When it comes to plumbing systems, the quality of PPR (Polypropylene Random Copolymer) pipes directly affects safety, longevity, and performance. Whether used in residential, commercial, or industrial applications, low-quality pipes can lead to costly repairs, leaks, or even health hazards. That’s why professional PPR pipe suppliers implement strict quality control procedures to meet global standards and customer expectations.

In this article, we’ll explore how reputable manufacturers like ifanpro, a leading PPR pipe supplier from China, ensure consistent pipe quality from raw material selection to final delivery.

1. Sourcing High-Quality Raw Materials

The foundation of any durable PPR pipe is the сырьё. Top suppliers use only virgin PPR granules, which are free from recycled content and impurities. This ensures:

- Better сопротивление давлению

- High thermal stability

- Long lifespan (up to 50 years under proper use)

At ifanpro, we partner with trusted raw material providers and inspect every batch to confirm compliance with ISO standards.

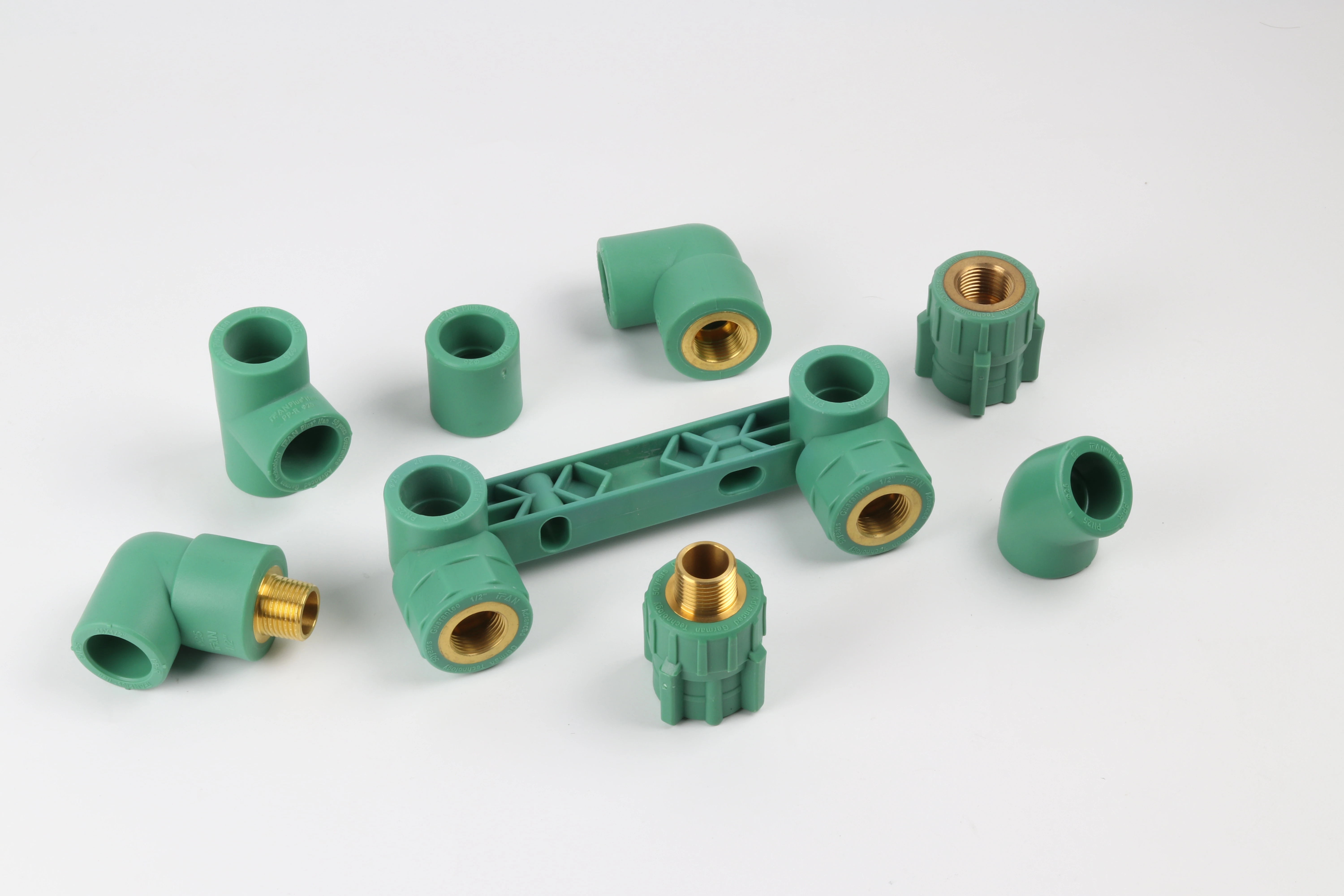

2. Advanced Extrusion and Injection Molding Technology

State-of-the-art manufacturing equipment plays a critical role in producing pipes with uniform wall thickness, smooth surfaces, and strong joint compatibility.

Our factory is equipped with fully automated extrusion lines and precision-controlled injection machines, ensuring each pipe and fitting is made to exact specifications. Consistent production quality also minimizes material waste and improves overall efficiency.

3. In-House Laboratory Testing

Before a pipe reaches the market, it undergoes a series of rigorous quality tests. These typically include:

- Hydrostatic pressure testing (for leakage and strength)

- Thermal aging resistance

- Impact resistance tests

- Dimensional accuracy verification

At ifanpro, we have an in-house lab that allows us to test every batch in real time, reducing risks of defect shipments and ensuring product integrity.

4. International Certification and Compliance

Reliable suppliers obtain certifications that reflect their commitment to quality. Common certifications for PPR pipes include:

- ISO 9001: Quality Management Systems

- ISO 15874: PPR Piping Systems Standard

- CE Certification (for European markets)

- WRAS Approval (for drinking water applications in the UK)

ifanpro products meet or exceed these standards, making them suitable for a global customer base.

5. Customization and Quality Traceability

Every project is different, and customization is often required. A reliable supplier provides:

- Custom sizes, colors, or branding

- OEM & ODM services

- Barcode or batch number tracking for quality traceability

We at ifanpro offer end-to-end customization services, ensuring that every client’s specific needs are met without compromising quality.

6. Continuous Improvement Through Customer Feedback

After-sales service and feedback mechanisms are essential for long-term success. Top manufacturers use customer insights to optimize production, packaging, and delivery.

ifanpro values long-term partnerships and provides responsive customer service and technical support. Your feedback directly shapes our product evolution.

Заключение

Choosing the right PPR pipe supplier is not just about price—it’s about reliability, safety, and long-term value. Quality assurance in PPR pipe manufacturing involves a comprehensive process that starts with sourcing and ends with customer satisfaction.

If you’re looking for a trusted partner with proven manufacturing capabilities, explore our PPR product range at ifanpro.com or связаться с нами for custom solutions tailored to your pipeline needs.

Последние комментарии