I recall a client’s frustration when a critical valve failed after just five years, causing costly water damage and system downtime. That event underscored why valve reliability is non-negotiable.

The valve ensures long-term reliability in PEX-AL-PEX networks through a combination of corrosion-resistant materials, precision manufacturing, a streamlined internal design that prevents clogging, and rigorous testing standards. This holistic approach guarantees consistent performance and prevents failures that can compromise the entire plumbing system over decades of use.

But how does each part contribute to this decades-long promise? Let’s examine the key factors that separate a reliable valve from one that is destined to fail.

How Do Its Material Choices Resist Scaling, Corrosion, and Fatigue Over Decades?

The wrong materials are a recipe for early failure. We’ve seen valves made from inferior brass develop pin-hole leaks from corrosion, destroying their sealing ability.

The valve resists scaling, corrosion, and fatigue by using high-grade, lead-free brass for the body, a durable polymer or stainless steel for the internal stem, and EPDM or similar high-grade rubber for the sealing washer. These materials are specifically chosen because they do not react with water, withstand constant pressure cycles, and remain flexible over time.

Breaking Down the Material Defense System

Every part of the valve faces a different challenge. Using the right material for each job is the first line of defense for long-term reliability.

First, consider the valve body. It is the main structure that holds pressure. High-quality valves use CW617N or equivalent lead-free brass. This brass alloy has excellent resistance to dezincification corrosion, a common problem where zinc leaches out of cheap brass, leaving a porous, weak structure. Lead-free brass also ensures safe drinking water. This strong body will not crack or corrode from the inside out.

Next, the internal moving parts. The stem, which you turn to open or close the valve, needs strength and smooth operation. Many reliable valves use glass-reinforced polypropylene (PP) or stainless steel for the stem. These materials will not corrode or fuse with the brass body over time, which can happen with two dissimilar metals. This prevents the valve from seizing shut.

Finally, and most critically, the seal. The washer or O-ring must create a perfect, watertight closure every time for years. EPDM (Ethylene Propylene Diene Monomer) rubber is the top choice. It has outstanding resistance to hot and cold water, retains its elasticity, and does not harden or crack. This elasticity is what fights fatigue from being compressed thousands of times.

How These Materials Solve Common Problems

The table below shows how each material targets a specific failure mode:

| Component | Primary Material | What it Resists | Why it Matters |

|---|---|---|---|

| Valve Body | Lead-Free Brass (CW617N) | Corrosion (Dezincification), Physical Impact | Prevents structural failure and leaks from the body itself. |

| Stem / Cartridge | Reinforced Polymer or Stainless Steel | Corrosion, Scaling, Seizing | Ensures smooth operation without sticking, even after years of no use. |

| Sealing Washer | EPDM Rubber | Fatigue, Temperature Swings, Chlorine | Maintains a perfect seal cycle after cycle; doesn’t harden and leak. |

Together, these material choices create a valve that is inert to the water flowing through it. It will not scale up with minerals because the smooth brass and polymer surfaces give deposits nothing to grab onto. It resists corrosion from both the water and, in the case of PEX-AL-PEX, possible electrochemical reactions. The materials can handle the constant stress of water pressure and temperature changes without wearing out. This multi-layer defense is the foundation of a reliable valve.

What Quality Controls During Manufacturing Guarantee Each Valve’s Performance?

Even the best design can fail with poor manufacturing. Consistent quality control is what turns a good design into a trustworthy product.

Strict quality controls guarantee each valve’s performance through a multi-stage process. This includes material certification checks, precision machining verification, 100% pressure testing of every single valve, and sample-based endurance cycling. These steps ensure no defective valve leaves the factory.

The Quality Control Journey: From Raw Material to Finished Product

Manufacturing a reliable valve is a process of constant verification. At IFAN, we implement checks at every critical point.

Stage 1: Incoming Material Inspection. Before production even begins, we verify the certifications of the brass rods and polymer compounds. We check for material grade and composition to ensure they meet our strict standards. This prevents problems from the very start.

Stage 2: In-Process Controls. During machining and assembly, we monitor key dimensions. We use gauges and automated systems to check critical areas like thread accuracy, seating surface smoothness, and assembly torque. This ensures all parts fit together perfectly with no room for leaks.

Stage 3: The Critical 100% Pressure Test. This is the most important step. Every single valve undergoes a hydrostatic pressure test. The valve is sealed in a test rig and filled with water at a pressure much higher than its rated working pressure (e.g., testing at 16 bar for a 10 bar valve). It holds this pressure for a set time. Any valve that shows even a micro-leak is immediately rejected. This test catches any sealing or structural flaw.

Stage 4: Sample-Based Fatigue and Life Testing. From each production batch, we take samples for destructive and endurance testing. These samples go through machines that simulate years of use—opening and closing them thousands of times under temperature and pressure cycles. This validates the long-term performance of the design and materials.

A Comparison of Standard vs. Rigorous QC

Not all factories follow the same protocol. Here is the difference it makes:

| Quality Control Step | Standard Factory Practice | Rigorous Practice (e.g., IFAN) | Result for Reliability |

|---|---|---|---|

| Material Check | Might rely on supplier paperwork only. | Physical verification and batch testing of incoming materials. | Eliminates risk from substandard raw materials. |

| Pressure Testing | Possibly sample-based (e.g., 1 in 100 valves). | 100% testing of every individual valve. | Catches 100% of sealing/manufacturing defects before shipment. |

| Performance Validation | Rare or based on outdated prototypes. | Regular sample life-cycle testing on current production. | Continuously confirms long-term durability in real-world conditions. |

This systematic approach removes chance from the equation. It guarantees that the valve you install is not just designed to be reliable, but is proven to be reliable before it even reaches your hands.

How Does Its Design Minimize Internal Flow Resistance and Deposit Buildup?

A valve should control flow, not hinder it. Poor design leads to pressure drops, noise, and clogs that degrade system performance over time.

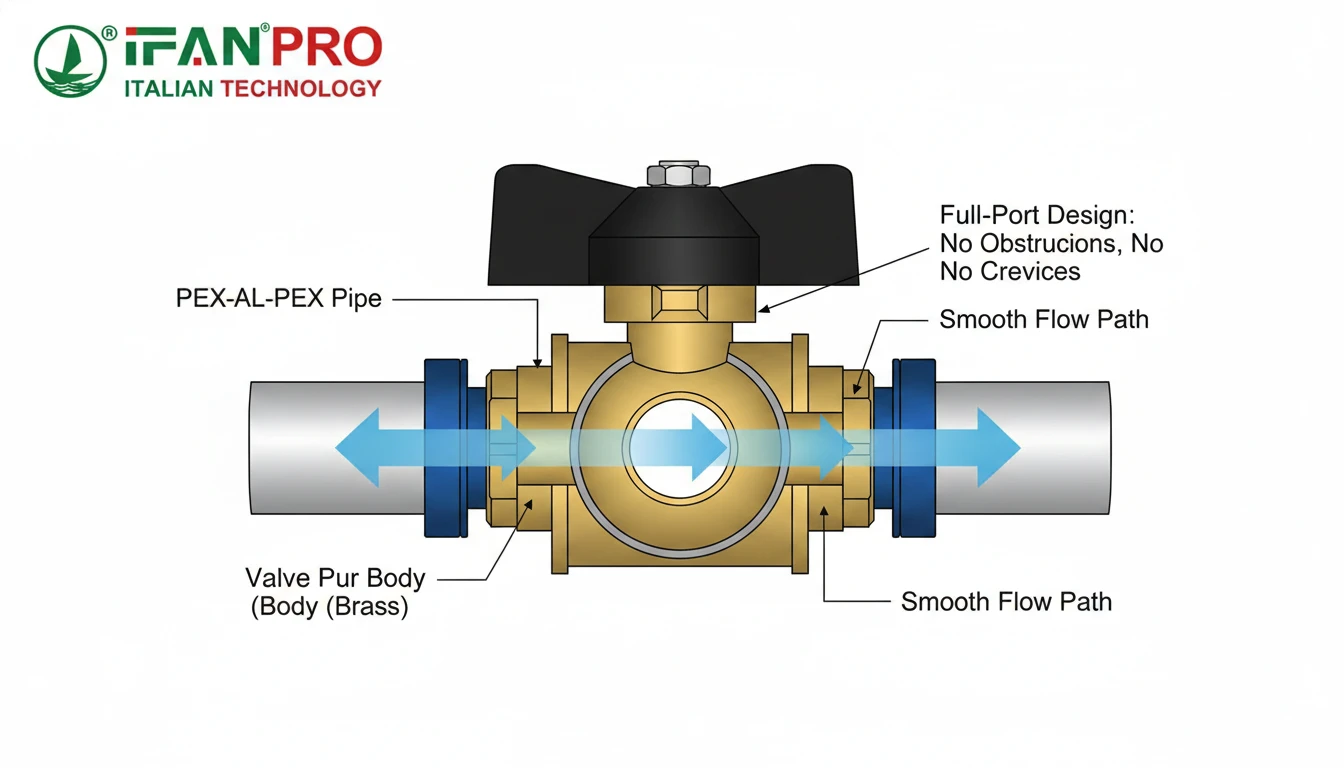

The valve minimizes internal flow resistance and deposit buildup through a full-port design, smooth internal waterways without sharp edges or cavities, and the use of non-stick materials. This creates a straight, unobstructed path for water that mimics the flow in the pipe itself, preventing turbulence where minerals can settle.

The Principles of Smooth, Unobstructed Flow

The goal is simple: water should flow through the valve as easily as it flows through the pipe. Resistance and buildup are caused by design flaws that disrupt this flow.

First, look at the port size. A standard valve often has an opening smaller than the pipe’s diameter, acting like a bottleneck. A full-port (or full-bore) valve has an internal opening that matches the inner diameter of the connecting pipe. This eliminates the major cause of pressure loss and allows for higher flow rates. It also makes the system easier to flush.

Second, examine the path the water takes. When you open a traditional angle valve, water must make a sharp 90-degree turn. This creates turbulence. Modern ball valves or specially designed cartridge valves offer a much straighter path. The smoother the journey, the less energy is lost, and the fewer the “dead zones” where water can stagnate and deposits can start to form.

Design Features that Prevent Buildup

Deposits need a place to start. Rough surfaces, sudden edges, and pockets of still water are perfect for scale and biofilm. A well-designed valve eliminates these.

- Mirror-Finish Waterways: The internal brass surfaces are polished smooth. This does two things: it reduces friction for water flow, and it gives calcium and other minerals nothing rough to cling to.

- Flush Sealing Surfaces: The design ensures that when the valve is fully open, the sealing mechanism (like a ball or gate) is completely out of the waterway. This prevents it from creating a partial obstruction that could collect debris.

- Self-Cleaning Action: In some ball valve designs, the rotation of the ball can help shear away any soft deposits that might try to form, keeping the passageway clear.

Impact on System Health

The benefits of a low-resistance, anti-clog design extend beyond just the valve.

| Design Feature | Benefit to Flow | Benefit to Long-Term Cleanliness |

|---|---|---|

| Full-Port Opening | Maximizes water pressure and volume to fixtures. | Allows for effective system flushing, pushing out debris. |

| Streamlined Internal Path | Reduces noisy turbulence and water hammer. | Prevents creation of low-flow zones where deposits settle. |

| Smooth, Polished Surfaces | Lowers pumping energy required. | Inhibits the nucleation point for limescale and biofilm. |

This thoughtful design means the valve maintains its performance. It won’t slowly choke the system with reduced flow over the years, and it won’t become a source of contamination or blockage.

What Is the Expected Service Life When Installed Correctly in a PEX-AL-PEX System?

Clients need a clear expectation. Vague promises are useless for planning maintenance or warranties.

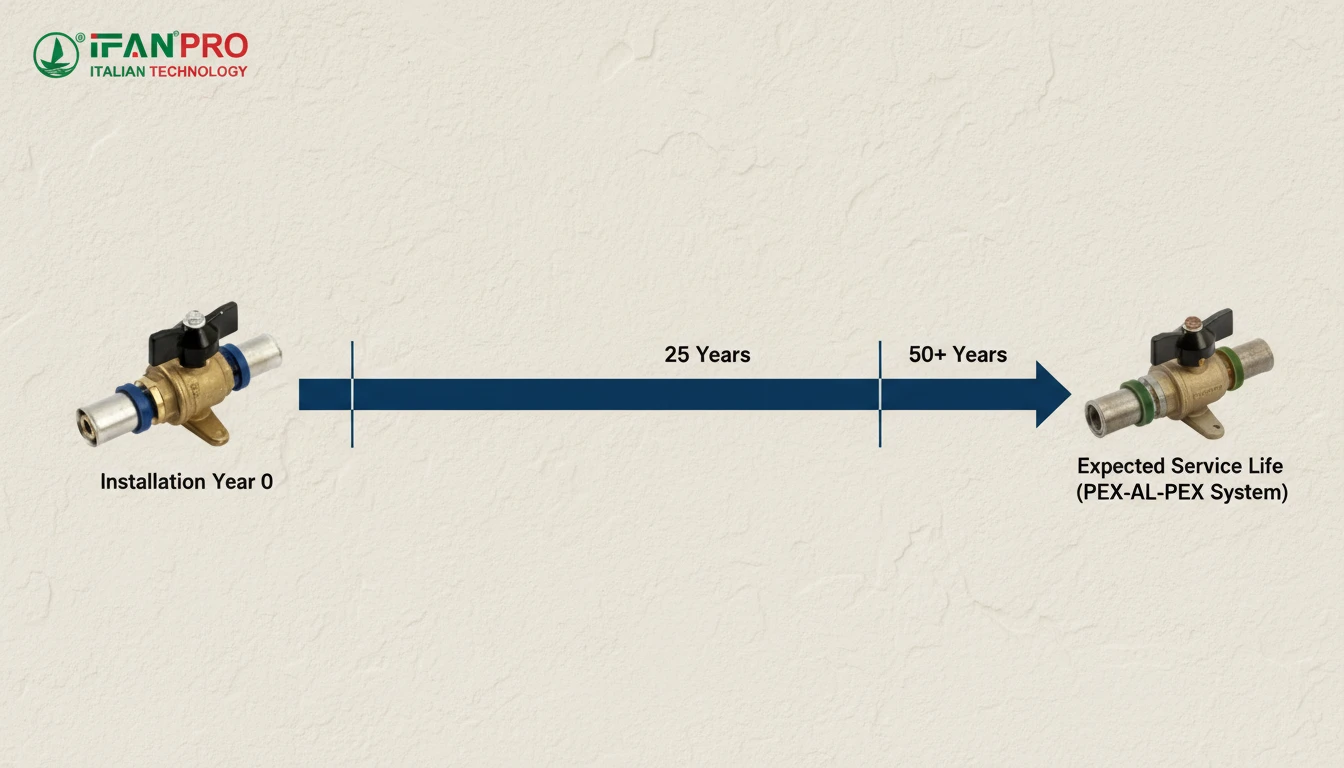

When installed correctly in a PEX-AL-PEX system, a high-quality valve has an expected service life of 50+ years. This lifespan is based on its materials resisting degradation and its design withstanding continuous operating pressures and temperature cycles typical in residential and commercial buildings.

Defining “Service Life” and “Correct Installation”

Service life means the valve will perform its function—opening, closing, and holding pressure—without failure for this period. “Correct installation” is the key condition that makes this promise valid.

Correct installation in a PEX-AL-PEX (121UC) system involves:

- Using the proper crimp or press fittings designed for the pipe.

- Not over-tightening or putting shear stress on the valve ports during installation.

- Ensuring the system is clean and pressure-tested before use.

- Protecting the valve from direct physical damage or UV exposure if in an open area.

The Factors That Enable a 50-Year Lifespan

This long life is not a guess; it’s a calculation based on proven factors:

- Material Durability: As discussed, the brass, polymer, and EPDM are selected for their long-term stability in water. They are tested to show minimal degradation over decades.

- Cycling Endurance: The valve is designed to be opened and closed thousands of times. For a residential valve, this far exceeds the actual use it will see in 50 years.

- Pressure and Temperature Ratings: The valve is rated for continuous use at high pressures and temperatures (e.g., 10 bar, 95°C). Normal household conditions are much milder, putting very little stress on it.

Realistic Life Expectancy Table

While the potential is 50+ years, actual life can vary based on water quality and usage. Here’s a realistic breakdown:

| System Environment | Expected Service Life | Key Influencing Factors |

|---|---|---|

| Standard Residential | 50+ years | Mild temperatures, stable pressure, moderate cycling. |

| Hard Water Area | 40-50+ years | Limescale may eventually affect movement, but materials resist corrosion. |

| Commercial (High-Use) | 30-40+ years | Increased mechanical cycling from frequent use is the main factor. |

It’s important to understand that this valve will typically outlast other components and the building’s renovation cycle. The valve itself is not the weak link in a properly designed PEX-AL-PEX system.

Заключение

A reliable valve for PEX-AL-PEX networks needs durable materials, rigorous manufacturing checks, and an unobstructed design. For a valve that meets all these criteria, choose IFAN’s lead-free brass ball valves, engineered for a lifetime of reliable service.

Последние комментарии