I once watched a DIYer struggle with a wobbly handsaw, leaving a jagged PVC edge that ruined a fitting seal. That moment proved why the right tool makes all the difference.

You should choose a pipe cutter over a saw for PVC because it produces a perfectly square, clean, and burr-free cut in seconds. This ensures leak-proof connections, increases your installation speed and safety, and reduces material waste, saving you time and money on your project.

If you’re still using a saw, you’re working harder, not smarter. Let’s cut through the confusion and see why a dedicated pipe cutter is the clear winner.

How Does a Pipe Cutter Create a Cleaner PVC Cut Than a Saw?

A jagged cut is the number one cause of leaks in DIY plumbing. I’ve seen it lead to costly callbacks and water damage.

A pipe cutter creates a cleaner PVC cut than a saw because it uses a sharp, guided rolling blade to score and evenly shear the pipe, producing a perfectly square end. Unlike a saw, which can wobble and tear the plastic, the cutter leaves a smooth edge ready for solvent welding, with minimal to no burrs that could interfere with a fitting.

The Science of a Clean Cut

Think about how a saw works. Its teeth rip and tear through material. With soft PVC plastic, this tearing action creates a rough, frayed edge and plastic dust. Even if you try to sand it smooth, you might not get a perfectly square end. An uneven end creates gaps in the joint, which is where leaks start.

A pipe cutter works on a different principle. You clamp it around the pipe and rotate it. A sharp, hardened steel wheel scores a deep, consistent groove into the PVC. As you tighten the tool and rotate it further, the pressure concentrates on this score line, causing the pipe to snap cleanly along it. The action is a controlled shear, not a tear.

Why Cleanliness Matters for Sealing

The cleaner the cut, the better the solvent weld. PVC cement works by melting the surface layers of the pipe and fitting, fusing them together. A smooth, square cut maximizes the surface area contact between the pipe and the fitting’s inner wall.

- Saw Cut Problems: Rough edges create tiny channels where water can seep through. Plastic dust can contaminate the joint, weakening the bond.

- Cutter Advantages: The smooth edge allows the cement to create a uniform, continuous seal around the entire pipe circumference.

Comparison of Cut Quality

| Feature | Pipe Cutter Result | Handsaw/Jigsaw Result |

|---|---|---|

| Edge Squareness | Perfectly 90-degree, even end. | Often angled or uneven. |

| Edge Smoothness | Smooth, sheared finish. | Rough, torn, or frayed plastic. |

| Burrs | Minimal or none. | Significant burrs requiring filing/sanding. |

| Plastic Dust | Almost none. | Significant amount created. |

| Readiness for Cement | Ready immediately. | Requires deburring and sanding. |

For a professional, reliable seal every single time, the quality of cut from a dedicated tool is unbeatable. It removes a major variable—human error—from the installation process.

Why is a Pipe Cutter Faster and Safer for PVC Pipe Installations?

Time is money on any job site, and safety is never optional. Switching from a saw to a cutter tackles both issues at once.

A pipe cutter is faster and safer because it makes a complete cut in under 30 seconds with simple rotations, eliminating the set-up and back-and-forth motion of sawing. It also has no exposed, fast-moving blade or teeth, greatly reducing the risk of cuts, kickbacks, or electrical hazards compared to power saws.

The Speed Advantage: Less Motion, More Action

Consider the steps for using a saw. You need to measure and mark the pipe, secure it in a vise or with your knee, align the saw, and then begin a laborious back-and-forth motion. For larger diameter pipes, this takes considerable effort and time.

Now, look at the steps with a pipe cutter:

- Measure and mark the pipe.

- Place the cutter on the mark and tighten until the blade touches.

- Rotate the tool around the pipe 2-3 times.

- Slightly tighten the knob and rotate again.

- Repeat until the pipe snaps cleanly.

The process is consistent, requires less physical exertion, and is dramatically faster. For multiple cuts, like in an irrigation system, the time savings are enormous.

The Safety Advantage: Control Over Chaos

Safety is the most compelling reason, especially for beginners or in tight spaces.

Common Saw Hazards:

- Handsaws: The blade can slip off the pipe, cutting your hand or leg.

- Power Saws (Jigsaws, Reciprocating Saws): These generate high speed and can bind or kick, causing loss of control. They also create flying plastic chips and require electrical cords in often wet work areas.

Pipe Cutter Safety Features:

- Enclosed Blade: The cutting wheel is recessed and only contacts the pipe’s surface. Your fingers never go near a sharp edge.

- No Kickback: The shearing action is controlled and gradual. There is no sudden, violent movement.

- One-Handed Operation: You can safely hold the pipe with one hand and operate the cutter with the other, even in awkward positions.

- No Power Needed: It’s completely manual, eliminating risk of electric shock in damp conditions.

Job Site Efficiency Comparison

| Task Aspect | Using a Pipe Cutter | Using a Power Saw |

|---|---|---|

| Time per Cut (1/2″ PVC) | 20-30 seconds | 60-90+ seconds |

| Setup Required | None. | Finding power, securing pipe, safety glasses. |

| Cleanup Required | None. | Sweeping up plastic dust. |

| Suitable for Tight Spaces | Excellent. | Poor or dangerous. |

| Overall Physical Effort | Low. | Moderate to High. |

For frequent PVC work, the speed and safety benefits alone justify the small investment in a proper pipe cutter.

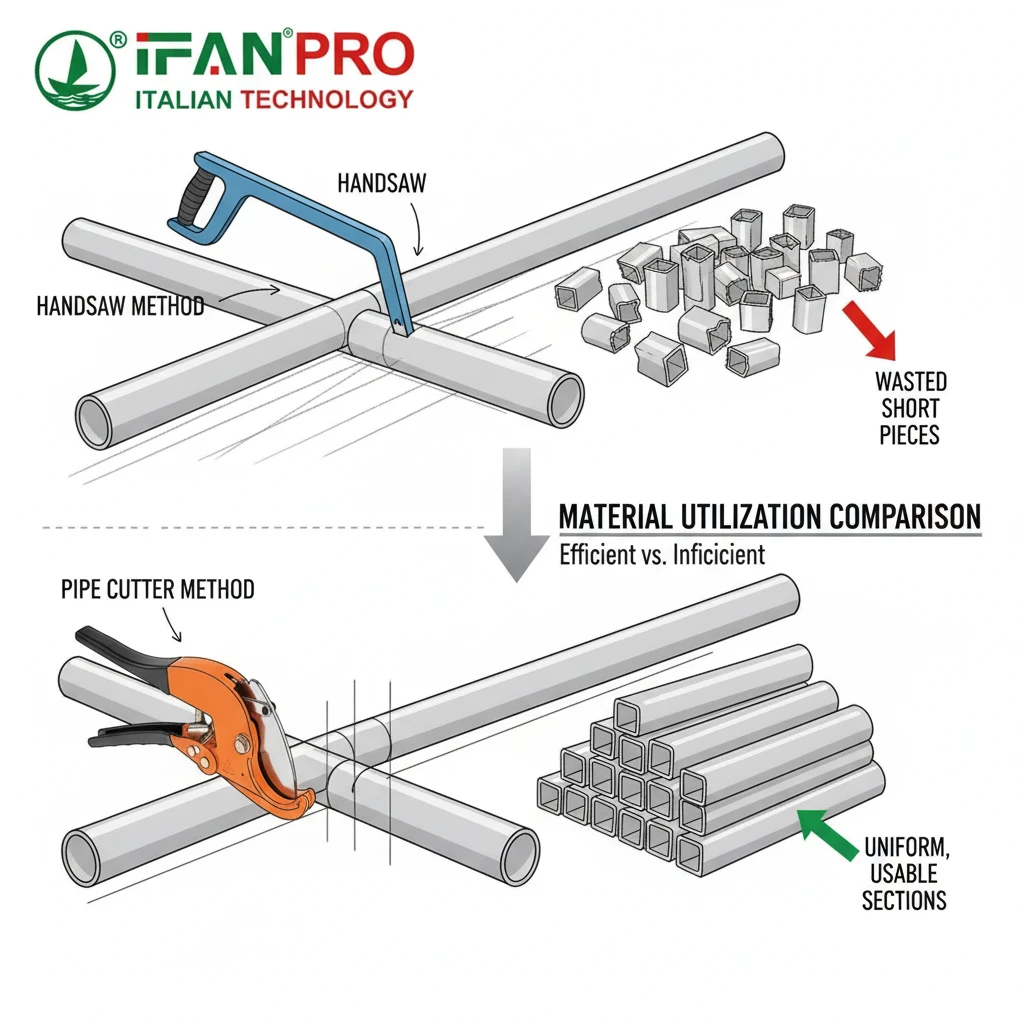

Can Using a Pipe Cutter Reduce Material Waste and Save Money on PVC Projects?

Wasted material is wasted money. In my projects, precise cutting with the right tool has directly lowered material costs.

Yes, using a pipe cutter reduces waste and saves money. Its precision allows for accurate cuts right to your measurement mark, maximizing usable pipe length. The clean cuts also prevent failed joints and leaks, which avoids the costly rework of cutting out and replacing entire sections of pipe due to a single bad connection.

Precision Cuts Maximize Material Use

When you use a saw, you often have to account for error. The blade width (kerf) removes material, and the wobble can mean you need to cut a second time, shortening your piece. You might start cutting an inch longer “just to be safe,” then sand it down. This habit leads to inches of wasted pipe on every cut.

A pipe cutter’s blade is thin and its path is exact. You can confidently cut directly on your measurement line. This precision means you get more usable pieces from a standard 10-foot or 20-foot pipe length. Over a large project, this can reduce the number of pipes you need to buy.

Avoiding the High Cost of Failed Joints

The real money-saving power of a pipe cutter isn’t just in the few inches of PVC saved. It’s in preventing catastrophic failures.

A leak caused by a poorly cut pipe often isn’t discovered until after the system is pressurized and the walls are closed up. Fixing it is a nightmare:

- You must shut off the water and drain the system.

- You have to cut out the faulty section (which now requires two new, precise cuts).

- You need new pipe, two new couplings, and more cement.

- You lose hours of labor on rework.

The cost of this repair in materials, time, and frustration dwarfs the price of a good pipe cutter. Using a tool that guarantees a clean, square first cut is the cheapest insurance policy you can buy for your plumbing project.

Cost Impact Analysis Table

| Cost Factor | With Pipe Cutter | With Saw (Potential Issues) |

|---|---|---|

| Material Utilization | High (~98% usable). Pipe cut to exact length. | Lower (~90-95%). Extra length allowed for error. |

| Joint Failure Rate | Very Low. Clean cuts ensure good seals. | Higher. Rough cuts increase leak risk. |

| Cost of Rework | Nearly $0. | High. Includes extra fittings, pipe, and 2-3 hours of labor. |

| Tool Investment | One-time cost of $20-$50. | Ongoing cost of blades, sandpaper, and risk. |

When you view the pipe cutter as a tool that prevents expensive mistakes rather than just making cuts, its value becomes undeniable.

When Should You Definitely Choose a Pipe Cutter for Your PVC Piping Work?

Some jobs make the choice obvious. I always insist on a cutter in these scenarios to guarantee a professional result.

You should definitely choose a pipe cutter when working in confined spaces, making multiple precise cuts, using larger diameter pipes (over 1 inch), or when the reliability of every joint is critical (like in pressurized water lines or behind finished walls). It’s the essential tool for any professional or serious DIYer.

Critical Job Scenarios for a Pipe Cutter

Let’s break down the specific situations where a saw is a poor choice and a cutter is non-negotiable.

1. Working in Confined Spaces:

Imagine cutting a pipe in a crowded crawl space, under a sink, or between wall studs. Swinging a saw is impossible. A compact pipe cutter can be operated with just a few inches of clearance, rotating around the pipe. This is its single greatest practical advantage.

2. Projects Requiring Multiple, Repetitive Cuts:

If you’re installing a sprinkler system, a DIY furniture project, or complex plumbing with many connections, efficiency is key. The speed and consistency of a pipe cutter will save you hours of labor and physical fatigue compared to sawing each piece.

3. Using Large-Diameter PVC (1″ and Above):

Sawing through a 2″ or 3″ PVC pipe is a major chore. The blade binds, the cut wanders, and it takes forever. A heavy-duty pipe cutter (a scissor-type or ratcheting model) handles these sizes with ease, applying steady, controlled pressure for a perfect cut every time.

Tool Selection Guide for Different PVC Jobs

| Type of PVC Project | Recommended Tool | Key Reason |

|---|---|---|

| Pressurized Water Lines | Pipe Cutter | Ensures leak-proof joints; safety is critical. |

| In-Wall or In-Floor Plumbing | Pipe Cutter | Clean cuts prevent future leaks inside walls. |

| Sprinkler/Irrigation Systems | Pipe Cutter | Speed and precision for dozens of cuts. |

| Large-Diameter Pipe (e.g., Drainage) | Ratcheting Pipe Cutter | Manages thick walls with controlled force. |

| Single, Non-Critical Craft Cut | Fine-Tooth Handsaw | Acceptable if you carefully deburr and sand. |

4. When Joint Reliability is Paramount:

Any pipe that will carry water under pressure, be sealed inside a wall, or be part of a critical system (like a pool or aquarium) deserves a perfect cut. The pipe cutter is the only tool that gives you this level of assurance consistently. It turns a variable into a constant.

For all other general purposes, it’s still the better, easier, and more professional choice. Once you use one, you’ll never go back to a saw for PVC.

Заключение

For a cleaner, faster, safer, and more reliable PVC installation every time, choose a pipe cutter. For a professional-grade tool that delivers perfect cuts, choose the ИФАН pipe cutter – your essential partner for flawless plumbing projects.

Последние комментарии