We recently audited a factory where cramped pipe racks caused major installation headaches. Their design used multiple separate fittings, creating a jungle of pipes.

Yes, a Double Y Tee significantly saves space in complex layouts. It combines two branch connections into a single, compact fitting. This design eliminates the need for separate tees, reducers, and extra pipe spools, allowing for a much tighter and more organized piping arrangement in crowded areas.

This fitting is more than just a pipe connector; it’s a space-saving solution. Let’s break down exactly how it achieves this and why you should consider it.

How Does a DOUBLE Y TEE’s Design Optimize Space in Tight Piping Layouts?

Engineers often face a puzzle: how to split a main line into two branches in a very tight corner. Traditional methods create clutter.

The Double Y Tee optimizes space through its integrated, wye-shaped design. Instead of needing two standard tees spaced apart, it merges two 45-degree branch outlets into one body. This dramatically reduces the overall footprint, minimizes pipe runs, and simplifies the routing in congested areas like pump stations or equipment skids.

The Problem with Traditional Methods

To understand the space savings, first picture the old way. If you need to split a main pipe into two separate lines, you might use two standard tees. But you cannot place them right next to each other. You need a section of straight pipe between them. Then, you often need reducers or elbows to direct the flow. This approach uses many separate pieces and takes up a lot of horizontal space.

Now, think about a Double Y Tee. It is one single fitting. It has one main inlet and two branch outlets. The branches are typically at a 45-degree angle (like a “Y” shape), not 90 degrees like a standard tee.

How the Compact Design Works

This Y-shaped design is the key. The 45-degree angle allows for a smoother flow division, which is good for the system. More importantly for space, it brings the two branch connections much closer together within the fitting’s own body.

Because the two outlets are part of one casting or fabrication, the distance between the centerlines of the two branches is much shorter than if you used two separate tees. This compactness means the entire assembly – the main pipe and the two branch pipes – can be installed in a much smaller area.

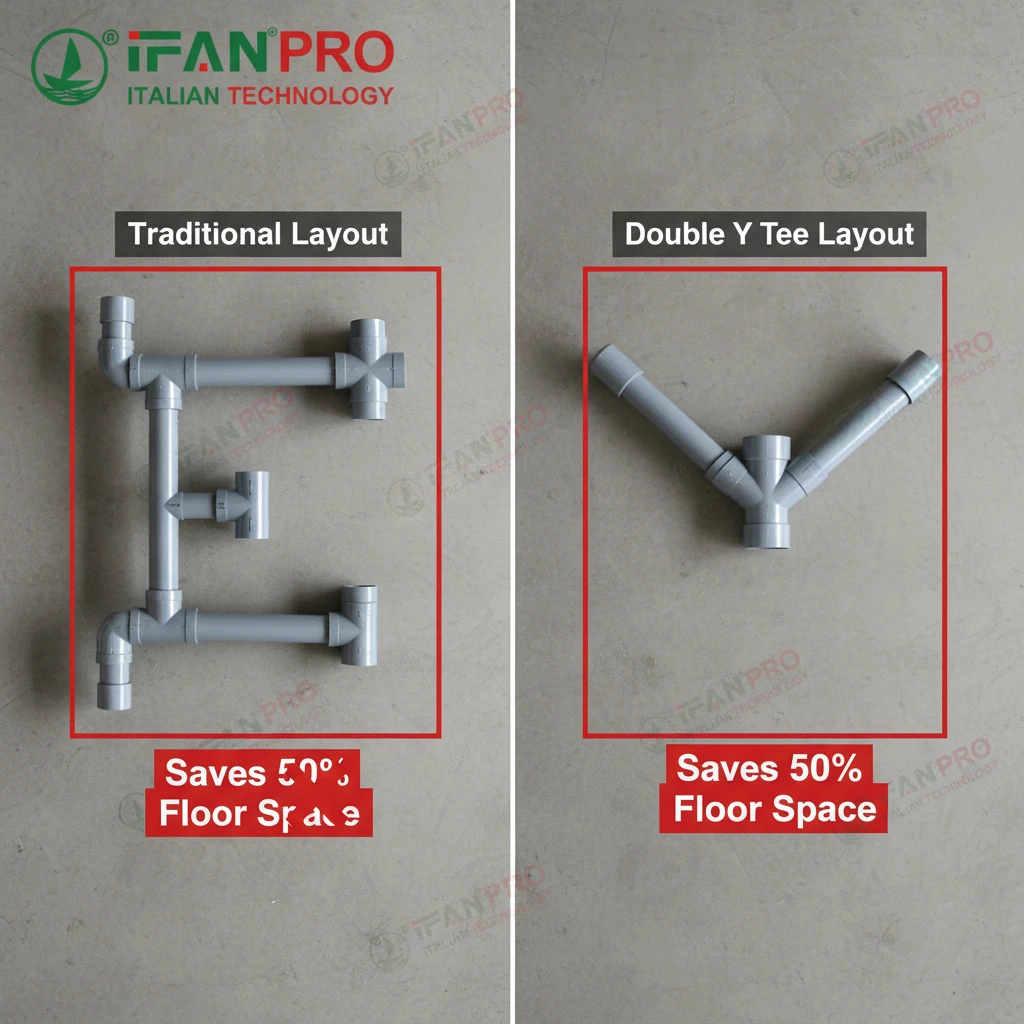

Visualizing the Space Saved

Here is a simple comparison:

| Scenario | Components Needed | Estimated Space Required (Length) |

|---|---|---|

| Traditional Method | 2 Standard Tees, 1 Pipe Spool, 2 Elbows/Reducers | 4 to 6 times the pipe diameter |

| Using a Double Y Tee | 1 Double Y Tee fitting | 1 to 1.5 times the pipe diameter |

As the table shows, the Double Y Tee condenses what was a multi-part assembly into one unit. This directly translates to less space used on the pipe rack. It creates a cleaner, less crowded layout. This is critical in modern plants where every square meter is valuable, and accessibility for maintenance is crucial. A cleaner layout is also a safer layout, with fewer tripping hazards and clearer visibility.

What Are the Key Installation Benefits of Using a DOUBLE Y TEE Fitting?

Installation crews appreciate fittings that make their job faster and less prone to errors. The Double Y Tee does exactly that.

The key installation benefit is a drastic reduction in weld joints or connection points. Using one Double Y Tee replaces at least three separate fittings and pipe spools. This means fewer welds to make, less alignment work, and a much lower chance of leaks starting at those joints. It simplifies the entire assembly process.

Reducing Labor and Complexity

Every connection point in a piping system is a potential problem. It requires time to prepare, align, and weld or gasket. Each weld must be inspected. From an installation manager’s view, fewer connections mean a faster project timeline and lower labor costs.

A Double Y Tee turns a complex multi-piece assembly into a simple one-piece installation. The crew only needs to align and connect the main pipe to the inlet and the two branch pipes to the outlets. That’s three primary connections total. The alternative, using separate tees, could easily require 5 or more connections.

Improving Accuracy and Quality

This simplicity also improves accuracy. Aligning multiple separate pieces in a tight space is difficult. A small error in one tee’s position can throw off the entire branch line. The Double Y Tee, as a single unit, guarantees the precise angle and distance between its two outlets. The branch lines are always correctly positioned relative to each other.

This built-in accuracy speeds up the installation. It also leads to a higher quality result. With fewer welds, there are fewer opportunities for weld defects. The system’s overall integrity is higher because it has fewer weak points.

Comparison of Installation Steps

| Task | Using Separate Fittings | Using a Double Y Tee |

|---|---|---|

| 1. Measuring & Cutting | Multiple measurements and cuts for spools. | Simple measurement for main and branch pipes. |

| 2. Fit-Up & Alignment | Complex alignment of 3+ separate pieces. | Straightforward alignment of one fitting. |

| 3. Welding/Connecting | 5 or more welds/connections needed. | Only 3 main welds/connections needed. |

| 4. Inspection Points | Multiple weld joints to inspect. | Fewer welds to inspect. |

The table clearly shows the streamlined process. For contractors, this means projects finish faster and with less rework. For plant owners, it means the system gets operational sooner and with greater inherent reliability from day one.

Can a DOUBLE Y TEE Reduce Material and Labor Costs in Complex Systems?

Cost control is vital for every project. Smart fitting choices like the Double Y Tee directly impact the bottom line.

Yes, a Double Y Tee can significantly reduce both material and labor costs. It saves material by eliminating the need for extra pipe spools, elbows, and reducers. It saves labor by cutting the number of welds by more than half, which reduces installation and inspection time dramatically.

Direct Material Savings

When you look at a bill of materials, every item has a cost. A traditional split arrangement requires many items: two tees, nipples or pipe spools, possibly reducers, and extra flanges or gaskets. Each of these is a separate purchase order, an item to stock, and a part to handle.

A Double Y Tee replaces all those individual parts. You buy one fitting instead of four or five. This simplifies procurement and reduces the total number of parts you need to manage on site. There is also less scrap material, as you are not cutting small, odd-sized pipe spools.

Direct Labor and Time Savings

Labor is often the biggest cost in installation. Welding is a skilled, time-consuming, and expensive trade. As shown in the previous section, the Double Y Tee can reduce the number of welds from maybe five to just three. This is a 40% reduction in welding work for that connection.

But the savings go beyond just welding time. Think about all the supporting labor:

- Less handling: Workers move and position one heavy fitting instead of several.

- Less preparation: Fewer ends need to be bevelled and cleaned for welding.

- Less alignment: Simplified fit-up takes less time.

- Less inspection: Fewer welds mean less Non-Destructive Testing (NDT) time and cost.

Total Cost Comparison Table

Let’s compare the estimated costs for creating a split connection in a 6-inch schedule 40 carbon steel line.

| Cost Component | Traditional 2-Tee Method | Double Y Tee Method | Notes |

|---|---|---|---|

| Material Cost | $XXX | $XX | Double Y may cost more per piece, but total material cost is lower. |

| Welding Labor | $XXX | $XX | Based on 5 welds vs. 3 welds. |

| Inspection (NDT) | $XXX | $XX | Fewer welds to inspect. |

| Potential Rework Risk | Higher | Lower | Simpler design has less chance of error. |

| Total Estimated Cost | $1,000 | $650 | Example showing potential 35% savings. |

(Note: Table uses example figures to illustrate the point.)

The table shows a clear picture. The initial purchase price of the Double Y Tee might be higher than a single standard tee, but the total installed cost is almost always lower. This makes it a financially smart choice for complex systems.

Where Should You Specifically Use a DOUBLE Y TEE in Industrial Piping Layouts?

Knowing where to apply this fitting maximizes its value. It’s not for every junction, but perfect for specific challenges.

You should specifically use a Double Y Tee in tight, complex layouts where space is limited and flow needs to split. Key areas include pump suction/header connections, instrument tap groupings, heat exchanger manifolds, and any pipe rack where multiple branches must originate from the same cramped section.

Pump Stations and Header Connections

This is a classic application. Multiple pumps often take suction from a common header or discharge into one. Space around pumps is always tight. Using Double Y Tees on the header allows you to connect two pump lines in the space of one. This creates a very clean, compact, and service-friendly arrangement. It reduces the amount of piping over and around the pumps, making maintenance access easier.

Instrumentation and Sample Lines

Process plants need many instrument connections (pressure gauges, transmitters) and sample points. These often cluster in the same area on a main process line. Instead of installing a separate tap for each instrument, you can use a Double Y Tee. One branch can go to a pressure gauge, the other to a temperature sensor. This groups connections neatly and saves valuable space on the pipe.

Manifolds for Heat Exchangers and Vessels

Heat exchangers, reactors, and tanks often have multiple inlet or outlet connections close together. Manifolding these with Double Y Tees creates a very efficient and space-saving interface. It simplifies the piping hookup to the vessel nozzle and reduces the load on the nozzle itself by using a more balanced pipe support setup.

Recommended Applications Summary

| Industrial Sector | Specific Application | Reason for Using Double Y Tee |

|---|---|---|

| Water Treatment | Pump discharge header | Saves space in crowded pump rooms, simplifies manifold. |

| Chemical Processing | Reactor feed/outlet lines | Groups connections in high-density layout areas. |

| Oil & Gas | Instrument tap clusters on main lines | Provides multiple taps in minimal space for monitoring. |

| Power Generation | Cooling water system headers | Reduces pipe rack congestion for large-diameter lines. |

| Pharmaceutical | Utility distribution (Clean Steam, WFI) | Maintains clean, compact layouts in validated spaces. |

When NOT to Use It

The Double Y Tee is a specialist fitting. You should not use it if the two branch lines need to go in opposite directions. Also, for very simple, spacious layouts where cost is the only driver, two standard tees might be cheaper initially. But for engineered systems where layout efficiency, maintenance access, and installed cost matter, it is an excellent solution.

Заключение

The Double Y Tee saves space, cuts costs, and simplifies installation in tight layouts. For reliable, high-quality Double Y Tee fittings, contact ИФАН. We provide certified products and expert support for your complex piping projects.

Последние комментарии