After seeing a plastic float valve fail and flood a client’s storage facility, I always advise looking at the material first. This experience taught me why material choice is critical in industrial settings.

Yes, brass float valves are generally more durable for demanding industrial applications. Their inherent strength, excellent corrosion resistance, and reliability under thermal stress make them a robust, long-lasting choice where failure is not an option, especially compared to common plastic alternatives.

So, why exactly does brass hold up so well under tough conditions? Let’s break down the key reasons that make it the preferred material for engineers and maintenance managers.

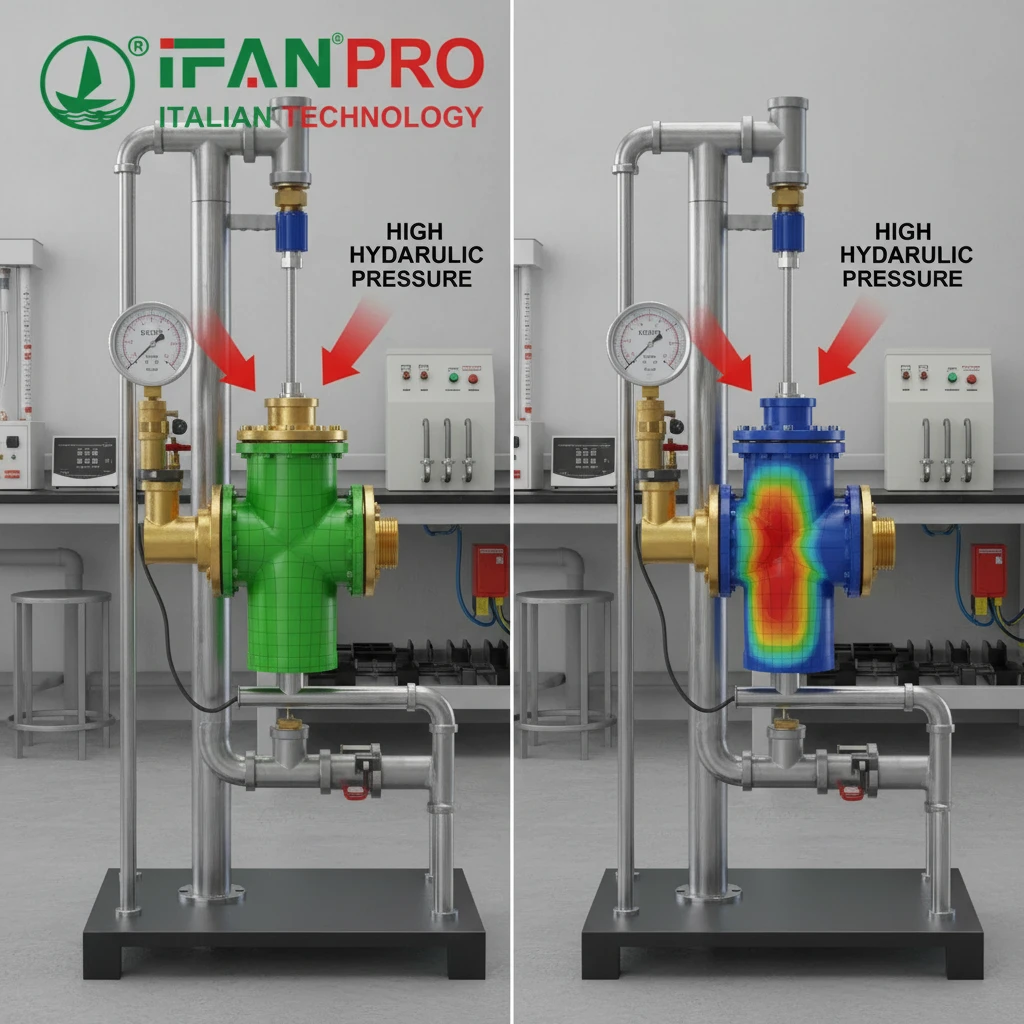

How Does Brass Material Withstand High Pressure and Mechanical Stress Better?

Imagine a valve constantly being bumped by equipment or handling uneven water pressure. I’ve replaced many cracked plastic valves in such scenarios.

Brass withstands high pressure and mechanical stress far better than plastics due to its superior tensile strength and structural rigidity. As a metal alloy, it resists deformation, impact, and fatigue from constant cycling, maintaining a reliable seal and mechanical function where plastic parts might warp, crack, or fail.

The Strength of Metal vs. Plastic

In industrial environments, equipment faces constant challenges. Vibrations from machinery, accidental impacts from tools or trolleys, and high internal water pressure are everyday occurrences. This is where the fundamental properties of brass shine.

First, let’s talk about tensile strength. This is a material’s ability to resist being pulled apart. Brass has a significantly higher tensile strength than engineering plastics like PVC or polypropylene. This means a brass valve body can handle much higher internal water pressures without risk of bursting. For example, while a plastic valve might be rated for a maximum of 150 PSI, a comparable brass valve can often handle pressures exceeding 600 PSI.

Second, consider rigidity and impact resistance. Plastic can be brittle, especially in colder temperatures. A sharp knock can crack a plastic valve body or its lever arm. Brass, however, is tough and malleable. It can absorb a significant impact without fracturing. It might dent, but it will rarely crack and cause an immediate catastrophic leak. This durability is crucial in busy plants where maintenance work is frequent.

Understanding Mechanical Stress and Fatigue

Float valves are mechanical devices. The float arm pivots up and down constantly, and the sealing mechanism engages every time the tank fills. This repeated motion causes mechanical fatigue.

- Plastic Components: Over thousands of cycles, plastic hinges and pivots can wear down, become loose, or even snap. The constant force on the seal can also deform plastic seating surfaces over time.

- Brass Components: Brass parts are much more resistant to this wear and fatigue. The pivot points on a brass valve are often reinforced with stainless steel pins, and the brass itself maintains its shape and strength over a vastly greater number of cycles.

Key Property Comparison Table

The table below shows why brass is the stronger material for tough jobs.

| Недвижимость | Brass (C36000) | PVC (Typical) | Polypropylene (Typical) |

|---|---|---|---|

| Tensile Strength (MPa) | 310 – 380 | ~50 | ~35 |

| Impact Resistance | High | Low (Brittle) | Moderate |

| Номинальное давление | Very High | Medium | Low-Medium |

| Resistance to Deformation | Excellent (High Rigidity) | Good (but can creep under load) | Poor (Flexible) |

In summary, for any application involving high system pressure, physical risk of impact, or constant heavy cycling, the mechanical strength of brass provides a fundamental layer of security and durability that plastics cannot match.

Why Is Brass Superior for Hot Water or Aggressive Water Conditions?

I recall a project where aggressive well water destroyed stainless steel components in months; we switched to a specific brass alloy, and the problem stopped.

Brass is superior for hot water and aggressive water because it offers excellent thermal stability, resisting deformation at high temperatures, and specific brass alloys have proven corrosion resistance to chemicals, minerals, and dezincification, ensuring reliable operation where plastic would soften or degrade.

Handling High Temperatures

Industrial processes often use hot water. Boiler feed systems, cleaning lines, and cooling circuits are typical examples. Temperature is a major factor in material selection.

- Plastic’s Weakness: Most plastics used in float valves, like PVC, have a maximum continuous service temperature below 140°F (60°C). At these temperatures, plastics begin to soften, losing their structural strength and rigidity. A plastic float valve in a hot water tank can warp, leading to seal failure and inaccurate level control.

- Brass’s Strength: Brass retains its mechanical properties well beyond the boiling point of water. It does not soften or deform under the thermal stress found in typical industrial hot water applications. This makes it the only safe choice for systems operating above 60°C.

Resisting Chemical and Mineral Attack

Water is not always pure. It can contain a variety of aggressive agents:

- Chlorides (common in cooling tower water and treated water)

- Sulfates

- High mineral content (hard water)

- Low pH (Acidic Water)

The Problem with Standard Brass: Traditional brass (an alloy of copper and zinc) can suffer from dezincification in certain aggressive waters, particularly soft, acidic water with high chloride levels. This is a process where the zinc is selectively leached out of the alloy, leaving behind a porous, weak copper structure that can fail.

The Solution: Superior Brass Alloys. This is where material engineering matters. Modern, industrial-grade brass valves are not made from simple alloys. They use dezincification-resistant (DZR) brass or naval brass. These alloys contain small amounts of elements like arsenic, antimony, or phosphorus, which dramatically inhibit the dezincification process.

Material Selection Guide for Water Conditions

Choosing the right material depends on your water chemistry.

| Water Condition | Risk to Standard Brass | Recommended Valve Material | Reason |

|---|---|---|---|

| Standard Potable Water | Low | DZR Brass | Cost-effective, durable, and safe. |

| Chlorinated Water / Cooling Towers | High (Dezincification) | DZR Brass or Naval Brass | Special alloys resist chloride attack. |

| Acidic or Soft Water | High (Dezincification) | DZR Brass | Protects against low-pH corrosion. |

| Very High Chloride / Marine | Severe | Bronze (Copper-Tin Alloy) | The highest corrosion resistance. |

| Hot Water Systems (>60°C) | Low (Thermal) | DZR Brass | Maintains strength at high temperatures. |

Plastic valves, while resistant to some chemicals, are vulnerable to others (like certain solvents) and offer no advantage in hot water. Therefore, for challenging water conditions, a correctly specified brass alloy provides predictable, long-term durability.

What Is the Typical Service Life Comparison Between Brass and Plastic Valves?

Clients often ask about lifespan to calculate true cost. One food plant still uses brass valves I supplied 15 years ago, while plastic ones are replaced every 3-5 years.

The typical service life of a brass float valve is often 3 to 5 times longer than that of a standard plastic valve in comparable industrial conditions. While a plastic valve may last 2-5 years under stress, a quality brass valve commonly provides 10-20 years of reliable service, making its total lifetime cost lower.

Defining “Service Life” in Industry

Service life doesn’t just mean the valve exists; it means it performs its function reliably—controlling water level accurately and without leakage. Failure can be sudden (a crack) or gradual (worn seals, inaccurate control).

Plastic valves tend to have a shorter, less predictable lifespan in industrial settings due to the factors we’ve discussed: material fatigue, thermal stress, and UV degradation if exposed to sunlight. Their failure mode is often catastrophic—a broken lever or a cracked body causing a flood.

Brass valves, conversely, typically wear out gradually. The primary wear components are the seal (washer or diaphragm) and the hinge pin. These are serviceable parts. The robust brass body and arm assembly, however, last for decades.

Factors That Shorten Valve Life

Let’s look at what kills valves faster and how materials compare.

| Factor | Effect on Plastic Valve | Effect on Brass Valve |

|---|---|---|

| Constant Cycling | High fatigue risk for plastic pivots and levers. | Minimal wear on metal pivots; seal is main wear item. |

| High Pressure | Can cause stress cracking or seal blow-out. | Easily handled by body strength; higher seal pressure. |

| Hot Water | Warping, softening, accelerated aging. | No effect on body; may require high-temp seal. |

| Outdoor/Sun Exposure | UV radiation makes plastic brittle. | No effect on metal; may require UV-resistant float. |

| Abrasive Particles in Water | Can score the plastic seating surface. | Can score the brass seat, but it’s harder and more resilient. |

Lifecycle Cost Analysis Table

The real story is told by the total cost over 15 years for a critical application.

| Cost Component | Plastic Valve (Replaced every 4 years) | Brass Valve (Installed once) |

|---|---|---|

| Initial Purchase Price | $50 | $150 |

| Installation Labor (x4) | $400 (4 x $100) | $100 (1 x $100) |

| Cost of Valve Failure | High Risk (Flood, downtime) | Very Low Risk |

| Total Cost over 15 Years | $450 + Risk Cost | $250 |

| Performance | Declining reliability, frequent checks | Consistent, reliable, low maintenance |

This comparison shows that while the brass valve has a higher upfront cost, its longer service life and lower maintenance needs lead to a significantly lower total cost of ownership. More importantly, it drastically reduces the risk and cost associated with unexpected valve failure, which in an industrial setting can include production downtime, water damage, and product loss.

When Is the Investment in a Brass Float Valve Absolutely Necessary?

Based on client feedback, the choice is clear in certain situations. Investing in brass upfront always saves money and trouble later.

Investing in a brass float valve is absolutely necessary in applications involving high temperatures, aggressive water chemistry, high system pressure, critical processes where failure is unacceptable, or when regulations require certified metallic components for safety and hygiene.

Non-Negotiable Application Scenarios

While plastic valves have their place in light-duty, low-risk applications, there are clear red flags that mandate the use of brass. Here are the key situations where you should always choose brass.

1. High-Temperature Applications:

If your water temperature consistently exceeds 60°C (140°F), plastic is not an option. The risk of the valve body softening and deforming is too high. This includes:

- Boiler feed tanks

- Industrial washing and sterilizing systems

- Any process involving steam or hot water return lines.

2. Chemically Aggressive or Variable Water:

If your water source is from a well, cooling tower, or municipal supply with known high chloride or mineral content, you need the corrosion resistance of DZR brass. Plastic may not corrode, but it can become brittle or permeable. Brass provides a proven, reliable barrier.

3. High-Pressure Systems:

In systems where water pressure is above 100 PSI and subject to surges, the mechanical strength of brass is required to prevent burst failures. Plastic valves at their pressure limit offer no safety margin.

Criticality and Risk Assessment

The cost of valve failure is a major deciding factor.

4. Critical Processes with High Downtime Cost:

If a valve failure would stop a production line, ruin a batch of product, or cause significant flooding damage, the higher reliability of brass is a cheap insurance policy. The investment in brass is justified by risk avoidance alone. Examples include:

- Food and beverage processing lines

- Pharmaceutical manufacturing

- Data center cooling systems

- Any automated process relying on precise tank levels.

5. Regulatory and Code Requirements:

Many industrial, commercial, and public health codes explicitly require the use of metallic valves in specific applications. This is common in:

- Backflow prevention assemblies (where brass or bronze is often mandated).

- Fire protection system connections.

- Plumbing systems in public buildings where durability and fire resistance are coded.

Decision-Making Checklist

Use this simple checklist to decide:

| Ask This Question | If YES, Choose Brass |

|---|---|

| Is water temperature above 60°C (140°F)? | ✅ |

| Is the water acidic, soft, or high in chlorides? | ✅ |

| Is system pressure consistently high (>100 PSI)? | ✅ |

| Would a valve failure cause major downtime or damage? | ✅ |

| Are there regulatory or insurance requirements for metal components? | ✅ |

| Is the valve in a hard-to-reach or high-maintenance-cost location? | ✅ |

If you answer “yes” to any of these questions, the initial higher investment in a brass float valve is not just advisable—it is necessary for safe, reliable, and cost-effective operation.

Заключение

For tough industrial jobs involving heat, pressure, aggressive water, or critical operations, brass float valves are the definitively more durable choice. For reliable, high-performance brass float valves built to last, consider the ИФАН industrial valve series.

Последние комментарии