I oversaw a hotel project where piping delays pushed the opening by a month. That experience convinced me that the old way of building on-site is holding the industry back.

Yes, modular piping systems are a defining part of construction’s future, especially for large-scale projects. They move critical fabrication work from the chaotic construction site to a controlled factory environment. This shift dramatically reduces on-site labor time, improves quality, and delivers predictable project schedules, which are essential for modern, cost-sensitive developments.

The evidence for this shift is clear. Let’s explore the concrete benefits that are driving this change and how you can successfully implement modular solutions.

How Do Prefabricated Modules Reduce On-Site Labor and Accelerate Project Timelines?

I’ve watched crews spend days cutting and threading pipes in dusty, cramped conditions. Prefabrication changes everything.

Prefabricated modules reduce on-site labor and accelerate timelines by completing up to 80% of the piping fabrication in a factory before the site is ready. This allows site work and pipe assembly to happen simultaneously. On-site, workers simply lift pre-assembled modules into place and connect them, cutting installation time from weeks to days and eliminating most skilled labor tasks from the hectic job site.

Transforming the Construction Sequence

The traditional pipe installation process is linear and slow. First, the building structure goes up. Then, the piping crew arrives to measure, cut, weld, and assemble everything piece by piece. This sequence creates a major bottleneck.

Modular construction breaks this bottleneck. In a modular approach, engineers finalize the piping design using 3D models while the building’s foundation is still being poured. Simultaneously, in an off-site factory, technicians begin fabricating complete pipe racks, skids, or bathroom assemblies. These modules can include pipes, valves, supports, and insulation—all pre-assembled and tested.

When the building structure is ready, these finished modules arrive just-in-time. Instead of a large crew performing complex tasks, a smaller team uses lifts to position the modules and makes a few final connections. This turns a lengthy, skill-intensive process into a fast, efficient installation operation.

Direct Impact on Labor and Schedule

The impact is measurable in two key areas:

- Labor Reduction & Efficiency: On-site labor is expensive and unpredictable. Weather, site congestion, and trade coordination all cause delays. By moving fabrication to a factory, you reduce the number of high-skill welders and fitters needed on-site. Their work is done more efficiently in a dedicated shop. The on-site team then focuses on faster, less error-prone installation.

- Schedule Compression: This is the biggest win. Because fabrication happens off-site in parallel with other construction, the overall project timeline shrinks. What used to be a critical path activity becomes a much shorter installation window. Projects can finish months earlier, leading to faster return on investment.

The table below contrasts the two approaches for a typical floor of a high-rise:

| Activity | Traditional On-Site Build | Modular Prefabricated Approach |

|---|---|---|

| Piping Fabrication | Occurs on-site after structure is complete. | Occurs in a factory concurrently with on-site structure work. |

| On-Site Work | Measuring, cutting, fitting, welding, testing. | Lifting, positioning, and connecting pre-tested modules. |

| Primary Labor Location | Entirely on the congested job site. | Mostly in a controlled factory; minimal on-site. |

| Typical Time Required | 4-6 weeks | 1-2 weeks |

| Weather/Logistics Risk | High – directly impacts the critical path. | Low – factory work is unaffected; on-site work is very fast. |

In short, prefabrication turns construction from a slow, sequential process into a fast, parallel one. This acceleration is why large projects are rapidly adopting modular solutions.

What Are the Quality Control Advantages of Factory-Built Versus Field-Built Systems?

Finding a pinhole leak in a field weld after a wall is closed is a nightmare. Factory control prevents these costly problems.

Factory-built systems offer superior quality control because work is performed in a controlled, stable environment by specialized technicians using calibrated equipment. This allows for strict, repeatable procedures, automated welding, and comprehensive testing before shipment. Field-built systems are subject to weather, dust, cramped spaces, and variable worker skill, leading to more inconsistencies and defects.

The Controlled Factory Environment

A factory provides a consistent, optimal setting for quality work that a construction site cannot match. Think about the differences:

- Environment: Factories are clean, well-lit, climate-controlled, and organized. Sites are often dusty, wet, too hot or cold, and chaotic.

- Equipment: Factories have stationary, calibrated machines for cutting, welding, and testing. On-site teams rely on portable equipment that can be less precise and harder to maintain.

- Personnel: Factory workers perform the same optimized tasks repeatedly, becoming highly skilled experts. On-site welders and fitters must adapt to constantly changing conditions and access issues.

This controlled setting allows for a standardized, documented quality process that is easy to enforce and audit.

A Step-by-Step QC Process

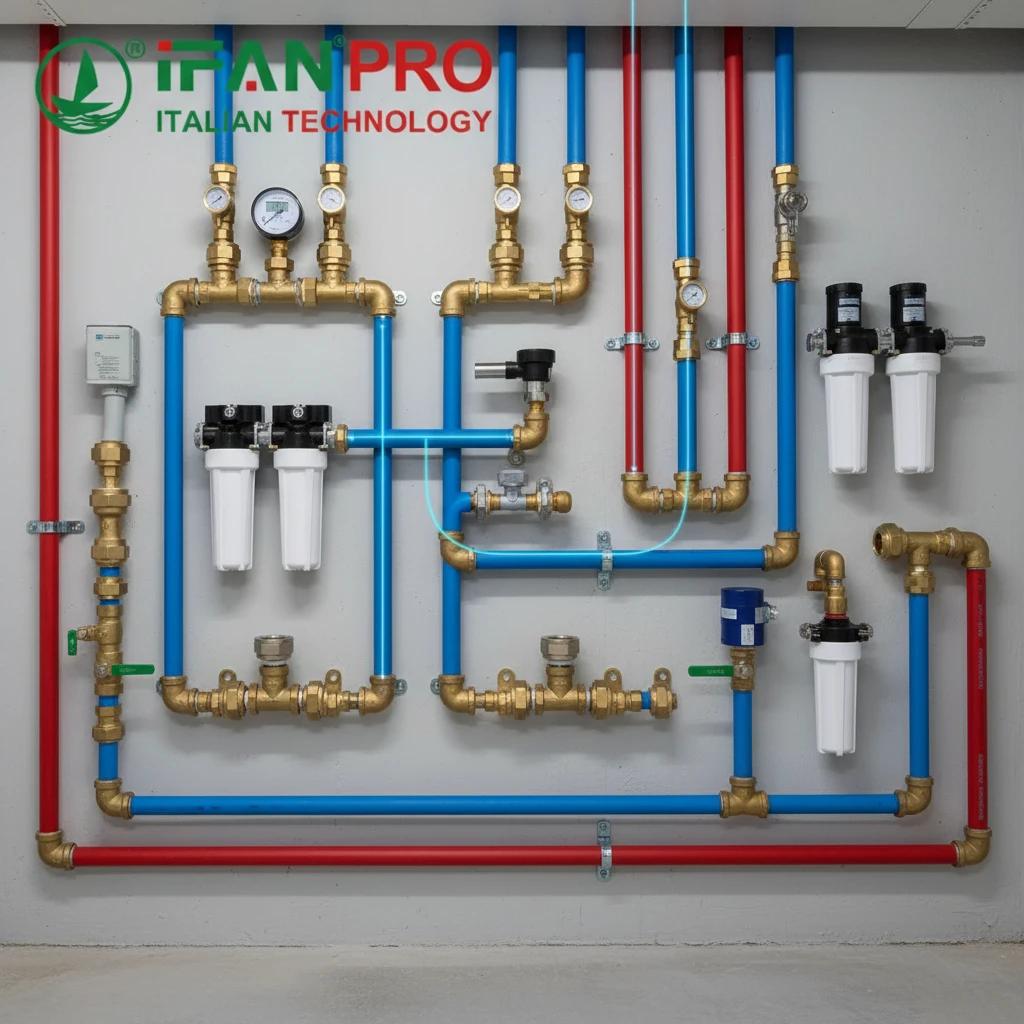

In a factory like IFAN’s, every module goes through a rigorous, multi-stage quality control process that is nearly impossible to replicate on-site:

- Material Inspection: All pipes, fittings, and valves are checked against certifications upon arrival.

- Fabrication Process Control: Technicians follow detailed work instructions. Automated welding machines ensure perfect, consistent welds every time.

- Dimensional Verification: Completed modules are checked against 3D models with laser scanners to ensure perfect fit.

- Pre-Shipment Pressure Testing: Every single module is hydrostatically pressure tested at 1.5x its working rating. This happens on the shop floor, where leaks are easy to find and fix.

- Final Audit & Protection: After passing tests, the module is cleaned, ports are capped, and it is protected for shipping.

Comparing the Outcomes

The result of this process is a predictable, high-quality product. On-site fabrication, however, faces constant challenges. A welder might have to work in an awkward position, leading to a subpar weld. Dust and moisture can contaminate a joint. Testing might be rushed due to schedule pressure.

The table below highlights key quality differentiators:

| Quality Factor | Factory-Built System | Traditional Field-Built System |

|---|---|---|

| Weld Consistency | High. Automated or positioned welding in ideal conditions. | Variable. Depends on welder skill and difficult site conditions. |

| Dimensional Accuracy | High. Uses jigs and laser verification from digital models. | Lower. Relies on manual measurements in a dynamic environment. |

| Testing Completeness | 100% of modules are fully tested before leaving the factory. | Often only sample or final system testing is done; hidden defects can remain. |

| Defect Discovery & Repair | Defects found early in a clean, equipped factory. Repair is cheap and fast. | Defects often discovered late, after concealment. Repair is very costly and disruptive. |

By building in a factory, you essentially guarantee a higher standard of quality and dramatically reduce the risk of costly, late-stage failures on the project site.

How Can Modular Design Adapt to the Specific Needs of Different Projects?

A common myth is that “modular” means “one-size-fits-all.” In reality, it’s the opposite.

Modular design adapts to project needs through flexible, configurable components and advanced digital planning. Engineers use Building Information Modeling (BIM) to create custom, project-specific modules from a library of standardized parts. This allows for precise customization for any building layout, code requirement, or performance need while still retaining the benefits of factory fabrication.

The Power of Digital Design and Standardization

The adaptability starts with digital tools. Engineers don’t draw lines; they build intelligent 3D models using BIM software. This model contains every pipe, valve, and hanger. It checks for clashes with electrical and structural elements before anything is built.

Within this model, designers use a library of standardized, pre-engineered components. Think of it like building with high-quality Lego blocks. You have many different types of blocks (elbows, tees, valves), but they all connect perfectly. This library includes parts for different systems:

- Domestic Water: PP-R, copper, or PEX assemblies.

- HVAC: Chilled water, heating, and ventilation duct modules.

- Fire Protection: Pre-assembled sprinkler racks.

The design process then becomes one of configuration, not invention. The system adapts because the digital model is tailored to the exact architectural plans.

Customization for Unique Requirements

Every project has unique needs, and modular design can meet them:

- Different Building Layouts: The BIM model is built to match the architect’s plans. Modules are designed to fit the specific dimensions and geometry of the building—they are not generic boxes.

- Local Codes and Standards: Modules can be engineered to meet specific regional codes, whether it’s GOST in Russia, EN in Europe, or UPC in the USA. Materials and certifications are selected accordingly.

- Performance Needs: For a hospital, modules might prioritize ease of future access and cleaning. For a data center, they might be designed for maximum cooling capacity and redundancy.

- Logistical Constraints: Modules can be designed to specific size and weight limits for shipping and handling on the actual job site.

This approach combines the efficiency of standardization with the specificity of custom design. You get a system built for your project, but built in the most efficient way possible.

Why Is Partnering with a System Expert Key to Implementing Modular Solutions?

Switching to modular is not just buying a product; it’s changing a process. Trying it without expert help is the biggest risk.

Partnering with a system expert is key because successful modularization requires deep experience in design-for-manufacture, logistics, and on-site integration. An expert guides the entire process—from early BIM coordination and module breakdown to factory production and installation sequencing—ensuring the promised savings in time and cost are actually realized, avoiding costly design or coordination errors.

The Role of the Expert Guide

A modular piping system is more than a collection of parts. It is an integrated product with a long journey from digital model to physical installation. A specialist partner like IFAN manages this entire journey. Here’s what they do:

1. Early Design Collaboration: They join the project during the design phase. Their engineers work with the MEP (Mechanical, Electrical, Plumbing) designer to “design for fabrication.” They advise on how to break the system into optimal modules for manufacturing, shipping, and installation. This upfront collaboration is crucial for success.

2. Process and Logistics Management: The expert manages the complex logistics. They create a detailed production schedule that aligns with the main construction timeline. They handle the packaging, shipping, and delivery sequence to ensure modules arrive just when needed, not cluttering the site.

3. On-Site Integration Support: They provide detailed installation manuals and often have field supervisors on-site for the first few installations. They ensure the contractor’s team knows exactly how to handle, position, and connect the modules correctly.

Avoiding Common Pitfalls

Going it alone or working with an inexperienced supplier leads to predictable problems:

- Poor Module Design: Modules that are too big to ship or lift, or too small to provide any efficiency benefit.

- Design Clashes: Modules that don’t fit because of last-minute changes to other building systems.

- Logistical Failure: Modules arriving late, out of sequence, or damaged, wiping out all schedule advantages.

- Installation Errors: On-site crews improperly connecting modules, causing leaks and system failures.

A true system expert acts as your single point of responsibility. They have done it before and have the processes to navigate these challenges. They ensure the transition from traditional to modular is smooth and delivers the expected return on investment.

Заключение

Modular piping systems are undoubtedly the future for efficient, high-quality large construction. To implement them successfully, choose a partner with proven expertise. IFAN provides complete modular PP-R and multi-system piping solutions, from expert design support to factory production and logistics management.

Последние комментарии