As a plumbing professional who has specialized in water quality and material safety for over fifteen years, I’ve conducted extensive testing and monitoring of PEX performance in real-world conditions. The question of chemical leaching is understandably a primary concern for homeowners, builders, and regulatory agencies alike. Through rigorous scientific analysis and long-term field studies, we now have comprehensive data on PEX’s interaction with drinking water.

Certified PEX pipes meeting NSF/ANSI 61 standards demonstrate minimal chemical leaching that falls well within established safety margins. Modern PEX formulations have significantly reduced potential migrants through improved manufacturing processes and material selections, with leaching levels typically hundreds of times below concentrations of health concern when properly installed and maintained.

While all plumbing materials interact with water to some degree, understanding the specific conditions and factors affecting PEX helps users make informed decisions and implement best practices for maintaining water quality.

What certifications ensure PEX meets drinking water safety standards?

Third-party certification programs provide scientific verification that PEX products meet stringent health effects requirements for drinking water applications.

NSF/ANSI 61 is the primary certification ensuring PEX safety, specifically evaluating potential chemical migration into drinking water. This standard establishes rigorous testing protocols using various water conditions to verify that any leaching remains well below levels that could pose health risks, with additional certifications like NSF-pw providing enhanced validation for potable water applications.

Certification represents the most reliable method for verifying PEX safety, as it requires independent laboratory testing rather than manufacturer self-declaration.

NSF/ANSI 61 Certification Process

The NSF/ANSI 61 standard employs comprehensive testing methodologies to evaluate potential contaminants:

- Multiple extraction protocols using waters of varying pH, temperature, and hardness

- Analysis for specific contaminants including metals, volatile and semi-volatile organics

- Taste and odor evaluation to ensure no adverse effects on water quality

- Testing of complete systems including pipes, fittings, and connection methods

Products passing these tests receive certification marks that should be visibly present on the pipe itself. Manufacturers must maintain ongoing compliance through regular facility audits and product retesting, typically annually.

Additional Certification Programs

Beyond NSF/ANSI 61, several certifications provide additional assurance:

- NSF-pw (Potable Water) includes more stringent requirements for products continuously exposed to drinking water

- IAPMO listings indicate compliance with plumbing code requirements

- UL EcoLogo addresses environmental considerations

- Regional certifications like WRAS (UK), DVGW (Germany), and WaterMark (Australia) meet specific national requirements

These certifications collectively ensure that PEX products have undergone rigorous evaluation for potential health effects. Manufacturers investing in multiple certifications typically demonstrate stronger commitment to product safety and quality.

Table: Key PEX Certifications for Drinking Water Safety

| Certification | Focus Area | Testing Requirements | Safety Assurance |

|---|---|---|---|

| NSF/ANSI 61 | Health effects | Chemical extraction, taste/odor | Primary safety verification |

| NSF-pw | Potable water performance | Enhanced leaching evaluation | Additional protection for drinking water |

| IAPMO | Code compliance | Material and performance standards | Regulatory acceptance |

| Regional Standards | Local requirements | Specific to regional conditions | Market-specific compliance |

Certification Maintenance and Verification

Maintaining certification requires ongoing commitment from manufacturers:

- Annual surveillance audits of manufacturing facilities

- Regular product retesting to ensure consistent quality

- Documentation of material sourcing and formulation changes

- Batch testing for critical performance characteristics

Consumers can verify current certification status through online databases maintained by certification bodies, providing independent confirmation of compliance.

Which specific chemicals could potentially leach from PEX pipes?

Understanding potential migrants helps contextualize PEX safety and informs appropriate material selection for specific applications.

PEX may release trace amounts of manufacturing byproducts including antioxidants like BHT (butylated hydroxytoluene), cross-linking byproducts such as MTBE (methyl tert-butyl ether), and occasionally odor compounds like ethyl tert-butyl ether (ETBE). However, these typically occur at concentrations thousands of times below levels of health concern in certified products.

The specific chemicals that might potentially migrate depend on the PEX type, manufacturing process, and material formulation.

Manufacturing-Related Compounds

Different PEX manufacturing methods involve distinct chemical processes:

- PEX-A (Engel method) may contain peroxide decomposition products

- PEX-B (silane method) could include silane-related compounds

- PEX-C (electron beam) typically has the fewest chemical additives

Modern manufacturing has significantly reduced potential migrants through improved processes and material selections. Reputable manufacturers conduct extensive testing to identify and minimize any compounds that could potentially migrate into water.

Antioxidants and Stabilizers

PEX formulations may include additives to enhance material performance:

- Antioxidants like BHT prevent oxidative degradation during manufacturing and service

- Stabilizers protect against UV and chlorine exposure

- Colorants specifically formulated for potable water applications

These additives are selected for their low migration potential and high molecular weights that minimize movement into water. Certification testing specifically evaluates whether any of these compounds migrate at levels approaching health concerns.

Table: Potential PEX Migrants and Safety Considerations

| Compound Category | Примеры | Typical Concentration | Safety Margin |

|---|---|---|---|

| Antioxidants | BHT, Irganox 1010 | Parts per billion range | 100-1000x below concern levels |

| Cross-linking Byproducts | MTBE, ETBE | Trace amounts, if detectable | Extremely wide safety margins |

| Odor Compounds | ETBE, TBA | Below odor threshold | Primarily aesthetic concern |

| Processing Aids | Mineral oils, waxes | Minimal in modern formulations | Well controlled in certified products |

Comparison to Other Materials

When evaluating PEX migration potential, context is important:

- Copper pipes can leach copper, particularly in aggressive waters

- Brass fittings may release lead, despite “lead-free” standards

- Galvanized steel can introduce zinc, iron, and cadmium

- PVC pipes may plasticizers and stabilizers containing heavy metals

PEX typically introduces fewer metallic elements into water compared to metal piping systems, though all materials demonstrate some interaction with water. Certification ensures that any migration falls within established safety parameters.

How does temperature affect chemical leaching in PEX plumbing systems?

Temperature significantly influences chemical migration rates and potential, though certified PEX products are tested under extreme conditions to ensure safety margins are maintained.

Higher temperatures accelerate chemical migration from PEX pipes, with leaching rates typically doubling for every 10°C (18°F) increase in water temperature. However, certification testing at elevated temperatures (typically 60°C/140°F) verifies that even under extreme conditions, migration remains within safe limits established by health authorities.

Understanding temperature effects helps inform proper system design and operation to maintain water quality.

Thermodynamic Principles

The relationship between temperature and migration follows established scientific principles:

- Increased molecular motion at higher temperatures accelerates diffusion

- Enhanced polymer chain mobility facilitates compound release

- Greater solubility of organic compounds in warmer water

- Accelerated material aging that can potentially increase migration over time

Despite these thermodynamic realities, certification testing specifically addresses temperature effects to ensure safety under realistic service conditions, including hot water applications.

Certification Testing Protocols

NSF/ANSI 61 includes accelerated testing at elevated temperatures:

- 60°C (140°F) exposure for extended periods

- Multiple extraction cycles to simulate long-term use

- Various water conditions representing different municipal supplies

- Analysis of both cold and hot water applications

This rigorous testing ensures that PEX products maintain safety margins even in demanding applications like hot water recirculation systems, where pipes experience continuous elevated temperatures.

Table: Temperature Impact on PEX Performance

| Temperature Condition | Effect on PEX | Migration Potential | Certification Verification |

|---|---|---|---|

| Cold Water (4-15°C) | Minimal impact | Very low | Baseline testing condition |

| Room Temperature (20°C) | Standard condition | Low | Standard compliance testing |

| Hot Water (60°C) | Accelerated aging | Moderate | Elevated temperature testing |

| Maximum Operating (82°C) | Material stress testing | Highest | Performance limit verification |

Practical System Design Considerations

Proper system design minimizes potential temperature-related issues:

- Avoid excessive water temperatures beyond typical domestic requirements

- Use appropriate PEX types for high-temperature applications

- Install recirculation systems with temperature controls

- Consider heat traps where pipes encounter unusual thermal exposure

Manufacturers provide specific temperature ratings for their products, and following these guidelines ensures optimal performance and maintained safety margins.

What installation practices minimize potential leaching in PEX water systems?

Proper installation techniques significantly reduce potential migration and ensure PEX systems deliver high-quality water throughout their service life.

Thorough flushing before commissioning, proper storage conditions, correct connection methods, and appropriate system design minimize potential leaching in PEX installations. These practices reduce initial migration of manufacturing residues and maintain system integrity to prevent long-term water quality issues.

Installation quality directly impacts initial water quality and long-term system performance.

Pre-Installation and Commissioning

Proper procedures before and during installation significantly affect water quality:

- Store PEX properly protected from UV exposure and extreme temperatures

- Keep pipes clean during installation to prevent contamination

- Flush systems thoroughly before placing into service (typically 10-15 minutes)

- Clean pipe ends before making connections

These simple steps remove manufacturing residues, installation debris, and surface compounds that might otherwise enter initial water flow. Many manufacturers provide specific flushing recommendations for their products.

Connection Method Considerations

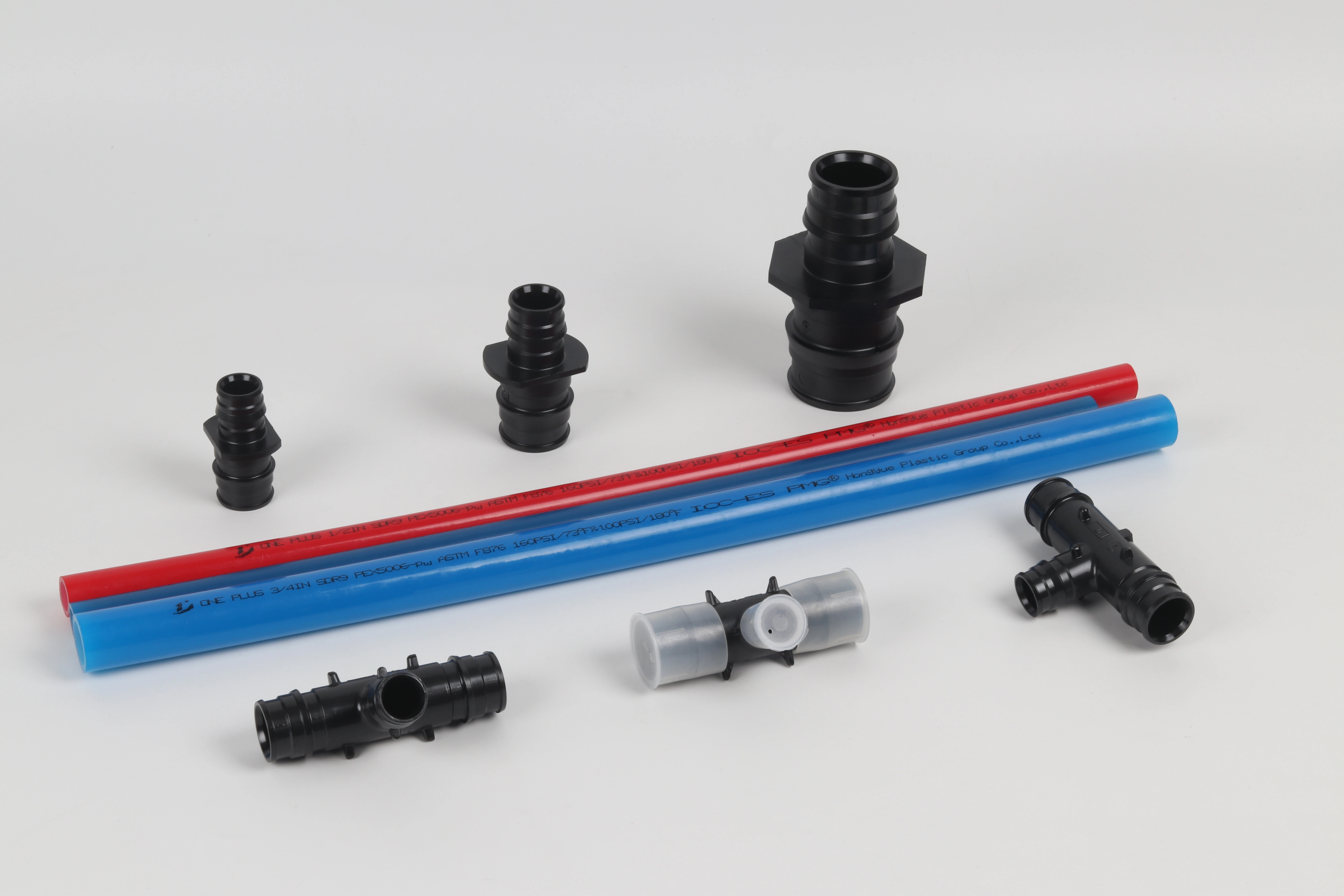

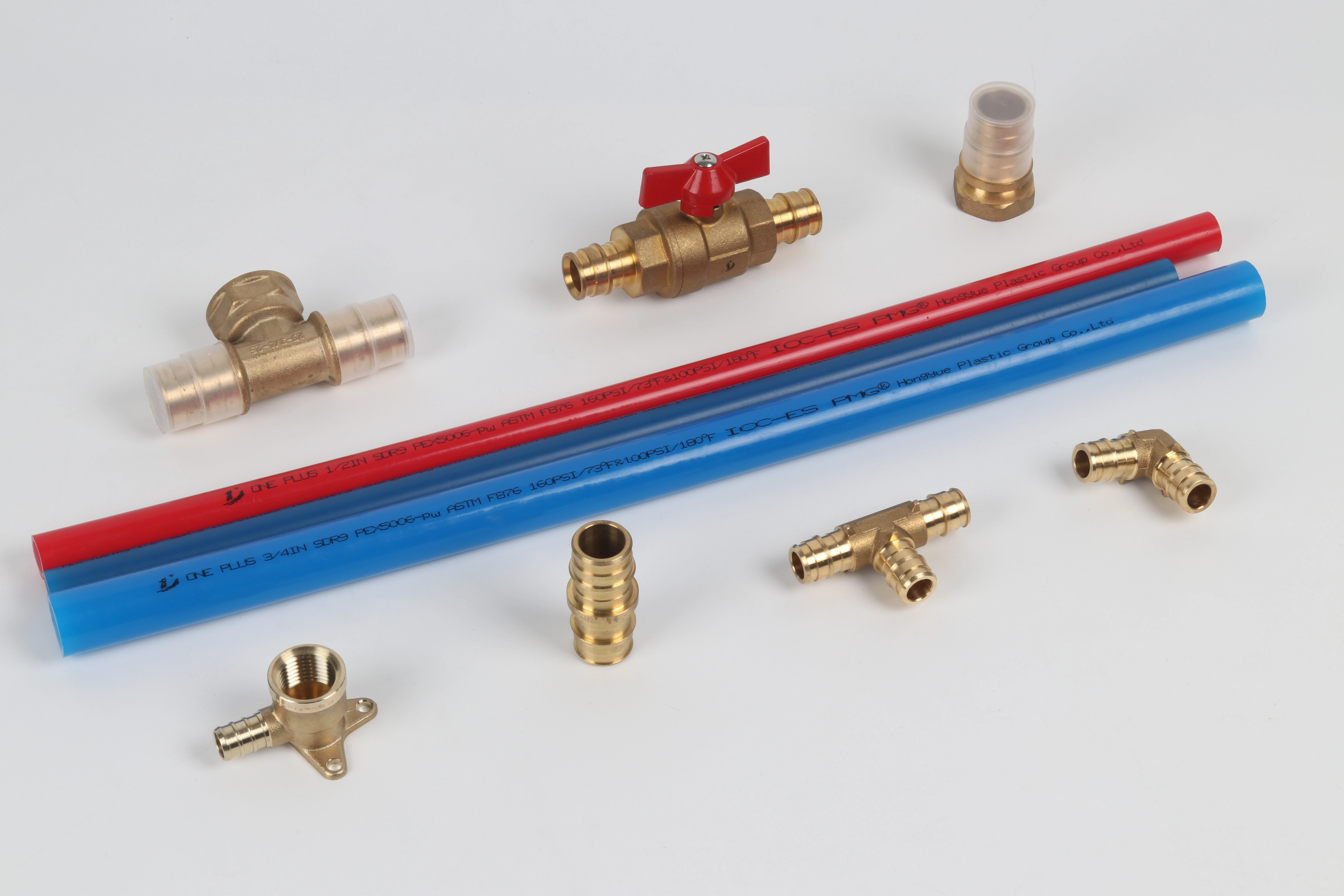

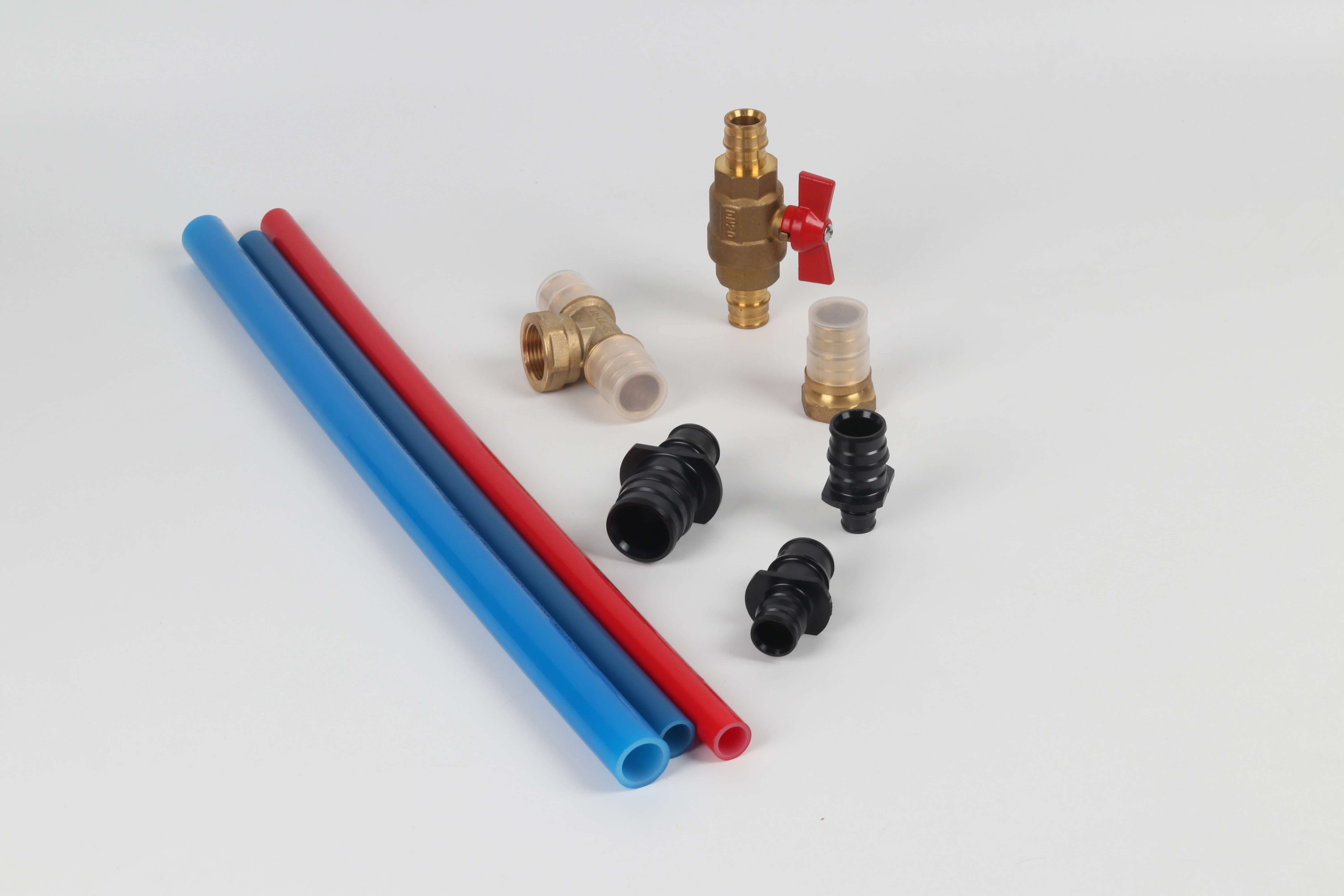

Different connection methods present varying considerations:

- Expansion systems typically introduce no additional materials

- Crimp systems use copper or stainless steel rings

- Clamp systems employ stainless steel clamps

- Push-fit systems incorporate various sealing materials

Select connection methods with components certified for drinking water contact. Proper installation per manufacturer instructions ensures optimal performance and minimizes potential migration pathways.

Table: Installation Practices for Optimal Water Quality

| Installation Phase | Best Practices | Water Quality Impact | Professional Tips |

|---|---|---|---|

| Storage & Handling | UV protection, clean conditions | Prevents surface degradation | Use original packaging until installation |

| System Flushing | Comprehensive initial flush | Removes initial migrants | Flush until water runs completely clear |

| Connection Method | Certified components, proper technique | Minimizes additional materials | Follow manufacturer torque specifications |

| System Design | Minimize dead ends, proper sizing | Reduces water stagnation | Design for efficient flushing and use |

System Design and Maintenance

Thoughtful system design enhances long-term water quality:

- Minimize dead legs and stagnant water areas

- Size systems appropriately for expected usage patterns

- Include isolation valves for segment flushing capability

- Design for accessibility for future maintenance

Regular maintenance, including periodic flushing of infrequently used lines, helps maintain optimal water quality. Additionally, monitoring water quality parameters provides early detection of any potential issues.

Common Client Pain Points Analysis

Homeowners and professionals frequently express specific concerns regarding PEX and water quality, which can be addressed through education and proper practices.

Clients primarily worry about plastic taste or odor, potential health effects from long-term exposure, compatibility with existing plumbing, and confusion regarding different PEX types and certifications. These concerns stem from early PEX issues, misinformation, and the technical nature of material science, creating hesitation despite extensive safety data.

Understanding these pain points allows professionals to address concerns directly with factual information and practical solutions.

Taste and Odor Perceptions

Early PEX formulations sometimes caused noticeable taste or odor issues:

- Plastic taste in initial water use

- Musty or earthy odors from certain manufacturing processes

- Chemical smells from residual compounds

Modern PEX has largely resolved these issues through improved manufacturing, though proper flushing remains essential. When taste or odor occurs, it’s typically temporary and resolves with continued use.

Health Concerns and Risk Perception

Despite extensive testing, health concerns persist due to:

- General suspicion of plastics in food and water contact

- Confusion with other plastics like PVC that have different formulations

- Limited understanding of certification processes and safety margins

- Anecdotal reports that may not reflect typical experience

Education about the rigorous certification process and extensive testing helps address these concerns. Comparing PEX’s safety record to traditional materials provides helpful context.

Practical Recommendations

Implementing specific practices addresses common concerns and ensures optimal PEX system performance.

Select NSF/ANSI 61 certified PEX products, flush systems thoroughly before use, maintain appropriate operating temperatures, and implement regular maintenance schedules. These practical steps maximize water quality while leveraging PEX’s installation and performance benefits.

Actionable recommendations help users achieve optimal results with PEX plumbing systems.

Product Selection Guidelines

- Choose certified products with current NSF/ANSI 61 certification

- Select appropriate PEX type for specific applications

- Use manufacturer-recommended connection systems

- Verify certification status through online databases

Installation and Commissioning Practices

- Flush systems thoroughly before initial use (minimum 10-15 minutes)

- Follow manufacturer instructions for specific products

- Protect PEX from UV exposure during and after installation

- Use clean techniques to prevent contamination

Ongoing Maintenance Recommendations

- Flush infrequently used lines periodically

- Monitor water quality for changes in taste, odor, or appearance

- Maintain system within design parameters for temperature and pressure

- Document installation details for future reference

By implementing these practical recommendations, users can confidently enjoy PEX’s benefits while maintaining excellent water quality throughout the system’s service life.

Последние комментарии