I once saw a multi-million dollar project stall for weeks because one factory shut down. That moment taught me that true supply chain resilience is not an option; it’s a necessity for survival and success.

To build a resilient supply chain, you must proactively identify and eliminate single points of failure, diversify your supplier base geographically, implement digital tools for real-time tracking, and partner with a reliable sourcing agent who can manage risks and ensure continuous supply. This multi-layered approach protects your projects from unexpected disruptions.

Building this resilience takes deliberate effort. Let’s break down the actionable strategies that turn a fragile chain into a robust network.

How Can You Identify and Mitigate Single Points of Failure in Your Supply Chain?

Many companies only see their supply chain’s weak links after they break. A resilient strategy finds and strengthens them beforehand.

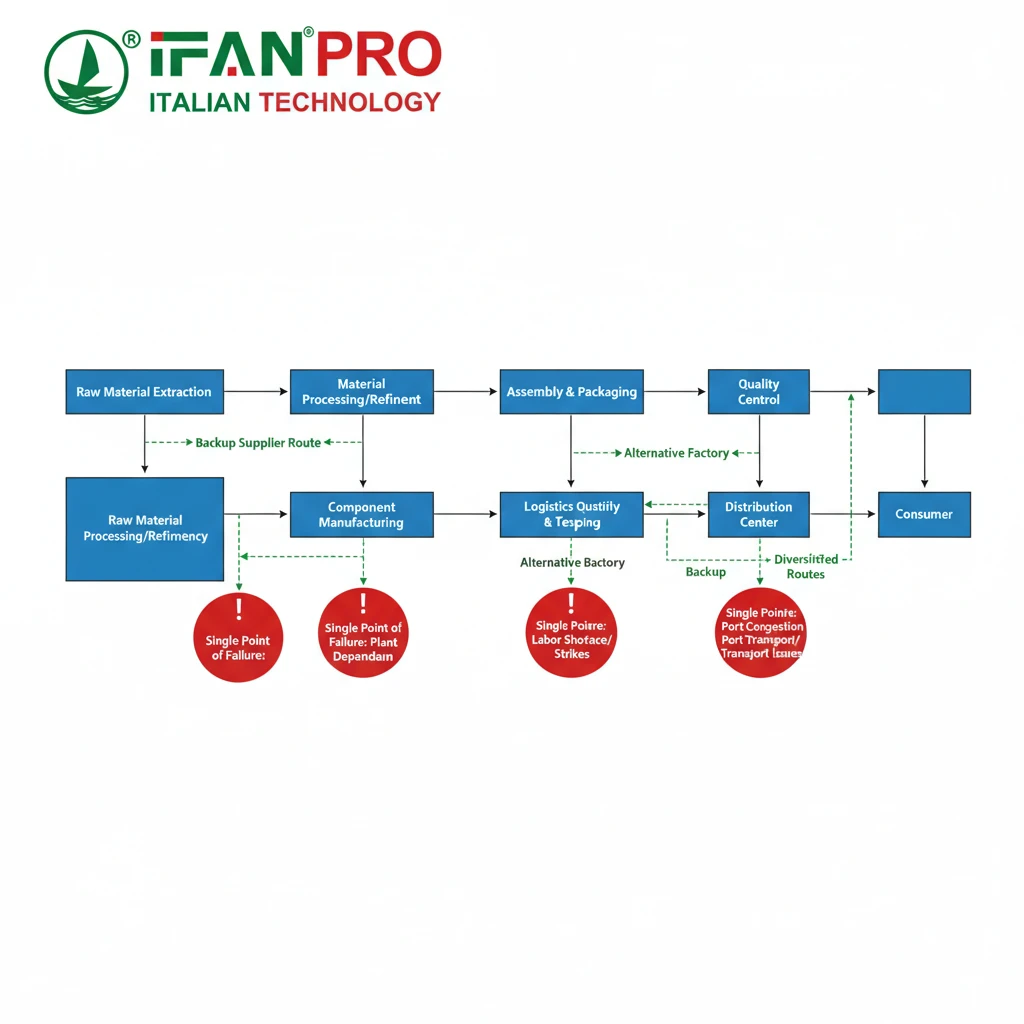

You can identify single points of failure by mapping your entire supply chain in detail, from raw materials to final delivery. Look for any component, supplier, or logistics route where you have only one source. You mitigate this risk by developing qualified backup options (alternative suppliers or materials) and creating contingency plans for critical nodes, such as stocking safety inventory for key items.

The First Step: Detailed Supply Chain Mapping

You cannot fix what you cannot see. The first and most critical task is to create a visual map of your entire supply chain. This goes beyond listing your main factory.

Start by asking these questions for every product or key component:

- Where do the raw materials come from?

- Who is the sole producer of a specialized part?

- Which factory performs a unique, irreplaceable process?

- What is the single shipping route or port you always use?

- Do you rely on one freight forwarder or customs broker?

Write down every step and every player. This map will instantly highlight your critical dependencies—the “single points of failure.” Common examples include a single source for a custom valve, one factory for all ceramic fittings, or reliance on a single shipping lane that is prone to congestion.

Developing a Proactive Mitigation Plan

Once you identify the weak spots, you take action to reinforce them. Here are three key mitigation strategies:

1. Develop Backup Suppliers: For every critical component or finished product, qualify a second (or even third) supplier. This doesn’t mean you must split every order, but it means you have a tested, ready-to-go alternative. The qualification process should include factory audits and sample testing, just like your primary source.

2. Implement Strategic Safety Stock: For items with long lead times or from high-risk single sources, consider holding a buffer of safety stock. Calculate this stock based on the “recovery time” it would take to switch to your backup supplier. This stock acts as a shock absorber during a disruption.

3. Diversify Logistics and Materials: Explore different shipping routes and ports. Also, work with engineers to see if certain components can be redesigned to use more common, readily available alternative materials without sacrificing performance.

A Practical Assessment Table

Use a simple table to assess and prioritize risks in your supply chain:

| Single Point of Failure | Potential Impact (High/Med/Low) | Mitigation Action | Responsible Team/Partner |

|---|---|---|---|

| Sole supplier for PPR raw material “X” | High | Source and qualify a backup resin supplier from a different region. | Sourcing Partner / R&D |

| All shipments via Port A | High | Negotiate rates and trial shipments through Port B. | Logistics Manager |

| Single mold for custom fitting “Y” | High | Produce a duplicate mold and store it at a separate facility. | Product Manager / Supplier |

| One QC inspector for final audit | Medium | Train a backup team member on the audit protocol. | Quality Manager |

By systematically identifying and addressing these points, you transform a linear, fragile chain into a more flexible and reliable network.

Why Is Diversifying Your Supplier Base Across Regions a Critical Strategy?

Putting all your eggs in one geographic basket is a major risk. Regional disruptions—from pandemics to political tensions—can halt your entire supply.

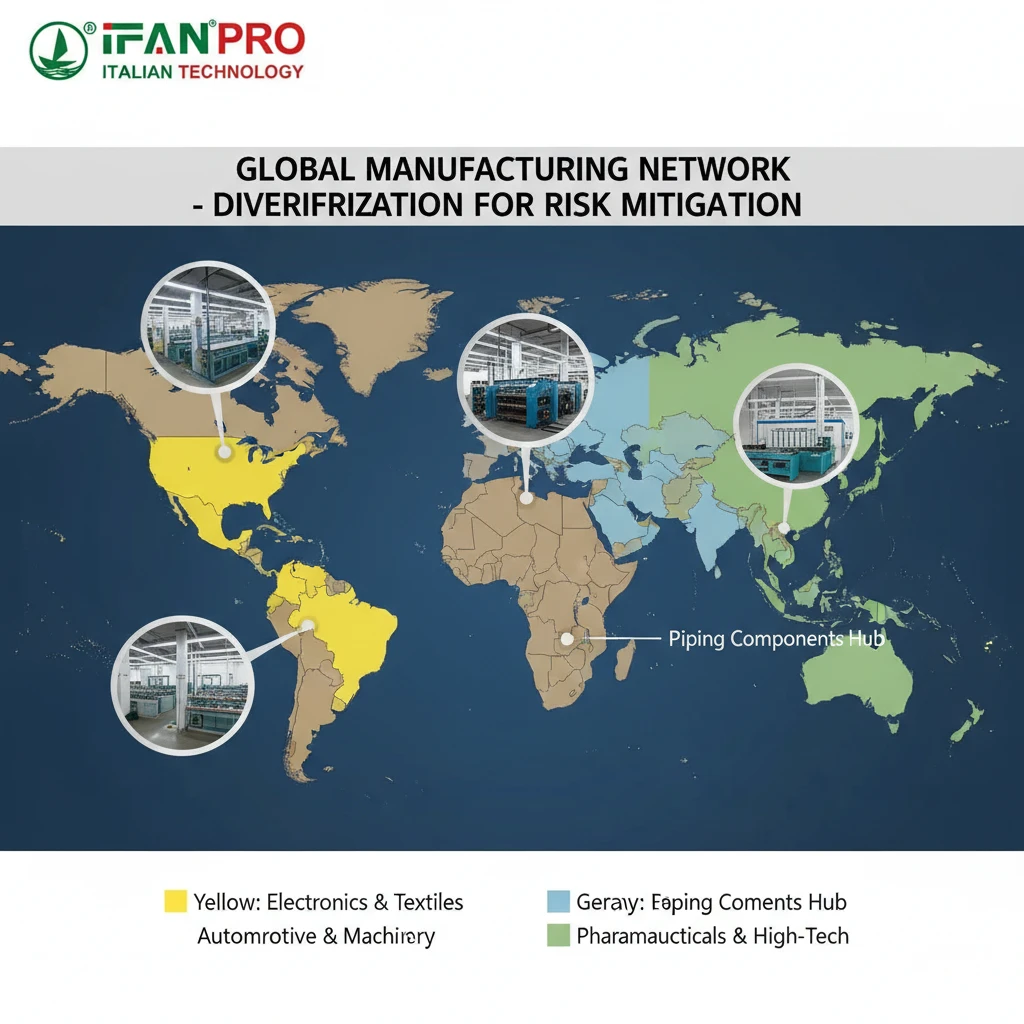

Diversifying your supplier base across regions is critical because it spreads your risk. When one region faces a lockdown, natural disaster, or logistical crisis, production and shipments can continue from another region. This geographic spread ensures continuity of supply, protects against local price volatility, and often exposes you to new technologies and competitive costs.

Understanding Regional Risk Profiles

Different regions have different strengths and inherent risks. A resilient strategy uses this to its advantage.

- Coastal China (e.g., Guangdong, Zhejiang): Offers high manufacturing sophistication, complete supply clusters, and scalability. Risks: Higher labor costs, vulnerability to global trade policy shifts, and regional power shortages.

- Inland China / Southeast Asia (e.g., Vietnam, Thailand): Often provides lower labor costs and is becoming a destination for manufacturing shifting out of coastal China. Risks: Possibly less mature supply chains for certain materials, varying levels of infrastructure.

- Multiple Regions within a Large Country: Even within a single country like China, diversifying between northern, southern, and eastern industrial zones can mitigate the impact of local environmental policies or power grid issues.

The goal is not to randomly source from everywhere, but to build a strategic portfolio. You might have your primary, high-volume supplier in one region and a qualified backup for the same product in another.

Benefits Beyond Risk Mitigation

Diversification offers several competitive advantages:

- Continuous Supply: This is the primary benefit. If a typhoon shuts down ports in Region A, your production schedule can continue with supplies from Region B.

- Cost Negotiation Power: Having alternative sources gives you leverage in price negotiations with your primary supplier. They know they are not your only option.

- Access to Innovation: Different manufacturing hubs often specialize. You might find a supplier in one region excels at injection molding, while another has superior expertise in metal finishing.

- Balanced Logistics Load: You can route shipments through different ports, avoiding the severe delays that can happen when one major port is congested.

Implementing a Smart Diversification Strategy

Start with a phased approach. Do not abruptly move all your business.

- Step 1: Identify 1-2 key products for diversification.

- Step 2: Use a sourcing partner to find and vet qualified suppliers in a new region. This partner handles the difficult task of navigating a new business environment.

- Step 3: Place a trial order to test quality, communication, and logistics.

- Step 4: Gradually integrate the new supplier into your supply plan as a secondary or backup source.

This strategy turns geographic diversity from a concept into a practical shield for your business operations.

How Does Digital Tracking Improve Supply Chain Visibility and Responsiveness?

Relying on phone calls and email updates for shipment status is like driving with a blindfold on. Digital tracking removes the blindfold.

Digital tracking improves supply chain visibility and responsiveness by providing real-time, accurate data on the location and status of your goods at every stage. This allows you to see delays as they happen, proactively inform customers, reroute shipments if necessary, and make faster, better-informed decisions to solve problems before they escalate.

From Reactive to Proactive Management

In a traditional supply chain, you often only discover a problem when a shipment fails to arrive on the expected day. You then spend days making calls to trace it. Digital tracking flips this model.

With IoT (Internet of Things) sensors, GPS trackers, and integrated platform updates, you can:

- See Real-Time Location: Know exactly where your container is—on a ship, at a port, on a truck.

- Monitor Conditions: Some sensors track temperature, humidity, or shock, which is crucial for sensitive materials.

- Receive Automated Alerts: Get instant notifications if a shipment is delayed at customs, misses a vessel, or deviates from its planned route.

This visibility transforms your role from a passive observer to an active manager. For example, if you see your shipment is stuck at a congested port, you can immediately work with your logistics partner to explore air freight for critical components, preventing a production line stoppage.

Key Digital Tools for Modern Supply Chains

Several types of digital tools create this visibility:

- Transportation Management Systems (TMS): These platforms provide end-to-end visibility on freight movements, often with carrier integration for real-time tracking.

- Supplier Portals: A shared platform where your supplier updates production milestones, uploads inspection reports, and provides packing list details. This replaces countless fragmented emails.

- Simple Shared Tracking Documents: Even a cloud-based spreadsheet shared between you, your supplier, and your forwarder, with updated ETAs and document status, is a vast improvement over offline files.

The Tangible Impact on Your Business

The benefits of digital tracking directly address common client pains:

- Eliminates “Where Is My Order?” Anxiety: You and your client can check status independently, 24/7.

- Improves Customer Service: You can proactively email a customer to say, “I see your shipment cleared customs and will be delivered tomorrow,” building immense trust.

- Reduces Inventory Costs: With more reliable ETAs, you can optimize your inventory levels more precisely, reducing the need for large buffer stocks.

- Enables Faster Problem-Solving: Data allows for root cause analysis. You can identify if delays consistently happen with a specific carrier, port, or supplier, and then address that specific issue.

Adopting these tools is no longer just for large corporations; it’s a fundamental requirement for any business that wants a responsive and reliable supply chain.

What Role Does a Sourcing Partner Play in Ensuring Continuous Supply?

A sourcing partner is not just an order-placer; they are your risk management team on the ground, actively ensuring your supply line never runs dry.

A sourcing partner ensures continuous supply by acting as your localized expert and buffer. They qualify and manage multiple backup factories, conduct regular quality audits, monitor production timelines proactively, handle logistics complexities, and solve problems locally in real-time. This allows you to focus on your core business while they protect your supply chain from daily operational risks.

The Sourcing Partner as a Force Multiplier

Think of a sourcing partner as an extension of your own procurement team, but with superpowers granted by their local presence, language skills, and established networks.

Here’s a breakdown of their critical roles:

1. Supplier Development and Management: They don’t rely on a single factory. A partner like IFAN has a pre-vetted network of manufacturers for the same product category across different regions. If your primary factory has a problem, they can quickly shift production to a backup without you starting a new supplier search from scratch.

2. Proactive Production Surveillance: Instead of waiting for updates, their project managers are on the factory floor or in constant communication. They track raw material arrival, production start dates, and line progress. They identify delays early—like a late component delivery—and work with the factory to get back on schedule before it impacts the final shipping date.

3. Integrated Quality Control: They build quality checks into the production process, not just at the end. This includes monitoring incoming materials, checking samples during production, and performing rigorous pre-shipment inspections. This prevents a whole batch of faulty products from being completed and shipped, which would cause a massive supply disruption.

A Comparison: Managing Supply With and Without a Partner

The table below illustrates the difference a professional partner makes:

| Task / Risk | Without a Sourcing Partner | With a Sourcing Partner (e.g., IFAN) |

|---|---|---|

| Supplier Failure | You must urgently find a new factory yourself, a process taking months. | They activate a pre-qualified backup supplier from their network within days. |

| Production Delay | You may not know until the missed delivery date. | Their on-site team flags the delay early and implements a recovery plan. |

| Quality Failure | Discovered upon arrival, causing rejections and stockouts. | Caught during production via their process control, allowing for in-factory correction. |

| Logistics Crisis | You spend hours across time zones resolving it with carriers. | Their local logistics team handles rerouting and problem-solving in real-time. |

The Strategic Outcome: Resilience and Focus

Ultimately, a sourcing partner transforms fixed, brittle supplier relationships into a dynamic, managed supply ecosystem. They absorb the daily volatility and complexity of international sourcing. This gives you the resilience to withstand shocks and the valuable time to focus on sales, product development, and serving your own customers. For plumbing projects where timelines are critical, this partnership is the ultimate insurance policy for continuous supply.

Заключение

Building a resilient supply chain requires a strategic mix of diversification, technology, and expert partnership. For a supply chain partner that embodies these principles, consider ИФАН for your plumbing project needs.

Последние комментарии