50-year strength.

2. ASTM F2164: Standard Specification for Field-Assembled Anodeless Risers

While focused on risers, the pressure testing philosophy aligns with other ASTM standards for PE materials (like D3035). ASTM standards are predominant in North America. They mandate:

- Short-Term Hydraulic Burst Pressure Test: Determines the minimum pressure at which the product will fail.

- Sustained Pressure Test: Similar to the ISO hydrostatic test, ensuring no failure or leakage over a prolonged period.

3. EN 12201: Plastics piping systems for water supply – Polyethylene (PE)

This European standard is very similar to ISO 4427 and is often harmonized. It includes detailed requirements for pressure testing components to ensure they match the performance of the PE pipes they are used with.

Standards Compliance Table

This table helps you understand what to look for in documentation.

| Standard | Region of Use | Key Pressure Test Aspect | What it Guarantees |

|---|---|---|---|

| ISO 4427 | Global | Long-Term Hydrostatic Strength (LTHS) | The PN rating is based on a 50-year minimum expected strength. |

| ASTM F2164 / D3035 | North America | Burst Pressure & Sustained Pressure | The product can withstand short-term surges and long-term pressure. |

| EN 12201 | Europe | Hydrostatic Test & LTHS | Conformity with EU requirements for water supply systems. |

| AS/NZS 4130 | Australia/NZ | Pressure Testing of PE Compounds | Ensures material quality for pressure applications. |

How to Use This Information as a Buyer

- Ask for Certificates: Request third-party test certificates that show compliance with ISO, ASTM, or EN standards.

- Check the Marking: A properly manufactured valve will be marked with its PN rating, material grade (e.g., PE100), manufacturer’s name, and often the standard it conforms to (e.g., ISO 4427).

- Specify in Orders: In your purchase orders, state clearly: “Valves must comply with [ISO 4427 or other] and be certified for PN16.” This sets an enforceable quality requirement.

Insisting on standardized products protects your project from the risks of substandard, non-tested valves that could fail under pressure.

Заключение

Selecting the right HDPE valve pressure requires understanding PN ratings, temperature effects, safety factors, and international standards. For guaranteed performance, choose IFAN’s certified HDPE female threaded valves, rigorously tested to meet global standards for your project’s safety and durability.

Последние комментарии