I recently walked through a facility where a hidden pipe leak caused massive damage. This incident convinced me that upgrading old systems with smart technology isn’t just a luxury—it’s a necessity for modern operations.

Yes, smart monitoring can be successfully integrated into traditional piping systems. Retrofitting is achieved using non-invasive clamp-on sensors, inline adapters, and wireless data loggers that attach to existing pipes without requiring a full system replacement. This integration transforms passive networks into intelligent systems capable of predicting failures and optimizing performance.

The journey from a traditional to a smart system may seem complex, but it is entirely feasible. Let’s explore the practical steps, benefits, and business case for making this critical upgrade.

What Are the Retrofit Solutions for Adding Sensors to Existing Piping Systems?

The idea of shutting down a whole plant for a tech upgrade is a major fear. I’ve helped clients navigate this, and the key is using the right non-invasive methods.

The primary retrofit solutions involve clamp-on external sensors, inline sensor ports, and wireless communication hubs. These solutions require minimal to no system downtime, as they attach to the pipe’s exterior or integrate via existing access points like valves or gauges, eliminating the need for costly and disruptive pipe cutting or replacement.

Non-Invasive External Sensors

The most straightforward retrofit method uses sensors that clamp onto the outside of the pipe. These are ideal for quick deployment and are perfect for measuring parameters like vibration, surface temperature, and ultrasonic flow.

- How they work: A piezoelectric sensor or a temperature probe is tightened around the pipe with a strap. It reads data through the pipe wall.

- Best for: Detecting changes in flow (using ultrasonic time-of-flight principles), spotting cavitation through vibration analysis, and monitoring for external temperature anomalies that suggest insulation failure or internal issues.

- Advantage: Zero intrusion, quick installation, and no risk of causing a leak. You can install them while the system is running.

Inline Adaptation with Hot-Tap Fittings

For direct fluid measurement—like pressure, precise temperature, or chemical composition—you need contact with the medium. Inline adaptation is the solution.

- How it works: Technicians install a sensor port, often called a “hot-tap” fitting, onto an existing pipe. This specialized fitting allows you to drill into a pressurized pipe safely and thread in a sensor probe without shutting down the system. It’s a controlled, professional process.

- Best for: Accurate pressure monitoring, pH sensing, conductivity measurement, and temperature readings directly from the fluid.

- Advantage: Provides highly accurate, direct fluid data with minimal downtime during installation.

Wireless Data Networks and Power

Retrofitting isn’t just about sensors; it’s about getting the data to where it needs to go. Running new wires in an old facility is expensive and disruptive.

- How it works: Each sensor node has a small, long-life battery and a wireless transmitter (using protocols like LoRaWAN, NB-IoT, or Wi-Fi). These nodes send data to a central gateway, which then uploads it to the cloud or a local server.

- Best for: Any facility where cabling is impractical. It dramatically reduces installation complexity and cost.

- Advantage: Creates a flexible, scalable network. You can add more sensors later without major infrastructure work.

Comparison of Retrofit Solutions

The table below helps choose the right method for your goal:

| Retrofit Solution | Measures | Installation Disruption | Best Use Case |

|---|---|---|---|

| Clamp-On (External) | Vibration, Ultrasonic Flow, Surface Temp | Very Low | Leak detection, pump health, flow verification. |

| Hot-Tap Fitting (Inline) | Pressure, Direct Fluid Temp, pH, Conductivity | Low (Professional Required) | Critical pressure monitoring, process control, water quality. |

| Wireless Data Node | Data Transmission from Sensors | Low | Any facility lacking sensor cabling; scalable monitoring. |

In summary, the technology exists to add “senses” to your old pipes without the need for major surgery. The first step is to define what you need to measure, then choose the least invasive method to achieve it.

How Does IoT Integration Enable Predictive Maintenance and Leak Detection?

Fixing something after it breaks is costly. The real value of smart monitoring is stopping problems before they even start.

IoT integration enables predictive maintenance by continuously collecting real-time data on pressure, flow, temperature, and vibration. Advanced software analyzes this data to establish normal baselines, then uses algorithms to spot subtle anomalies that signal early wear, clogs, or leaks, allowing for scheduled intervention before a catastrophic failure occurs.

From Data to Foresight

A traditional maintenance schedule is based on time—for example, checking pumps every six months. IoT transforms this into condition-based maintenance. The system tells you when something needs attention, not when the calendar says to check it.

Here’s how the process works step-by-step:

- Continuous Data Collection: Sensors take readings every few seconds or minutes, creating a massive, detailed history of your system’s “vital signs.”

- Baseline Establishment: Machine learning algorithms learn what “normal” looks like for your specific system—its typical pressure ranges, flow profiles, and vibration signatures.

- Anomaly Detection: The software constantly compares new data to the baseline. It flags deviations, like a gradual pressure drop in a line (suggesting a buildup) or a tiny, persistent flow reading when a valve is closed (indicating a leak).

- Alert Generation: The system sends automatic alerts—via email, SMS, or a dashboard—to maintenance teams, pinpointing the likely location and nature of the issue.

- Predictive Analysis: Trends are analyzed to predict future failure. For instance, increasing vibration in a pump bearing suggests it may fail in the next 30 days, allowing you to order the part and schedule repair during a planned downtime.

Real-World Leak Detection Scenarios

Leak detection is one of the most valuable applications. IoT systems use different methods:

- Pressure Trend Analysis: A small leak causes a slow but steady pressure decline in a sealed section. The software detects this trend long before it becomes visible.

- Flow Monitoring: Installing flow meters at key zones (like building inlets or specific process lines) allows the system to compare inflow and outflow. A discrepancy signals a leak in that zone.

- Acoustic Monitoring: Sensitive vibration sensors can “hear” the high-frequency hiss of fluid escaping from a small crack or loose fitting, even underground.

The outcome is a shift from reactive panic to proactive control. You replace surprise emergencies with planned, lower-cost repairs, dramatically reducing downtime, water loss, and energy waste.

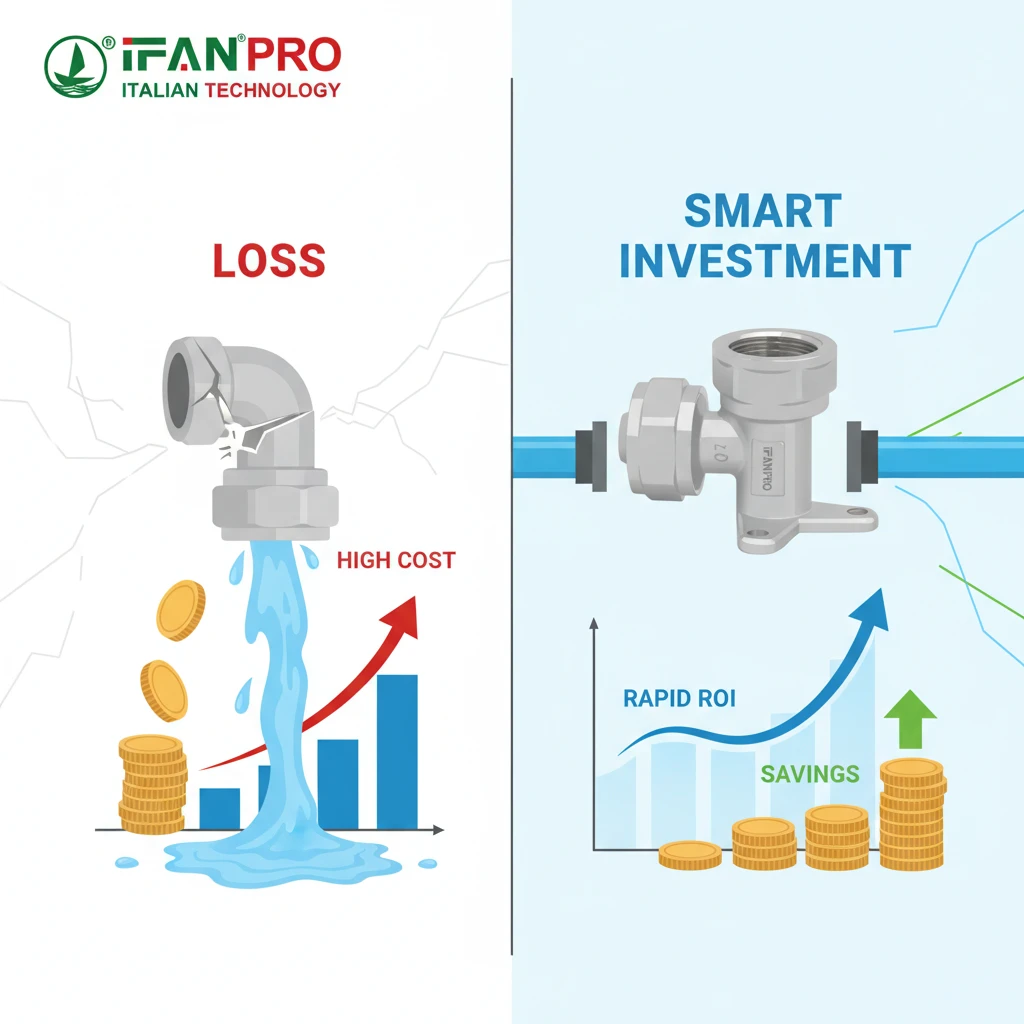

What Is the Return on Investment for Smart Piping Monitoring Systems?

Convincing management requires clear numbers. I always frame smart monitoring not as an expense, but as an investment with a measurable payback.

The Return on Investment (ROI) for smart piping systems comes from avoiding major losses. Key savings include preventing catastrophic water damage and production halts, reducing non-revenue water loss, cutting emergency repair labor costs, and lowering energy bills through optimized system pressure and pump operation. For many facilities, the system pays for itself by preventing just one major incident.

Calculating the Cost of Doing Nothing

To understand ROI, you first must quantify the risks of your current “dumb” system. Consider these potential costs:

- Catastrophic Failure: A major pipe burst can cause tens or hundreds of thousands in property damage, environmental fines, and production downtime.

- Chronic Water Loss: A small, undetected leak can waste millions of gallons annually, directly impacting water and sewage bills.

- Emergency Repairs: Off-hours emergency call-outs for plumbers and contractors are 3-5 times more expensive than scheduled maintenance.

- Energy Waste: Over-pressurizing a system or running pumps inefficiently due to unseen problems (like clogs) wastes significant electricity.

- Product/Resource Loss: In manufacturing, a leak of process fluids or chemicals represents lost raw material.

Building the ROI Case: A Practical Example

Let’s model a simple ROI for a mid-sized commercial building.

Upfront Investment:

- Sensor Network & Gateway: $5,000

- Software Platform (Annual Subscription): $1,200/year

- Professional Installation: $3,000

- Total Year 1 Cost: $9,200

Annual Savings (Projected):

- Water Savings: Detecting and fixing minor leaks saves 10% on water/sewer bill ($4,000 bill -> $400 saved).

- Energy Savings: Optimizing pump run-time and pressure saves 8% on related energy ($2,500 bill -> $200 saved).

- Maintenance Savings: Converting two emergency repairs ($1,500 each) to scheduled repairs ($500 each) saves $2,000.

- Avoided Major Loss: The system is designed to prevent at least one major incident. Assigning a conservative 50% probability of avoiding a $20,000 loss equals a $10,000 risk-adjusted saving.

- Total Annual Savings (Risk-Adjusted): $12,600

ROI Calculation:

- Payback Period: $9,200 / $12,600 ≈ 0.73 years (or about 9 months).

- Annual ROI after Year 1: ($12,600 – $1,200 software) / $9,200 ≈ 124%.

Key ROI Factors Table

Different sites will have different savings drivers:

| Savings Category | Typical Impact | Best For |

|---|---|---|

| Catastrophic Failure Prevention | Very High ($10,000s) | Data centers, manufacturing plants, multi-story buildings. |

| Non-Revenue Water Reduction | High (5-20% of water bill) | Large campuses, municipalities, hotels, universities. |

| Energy Efficiency | Medium (5-15% of pump energy) | Systems with large pumps or pressure-boosting stations. |

| Maintenance Labor Reduction | Medium (Reduces overtime/emergency calls) | Any facility with high labor costs or remote locations. |

The financial argument is strong. The investment is often less than the cost of cleaning up a single major leak.

How Can a Sourcing Partner Help Navigate Smart System Component Compatibility?

The tech landscape is fragmented. A client once bought expensive sensors that couldn’t talk to their software—a frustrating and costly mistake.

A sourcing partner helps navigate compatibility by providing a single point of accountability for the entire sensor-to-software chain. They vet and select components (sensors, gateways, software) that are pre-verified to work together, manage procurement and logistics from multiple suppliers, and often provide the technical integration support to ensure the system functions as one cohesive unit.

The Compatibility Challenge

Building a smart monitoring system is like assembling a computer from parts. You need a CPU (gateway), hard drive (data storage), peripherals (sensors), and an operating system (software). If the parts use different “languages” (communication protocols like Modbus, MQTT, LoRaWAN) or power standards, they simply won’t work together.

A specialized sourcing partner, like IFAN for piping systems, acts as your system architect and general contractor.

The Value of a Single-Point Partner

Here’s what a good partner does to eliminate compatibility headaches:

1. Pre-Validation and System Design: They don’t just sell parts; they sell a solution. Based on your goals (leak detection, pressure monitoring), they design a system architecture and select sensors, communication modules, and software platforms that are known to be interoperable. They have already done the testing to ensure Data from Sensor A can be read by Gateway B and displayed correctly in Software C.

2. Simplified Procurement and Logistics: Instead of you managing purchase orders and shipping from five different tech companies and a pipe fitting supplier, you have one order, one invoice, and one shipment that includes both the physical sensor housings and the electronic components. This saves immense administrative time and reduces risk.

3. Technical Integration Support: The partner provides the crucial “glue.” This includes:

- Configuration files to set up the gateway.

- Assistance in mapping sensor locations in the software dashboard.

- Support during commissioning to ensure data is flowing correctly.

4. Ongoing Supply Chain Assurance: Technology evolves. If a sensor model is discontinued, a good partner will have already qualified an alternative that is compatible with your existing system, ensuring long-term support and scalability.

Partner vs. DIY Approach: A Comparison

| Task | Going It Alone (DIY) | Using a Sourcing Partner |

|---|---|---|

| Component Research | Hours spent reading specs, risking mismatch. | Partner provides a pre-validated bill of materials. |

| Procurement | Multiple vendors, shipments, and invoices. | Single point of order and responsibility. |

| Compatibility Testing | Your risk and cost if parts don’t communicate. | Pre-tested solution; partner liable for integration. |

| Technical Support | Calling multiple tech support lines for different parts. | Single point of contact for the entire system. |

| Future Upgrades/Scaling | You must re-do compatibility research. | Partner advises on compatible add-ons. |

For a business focused on its core operations, a sourcing partner reduces risk, saves time, and guarantees a functional outcome. It turns a complex technical project into a managed service.

Заключение

Integrating smart monitoring into traditional piping is a practical and highly profitable upgrade. For a compatible, reliable sensor-to-software solution designed for piping networks, partner with ИФАН for your intelligent system components.

Последние комментарии