I’ve seen poorly chosen fittings fail in under a year, causing leaks and costly shutdowns. This experience makes the long-term performance of brass Double Y Tees a critical question for any project.

Yes, brass Double Y Tees are highly corrosion-resistant for long-term use. This resistance comes from the natural properties of the brass alloy itself, which forms a protective surface layer. This inherent quality makes them a reliable, low-maintenance choice for diverse plumbing systems, effectively outlasting many alternative materials.

Understanding the science behind this durability is key to making an informed purchasing decision. Let’s break down the reasons for their exceptional performance.

What Chemical Composition Makes Brass DOUBLE Y TEES Inherently Corrosion-Resistant?

Clients often ask what’s inside the fitting that makes it so tough. The secret lies in the metal mix.

The corrosion resistance of brass Double Y Tees comes primarily from their copper and zinc composition. Copper naturally resists many forms of corrosion, and when combined with zinc, it forms a stable alloy. This alloy quickly develops a protective patina layer on its surface that shields the underlying metal from further attack.

The Role of Copper and Zinc

To understand why brass lasts, we need to look at its recipe. Brass is not a pure metal; it is an alloy made mostly of copper and zinc. The typical ratio for plumbing-grade brass is around 60-70% copper and 30-40% zinc, though this can vary.

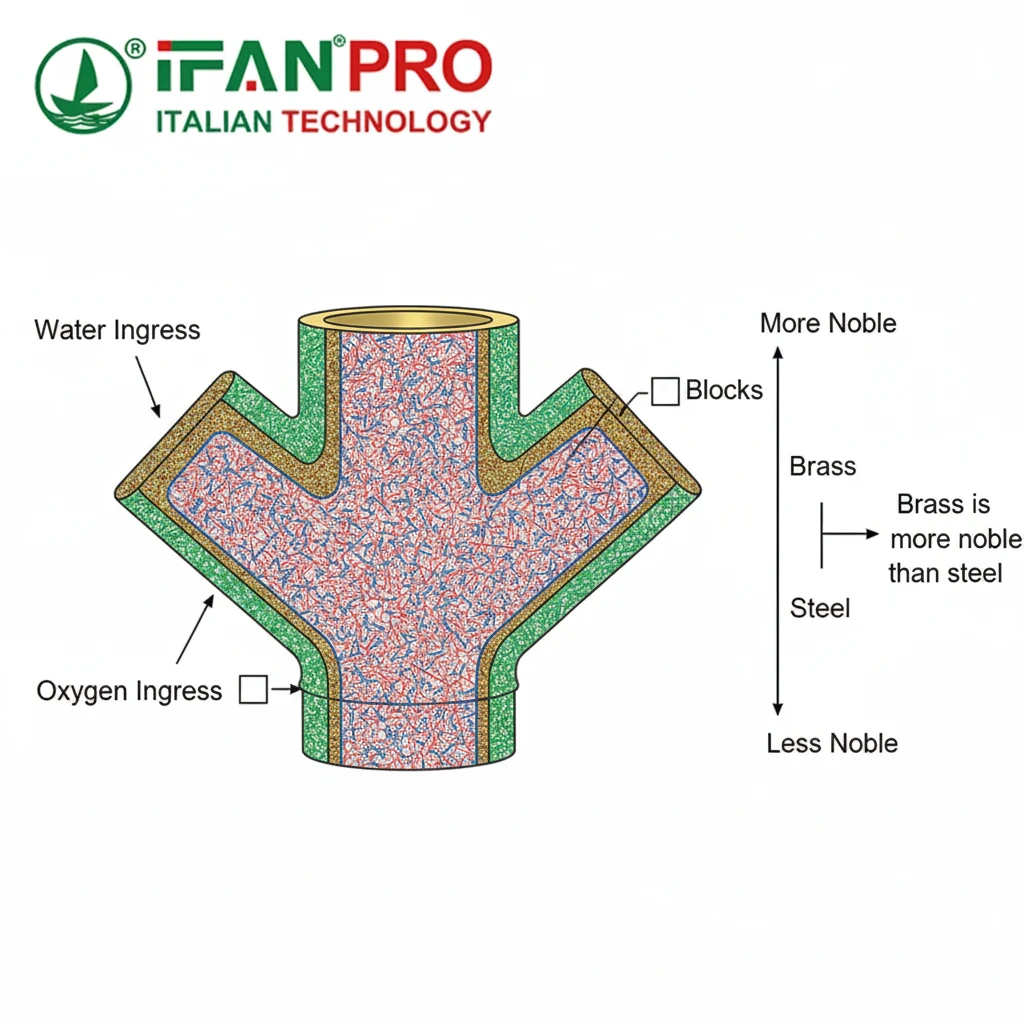

Copper is the star player here. It is a noble metal, which means it has a natural tendency to resist corrosion. When exposed to water and air, copper doesn’t rust like iron. Instead, it undergoes a very slow process that forms a thin, stable layer on its surface. Zinc, the other main component, adds strength and durability to the alloy. Together, they create a material that is both strong and resilient.

The Magic of the Protective Patina

The key to long-term resistance is the “patina.” Immediately upon exposure to oxygen and moisture, the surface of the brass begins to react. This reaction doesn’t harm the metal; instead, it creates a tightly bonded, thin film of corrosion products—primarily copper carbonate and copper oxide.

Think of this patina like a shield. Once this layer forms, it acts as a barrier. It prevents oxygen, water, and other corrosive agents in the environment from reaching the fresh metal underneath. So, the corrosion process essentially stops itself. This is different from steel, where rust (iron oxide) flakes off, constantly exposing new metal to rust again.

How Lead-Free Standards Improve Safety and Resistance

Modern standards require brass for potable water to be “lead-free.” This means any lead present is less than 0.25% of the alloy’s content. Manufacturers use other elements like bismuth or silicon to maintain the alloy’s workability. Importantly, these lead-free alloys are not just safer for drinking water; they often have even better corrosion resistance against dezincification, a specific type of corrosion we’ll discuss next.

Comparing Alloy Compositions

The table below shows how different brass compositions balance properties.

| Brass Type (Common Name) | Typical Copper % | Typical Zinc % | Key Additives | Best Use For |

|---|---|---|---|---|

| Standard Lead-Free (CW510L) | ~62% | ~36% | Trace Bismuth | General plumbing, cold water systems. |

| Dezincification Resistant (DZR/CW602N) | ~62% | ~36% | Added Arsenic or Antimony (tiny amounts) | Hot water systems, aggressive water areas. |

| Red Brass (85-5-5-5) | ~85% | ~5% | ~5% Tin, ~5% Lead (not for potable water) | Older systems, non-potable applications. |

| Naval Brass | ~60% | ~39% | ~1% Tin | Marine environments, high corrosion areas. |

In summary, the specific blend of copper and zinc, along with modern lead-free additives, creates a material that is fundamentally designed to withstand time. The self-limiting patina formation is nature’s way of protecting the fitting, making brass Double Y Tees inherently durable from the moment they are installed.

Which Specific Types of Corrosion Can Brass DOUBLE Y TEES Effectively Resist in Plumbing Systems?

Knowing a fitting is “corrosion-resistant” is good. Knowing exactly what it fights off is better for system design.

Brass Double Y Tees effectively resist several common types of corrosion, including general surface corrosion, dezincification (when specially formulated as DZR brass), and erosion-corrosion from flowing water. They also show strong resistance to corrosion caused by chlorinated water and biofilm formation compared to other metals.

Resistance to General and Galvanic Corrosion

In most standard water supply environments, brass performs excellently against general uniform corrosion. The protective patina ensures the fitting wears down incredibly slowly over decades. Furthermore, brass holds up well in mixed-metal systems. Its electrochemical potential is closer to copper than steel is. This means if a brass tee is connected to a copper pipe, the risk of galvanic corrosion (where one metal sacrificially corrodes to protect another) is very low. This compatibility is a major advantage in complex plumbing networks.

The Challenge of Dezincification and the DZR Solution

One specific threat to brass is dezincification. In certain aggressive water conditions—especially soft, acidic, or low-salt water—the zinc in the alloy can be selectively leached out. This leaves behind a porous, weak, copper-rich structure that can crack or fail under pressure.

The plumbing industry has a powerful solution: Dezincification Resistant (DZR) brass, also called “marine brass.” High-quality Double Y Tees are made from this material. DZR brass contains a small amount of an inhibitor element, like arsenic or antimony. This element dramatically slows down the dezincification process, making the fitting safe for even aggressive water conditions, including hot water systems. Always specify DZR brass for long-term reliability.

Fighting erosion-Corrosion and Scale

Flowing water, especially at high velocities or with suspended particles, can wear away materials. This is erosion-corrosion. The inherent toughness and hardness of brass make Double Y Tees very resistant to this wear. The smooth interior surface of a well-manufactured tee also minimizes turbulence and particle impact.

Unlike steel, brass does not rust, so it cannot suffer from under-deposit corrosion where rust pits form under scale. While mineral scale (lime) can deposit on brass, it does not typically promote localized corrosion beneath it. In fact, a scale layer can sometimes add to the protective barrier, though it may reduce flow.

Performance Against Common Plumbing Corrosives

Modern plumbing systems expose fittings to various chemicals. Here’s how brass fares:

| Corrosive Agent | Effect on Standard Brass | Effect on DZR Brass | Recommendation |

|---|---|---|---|

| Chlorinated Water (Municipal Supply) | Good resistance. Patina stabilizes. | Excellent resistance. | Both are suitable. DZR offers a safety margin. |

| Soft, Acidic Water (pH < 7) | Prone to dezincification over time. | Highly resistant. | Must use DZR brass. |

| Sulfates & Chlorides (Found in some well water) | Moderate resistance; can pit if concentrations are very high. | Very good resistance. | DZR brass is strongly preferred. |

| Ammonia Compounds | Can cause stress corrosion cracking in specific conditions. | Similar susceptibility. | Avoid use in concentrated ammonia environments. |

| Biofilm & Microbiologically Influenced Corrosion (MIC) | More resistant than steel or iron, as it doesn’t provide iron nutrients for bacteria. | More resistant than steel or iron, as it doesn’t provide iron nutrients for bacteria. | Good choice for systems prone to stagnation. |

By resisting these specific and common forms of degradation, brass Double Y Tees maintain their structural integrity and sealing capability for the long haul. This translates directly to fewer leaks, less maintenance, and lower lifetime costs for the plumbing system.

How Can You Verify the Corrosion Resistance Standards of Brass DOUBLE Y TEES Before Purchase?

Trust is good, but proof is essential. You should never just take a supplier’s word for it.

You can verify corrosion resistance by demanding official material test certificates, checking for product markings like “DZR” or “CR” (Corrosion Resistant), and ensuring certifications from independent bodies like NSF/ANSI 61, ASTM, and EN standards. Reputable suppliers like IFAN provide this documentation upfront.

Start with Material Certifications

The most reliable proof is a Material Test Certificate (MTC) or Mill Certificate from the manufacturer. This document is the “birth certificate” for the batch of brass used. A professional supplier should provide this upon request. Key things to look for on an MTC:

- Alloy Designation: It should clearly state a recognized standard, such as CW510L (for standard lead-free brass) or CW602N (for DZR brass). These European (EN) codes are globally respected.

- Chemical Composition: The certificate will list the exact percentage of copper, zinc, lead, iron, and other elements. Verify that lead content is below 0.25% for lead-free and that arsenic or antimony is present for DZR.

- Test Results: It may include results of specific corrosion tests, like the Mercury Nitrate Test for dezincification resistance.

Look for Physical Markings on the Product

Inspect the fitting itself. Reputable manufacturers permanently mark their products. Use a magnifying glass if needed. Look for:

- The “DZR” mark: This explicitly means Dezincification Resistant.

- The “CR” (Corrosion Resistant) mark: Another common indicator.

- Alloy Number: Such as “CW602N.”

- Manufacturer’s Brand or Logo: Trusted brands stake their reputation on quality.

- Certification Marks: Like the NSF logo or WRAS symbol. The NSF/ANSI 61 certification, in particular, includes tests for lead leaching and material safety, implying good corrosion stability.

Understand and Request Relevant Performance Standards

Your purchase should comply with established industry standards. Ask your supplier which standards their fittings meet. Here are the critical ones:

| Standard | Full Name | What It Verifies |

|---|---|---|

| ASTM B16/B134 | Standard Specification for Brass Fittings | Covers material, dimensions, and general requirements. |

| ASME B16.15 | Cast Brass Threaded Fittings | Dimensions, tolerances, and pressure ratings. |

| EN 1254 | Copper and copper-alloy fittings | European standard for material composition (CW510L, CW602N) and performance. |

| NSF/ANSI 61 | Drinking Water System Components | Safety and low leachability, which correlates with stable, non-corroding material. |

| ISO 9001 | Quality Management Systems | Indicates the manufacturer has controlled production processes. |

Conduct or Request a Simple Spot Test

For added peace of mind, especially on large projects, you can perform a basic visual and magnet test. A high-quality brass fitting should have a consistent golden color, smooth surfaces without porosity or sand holes, and clean, sharp threads. Also, brass is not magnetic. If a magnet sticks strongly to the fitting, it may be a cheap, steel-based imitation with only a thin brass plating, which will corrode quickly.

By taking these steps to verify standards, you move from hoping a product is good to knowing it is. This due diligence is the best way to avoid the costly nightmare of system-wide corrosion failures.

Why Does the Corrosion Resistance of Brass DOUBLE Y TEES Ensure Long-Term Reliability and Low Maintenance?

The ultimate goal is a system you can install and forget. Corrosion resistance makes this possible.

The corrosion resistance of brass Double Y Tees ensures long-term reliability by preserving the fitting’s wall strength and thread integrity. This prevents leaks, pressure drops, and sudden failures. Low maintenance results because the fittings do not need inspection, treatment, or replacement due to rust or decay, saving significant time and money over decades.

Preserving Structural Integrity and Preventing Leaks

A plumbing system is only as strong as its weakest point. Corrosion eats away at metal, thinning walls and creating pits. For a Double Y Tee, which manages flow from three directions, maintaining a robust internal structure is critical. Corrosion-resistant brass maintains its original wall thickness over time.

The most common point of failure in any threaded system is at the connections. Corrosion can “weld” threads together, making future disassembly impossible without breaking the fitting. More dangerously, it can erode the threads, destroying the seal. The non-corrosive nature of brass ensures the threads remain clean and intact. This means seals stay tight, preventing leaks that can cause water damage, mold growth, and costly repairs.

Ensuring Consistent System Performance

Corrosion products—rust, scale, and dissolved metals—can travel through pipes. This debris can clog valves, faucets, and appliances downstream. By not corroding, brass tees keep the water clean and the system’s flow rate and pressure stable. You won’t experience mysterious pressure drops or have to clean sediment screens frequently.

For hot water systems, reliability is even more crucial. Heat accelerates most chemical reactions, including corrosion. A DZR brass tee’s resistance to hot water corrosion means it won’t become the weak link that causes a leak inside a wall or ceiling, leading to extremely expensive damage.

The Direct Link to Low Maintenance

Maintenance costs are a huge part of a building’s lifetime expenses. Corrosion-resistant fittings directly reduce these costs in clear ways:

- No Need for Replacement: You won’t be scheduling a plumber to replace corroded tees every 10-15 years, as you might with lower-quality materials.

- No Chemical Treatments: Some systems require inhibitors to be added to the water to control corrosion. With brass, this need is greatly reduced or eliminated.

- Easy Modifications and Repairs: Years later, if you need to modify the system, the brass tees will be in the same condition as when installed. You can easily unscrew them without fear of them crumbling or being seized solid by corrosion.

Lifetime Cost Comparison: Brass vs. Alternative

Consider the total cost over a 30-year period for a single Double Y Tee in a commercial building:

| Cost Factor | DZR Brass Double Y Tee | Coated Steel Double Y Tee | Low-Quality Non-DZR Brass Tee |

|---|---|---|---|

| Initial Fitting Cost | $10.00 | $6.00 | $8.00 |

| Installation Labor | $50.00 | $50.00 | $50.00 |

| Risk of Failure | Very Low | High | Moderate to High |

| Estimated Maintenance/Replacement Cost (30 yrs) | $0 | $300 (for one replacement + leak repair) | $150 (for one replacement) |

| Total 30-Year Cost | $60.00 | $356.00 | $208.00 |

The table shows that the slightly higher upfront cost for a certified, corrosion-resistant DZR brass fitting is an investment. It buys you decades of trouble-free service and avoids hidden future expenses. This reliability and low maintenance are why engineers and plumbers consistently specify high-grade brass for critical applications.

Заключение

Brass Double Y Tees, especially DZR grade, offer proven corrosion resistance that ensures decades of reliable, low-maintenance service. For guaranteed quality, specify IFAN’s DZR Brass Double Y Tees, which come with full certification and technical support for your project’s long-term success.

Последние комментарии