A client once had a major leak because a cheap end cap cracked under pressure. This taught me that even the smallest fittings demand the right choice and care.

A PVC end cap with a threaded hole is a fitting that seals the end of a PVC pipe while providing a threaded port, usually NPT, for connecting valves, gauges, or drains. Choosing the right one requires matching the pipe size, thread specification, pressure rating, and material grade to your specific application to ensure a leak-proof and durable seal.

Let’s break down the key questions you need to ask to select, install, and use this versatile fitting correctly.

How to Choose the Right PVC End Cap Size and Thread Specification?

Getting the size wrong is the most common and costly mistake. I’ve seen projects delayed for weeks waiting for the correct fitting.

To choose the right PVC end cap, you must know two key measurements: the Socket Size (the pipe size it glues onto, like 1/2″ or 2″) and the Thread Specification (the size and type of the threaded hole, such as 1/4″ NPT). Always verify both against your system’s design requirements and never assume they are the same.

Step 1: Identify Your Pipe Size (The Socket)

This is the most critical step. The end cap has a socket (a smooth, unthreaded inner wall) that is designed to be cemented onto a specific Schedule (Sch) of PVC pipe.

- Action: Measure the outer diameter (OD) of your pipe. Do not measure the inner diameter. Then, check the pipe’s labeling for its nominal size (e.g., 1″, 2″) and Schedule (e.g., Sch 40, Sch 80).

- Common Mistake: A 1″ Sch 40 pipe and a 1″ Sch 80 pipe have different outer diameters. An end cap for Sch 40 will not fit Sch 80 pipe. You must match the schedule.

Step 2: Understand Thread Specifications

The threaded hole allows for future access or connections. You must specify two things:

- Thread Size: This is the nominal size of the threaded port (e.g., 1/4″, 1/2″, 3/4″). It determines what accessory (a plug, drain valve, gauge) will screw into it.

- Thread Type: For plumbing in the US, this is almost always NPT (National Pipe Tapered). The tapered threads create a seal when tightened. Other types exist (e.g., BSPP), so confirmation is key, especially for international projects.

Key Selection Table

Use this table to clarify the specifications you need to provide or look for when ordering.

| Specification | What It Means | How to Determine It |

|---|---|---|

| Socket Size | The PVC pipe size the cap glues onto. | Match the exact nominal size and Schedule (Sch 40/80) of your existing pipe. |

| Thread Size | The size of the threaded port on the cap. | Determine based on the accessory (valve, gauge) you need to install. |

| Тип резьбы | The standard of the threads. | NPT is standard for North America. Confirm for other regions. |

| Номинальное давление | The maximum pressure the cap can handle. | Must meet or exceed your system’s maximum operating pressure. Sch 80 caps have a higher rating than Sch 40. |

| Материал | Usually PVC (Type I) or CPVC. | Match the material of your pipe system. CPVC is for higher temperature applications. |

Step 3: Consider Pressure and Material

Finally, think about your system’s environment.

- Pressure Rating: Schedule 80 end caps have thicker walls and a higher pressure rating than Schedule 40. For high-pressure lines or safety-critical applications, always choose Sch 80.

- Material: Standard PVC is for cold water and general use. CPVC can handle higher temperatures, like for hot water lines. Ensure the cap material is compatible with your pipe cement.

Choosing correctly from the start prevents leaks, system failures, and costly replacements.

What is the Proper Method for Sealing a Threaded PVC End Cap?

A perfect cap can still leak if installed poorly. The sealing process involves two independent seals: one for the socket and one for the threads.

Sealing a threaded PVC end cap requires a two-step process: First, permanently cement the smooth socket onto the pipe using PVC primer and solvent cement. Second, seal the internal threaded port using Teflon tape (thread seal tape) or a non-hardening pipe thread sealant on the male threads of the accessory being screwed in, ensuring a leak-proof connection at both points.

Seal 1: The Socket Joint (Permanent)

This joint is designed to be fused permanently with cement. You cannot rely on the threads to hold the cap onto the pipe.

- Dry Fit: First, test the fit by pushing the cap onto the pipe without cement. It should slide on easily but snugly.

- Clean and Prime: Use a clean, dry cloth to remove dirt from the pipe end and the inside of the cap socket. Then, apply PVC primer (purple or clear) to both surfaces. The primer cleans and softens the plastic for a stronger bond.

- Apply Cement: While the primer is still wet, apply a uniform layer of PVC solvent cement to the pipe end and a light layer inside the cap socket.

- Assemble and Hold: Immediately push the cap onto the pipe, giving it a quarter turn to spread the cement. Hold it firmly in place for about 15-30 seconds to prevent it from pushing off.

- Cure: Allow the joint to cure for the time recommended on the cement can (usually 15 minutes for handling, several hours for full strength) before pressurizing the system.

Seal 2: The Threaded Port (Serviceable)

The NPT threads are tapered and designed to create a seal when tightened, but they need help.

- Never put cement on the NPT threads. This will make the accessory permanent and likely crack the fitting.

- Use Teflon Tape: Wrap PTFE thread seal tape clockwise around the male threads of your plug or valve. Use 3-4 wraps for a good seal. The tape fills the gaps between the threads.

- Alternative: Pipe Dope: Use a non-hardening, paste-type pipe thread sealant compatible with plastic. Apply it evenly to the male threads.

- Screw in the Accessory: Hand-tighten the accessory (plug, drain valve) into the cap’s threaded hole, then use a wrench to tighten it an additional 1-2 turns. Do not over-tighten, as this can stress and crack the PVC cap.

Comparison of Thread Sealing Methods

| Method | Best For | Pros | Cons | Application Tip |

|---|---|---|---|---|

| PTFE Tape (Teflon) | Most applications, especially water lines. | Clean, easy to remove, doesn’t drip. | Can shred if applied wrong. | Wrap clockwise 3-4 times. Do not cover the first thread. |

| Pipe Thread Sealant | Applications with vibration, or gas lines (check compatibility). | Fills thread imperfections well. | Messy, requires curing time. | Apply a thin, even coat on male threads. |

Following this two-step sealing method ensures your end cap installation is both structurally sound and easily serviceable in the future.

Where are Threaded PVC End Caps Commonly Used in Plumbing Systems?

These fittings are more than just simple stoppers. Their design provides a sealed end with future access, making them problem-solvers.

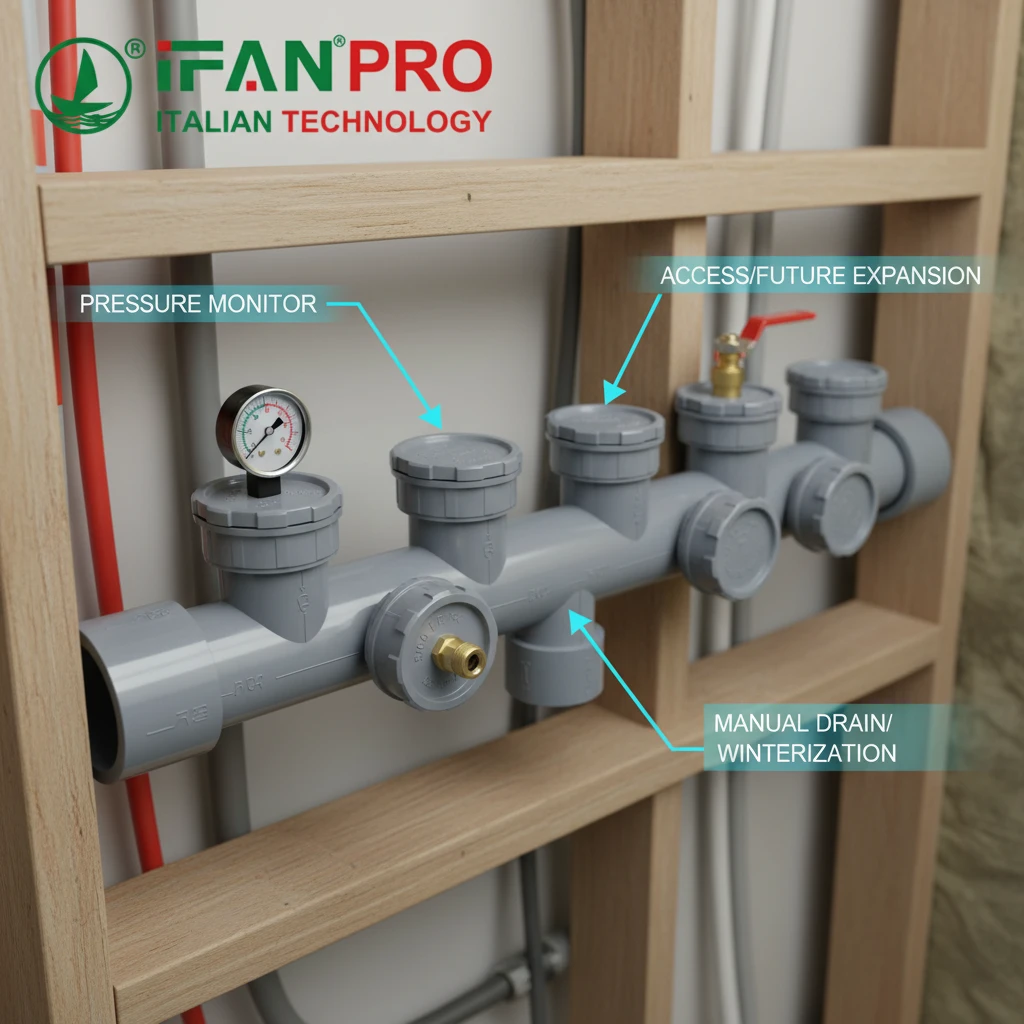

Threaded PVC end caps are commonly used at the termination points of pipelines where future access, drainage, or pressure monitoring is needed. Key applications include system cleanouts, future expansion points, drain valves on low points, pressure gauge ports, and as test caps during system installation and pressure testing.

1. System Cleanouts and Future Access

This is one of the most practical uses. Instead of permanently cementing a plain end cap, using a threaded version allows for easy future access.

- Scenario: A drain line runs under a concrete slab and terminates at a wall. A threaded end cap is installed. If a blockage occurs downstream, a plumber can simply unscrew the cap and insert a drain auger (snake) to clear it, saving the cost and mess of cutting into the pipe.

- Future Expansion: When a system might be expanded later, a threaded end cap provides a perfect, sealed termination point. When ready, the cap is unscrewed, and a new section of pipe can be connected via a threaded adapter.

2. Drain and Boiler Drain Valves

In any system, you need to drain water for maintenance or winterization.

- Application: A threaded end cap is installed at the lowest point of an irrigation line or a outdoor water pipe. A standard hose thread boiler drain valve is then screwed into the cap’s NPT port. When you need to drain the line, you simply attach a hose to the valve and open it. This is far superior to trying to cut into a pipe each time.

3. Pressure Measurement and Relief Points

For system monitoring and safety, you need ports for instruments.

- Pressure Gauge Port: A threaded end cap on a supply line can host a pressure gauge, allowing you to monitor system pressure. The gauge screws directly into the NPT port.

- Air Relief or Vacuum Breaker: In some systems, you need to release trapped air. A small air vent valve can be installed into the threaded port of an end cap placed at a high point in the system.

4. Critical Role in Construction and Testing

During the installation of a plumbing system, these caps are indispensable.

- Test Cap: Before a system is finalized, plumbers perform a pressure test to check for leaks. Threaded end caps, sealed with a plug, are used to temporarily close off all open ends of the system. After the test passes, they can be easily removed for the final connections to fixtures.

- Protection: They are also used to seal off open pipe ends during construction to prevent debris, insects, or animals from entering the pipes.

By understanding these common applications, you can better plan your system for efficiency, maintenance, and future flexibility.

What Should You Check for Quality in a Threaded PVC End Cap?

Not all end caps are created equal. Poor quality leads to cracks, leaks, and thread failure.

Check a threaded PVC end cap for quality by inspecting its material consistency, wall thickness, thread precision, and certifications. Look for smooth, bubble-free material, uniform socket and thread walls, cleanly cut and precise NPT threads, and markings indicating pressure rating, material type (e.g., ASTM D1784), and NSF certification for potable water use.

Visual and Physical Inspection Points

Before you even install a fitting, you can catch many quality issues with a simple inspection.

1. Material Integrity:

- Look: The PVC should have a consistent color (usually white, gray, or cream) throughout, with no discoloration, black specks, or visible impurities.

- Feel: The surface should be smooth. Run your finger along the socket and threads. There should be no rough spots, flash (excess plastic from molding), or sharp edges that could cause stress concentrations.

- Warning Sign: Brittleness or a chalky feel indicates poor-quality resin or material that has degraded, often from UV exposure during improper storage.

2. Wall Thickness and Structure:

- Compare: A Schedule 80 cap should have noticeably thicker walls than a Schedule 40 cap of the same size. This is its primary safety feature.

- Check Uniformity: Look at the cross-section. The walls should be of even thickness all around. Thin or uneven spots are weak points that will fail under pressure.

- Socket Depth: The cement socket should be deep enough to provide sufficient glue surface area for a strong joint.

3. Thread Quality:

This is critical. Poor threads will never seal properly.

- Visual: The threads should be sharp, clean, and continuous. They should not be flattened, misshapen, or have plastic debris (“thread chatter”) in the grooves.

- Fit Test: Do a dry fit with a standard metal or plastic NPT plug of the correct size. It should screw in by hand for the first few turns smoothly, without forcing or wobbling. Resistance should increase evenly as you hand-tighten it.

Certification and Markings

A quality manufacturer will permanently mark their fittings. These markings are your guarantee.

Essential Markings Table:

| Marking | What It Tells You | Why It Matters |

|---|---|---|

| Nominal Size | e.g., “2 x 1/2″” | Confirms socket size (2″) and thread size (1/2″). |

| Schedule | “Sch 40” or “Sch 80” | States the pressure rating standard. |

| Material Code | “PVC 1120” or “ASTM D1784” | Specifies the exact PVC compound and its performance grade. |

| Номинальное давление | e.g., “220 PSI @ 73°F” for Sch 80 | The maximum safe operating pressure. |

| Manufacturer’s Name/Logo | e.g., “IFAN” | Identifies the source for accountability. |

| NSF-pw or NSF-61 | Certification Mark | Crucial for drinking water. Indicates the material is certified not to leach contaminants. |

Investing a few moments in a quality check can prevent the major headache of a fitting failure after the system is buried in a wall or under the ground. Choosing a reputable supplier like ИФАН ensures you get products that consistently meet these high-quality standards, with clear markings and reliable performance.

Заключение

Choosing, installing, and using the right threaded PVC end cap ensures system integrity and simplifies future maintenance. For high-quality, clearly marked, and reliably performing PVC fittings, trust ИФАН‘s range of end caps and plumbing solutions.

Последние комментарии