I once visited a mining site where a failed metal elbow caused a full day of shutdown, and the cost was staggering. That moment cemented my belief in choosing the right material for the job.

Yes, a seated HDPE elbow can excellently withstand abrasive material flow. Its ultra-high molecular weight polyethylene construction offers innate abrasion resistance far superior to metals, and its smooth, seamless interior prevents turbulence that accelerates wear. For slurry applications, it often outlasts steel alternatives by a factor of 10 to 1.

If you handle sand, tailings, or any gritty slurry, the choice of elbow is critical. Therefore, let’s break down exactly how and why HDPE succeeds where other materials fail.

What HDPE Material Grade Offers the Best Abrasion Resistance for Slurry Flows?

Not all HDPE is the same. In fact, I’ve seen projects fail by choosing a standard grade for a highly abrasive job.

For the best abrasion resistance in slurry flows, you need HDPE with a high Molecular Weight (MW) and high density. PE100 RC (Resistant to Crack) is often the top choice because it offers an optimal balance of high density for wear resistance and enhanced stress-crack resistance for long-term durability under pressure.

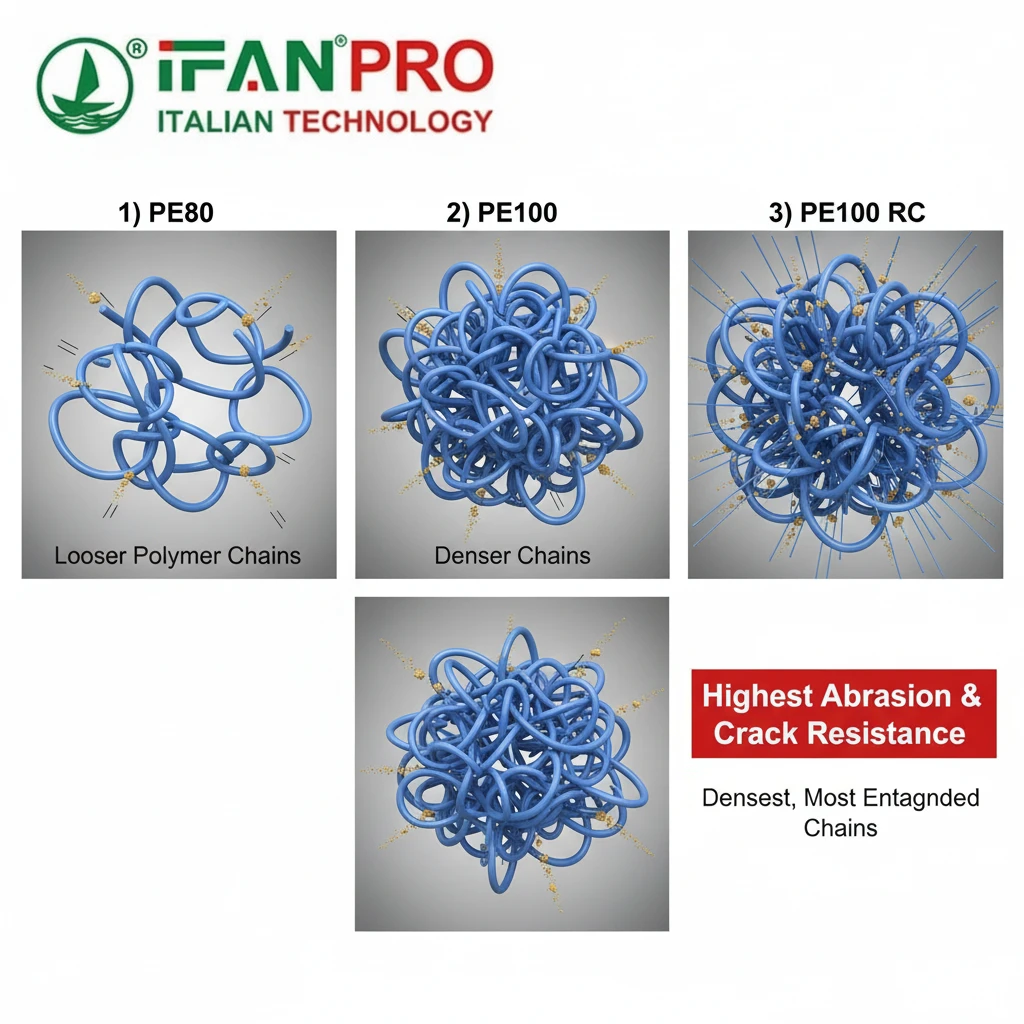

Understanding the Material Science

First, the key to abrasion resistance lies in the plastic’s molecular structure. Think of HDPE as a dense, tangled net. The longer and more tangled the polymer chains (higher molecular weight), and the tighter they’re packed (higher density), the harder it is for abrasive particles to cut through and scrape material away.

Standard HDPE grades (like PE80) work for general use. But for continuous, high-speed slurry flows, you need the premium tier: PE100 and, more specifically, PE100 RC.

Comparing HDPE Grades for Abrasion

Here is a simple comparison of common grades:

| HDPE Grade | Key Characteristics | Best For Abrasive Slurry? |

|---|---|---|

| PE80 | Good strength and durability for general pressure piping. | No. Adequate for mild abrasion but may wear too quickly in severe conditions. |

| PE100 | Higher density and strength. Excellent pressure rating and general abrasion resistance. | Yes. A strong, reliable choice for most abrasive applications. |

| PE100 RC | The “RC” stands for “Resistant to Crack.” It has enhanced resistance to slow crack growth and stress cracking. | Best Choice. Offers the highest level of long-term durability under the combined stress of pressure, abrasion, and potential impact. |

Why PE100 RC is the Superior Choice

Choosing PE100 RC for your elbows is a strategic decision for long-term performance. Importantly, slurry systems don’t just cause wear; they also subject pipes to pressure surges, water hammer, and mechanical stress. The “RC” quality means the material is specially formulated to resist the initiation and growth of microscopic cracks. This is crucial because a tiny scratch from abrasion can, in a weaker material, turn into a major crack under pressure. As a result, PE100 RC ensures the elbow maintains its integrity over a vastly extended lifespan, even in the harshest mining or dredging environments.

How Does the Elbow’s Smooth Interior Surface Minimize Material Wear and Buildup?

A rough pipe interior is an abrasive’s playground. For example, I’ve measured metal pipes that lost 30% of their wall thickness in key areas due to turbulent flow patterns.

The elbow’s smooth interior minimizes wear and buildup by allowing abrasive particles to flow through with minimal friction and turbulence. This streamlined flow prevents particles from scouring the wall and reduces low-velocity zones where material can settle, harden, and create uneven wear points.

The Principle of Smooth Flow

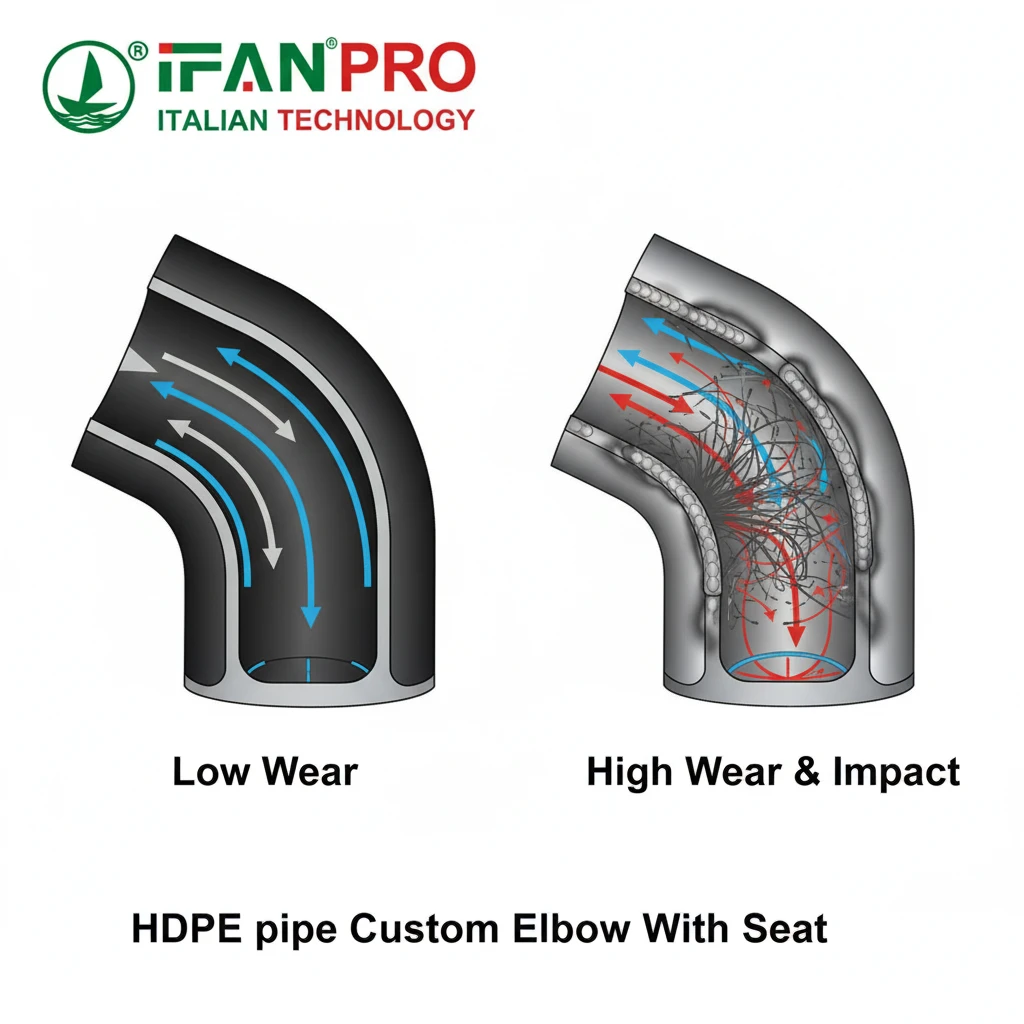

Abrasion isn’t just about hardness; it’s also about friction and impact. When a slurry flows through a pipe, two main things cause wear:

- Frictional Scouring: Particles rubbing along the wall.

- Turbulent Impact: Particles colliding with the wall at angles due to chaotic flow.

A seamless HDPE elbow, manufactured without internal joints or ridges, creates a hydraulically smooth bore. Consequently, this encourages laminar flow—a smooth, layered flow pattern. In laminar flow, the central core of fast-moving fluid is surrounded by slower-moving layers, with the layer closest to the wall being almost stationary.

How This Reduces Wear

This flow profile is a game-changer for several reasons:

- Reduced Friction: The abrasive particles are carried in the faster-moving central core, so they have less contact and rubbing against the pipe wall itself.

- Less Turbulence: At the elbow (the bend), a smooth radius helps guide the flow direction gradually. In contrast, a rough or poorly designed elbow creates violent turbulence, slamming particles against the outer wall of the bend—the most common failure point. Therefore, the HDPE elbow’s smooth design minimizes this destructive impact.

- Prevents Buildup: Buildup, or scaling, occurs when material gets trapped. A smooth surface offers no grooves or pits for particles to latch onto. Combined with the consistent flow velocity, it prevents the settlement of solids that can harden into a rocky, obstructive layer. This not only maintains flow capacity but also prevents a condition called “under-deposit wear,” where trapped material creates uneven wear patterns.

Direct Comparison with Metal Elbows

The problem with traditional metal elbows, even when new, is their inherent roughness. Specifically, welded seams, flanges, and corrosion pitting all create microscopic “speed bumps.”

| Surface Condition | Effect on Slurry Flow | Result for the Elbow |

|---|---|---|

| HDPE: Smooth, Seamless | Promotes laminar, streamlined flow. Particles stay in suspension. | Even, predictable, and very slow wear. |

| Metal: Rough, Seamed, Corroded | Creates turbulent, chaotic flow. Particles impact the wall repeatedly. | Rapid, uneven wear, especially at the outer bend. Buildup is common. |

In short, the HDPE elbow doesn’t just “resist” abrasion; its smart design actively “manages” the flow to minimize the abrasive action in the first place.

Can the Wall Thickness Be Customized to Extend Service Life in Abrasive Applications?

Absolutely. This is where a good supplier becomes a partner. For instance, we recently customized elbows for a gravel pump, doubling the wall at the bend to match the wear pattern.

Yes, you can customize the wall thickness of HDPE elbows to extend service life. By applying extra material (called “reinforcement”) specifically to the outer radius of the bend—the area that suffers the most impact—you can dramatically increase the elbow’s lifespan without making the entire fitting bulky and expensive.

The Logic of Strategic Reinforcement

In an abrasive slurry system, wear is not even. Typically, the outer curve of the elbow bears the brunt of the force as particles are flung against it by centrifugal force. Conversely, the inner curve experiences much less wear. A standard, evenly thick elbow will fail once the outer wall is worn through, while the inner wall remains nearly new—a waste of material and money.

Customization solves this by aligning the product’s geometry with the application’s reality. We often call this a “reinforced” or “abrasion-resistant” design.

Common Customization Options

Here are typical ways you can customize wall thickness:

| Customization Type | Description | Ideal Application |

|---|---|---|

| Standard Wall (SDR) | Uniform thickness based on Standard Dimension Ratio. | General water, non-abrasive flows. |

| Full Reinforcement | The entire elbow has a thicker wall than standard. | For applications with very high pressure PLUS abrasion. |

| External Bend Reinforcement | Extra material is added only to the outside curve of the elbow. | Most Common & Efficient for pure abrasion. Targets the wear zone directly. |

| Full Liner System | A replaceable, thick HDPE liner inside a structural outer shell. | For extremely aggressive abrasion where only the liner is sacrificed and replaced. |

How Customization Translates to Value

Choosing a customized, reinforced elbow is an exercise in calculating Total Cost of Ownership. Although the initial unit cost is higher than a standard elbow, the extended service life brings significant savings. Specifically:

- Fewer Replacements: You change elbows less often.

- Reduced Downtime: Each replacement requires a system shutdown. Fewer replacements mean more production time.

- Lower Maintenance Costs: You need less labor and equipment for frequent changes.

For example, if a standard elbow lasts 6 months and a customized, reinforced elbow lasts 3 years, you avoid 5 replacement cycles. Usually, the cost savings in downtime alone far outweigh the higher initial price.

What Real-World Tests Verify HDPE Elbow Performance in Abrasive Mining Conditions?

Clients need proof, not promises. That’s why we validate performance with standardized tests and, more importantly, documented field histories.

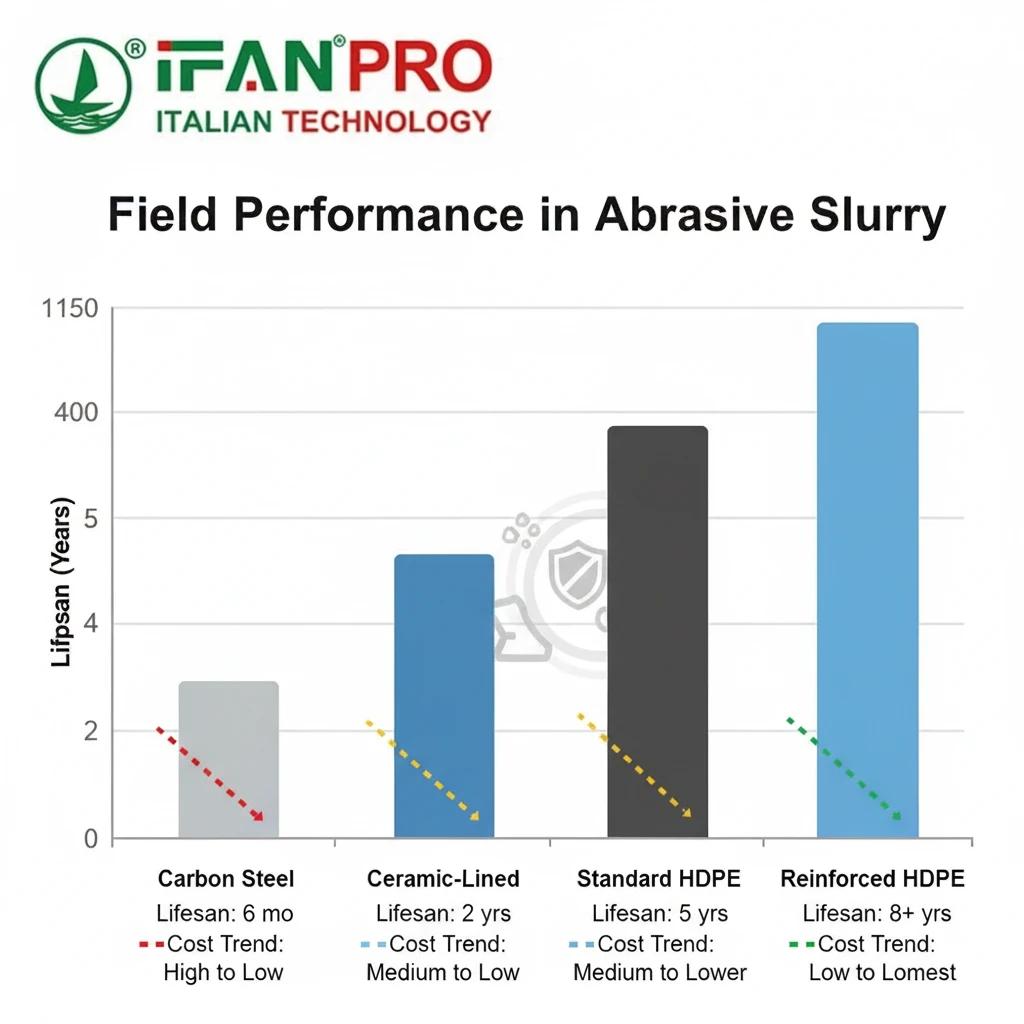

Real-world tests verify HDPE elbow performance through a combination of standardized lab tests, like the ASTM D256 Sand Slurry Abrasion Test, and long-term field trials in actual mining operations. The most convincing data comes from side-by-side comparisons showing HDPE elbows lasting multiple times longer than steel or ceramic-lined alternatives in the same transfer line.

Laboratory Testing: The Baseline

Before we specify any product for a harsh job, it should pass recognized industry tests. These tests provide a controlled, comparative measure of abrasion resistance.

The key standard is ASTM G65 / ASTM D256. This test involves placing a sample of the material in a chamber with a controlled slurry of sand and water. Then, a wheel or impeller agitates the slurry against the sample for a set period. After that, we measure the material loss precisely in grams or millimeters. While labs often perform this test on flat plaques, reputable HDPE manufacturers use it to validate their raw material’s grade and quality against competitors.

The Crucial Role of Field Trials

Although lab tests are essential, the real proof is in the field. Mining conditions involve variables no lab can perfectly replicate, such as varying particle sizes, unexpected chemical exposures, temperature cycles, and pressure shocks.

Therefore, the most trusted verification comes from documented case studies. A reliable supplier like IFAN will have evidence from installations where HDPE elbows were monitored for years. Key performance indicators include:

- Measured Wear Rates: Using ultrasonic thickness gauges to measure wall loss over time at the elbow’s outer bend.

- Mean Time Between Failure (MTBF): Comparing the operational hours before replacement against previous materials used.

- Total Cost Analysis: Documenting the reduction in replacement parts, maintenance labor, and system downtime.

Performance Comparison Table

The table below summarizes typical outcomes from these real-world verifications:

| Pipe Material | Typical Field Lifespan in Severe Abrasive Slurry | Main Failure Mode | Relative Cost Over 5 Years |

|---|---|---|---|

| Carbon Steel Elbow | 3 – 12 months | Rapid wear-through at outer bend. Frequent replacement. | Very High (material + frequent downtime) |

| Ceramic-Lined Steel | 1 – 3 years | Brittle liner cracks or shatters upon impact. Failure can be sudden. | High |

| Standard HDPE (PE100) Elbow | 2 – 5 years | Slow, even wear. Predictable end-of-life. | Medium |

| Reinforced HDPE (PE100 RC) Elbow | 5+ years | Extremely slow wear. You can monitor and plan for replacement. | Lowest (Highest Value) |

The data consistently shows that while the upfront cost of a premium HDPE elbow might be higher than steel, its vastly extended life and reliability deliver the lowest total cost and the fewest operational headaches.

Заключение

For abrasive flows, a seated HDPE elbow is not just an alternative; it’s often the optimal choice for durability and cost savings. For guaranteed performance, specify IFAN’s reinforced PE100 RC HDPE elbows for your most demanding slurry systems.

Последние комментарии