I once had a client whose metal valve failed in months, leaking dangerous acid. This costly failure made us switch to HDPE, and the solution has lasted for years without issue.

Yes, HDPE (High-Density Polyethylene) female valves are exceptionally good at handling corrosive fluids. The HDPE material is chemically inert, which means it does not react with most strong acids, alkalis, and solvents. This natural resistance prevents the valve body from corroding, degrading, or contaminating the fluid, making it a reliable choice for harsh chemical applications.

If you are tired of replacing corroded metal valves, understanding why HDPE works so well can save you significant time and money. Let’s look at the specific properties and practices that make this possible.

What Chemical Resistance Properties Allow HDPE Valves to Handle Corrosive Fluids?

Seeing a stainless steel valve eaten away by a chemical is shocking. HDPE resists this because of its fundamental plastic structure.

HDPE valves handle corrosive fluids due to the material’s high molecular density and non-polar nature. These properties create a barrier that prevents corrosive substances from penetrating and breaking down the polymer chains. Essentially, HDPE does not chemically react with a wide range of aggressive agents, maintaining its structural integrity where metals often fail.

The Science Behind the Resistance

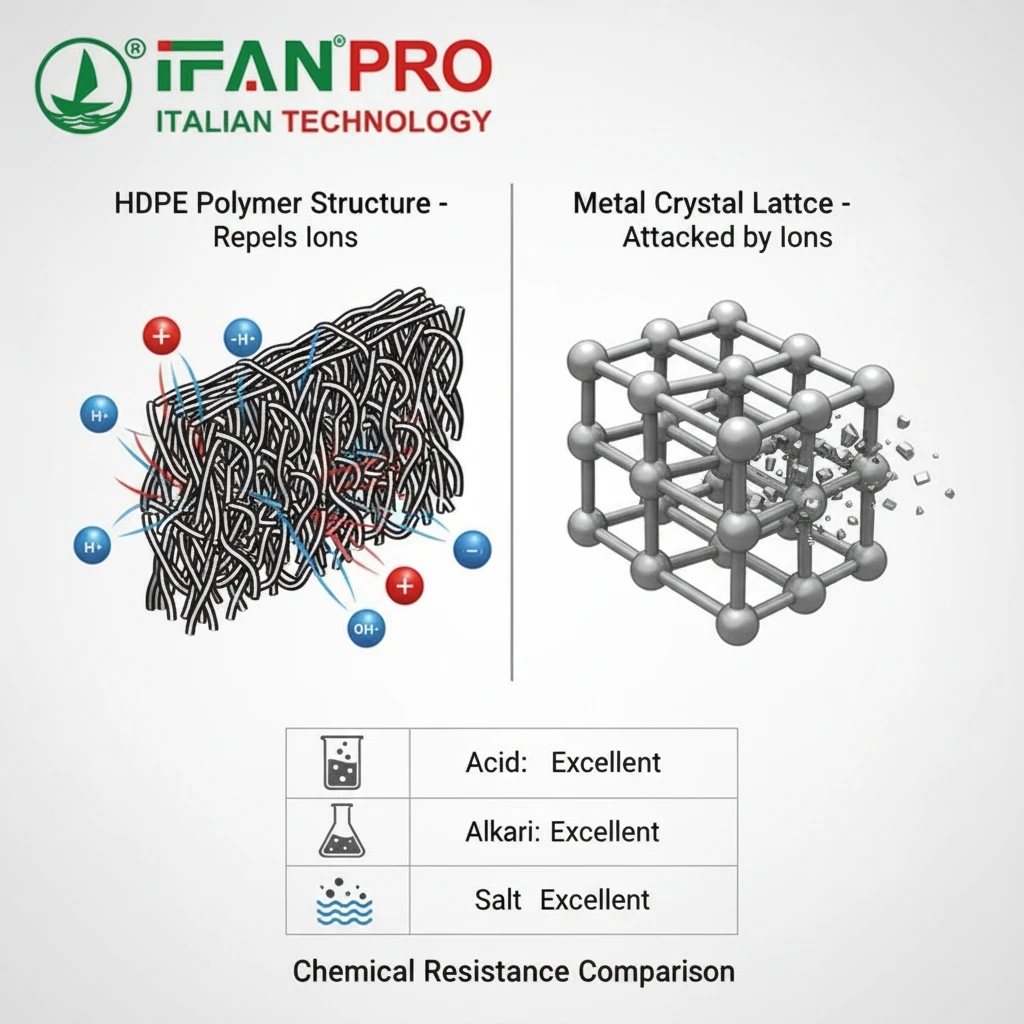

To understand why HDPE works, we need to look at two key ideas: molecular structure and chemical reactivity.

First, HDPE has a very tight, crystalline structure. Imagine it like a densely packed, tangled net. This high density makes it very hard for liquid molecules, including corrosive ones, to seep into the material. Metals, on the other hand, have a crystalline structure that can be directly attacked and dissolved by acids or alkalis.

Second, and more importantly, HDPE is chemically inert. Its molecules are non-polar, meaning they have no electrical charge that attracts reactive ions from acids or bases. Most corrosion in metals is an electrochemical reaction. Since HDPE doesn’t conduct electricity and has no charge, this reaction simply cannot start.

Common Chemicals HDPE Can Resist

Based on our experience at IFAN, here is a practical guide to what HDPE female valves typically withstand. This knowledge helps in selecting the right valve for your specific fluid.

| Chemical Category | Примеры | HDPE Valve Performance |

|---|---|---|

| Strong Acids | Hydrochloric Acid (HCl), Sulfuric Acid (H2SO4) | Excellent resistance at room temperature. Perfect for acid handling and drainage systems. |

| Strong Alkalis | Sodium Hydroxide (NaOH), Potassium Hydroxide (KOH) | Excellent resistance. Widely used in chemical processing and cleaning solution lines. |

| Salt Solutions | Seawater, Chlorides | Excellent resistance. No risk of chloride stress corrosion cracking, which is a major problem for stainless steel. |

| Various Solvents | Alcohols, Diluted Oxidizing Agents | Good to excellent resistance. Performance depends on concentration and temperature. |

A Real-World Comparison

Let’s compare HDPE to common metal alternatives in a corrosive environment. A client was transporting a 20% hydrochloric acid solution. Their cast iron valve showed severe corrosion within weeks, leading to leaks and safety hazards. After switching to an HDPE ball valve, the system ran for over three years with no signs of degradation. The main difference was the absence of a chemical reaction between the fluid and the valve body.

The inert nature of HDPE also means it won’t contaminate the fluid stream. Metal ions from a corroding valve can ruin a batch of chemicals or purified water. HDPE keeps the fluid pure. In summary, the combination of a dense physical barrier and inherent chemical inactivity is what gives HDPE its superior resistance.

How Does HDPE Material Prevent Degradation from Acids and Alkalis in Pipelines?

Acids and alkalis attack materials in different ways, but HDPE stands strong against both. I’ve seen pipelines where only the HDPE sections survived an accidental chemical spill.

HDPE prevents degradation because it undergoes no chemical reaction with most acids and alkalis. Acids release hydrogen ions, and alkalis release hydroxide ions, both of which readily react with metals. HDPE, being a saturated hydrocarbon polymer, is unaffected by these ions, so there is no oxidation, dissolution, or loss of material thickness over time.

The Mechanism of Resistance

Understanding the “how” requires a simple look at chemistry. Degradation from corrosive fluids usually happens through a chemical reaction that changes the material’s structure.

Attack by Acids: Acids work by donating positive hydrogen ions (H+). These ions are very reactive. In metals, they initiate a redox reaction, essentially tearing electrons away from the metal atoms, causing them to dissolve. For example, iron reacts with acid to form iron salt and hydrogen gas. HDPE, made of carbon and hydrogen atoms linked by strong covalent bonds, does not offer free electrons for this reaction. The hydrogen ions from the acid have no effect on the stable HDPE polymer chains.

Attack by Alkalis: Alkalis or bases release negative hydroxide ions (OH-). These are corrosive to many materials, including some plastics like polycarbonate, causing them to break down (a process called hydrolysis). However, the molecular structure of HDPE is highly resistant to hydrolysis. The bonds in HDPE are not easily broken by hydroxide ions, especially at ambient temperatures. This makes it ideal for caustic soda (sodium hydroxide) transport, a common yet highly corrosive industrial chemical.

Long-Term Performance Factors

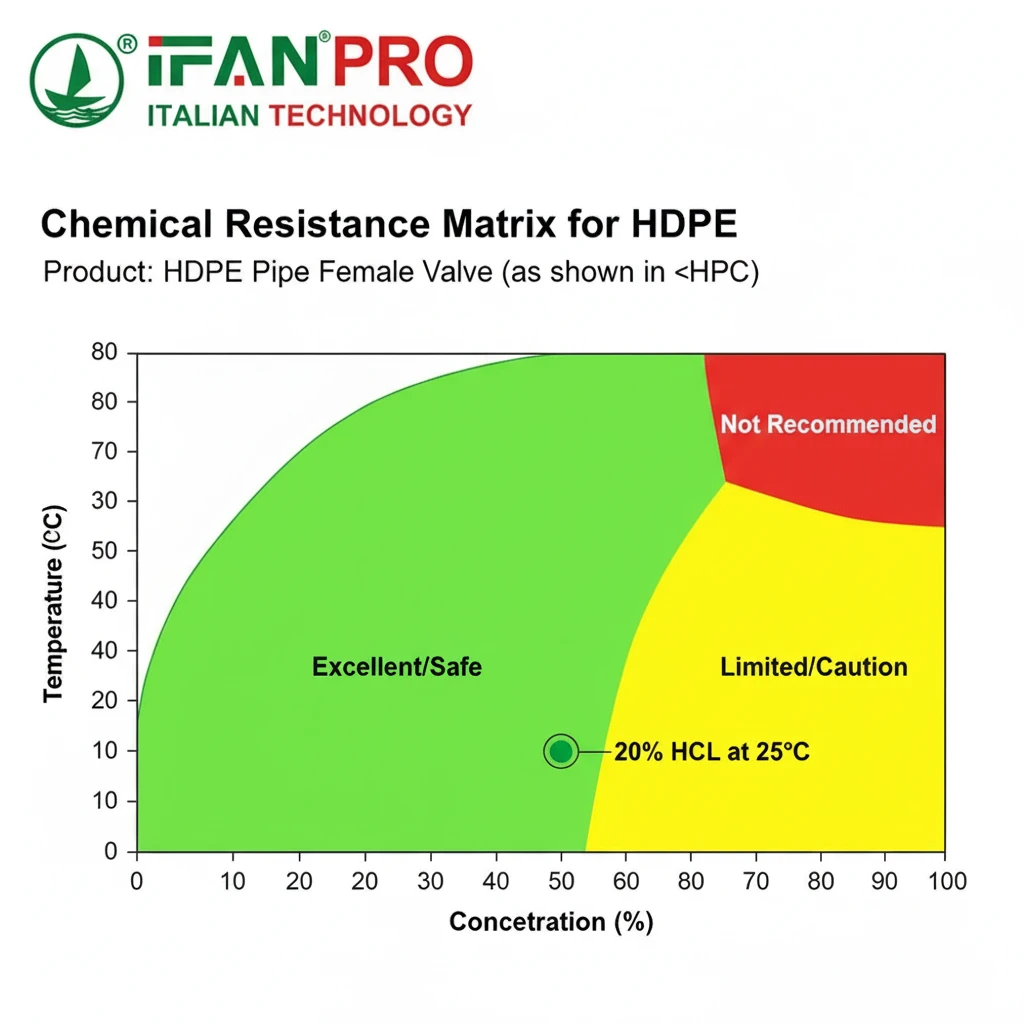

While HDPE is resistant, its performance is not infinite and depends on two main factors: concentration and temperature.

- Concentration: A low-concentration acid may have little effect, while a concentrated one might cause slow stress cracking over many years if the valve is under pressure. The table in the previous section gives a general guide, but for critical applications, always consult the chemical resistance charts provided by material suppliers.

- Temperature: Heat increases the energy of molecules, making any potential chemical reaction more likely. HDPE resistance is excellent at room temperature. For hot corrosive fluids, the maximum service temperature must be checked. Typically, HDPE valves are rated for service up to 60°C (140°F) for many chemicals, but this can vary.

Addressing a Common Misconception

A common concern is that plastics become “brittle” in chemicals. For some plastics, this is true. They absorb the chemical and swell or become weak. HDPE has very low absorption rates for most corrosive fluids. It does not swell or soften significantly, meaning its mechanical strength—its ability to hold pressure and resist impact—remains intact throughout its service life. This dimensional stability is crucial for valve operation, ensuring a tight seal is maintained for years.

Are There Specific Standards Certifying HDPE Valves for Corrosive Fluid Service?

You should never guess if a valve is safe for your chemical. Certifications provide the proof you need. We always ensure our products meet these benchmarks.

Yes, several international standards certify HDPE valves for corrosive service. Key standards include ISO 4427 for polyethylene piping systems, ASTM F714 for PE pipe dimensions, and NSF/ANSI 61 for drinking water component safety. Additionally, manufacturer-specific chemical resistance ratings and certifications like WRAS or KIWA provide validated performance data for aggressive fluid handling.

Understanding the Role of Standards

Standards are not just paperwork; they are a guarantee of quality, performance, and safety. They mean an independent body has tested the product according to strict, repeatable methods.

For HDPE valves used in corrosive service, standards cover three main areas:

- Material Quality: Ensuring the HDPE resin is of a specific grade with known chemical and physical properties.

- Dimensional Integrity: Ensuring the valve is manufactured to precise sizes so it fits and seals correctly in the pipeline.

- Performance Testing: Ensuring the valve can withstand pressure, temperature, and endurance cycles.

Key Standards Explained

Here is a breakdown of the most important certifications to look for when sourcing HDPE female valves for corrosive applications.

| Standard / Certification | Focus Area | Why It Matters for Corrosive Service |

|---|---|---|

| ISO 4427 | Polyethylene (PE) pipes and fittings for water supply. | Defines material grades (e.g., PE100), which have high stress crack resistance and long-term strength. A valve made from certified PE100 material is inherently robust. |

| ASTM Standards (e.g., D3350, F714) | Material specification and pipe dimensions. | Ensures the HDPE material meets minimum density, melt index, and strength requirements. Consistent dimensions ensure leak-free fusion. |

| NSF/ANSI 61 | Drinking water system components. | While for potable water, this certification proves the valve does not leach harmful substances. This is a strong indicator of material purity and inertness. |

| Manufacturer’s Chemical Resistance Chart | Compatibility with specific chemicals. | The most practical guide. Reputable manufacturers test their HDPE with hundreds of chemicals and provide ratings (e.g., “A=Excellent”) for concentration and temperature. |

How to Use This Information as a Buyer

As a procurement manager, your process should be:

- Identify the Fluid: Know the exact chemical name, concentration, temperature, and any impurities.

- Check Material Ratings: Ask the supplier (like IFAN) for their HDPE chemical resistance chart. Cross-reference your fluid.

- Verify Certifications: Request copies of the relevant certificates (ISO, NSF, etc.) for the valve product line. This ensures you are not buying uncertified, sub-standard material.

- Consider the System: Ensure the valve standard is compatible with the HDPE pipe standard you are using (e.g., both should be ISO 4427 PE100) for a perfect fusion joint.

Choosing a valve with the right certifications eliminates guesswork and reduces risk. It is your objective evidence that the product is fit for your specific corrosive service purpose.

What Maintenance Ensures Long-Term Performance of HDPE Valves with Harsh Chemicals?

Even the best valve needs proper care. Simple, proactive maintenance can prevent unexpected shutdowns. I advise all my clients on these basic steps.

To ensure long-term performance, maintain HDPE valves by conducting regular visual inspections for surface cracks or deformation, keeping moving parts (like the ball and stem) clean from chemical buildup, operating the valve fully open or closed regularly to prevent seizing, and protecting the system from excessive physical stress or UV exposure. Proper installation via butt fusion is also critical initial “maintenance.”

A Proactive Maintenance Mindset

The good news is that HDPE valves require far less maintenance than metal ones. You won’t be dealing with rust, heavy lubrication, or corroded bolts. However, “low maintenance” does not mean “no maintenance.” A simple, scheduled check can extend valve life by decades.

Your maintenance plan should focus on inspection, operation, and system protection.

Recommended Maintenance Schedule and Actions

The table below outlines a simple, effective routine for valves in continuous corrosive service.

| Frequency | Maintenance Action | Purpose & What to Look For |

|---|---|---|

| Weekly / Monthly | Visual Inspection. | Look for any visible surface cracks, deep scratches, or unusual swelling/deformation. Check for leaks at the fusion joints and valve stem. |

| Quarterly | Full Operation Cycle. | Slowly turn the valve from fully open to fully closed and back several times. This prevents chemical residue from solidifying and seizing the mechanism. It keeps the stem seals lubricated by the internal media. |

| Annually | External Cleanliness Check. | Remove any external buildup of dirt or chemical spills. For valves in agitated or slurry service, inspect for internal erosion on the ball/disc if possible during a system shutdown. |

| As Needed | Protection from UV and Impact. | Ensure valves installed outdoors are painted or covered to protect from direct sunlight (UV), which can slowly degrade HDPE over years. Shield valves from potential physical damage. |

Critical Installation: The First Step of Maintenance

The most important factor for long-term performance happens before the valve is even used: installation. An HDPE valve must be connected to the pipeline using the correct heat fusion technique (butt fusion or socket fusion). A poor fusion joint is the number one cause of failure in HDPE systems—not material degradation. Ensure your installers are trained and certified. A properly fused joint is monolithic and leak-free, forming the foundation for years of reliable service.

Handling Specific Issues

- Stem Seals: Over very long periods, the stem seals (O-rings) may wear. Quality HDPE valves like those from IFAN use EPDM or Viton seals with excellent chemical resistance. Keeping the valve operating regularly helps maintain seal flexibility.

- Freezing and Stress: While HDPE is tough, avoid exposing a pressurized, water-filled valve to freezing temperatures, as ice expansion can cause damage. Also, ensure the pipeline is properly supported so the valve does not bear excessive mechanical stress from pipe weight or movement.

By following these straightforward steps, you maximize the inherent durability of HDPE. The goal is to monitor the system’s condition and prevent minor issues from becoming major failures, ensuring your investment delivers its full, decades-long potential.

Заключение

HDPE female valves offer outstanding, certified resistance to corrosive fluids with minimal maintenance. For reliable, long-lasting performance in your harsh chemical applications, choose IFAN’s certified HDPE ball valves and fittings.

Последние комментарии