On a recent project, we found old metal drainage pipes completely eaten away by acidic soil. This costly repair made the client ask us one clear question.

Yes, PVC (Polyvinyl Chloride) drainage pipe is highly resistant to soil corrosion. Unlike metal pipes, PVC is an inert plastic that does not electrochemically corrode or rust when buried. It withstands a wide range of soil chemicals, acids, and salts, making it a premier choice for durable, long-lasting underground drainage systems where soil aggression is a concern.

This inherent resistance is a key reason PVC dominates modern drainage. However, understanding the details ensures you select the right pipe for your specific conditions. So, let’s dig deeper into the standards, science, and best practices.

What International Standards Certify PVC Drainage Pipe for Soil Corrosion Resistance?

Clients often show us pipes that failed and ask, “Was this even certified?” Trusting the right standards prevents this problem.

Major international standards like ASTM, ISO, and EN certify PVC drainage pipes for soil corrosion resistance by setting strict requirements for material composition, wall thickness, stiffness, and chemical resistance. Compliance with standards such as ASTM D3034, ISO 4435, and EN 1401 provides a verified benchmark for performance in buried, corrosive environments.

The Role of Standards in Guaranteeing Quality

Standards are not just paperwork. They are a set of rules created by experts to ensure products are safe, reliable, and fit for their purpose. For PVC drainage pipes, several key standards prove their suitability for corrosive soils. These standards test the pipe’s ability to handle physical stress and chemical attack over decades.

First, let’s look at material composition. Standards specify the type and grade of PVC compound that must be used. This ensures the pipe is made from high-quality, virgin material with the right additives for durability. A pipe made from recycled or substandard material might crack or degrade quickly, even if it looks the same on the outside.

Key Standards and Their Focus

Different standards apply in different regions, but they all share a common goal: ensuring long-term performance.

| Standard | Region/Scope | Key Requirements for Corrosion/Soil Resistance |

|---|---|---|

| ASTM D3034 | North America | Specifies dimensions, tensile strength, and impact resistance for PVC sewer pipe. Ensures it can handle burial loads and resist environmental stress cracking. |

| ISO 4435 | International | Defines requirements for PVC-U (unplasticized) pipes for soil and waste discharge. Includes tests for chemical resistance and long-term hydrostatic strength. |

| EN 1401 | Europe | Covers PVC pipes for non-pressure underground drainage. Includes rigorous tests for resistance to environmental stress cracking when exposed to chemicals. |

| AS/NZS 1260 | Australia/New Zealand | Includes requirements for PVC pipes for drainage, waste, and vent. Mandates tests for chemical resistance relevant to local soil conditions. |

Why Certification Matters for You

When a manufacturer like IFAN states compliance with these standards, it means their pipes have passed independent laboratory tests. For example, the chemical resistance test often involves immersing pipe samples in aggressive solutions and checking for cracks or weight changes. Choosing certified pipes removes guesswork. You get a product with a proven track record. You avoid the huge cost and disruption of replacing a failed drainage system in just a few years. Always ask your supplier for proof of compliance with the relevant standard for your project location.

How Does PVC Drainage Pipe Ensure Long-Term Durability Against Soil Chemicals?

We replaced a corroded concrete pipe system last year. The client was amazed that PVC, a plastic, could outlast concrete. The secret is in its chemistry.

PVC ensures long-term durability against soil chemicals because its molecular structure is inherently inert. It does not react with most acids, alkalis, and salts found in soil. Additionally, its smooth, non-porous surface prevents chemical adhesion and microbe-induced corrosion, maintaining its structural integrity and flow capacity for over 100 years in most soil conditions.

The Science of Inertness

To understand PVC’s durability, think about a glass bottle. Glass doesn’t react with most liquids inside it; it just holds them. PVC acts similarly in the ground. Its long-chain polymer structure is very stable. Common corrosive agents in soil—like sulphates, chlorides, or acidic compounds from decomposing organic matter—cannot easily break these molecular bonds. This is completely different from metal pipes, which undergo an electrochemical reaction (rusting) when in contact with soil and moisture.

Another key point is that PVC is non-conductive. Stray electrical currents in the soil, which can rapidly destroy metal pipes through electrolytic corrosion, have no effect on PVC.

Maintaining Flow and Structural Integrity

The smooth inner wall of a PVC pipe does more than just let water flow fast. It also prevents scale and corrosion by-products from sticking. In metal pipes, corrosion creates rust and scale that builds up inside, narrowing the pipe over time. This is called “tuberculation.” PVC pipes have no corrosion by-products. Their internal diameter stays the same for the entire life of the system, so the flow capacity never decreases. This is a major advantage for drainage, where maintaining capacity is critical during heavy rains.

Real-World Performance Factors

While the material itself is resistant, the pipe’s design also contributes to longevity. PVC pipes have excellent ring stiffness, meaning they can resist the crushing forces of soil and traffic loads without deforming. A deformed pipe can develop stress points and potentially crack. Modern PVC drainage pipes also contain additives that protect them from ultraviolet (UV) light during storage and, more importantly, from oxidative degradation over decades in the ground.

The jointing method also matters. PVC pipes are typically joined with solvent cement, which literally welds the pipes and fittings into a single, monolithic piece. This creates a continuous, leak-free line that prevents soil chemicals from seeping into the joints and causing localized attack, which is a common failure point in other piping systems.

Which Soil Conditions Are Most Suitable for PVC Drainage Pipe Installation?

A contractor once called us in a panic. Their newly installed drainage line was failing. The problem wasn’t the pipe; it was the highly abrasive, rocky soil they didn’t assess.

PVC drainage pipe is most suitable for installation in stable, well-compacted soils with a neutral to mildly acidic or alkaline pH. Typical backfill materials like sand, gravel, and select native soils provide excellent, uniform support. It performs reliably in common conditions found in residential, commercial, and agricultural settings.

Ideal Soil and Backfill Properties

The pipe itself is resistant, but the soil around it must provide proper support. Think of the pipe as a long, flexible tube. It needs consistent, firm bedding to carry the load from above without sagging or developing pressure points.

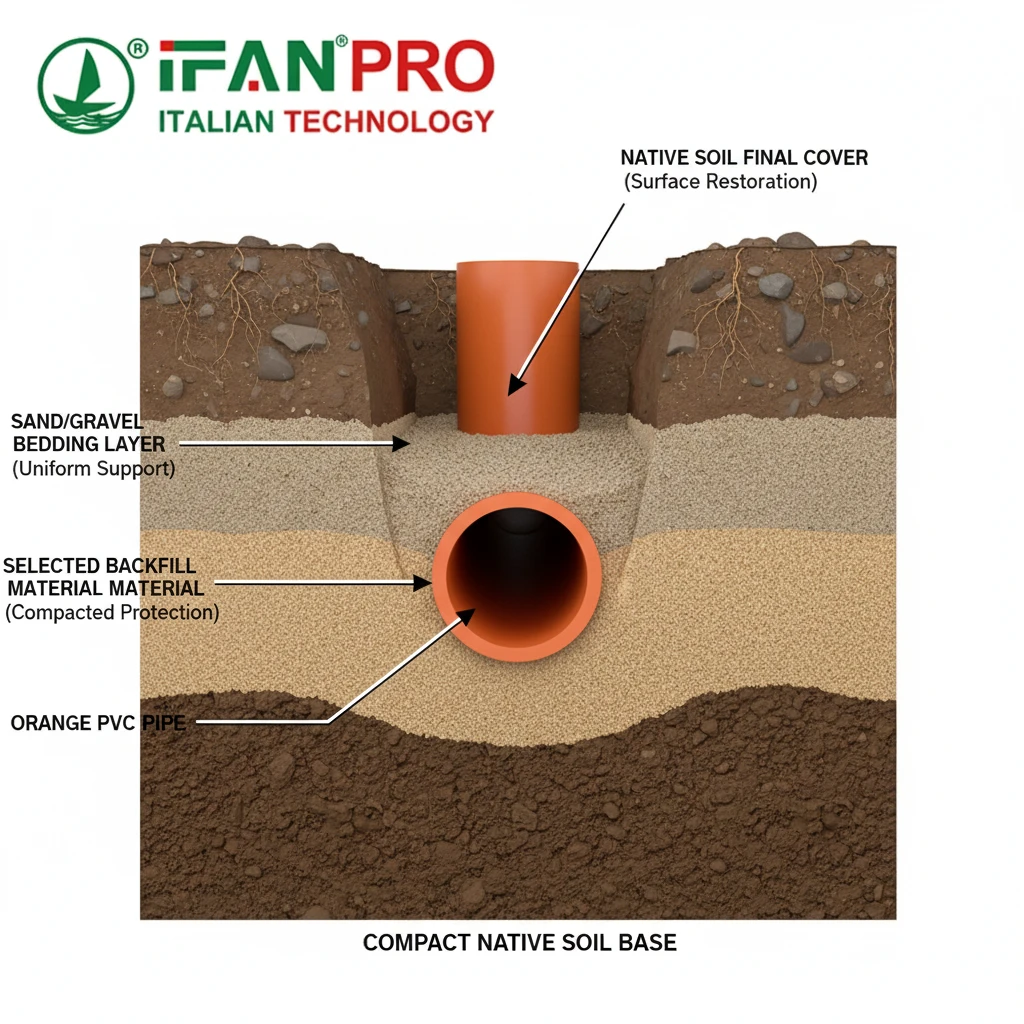

The best practice is to place the pipe on a bedding layer of granular material like coarse sand or small, smooth gravel. This layer should be free of large, sharp rocks or frozen clumps. After the pipe is laid and joined, backfill is placed around it. The initial backfill (6-12 inches above the pipe) should also be select, compactible material without large stones. This “haunching” material locks the pipe in place and distributes loads evenly.

Soil Conditions and PVC Performance Guide

Here is a simple guide to how PVC fares in different environments:

| Soil Condition | Suitability for PVC Pipe | Reason & Consideration |

|---|---|---|

| Well-Graded Sand/Gravel | Excellent | Provides ideal drainage and uniform support. Easy to compact. |

| Native Clay/Silt (when stable) | Good | Can be used if properly compacted in layers. Ensure proper drainage to avoid washouts. |

| Highly Organic (Peat) or Expansive Clay | Fair to Poor | Unstable, prone to shifting. Requires special engineering, like a reinforced concrete cradle. |

| Aggressive Industrial Waste Sites | Requires Assessment | May contain unusual solvents or chemicals. A specific chemical resistance test is advised. |

| Rocky Trench with Sharp Edges | Poor (unless bedded) | Sharp rocks can gouge or point-load the pipe. Must use a thick, soft bedding layer. |

Conditions to Evaluate Carefully

While PVC is versatile, some conditions require extra attention. First, soil pH. PVC performs well across a wide pH range (approximately 2 to 12). Extremely acidic soils (pH <2) or extremely alkaline soils (pH >12) are rare but may require review. Second, temperature. PVC can become more brittle in sustained, very cold conditions (below -5°C / 23°F). In such environments, handling during installation is crucial, and deeper burial below the frost line is standard.

The key is site assessment. Before installation, understand your soil type and condition. A simple visual and manual test can often tell you if you have sandy, clayey, or rocky soil. For large or critical projects, a professional geotechnical report is a wise investment. This proactive step ensures the long-term success of your PVC drainage system.

What Protective Measures Enhance PVC Drainage Pipe Performance in Corrosive Soils?

We worked on a coastal wastewater project where the salt-laden soil was a nightmare. Standard pipe wouldn’t last. The solution involved a combination of smart choices.

Protective measures for PVC pipe in corrosive soils include using pipes with higher thickness and stiffness (SDR rating), ensuring impeccable jointing, providing a protective bedding/backfill envelope, and in extreme cases, using geotextile wraps or secondary containment. Proper installation is the most critical enhancement of all.

Selecting the Right Pipe: SDR is Key

Not all PVC pipes are identical. The Standard Dimension Ratio (SDR) is a crucial number. It is the ratio of the pipe’s outside diameter to its wall thickness. A lower SDR number means a thicker wall. For example, SDR 35 has a thicker wall than SDR 41.

In corrosive or demanding soil conditions, choose a pipe with a lower SDR rating (i.e., a thicker wall). The thicker wall provides a greater margin of safety against any potential long-term chemical attack and offers higher ring stiffness to resist soil loads. It is your first and most important line of defense.

Mastering Installation: The Bedding and Backfill Envelope

The correct installation creates a “protective envelope” around the pipe. This is a step-by-step process that shields the pipe from physical and chemical stress.

- Trench Preparation: Dig the trench to the correct depth and width. The width should be wide enough to work comfortably but not so wide that compaction becomes difficult.

- Bedding Layer: Place and compact a minimum 4-inch (100mm) layer of select, fine-grained bedding material (like sand). This creates a uniform, rock-free foundation.

- Pipe Placement & Joining: Carefully place the pipe and make all joints cleanly and according to the manufacturer’s instructions. Proper solvent welding is vital for a continuous, leak-free line.

- Initial Backfill: Carefully place the selected backfill material around the pipe in layers (lifts) of 6 inches (150mm), compacting each layer gently but firmly. Avoid using heavy machinery directly over the unprotected pipe. This material should be free of rocks, debris, and frozen clumps.

- Final Backfill: Once the pipe is covered by at least 12 inches (300mm) of compacted backfill, you can use standard native soil to finish filling the trench, compacting as you go.

Advanced Protection Strategies

For severely aggressive conditions, such as industrial sites or landfills, additional measures can be taken:

- Geotextile Wrap: Wrapping the pipe in a protective geotextile fabric can filter out fine, abrasive soils and create a physical barrier against direct contact with aggressive chemicals.

- Secondary Containment: In the most extreme cases, the primary PVC pipe can be placed inside a larger, secondary pipe or conduit. This creates an annulus that can be monitored or filled with an inert material.

Summary of Protective Measures

This table outlines the measures from basic to advanced:

| Protection Level | Measure | Purpose & Benefit |

|---|---|---|

| Fundamental | Choose lower SDR pipe (thicker wall). | Provides greater inherent strength and chemical resistance margin. |

| Critical | Use proper granular bedding & select backfill. | Shields pipe from point loads, abrasion, and provides uniform support. |

| Essential | Ensure expert, leak-free solvent-cement jointing. | Preents joint infiltration, the weakest link in any system. |

| Advanced | Use geotextile fabric wrap. | Filters soil and adds a protective separation layer in harsh soils. |

| Specialist | Design for secondary containment. | Provides ultimate protection for extreme environments. |

Remember, the quality of installation often matters more than the soil’s natural aggressiveness. A perfectly installed PVC pipe in moderately aggressive soil will outlast a poorly installed pipe in perfect soil every time.

Заключение

PVC drainage pipe’s natural corrosion resistance makes it a top choice for buried systems. For guaranteed quality and performance, choose IFAN’s certified PVC drainage pipes and fittings for your next project.

Последние комментарии