I have watched installers struggle for hours, trying to align a rigid pipe perfectly with a water heater’s ports. A simple union elbow would have saved the day.

Yes, union elbows are an ideal solution for connecting PEX tubing to fixed equipment like water heaters and boilers. They combine a 90-degree turn with a detachable union joint, which simplifies alignment, allows for easy disconnection for service or replacement, and safely absorbs minor stresses from equipment vibration or thermal expansion.

Let’s explore the specific reasons why this fitting is a best practice for both installers and homeowners.

How Do They Simplify the Final Connection to Water Heaters or Boilers?

Making the last connection to an appliance in a tight space is often the most frustrating part of an installation.

Union elbows simplify the final connection by allowing the installer to make the permanent PEX-to-elbow connection away from the appliance. They then only need to thread or hand-tighten the free-spinning union nut onto the equipment’s port, eliminating complex maneuvers with tools in confined spaces and ensuring a straight, stress-free attachment.

The Step-by-Step Advantage

Imagine connecting a water heater in a cramped closet. With a fixed elbow or a straight piece of pipe, you must hold the fitting perfectly to the port, apply pipe sealant, and wrench it tight—all while bent over in an awkward position. It’s easy to cross-thread or apply uneven force.

A union elbow changes this process completely. Here’s how it works in practice:

- Prepare Separately: First, you securely crimp or clamp the PEX tubing onto the elbow side of the fitting on your workbench. This is a straightforward, easy task.

- Attach to Equipment: Next, you screw the metal threaded end of the union elbow directly onto the water heater’s port. Because it’s just one piece (not attached to the pipe yet), you can see what you’re doing and apply force correctly to avoid cross-threading.

- Make the Final Connection: Finally, you bring the pre-assembled PEX and elbow to the appliance. You simply align it and spin the large union nut by hand for several turns before finishing with a wrench. The nut spins freely, so the PEX tubing does not twist.

This method is faster, less physically demanding, and results in a more reliable connection because each step is done under optimal conditions.

Why Is a Union Preferred Over a Fixed Elbow for Appliance Hookups?

A fixed connection assumes everything will remain perfect forever, but in the real world, appliances need service.

A union elbow is preferred because it is serviceable. It creates a deliberate, sealed disconnect point. When the appliance fails or needs maintenance, you can quickly disconnect the water supply at the union without cutting into the permanent plumbing, saving significant time, money, and hassle during repairs or replacements.

The Critical Difference: Serviceability

The core benefit of a union is right in the name: it unites two parts in a way that can be dis-united. A fixed elbow, whether glued (PVC/CPVC), soldered (copper), or crimped (PEX), creates a permanent bond. This permanence becomes a problem when the appliance it’s connected to fails.

Scenario with a Fixed Elbow: Your 10-year-old water heater springs a leak. To replace it, a plumber must either:

- Cut the pipe on both sides of the heater to remove it.

- Un-solder or cut the fixed elbows if they are very close to the ports.

Then, they must install new fittings and pipe to connect the new unit. This turns a simple appliance swap into a larger plumbing job, increasing labor costs.

Scenario with a Union Elbow: For the same leak, the plumber:

- Shuts off the water.

- Uses two wrenches to loosen the union nuts on the hot and cold lines (a 2-minute task).

- Removes the old heater.

- Installs the new heater and re-tightens the existing union elbows.

The existing plumbing stays completely intact. The job is cleaner, faster, and cheaper. For a homeowner or building manager, this design-for-service is a major long-term advantage.

Summary of Benefits

| Feature | Fixed Elbow | Union Elbow |

|---|---|---|

| Initial Installation | Standard. | Slightly easier alignment. |

| Future Service/Replacement | Requires cutting pipe, new fittings. | Simple disconnection; no pipe damage. |

| Cost of Appliance Replacement | Higher (more labor & materials). | Lower (mostly labor for the swap). |

| System Flexibility | None. Rigid connection. | Allows for disconnection and reconnection. |

Can They Accommodate Minor Misalignments During Equipment Installation?

Even the best plans can have small errors on installation day. Perfect alignment between pipe and port is rare.

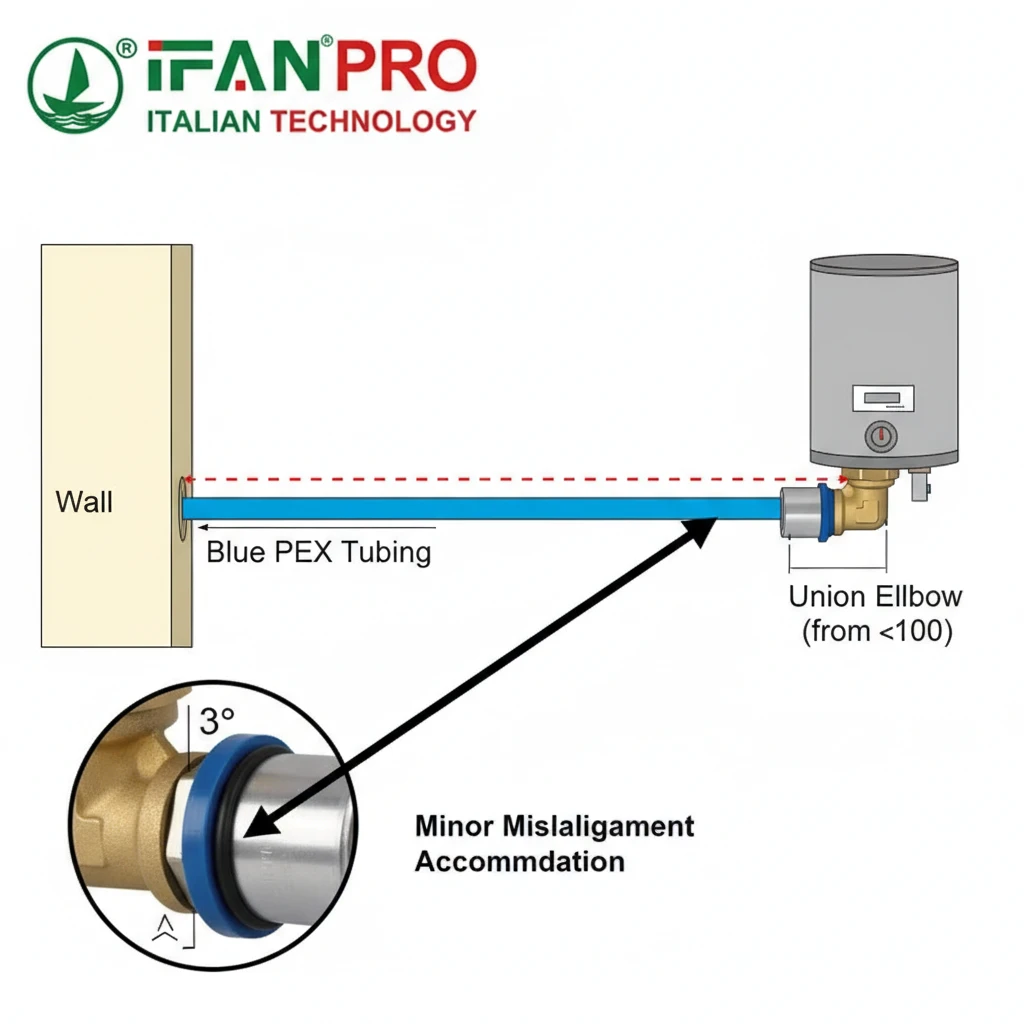

Yes, union elbows can accommodate minor misalignments. The union joint provides a small amount of angular “play” (usually a few degrees) before final tightening. This allows the installer to slightly pivot the PEX line to meet the equipment port squarely, compensating for small measurement errors or shifts without stressing the pipe.

How the Design Allows for Adjustment

During installation, pipes may not line up perfectly for several reasons: the wall stub-out is off by half an inch, the new appliance’s ports are in a slightly different location, or the floor isn’t level. A rigid fixed elbow offers no forgiveness; you must force the connection, which puts stress on the pipe, the fitting, and the appliance port. This stress can lead to immediate leaks or failures years later.

A union elbow solves this with its two-part design. The sealing mechanism (usually a gasket or O-ring compressed inside a seat) does not require the two halves to be in perfect, rigid alignment to seal. As you hand-tighten the union nut, you can gently guide the PEX line into the best position. The joint will seal effectively as long as the misalignment is within the fitting’s design limits (typically up to 3-5 degrees off-axis).

This flexibility is crucial because it:

- Prevents Stress: Avoids putting shear or bending stress on the PEX tubing or the appliance’s internal connections.

- Saves Time: Eliminates the need to re-cut and re-plumb sections of pipe for minor alignment issues.

- Ensures a Better Seal: A connection made without force is a more reliable connection.

Practical Application Example

Let’s say the cold water line comes out of the wall 2 cm too far to the left of the water heater’s inlet. With a fixed setup, you would need to add an offset or redo the wall connection. With a union elbow, you can slightly angle the PEX line from the wall to the heater. The union joint absorbs this angle, the connection is made smoothly, and no stress is transferred.

How Do They Facilitate the Replacement of a Faulty Appliance?

The true test of a plumbing design is not installation, but repair. A good system makes maintenance easy.

Union elbows facilitate appliance replacement by providing a built-in, watertight disconnect point. To remove an old appliance, you simply loosen the union nuts to separate the plumbing. After installing the new appliance, you reconnect the same unions, restoring the system quickly without modifying the permanent pipes.

The Step-by-Step Replacement Process

Here is a clear breakdown of how union elbows turn a complex plumbing job into a straightforward appliance swap:

1. Preparation:

- Turn off the water supply and power/gas to the old appliance (e.g., water heater, boiler).

- Drain the old appliance.

2. Disconnection (The Key Advantage):

- Use one wrench to hold the body of the union elbow attached to the pipe. Use another wrench to loosen the union nut connected to the appliance.

- Once loose, the appliance is free from the plumbing. Disconnect any other lines (gas, electrical, drain).

- Remove the old appliance.

3. Reconnection:

- Position the new appliance.

- Connect the union elbow from the existing plumbing to the new appliance’s port. Hand-tighten the union nut, then give it a final snug turn with a wrench.

- Reconnect other services.

Comparing the Work Involved

The table below shows the dramatic difference in effort:

| Task | With Fixed Plumbing | With Union Elbows |

|---|---|---|

| Disconnect Plumbing | Cut pipes with a saw. May require soldering torch or special cutters. | Loosen two nuts with wrenches. |

| Prepare New Connections | Measure and cut new pipe. Install new elbows/fittings. Apply sealant/solder/crimp. | No new materials needed. Existing fittings are reused. |

| Reconnect Plumbing | Solder, glue, or crimp new fittings in tight space. | Hand-tighten and wrench existing union nuts. |

| Total Time & Material Cost | High. Significant labor, new materials. | Low. Minimal labor, no new plumbing materials. |

Additional Benefit for Emergency Situations: If an appliance fails catastrophically (e.g., a major leak), the ability to disconnect it instantly from the plumbing can prevent extensive water damage. Speed is critical, and union elbows provide that speed.

Заключение

Union elbows are the professional choice for connecting PEX to water heaters and boilers, offering easy installation, alignment forgiveness, and simple future service. For reliable, service-ready connections, choose IFAN’s PEX union elbows.

Последние комментарии