We once had a project where a fixed elbow caused a major rework. That frustrating experience solidified my belief in the value of a truly reliable adjustable union.

Yes, a well-designed adjustable union (or swivel elbow) effectively prevents leaks at various angles. It achieves this through a precision swivel mechanism that maintains constant pressure on a specialized sealing surface, like an O-ring or gasket, regardless of rotation. This design allows for field adjustment without compromising the integrity of the watertight seal.

However, not all adjustable fittings are created equal. Let’s break down exactly how a quality union maintains a seal and where common failures happen.

How Does the Swivel Mechanism Maintain Seal Integrity at Various Angles?

A loose, leaking swivel is worse than a fixed pipe. I’ve seen cheap imitations fail because their swivel design was an afterthought.

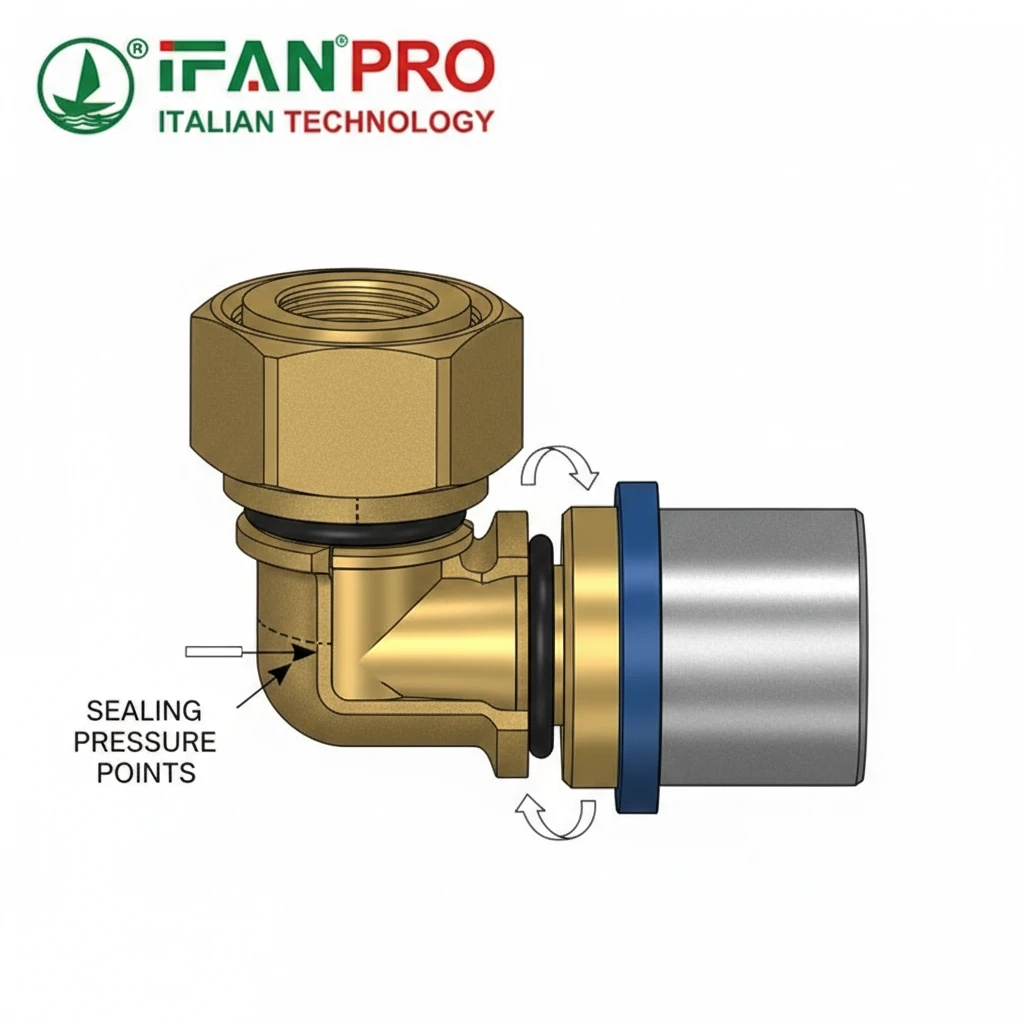

The swivel mechanism maintains seal integrity by keeping the primary sealing element—such as an O-ring, gasket, or precision-machined surface—under constant, even pressure during rotation. This is typically achieved through a threaded compression nut, a captive retaining ring, or a precision ball-and-socket design that prevents the seal from being pinched or gapped when adjusted.

The Core Principle: Constant Compression

The fundamental challenge of an adjustable joint is making something move without letting water escape. The solution relies on a seal that stays properly compressed.

Think of it like closing a lid on a jar. If the lid is crooked, it leaks. A good swivel mechanism ensures the “lid” (the seal) is always perfectly square and pressed down evenly, even as you turn it. Typically, a nut threads onto the body of the fitting. As you tighten the nut, it presses a movable part against a stationary seal. Importantly, the swivel action happens behind this compression point. Therefore, the seal itself doesn’t twist or shear; it just stays clamped.

Common Swivel Designs and Their Weaknesses

Different mechanisms handle this task in different ways, with varying levels of reliability.

1. The Compression Nut Design: This is the most common and reliable type for residential and commercial PP-R systems. A nut threads onto the main body, compressing a rubber or EPDM O-ring against a smooth, tapered seat. The inner pipe can swivel before the nut is fully tightened. Once tightened, the compression locks in, securing the seal at that angle.

- Advantage: Simple, strong, and easy to install.

- Potential Weak Point: Low-quality O-rings or rough seating surfaces can cause leaks.

2. The Captive Ring Design: In this design, a plastic or metal ring holds the sealing components together. The adjustment is often hand-tightened and then locked with a separate clip or screw.

- Advantage: Very quick to adjust.

- Potential Weak Point: The locking mechanism can vibrate loose over time, reducing seal pressure.

3. The Integrated Ball Joint: This is a more industrial design, often found in metal fittings. A spherical end rotates inside a socket that contains the seal.

- Advantage: Allows for multi-directional movement.

- Potential Weak Point: More complex and expensive; seals can wear out with constant movement.

The table below summarizes how these designs manage the seal during movement:

| Swivel Mechanism Type | How it Maintains Seal Compression | Best For |

|---|---|---|

| Threaded Compression Nut | Nut applies direct, adjustable pressure on the O-ring/gasket. | Most PP-R/PVC water systems; general plumbing. |

| Captive Retaining Ring | Ring holds components under preset pressure; often tool-less. | Temporary setups, irrigation, where frequent adjustment is needed. |

| Ball-and-Socket Joint | The spherical surface constantly presents a uniform curve to the socket’s seal. | Industrial applications, places requiring vibration absorption. |

In summary, the mechanism creates the perfect, unchanging environment for the seal to work, no matter what angle you choose.

What Sealing Surfaces Ensure a Leak-Proof Connection When Adjusted?

The mechanism applies the force, but the seal does the work. The choice of sealing material makes or breaks the connection.

Two main sealing surfaces ensure a leak-proof connection: 1) A soft, elastic seal (like an EPDM or Nitrile O-ring or a flat gasket) that deforms to fill microscopic gaps, and 2) A hard, precision-machined seating surface on the fitting body that is perfectly smooth and free of defects to allow for even compression of the soft seal.

The Dynamic Duo: Elastic Seal and Hard Seat

A reliable adjustable seal is a partnership between two different materials. One is soft and forgiving; the other is hard and precise.

The Soft Seal (O-ring/Gasket): This is the key component. Its job is to deform. When you tighten the compression nut, the O-ring squeezes between the nut and the fitting’s seat. It flows into every tiny imperfection, creating a custom barrier. The material must be elastic enough to compress but tough enough not to permanently degrade in water.

- EPDM Rubber: Excellent for hot and cold water, resistant to weathering. This is the industry standard for potable water.

- Nitrile (Buna-N): Good for oils and fuels, but less common for domestic water.

The Hard Seating Surface: This is the stage for the seal. It is usually part of the main polypropylene body of the fitting. This surface must be:

- Smooth: Roughness will cut into the soft O-ring over time.

- Consistent: Its angle and finish must be uniform all the way around.

- Clean: Mold release agents or scratches can prevent a perfect seal.

The Impact of Manufacturing Quality

Cheap fittings often fail here. They might use a recycled rubber O-ring that hardens and cracks quickly. Their seating surface might have visible mold lines. When you adjust and tighten it, it may seem fine initially, but the poor seal material degrades, causing a slow leak.

Conversely, a high-quality fitting from IFAN uses virgin, certified EPDM O-rings designed for long service life. The seating surface has high precision to ensure flawless contact. This combination guarantees the seal remains intact after every adjustment.

Are There Limits to the Angular Adjustment Before Sealing is Compromised?

Clients often ask, “Can I just bend it anywhere?” The answer is yes, but within a defined safe range.

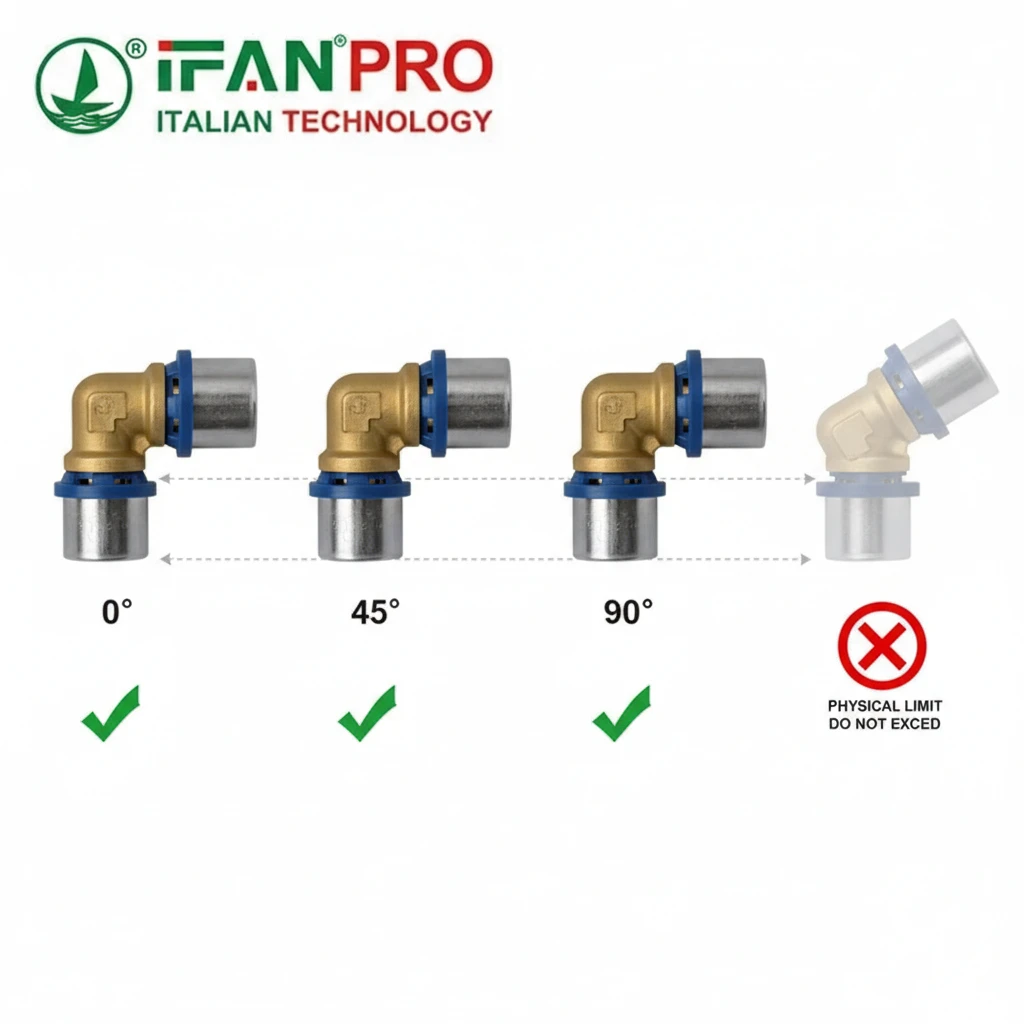

Yes, all adjustable elbows have angular adjustment limits, typically between 0 to 90 degrees, to prevent the sealing surfaces from separating or the O-ring from rolling or twisting out of its groove. Exceeding this limit can directly compromise the seal by causing a gap, pinching, or dislodging the sealing element.

Understanding the Physical Limits of the Seal

The seal works within a specific range of motion. Think of it like a door on a hinge. It works perfectly from closed to open. But if you try to swing it past the hinge’s stop, you break it.

In an adjustable elbow, the physical construction creates stops. These stops prevent the inner swiveling part from rotating so far that it:

- Pulls away from the sealing surface: This creates a direct gap for water.

- Over-compresses one side of the O-ring: This can make the O-ring roll or twist out of its groove.

- Shears the O-ring: If hard plastic parts scrape across the O-ring, they can cut it.

Recommended Angles for Different Applications

Most standard adjustable PP-R elbows allow a full 90-degree adjustment. However, for maximum reliability, consider the application’s demands. The most reliable seal often sits in the middle of the range, not at the extreme ends.

The following table outlines practical guidelines:

| Application Type | Recommended Max Angle | Reasoning |

|---|---|---|

| Residential Hot/Cold Water | Up to 90° | Systems are low-stress; quality fittings perform reliably at max range. |

| Commercial Pressure Lines | 75° – 80° | Provides a safety margin away from the mechanical stop for critical systems. |

| Systems with Vibration | 60° – 75° | Keeps the O-ring in its most stable compression zone, reducing fatigue. |

Always check the manufacturer’s specifications for exact limits. Never force a fitting past its built-in stop.

How Do You Test for Leaks After Adjusting the Elbow’s Orientation?

Adjustment is useless if you can’t trust the connection. We never consider an installation complete without a proper test.

You test for leaks after adjustment by performing a static pressure test. This involves pressurizing the entire plumbing system with water or air at 1.5 times its normal operating pressure, holding that pressure for a set time (e.g., 1-2 hours), and monitoring the pressure gauge for any drop, which indicates a leak.

The Gold Standard: The Static Pressure Test

A visual check is not enough. Small leaks may only show under sustained pressure. The static pressure test is the definitive method for professionals.

Follow this step-by-step guide:

1. Isolate the Section: Close all valves to isolate the pipe section with the adjusted fittings.

2. Attach a Test Pump: Connect a hand pump or compressor to the system. For safety, testing with water is best.

3. Pressurize the System: Fill the system with water and purge air. Then, pump to the test level. A common standard is 1.5 times the system’s maximum working pressure. For a home system (max 80 PSI), test at 120 PSI.

4. Hold and Monitor: Once at target pressure, close the inlet valve. The pressure must remain stable for at least 60 minutes.

5. Inspect: During the test, check all joints for weeping. Afterward, confirm the gauge shows no pressure drop.

Supplementary Methods for Quick Checks

For smaller jobs, other methods can help:

- Soap Solution Test: After pressurizing with air, spray soapy water on joints. Bubbles will form at any leak. Use low air pressure for safety.

- Tissue Paper Test: Wipe a dry tissue around the joint. A tiny weep will dampen the paper.

A Crucial Final Step

After you adjust an elbow, always perform a final pressure test on the entire system. The adjustment process can shift pipes and stress other connections. Do not assume an old joint will still hold.

Заключение

A properly designed adjustable union reliably prevents leaks at various angles. For guaranteed performance, specify IFAN’s adjustable PP-R elbows with precision seats and durable seals.

Последние комментарии