I once saw a standard brass elbow split at the seam under high-pressure steam. That failure taught me why a simple design detail, like a reinforced heel, matters so much.

Some brass elbows have a reinforced heel to provide extra strength and durability at the point of highest stress. The heel is the outer curve of the elbow, where pressure and flow forces converge, making it the most likely area to crack or fail. Adding material here significantly extends the fitting’s lifespan in demanding applications.

This design isn’t always necessary, but in the right situations, it’s critical. Let’s explore the engineering behind the reinforcement and when you absolutely need it.

How Does Extra Material at the Heel Strengthen the Elbow Against Stress?

A crack usually starts at the weakest point. In an elbow, that point is almost always the thin outer curve.

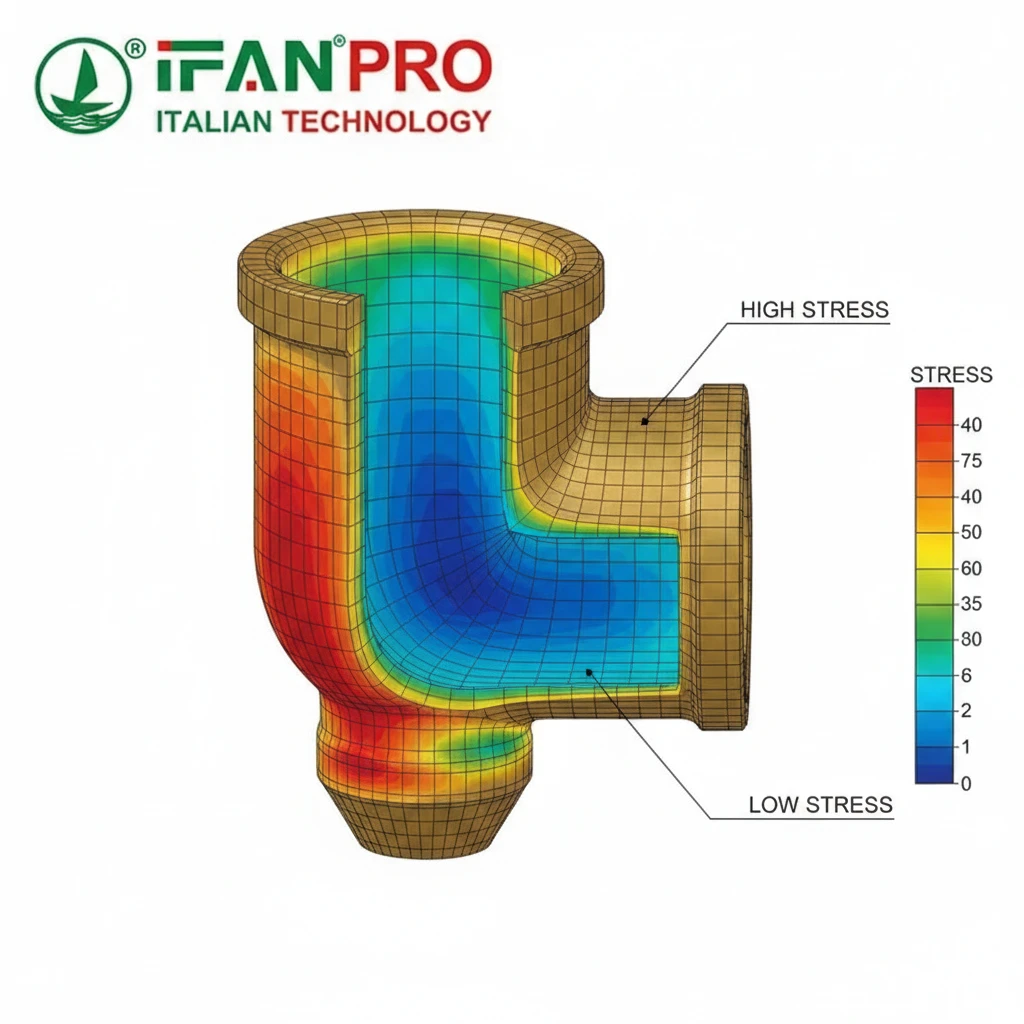

The extra material at the heel strengthens the elbow by distributing mechanical stress over a larger area and increasing the wall thickness at the most vulnerable point. This prevents stress concentrations from building up, which can lead to metal fatigue, cracks, and eventual failure, especially under repeated pressure cycles or water hammer.

Understanding the Problem: Stress Concentration

First, let’s understand the forces at play. When water or gas flows through a pipe and changes direction in an elbow, it pushes hard against the outer curve—the heel. This creates two main types of stress:

- Internal Pressure Stress: The fluid pressure inside tries to push the pipe walls outward.

- Flow-Induced Stress: The momentum of the fluid slams into the heel, creating a point of high impact.

In a standard elbow with uniform thickness, the heel is the thinnest section facing the greatest force. Think of bending a plastic ruler. It’s easier to snap at a point where there’s a nick or where it’s thinnest. Similarly, stress “concentrates” at the thin heel of a fitting, making it the natural starting point for failure.

The Solution: How Reinforcement Works

Adding material here is a direct and effective engineering solution. Here’s how it works:

- Increases Wall Thickness: More brass directly translates to greater strength to contain internal pressure. It simply takes more force to deform or crack a thicker wall.

- Reduces Stress Concentration: The reinforced area, often a smooth, thickened bulge, allows stress to spread out evenly. Instead of a sharp, focused point of pressure, the force dissipates across the stronger, beefier section.

- Combats Fatigue: Systems with pumps (which cause vibration) or that experience frequent pressure changes (like opening and closing valves) cause metal to “flex” slightly. Over time, this flexing at a weak point leads to metal fatigue. A reinforced heel resists this flexing, drastically increasing the fitting’s cycle life.

A Simple Analogy

Imagine two identical bookshelves. One has a thin support bracket in the middle, and the other has a thick, triangular gusset reinforcing that same corner. Which one can hold more weight and sway without breaking? The reinforced one. The reinforced heel in a brass elbow acts exactly like that gusset, providing essential support where it’s needed most.

In Which High-Pressure or High-Vibration Applications is a Reinforced Heel Vital?

Using a standard elbow in the wrong place is asking for trouble. We specify reinforced designs based on the system’s “personality.”

A reinforced heel is vital in applications involving sustained high pressure (above 150 PSI/10 Bar), frequent pressure surges (water hammer), high-temperature fluids, or constant vibration. Common examples include industrial process lines, fire sprinkler systems, hydraulic and pneumatic systems, shipboard plumbing, and installations near pumps or compressors.

High-Pressure Systems

In these systems, every component must contain immense energy. A standard fitting is a liability.

- Industrial Process Lines: Factories that use steam, chemicals, or high-pressure water for manufacturing.

- Hydraulic Power Systems: These operate at extremely high pressures (often 2000+ PSI) to power machinery. Every fitting must be over-engineered for safety.

- Fire Sprinkler Mains: While not always flowing, these lines are constantly under high static pressure and must withstand immense surge pressure when activated instantly.

High-Vibration and Dynamic Stress Environments

Constant shaking or pounding quickly fatigues weak points.

- Near Pumps & Compressors: The mechanical vibration from this equipment transmits directly into the pipes. A reinforced fitting resists fatigue cracking.

- Marine & Shipboard Plumbing: Engine vibrations and the flexing of a ship’s hull create a uniquely demanding environment.

- Heating Systems with Circulator Pumps: The constant on-off cycle of pumps creates thermal and pressure cycles that stress fittings.

Applications Prone to Water Hammer

Water hammer is a sudden pressure spike that can be many times higher than normal working pressure. It’s like hitting the pipe with a hammer.

- Commercial Buildings: Fast-closing solenoid valves in commercial dishwashers, laundry systems, or irrigation controls.

- Any system with quick-acting valves.

The table below helps decide when reinforcement is non-negotiable:

| Application | Risk Factor | Why Reinforced Heel is Vital |

|---|---|---|

| Industrial Hydraulics | Extremely High Constant Pressure | Prevents catastrophic blowouts that could cause injury or machine damage. |

| Fire Sprinkler System Riser | High Static Pressure & Surge Pressure | Ensures reliability during an emergency; a burst fitting renders the system useless. |

| Pump Discharge Line | Constant Vibration & Pulsation | Prevents fatigue failure from the constant “flexing” induced by the pump. |

| Steam Lines | High Pressure & High Temperature | Combats the combined stresses of heat and pressure, which accelerate metal fatigue. |

| Commercial Appliance Supply | Frequent Water Hammer | Withstands repeated shock loads from solenoid valves without cracking. |

If your project falls into any of these categories, specifying a reinforced elbow is a critical safety and reliability measure, not an optional upgrade.

Does the Reinforced Design Affect the Internal Flow Characteristics?

This is a common technical concern. People worry that a bulging heel might disrupt smooth flow.

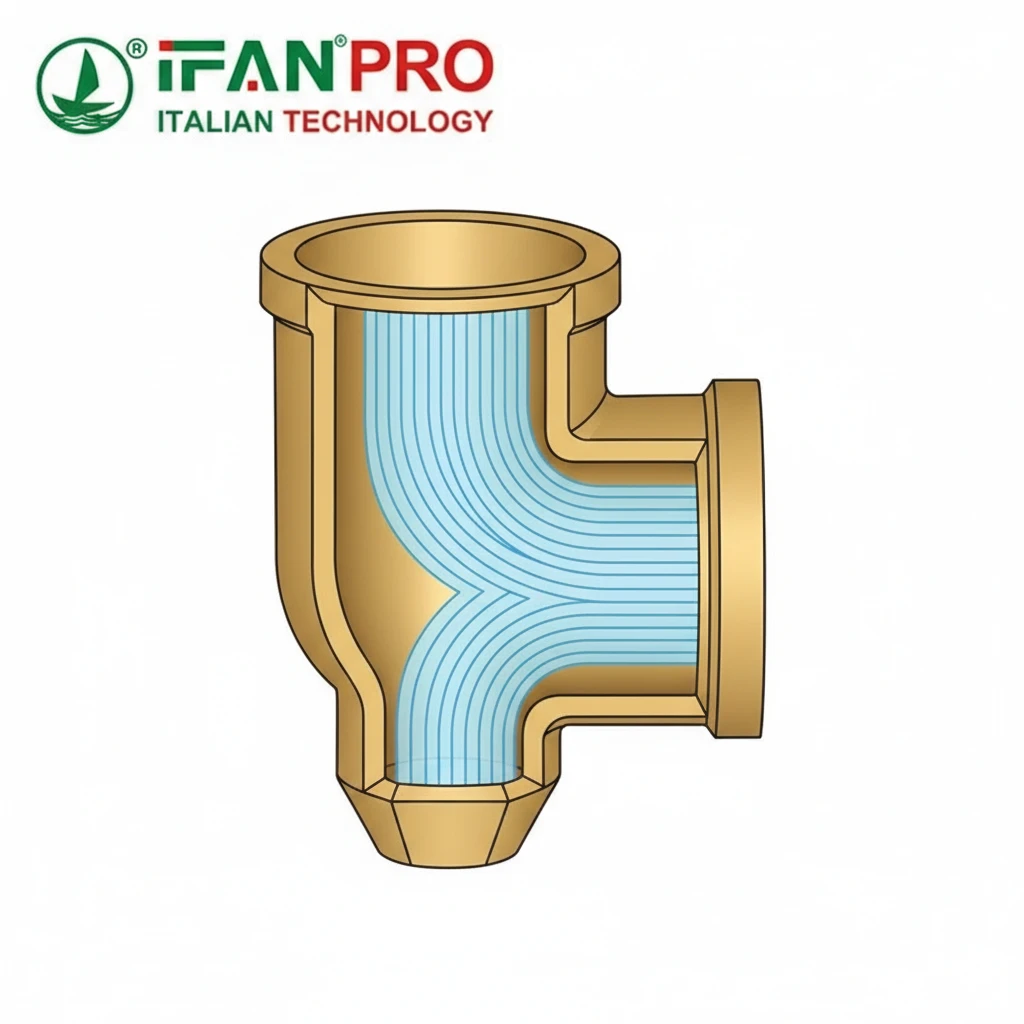

The reinforced design has a minimal negative impact on internal flow in liquid systems. While the slightly altered inner contour can create a tiny area of slightly more turbulent flow, the significant gain in pressure-containing strength and durability far outweighs this negligible hydraulic effect. For gas systems, the impact is even less noticeable.

Flow Dynamics: The Detailed Look

To understand this, we need to picture what happens inside the elbow.

In a Standard Elbow: The fluid hits the heel and must change direction. This already creates turbulence and a “dead zone” of slower flow right at the heel, regardless of wall thickness. The main pressure loss comes from the change in direction itself.

In a Reinforced Elbow: The inner wall at the heel is slightly thicker. This means the fluid’s path might be very slightly more constricted or the curve might be marginally tighter at that exact point. This could theoretically increase turbulence or pressure drop by a fractional amount.

Why the Practical Impact is Tiny

For almost all practical plumbing and industrial applications, this effect is insignificant. Here’s why:

- Scale of Change: The reinforcement is on the outside. The increase in the inner wall thickness is very small—often just a millimeter or two. Compared to the overall pipe diameter and the sharp 90-degree turn, this tiny change is lost in the overall turbulence of the bend.

- Energy Trade-off: The microscopic amount of energy lost to potential extra turbulence is irrelevant compared to the massive amount of energy contained by preventing a fitting rupture. System reliability is paramount.

- Engineered Designs: High-quality manufacturers like IFAN design the reinforcement to be as hydrodynamically smooth as possible. The internal transition is gradual, not an abrupt step, minimizing any flow disruption.

When It Might Matter (And When It Doesn’t)

- Does Not Matter: In water supply, hydronics, compressed air, steam, fuel lines, and most process applications. Strength is the key factor.

- Might Be Considered: In highly sensitive, precision laboratory fluidics or specific aerodynamic gas systems where every millibar of pressure drop is calculated. In these rare cases, engineers use specialized fittings, not standard plumbing components.

The consensus is clear: The benefit of preventing leaks and catastrophic failures completely overshadows any immeasurable impact on flow. You should always choose strength when the application demands it.

How Can You Visually Identify an Elbow with a Reinforced Construction?

You can’t trust part numbers alone. Knowing how to spot a reinforced fitting on-site or before purchase prevents costly mistakes.

You can visually identify a reinforced elbow by looking for a noticeable bulge or thicker profile on the outer curve (heel) of the fitting. Compared to a standard elbow’s smooth, even curve, a reinforced one will appear visibly beefier, chunkier, or have a distinct “hood” or extra material cast over the heel area. Always compare it side-by-side with a standard fitting if possible.

Key Visual Identification Points

Don’t just glance; inspect. Here are the tell-tale signs:

1. The Side Profile (Most Reliable Method):

Hold the elbow so you’re looking at its side, focusing on the 90-degree bend.

- Standard Elbow: The arc from one end to the other will look like a smooth, continuous curve with a consistent wall thickness. It looks slim.

- Reinforced Elbow: The outer curve will look “swollen” or have a distinct, rounded bulge. It looks stout and robust.

2. The Weight Test:

Pick it up. A reinforced elbow will feel noticeably heavier and more substantial in your hand than a standard one of the same size and rating. This is the direct result of the extra brass.

3. Markings and Standards:

Look for stamps or engravings on the fitting. While not all manufacturers mark them differently, some might include:

- A “Class” rating (e.g., Class 150, 300). Higher classes often use reinforcement.

- The pressure rating in PSI or Bar. A rating like “200 PSI WOG” is more likely to be reinforced than “125 PSI WOG”.

- Sometimes a simple “R” or “Heavy Duty” stamp.

A Practical Comparison Table

Use this guide during inspection:

| Feature | Standard Brass Elbow | Reinforced Brass Elbow |

|---|---|---|

| Outer Curve (Heel) Profile | Smooth, even, slim curve. | Visible bulge, thickened, chunky appearance. |

| Weight | Relatively lighter for its size. | Substantially heavier and more solid. |

| Wall Thickness (at heel) | Uniform, feels thin. | Obviously thicker, often hard to pinch. |

| Common Pressure Rating | Lower (e.g., up to 125 PSI). | Higher (e.g., 200 PSI, 300 PSI, or more). |

| Typical Cost | Lower. | Higher, due to more material. |

A Crucial Piece of Advice

If you are unsure, ask the supplier for a cut-away sample or a technical drawing. A reputable supplier like IFAN can provide this. A cut-away will clearly show the thicker wall section at the heel. Never assume a fitting is reinforced based on price or a generic product photo alone. A visual or physical check is the best way to be sure you’re getting the strength you’re paying for.

Заключение

A reinforced heel is a critical design for strength in demanding systems. For reliable performance in high-pressure or high-vibration applications, always choose IFAN’s reinforced brass elbows.

Последние комментарии