I once had a client whose metal valves failed in just two years due to corrosive chemicals. They switched to PVC, and the solution lasted over a decade. This firsthand experience taught me the real meaning of durability.

PVC valves are highly durable in pumping systems when selected and installed correctly for the specific application. Their primary durability comes from an exceptional resistance to corrosion and chemical attack, which often makes them outlast metal alternatives in handling water, acidic, alkaline, and saline fluids.

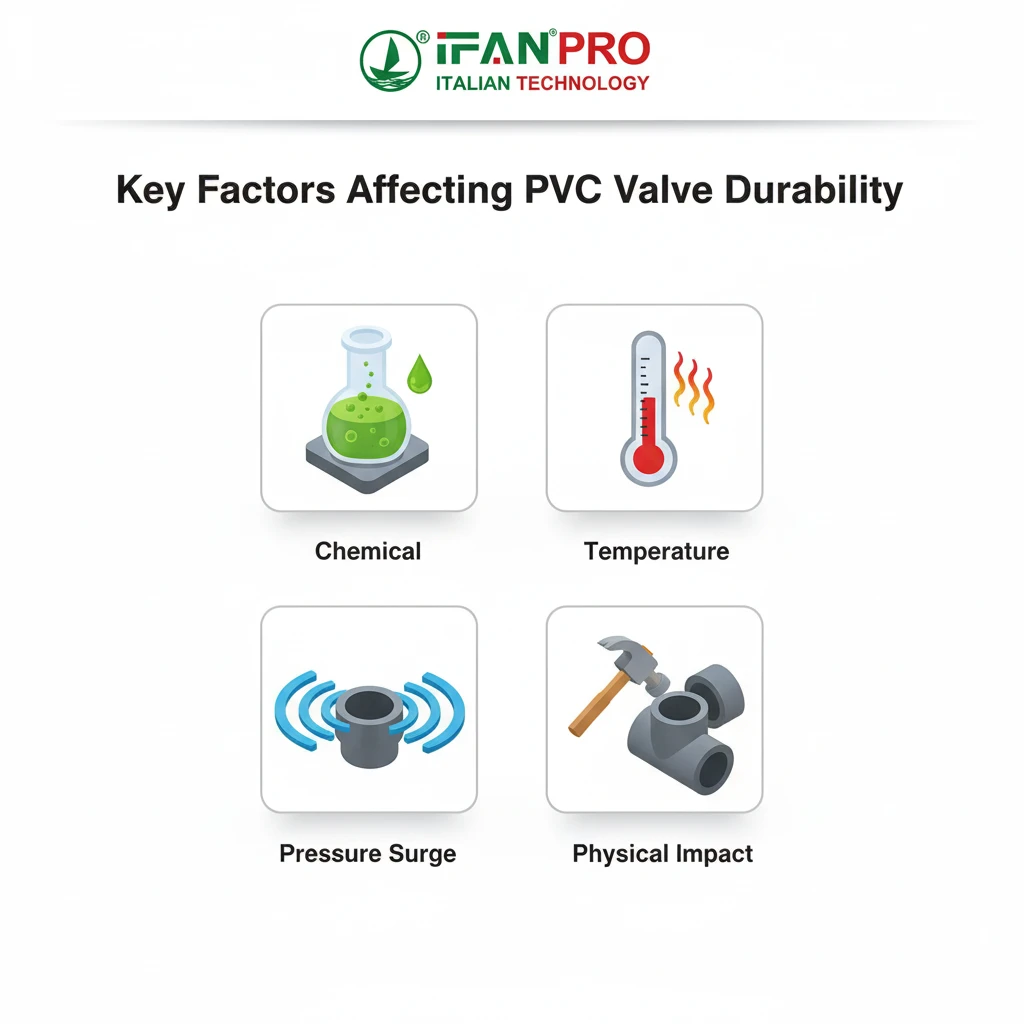

However, their durability isn’t automatic. It depends on several key factors. Let’s examine what determines the lifespan of a PVC valve in your system.

What Factors Affect PVC Valve Durability in Pumping Systems?

Seeing a valve crack under pressure is a system designer’s nightmare. Durability isn’t just about the plastic; it’s about the entire operating environment.

The durability of a PVC valve is primarily affected by four key factors: the fluid’s chemical composition and temperature, the system’s operating pressure and pressure surges, the quality of installation and support, and exposure to physical impact or ultraviolet (UV) light from the sun.

The Role of Fluid and Temperature

First and foremost, what’s flowing through the valve? PVC has excellent resistance to a wide range of chemicals, but it’s not universal. The chemical compatibility is the most critical factor. For example, PVC handles dilute acids, bases, and salts very well but can be damaged by strong solvents, concentrated acids, or certain hydrocarbons. Always check a chemical compatibility chart for your specific fluid.

Next, consider temperature. Every PVC valve has a maximum operating temperature, usually around 140°F (60°C) for standard Schedule 40 valves. Exceeding this temperature significantly reduces the material’s strength and pressure rating, making it prone to deformation and failure. The fluid temperature, not just the ambient air temperature, is what matters here.

Pressure and Physical Stress Factors

Pressure is the next major player. PVC valves are rated for a specific pressure at a specific temperature. Operating at or below this rated pressure is crucial. Furthermore, sudden pressure spikes, known as water hammer, can be very damaging. PVC is more brittle than metal and can crack under severe hydraulic shock. Using pressure relief valves, surge arrestors, and ensuring slow valve operation can mitigate this risk.

Physical installation and support are often overlooked. PVC is a rigid but somewhat flexible material. Long, unsupported pipe runs can transfer stress to the valve body, especially at connection points. Properly supporting the pipes on both sides of the valve prevents misalignment and stress. Also, avoid over-tightening connections, as this can create stress cracks.

Environmental Exposure

Finally, consider the valve’s location. If installed outdoors, exposure to direct sunlight (UV radiation) will degrade standard PVC over time, making it brittle. For outdoor applications, you must specify valves made from UV-stabilized (gray) PVC or ensure they are painted or shielded. Physical impact from tools, equipment, or personnel can also crack or break valves, so they need protection in high-traffic areas.

Understanding and controlling these four factors—chemical, thermal, pressure, and physical—is the foundation for achieving maximum durability from any PVC valve.

How Does Chemical Resistance Impact PVC Valve Lifespan?

A valve that looks intact but has degraded from the inside is a hidden danger. Chemical resistance defines PVC’s core advantage.

Chemical resistance directly dictates PVC valve lifespan by preventing the material from corroding, swelling, cracking, or losing its structural integrity. Unlike metals that corrode from the outside in, incompatible chemicals can cause PVC to undergo stress corrosion cracking or become brittle from within, leading to sudden failure.

The Mechanism of Chemical Attack

To understand its importance, let’s look at how chemicals affect different materials. Metal valves fail primarily through corrosion—an electrochemical reaction that eats away at the metal surface, thinning the walls until they leak or rupture. PVC, being a non-conductive thermoplastic, is immune to this type of galvanic corrosion. This is its biggest advantage in many applications.

However, PVC can be affected by chemical exposure in different ways. Some aggressive chemicals, like certain strong solvents, can actually dissolve or soften the PVC, causing it to swell and lose its shape. This is a clear compatibility failure. A more insidious threat is Environmental Stress Cracking (ESC). This happens when a chemical agent, even at low concentrations, weakens the polymer’s structure while the valve is under mechanical stress (like pressure). This combination can lead to the formation and rapid propagation of cracks, causing sudden brittle fracture without warning.

Common Compatibility Scenarios

Here is a quick guide to PVC’s chemical resistance in common pumping scenarios:

| Тип жидкости | PVC Valve Compatibility & Expected Lifespan Impact |

|---|---|

| Fresh Water, Sea Water | Excellent. No corrosion, leading to very long lifespan (20+ years). |

| Dilute Acids & Bases (e.g., pool chemicals) | Very Good to Excellent. Far outlasts metals, lifespan similar to water service. |

| Bleach & Chlorine Solutions | Good. UV-stabilized PVC is often used. Lifespan is long but may be reduced vs. water. |

| Oils & Petroleum Products | Poor. PVC can soften or crack. Not recommended; lifespan would be very short. |

| Strong Oxidizing Acids | Variable. Must consult specific compatibility charts. Can cause ESC. |

Choosing the Right Material Grade

Therefore, the single most important step to ensure a long valve lifespan is to match the PVC valve to the fluid. This requires:

- Identifying all chemicals in the fluid, including cleaning agents.

- Consulting a chemical resistance chart from a reputable manufacturer like IFAN.

- Considering temperature, as chemical attack accelerates with heat.

By prioritizing chemical compatibility, you leverage PVC’s greatest strength and avoid its primary mode of premature failure.

What Maintenance Extends PVC Valve Service Life?

Many assume PVC is “maintenance-free,” but proactive care prevents most failures. Simple habits make a big difference.

Regular visual inspections for cracks or leaks, operational checks to ensure smooth cycling, protecting valves from UV exposure and physical impact, and keeping the system clean to prevent debris from damaging sealing surfaces are the key maintenance practices that significantly extend PVC valve service life.

Routine Inspection and Operational Checks

While PVC valves require less maintenance than metal ones, they are not “install and forget” components. A simple, scheduled maintenance routine can catch small issues before they become big problems.

First, conduct regular visual inspections. Look for any signs of cracks, especially around the valve body, stems, and connection points. Check for discoloration or whitening (a sign of stress) and any signs of leakage. Valves that are constantly under stress or exposed to incompatible chemicals may show these early warning signs.

Second, perform operational checks. Cycle the valve (open and close it) periodically, even if it normally stays in one position. This prevents the stem or ball from seizing due to mineral deposits or slight chemical buildup. If the valve becomes hard to operate, don’t force it. Forcing can crack the handle or internal components. Instead, investigate the cause—it might be debris or early signs of compatibility issues.

Proactive Protection and System Care

Third, provide environmental protection. For outdoor valves, ensure they are made from UV-stabilized material or are properly shielded from direct sunlight with paint or covers. Also, protect valves in walkways or work areas from potential impact by installing protective barriers or guards.

Fourth, maintain system cleanliness. Before initial startup and after any system work, flush the lines to remove debris like metal filings, sand, or pipe chips. These particles can score the sealing surfaces of ball valves or clog and abrade diaphragm valves, causing leaks and reducing lifespan. Installing a simple strainer upstream of critical valves is a very effective protective measure.

Recommended Maintenance Schedule

Here is a simple maintenance table for typical PVC valves in continuous service:

| Maintenance Task | Frequency | Action |

|---|---|---|

| Visual Inspection | Monthly | Look for cracks, leaks, discoloration, or deformation. |

| Operational Check | Quarterly | Cycle the valve fully open to closed. Feel for smooth operation. |

| System Flush/Strainer Check | After maintenance or annually | Flush lines; clean any installed strainers to remove debris. |

| Support & Alignment Check | Annually | Ensure pipe supports are secure and no stress is on valve bodies. |

| Record Keeping | Ongoing | Log inspections and any issues to track valve performance over time. |

This low-effort, proactive approach prevents the vast majority of PVC valve failures, ensuring you get the full, long service life the material is capable of providing.

How Do PVC Valves Compare to Metal in Pumping Systems?

The choice between plastic and metal isn’t always obvious. I guide clients by focusing on the specific job, not just tradition.

PVC valves generally outperform metal valves in corrosion resistance, cost, and weight for handling water and many chemicals, but metal valves (like brass, stainless steel) are superior for high-temperature, high-pressure, or applications involving solvents, oils, or external physical abuse. The best choice depends entirely on the system’s specific fluid, pressure, temperature, and budget.

A Side-by-Side Comparison

Let’s break down the comparison across key operational factors to make an informed decision.

1. Corrosion and Chemical Resistance:

This is PVC’s defining victory. For water, wastewater, acids, alkalis, and chlorinated solutions, PVC is inert and will not rust or corrode. Metal valves require specific, often expensive alloys (like 316 stainless steel) to handle similar fluids, and even then, they can fail from pitting or crevice corrosion. For corrosive duty, PVC offers a longer lifespan at a lower cost.

2. Temperature and Pressure Limits:

This is where metal reigns supreme. Standard PVC valves are limited to about 140°F (60°C) and pressures reducing as temperature rises. Metals like brass, carbon steel, and stainless steel can handle much higher temperatures and pressures, making them the only choice for steam, hot oil, or high-pressure hydraulic lines.

3. Cost and Weight:

PVC valves are almost always less expensive than their metal counterparts, especially compared to corrosion-resistant alloys. They are also significantly lighter, making them easier to install and support, reducing overall system material and labor costs.

4. Mechanical Strength and Abrasion:

Metal is tougher. PVC can be brittle at low temperatures and is susceptible to damage from impact or crushing. In applications with heavy abrasion (slurries with hard particles) or high risk of physical damage, a metal valve is more durable.

Decision-Making Guide Table

Use this table to guide your initial material selection:

| Application Factor | Choose PVC Valves When… | Choose Metal Valves When… |

|---|---|---|

| Тип жидкости | Handling water, acids, bases, chlorinated water. | Handling oils, solvents, steam, or very high-purity fluids requiring special metals. |

| Temperature | Fluid is below 140°F (60°C). | Fluid is above 140°F (60°C) or in high-temperature environments. |

| Pressure | Operating pressure is within PVC’s rated limits. | Very high pressure or extreme pressure surges (water hammer) are common. |

| Budget & Weight | Initial cost and light weight are priorities. | Higher initial cost is acceptable for perceived strength or tradition. |

| Окружающая среда | Corrosion from atmosphere or fluid is the main concern. | Risk of physical impact, abrasion, or external damage is high. |

In summary, PVC is not a “cheap alternative” but a superior specialist for corrosive, low-to-medium temperature water and chemical services. Metal remains the choice for high heat, high pressure, and mechanical abuse. Knowing the difference saves money and prevents system failures.

Заключение

PVC valve durability hinges on selecting the right grade for your fluid and pressure, then supporting and maintaining it properly. For chemically resistant, cost-effective PVC valves engineered for long service life, explore the range from ИФАН.

Последние комментарии