I once saw a plumber struggle for an hour in a tight cabinet, trying to connect two female-threaded pipes. The solution was a simple street elbow, which saved the day and taught me a clear lesson about fitting selection.

The main difference is their connection type. A regular elbow has two female (internal) threads. A street elbow has one female (internal) thread and one male (external) thread. This design lets the street elbow connect directly into another female fitting, saving space and often eliminating the need for a separate nipple.

This simple difference changes how you plan your plumbing runs. Let’s look at how each fitting works and when to use them.

How Does a Street Elbow Connect Male and Female Threads in One Fitting?

A street elbow looks different from a regular one. Its unique shape solves a common connection problem.

A street elbow connects male and female threads by having one end with external threads (male) and the other end with internal threads (female). The male end screws directly into a port, valve, or another female fitting. The female end then receives a pipe or the male end of another fitting. This creates a direct, compact turn in the pipeline.

The Anatomy of a Street Elbow

Understanding the fitting starts with its two ends. One end looks like a pipe with threads on the outside. The other end looks like a nut with threads on the inside.

The male end is like the pipe you are trying to connect. The female end is like the common elbow you already know. By combining them, the fitting becomes both a connector and a directional turn.

The Direct Connection Advantage

This design offers a key advantage: it makes a direct connection. With a regular female-by-female elbow, you need a short pipe nipple to connect it to another female port. The street elbow removes that middle piece.

Here is a simple comparison of the connection stack:

| Connection to a Valve using… | Required Components | Total Number of Joints |

|---|---|---|

| A Regular Female Elbow | Valve + Nipple + Elbow + Pipe | 3 threaded joints |

| A Street Elbow | Valve + Elbow + Pipe | 2 threaded joints |

Fewer joints mean two things:

- Less Potential for Leaks: Every threaded joint is a potential leak point. By eliminating one nipple and its two joints, you reduce the risk.

- Faster Installation: You have fewer pieces to assemble and tighten.

The street elbow’s male end effectively acts as a built-in nipple that is already perfectly aligned with the turn. This simple, smart design is why it’s a staple in any plumber’s toolbox.

Why is a Street Elbow Used to Save Space in Compact Plumbing Layouts?

Space is always limited behind walls, under sinks, or inside equipment panels. This is where the street elbow shines.

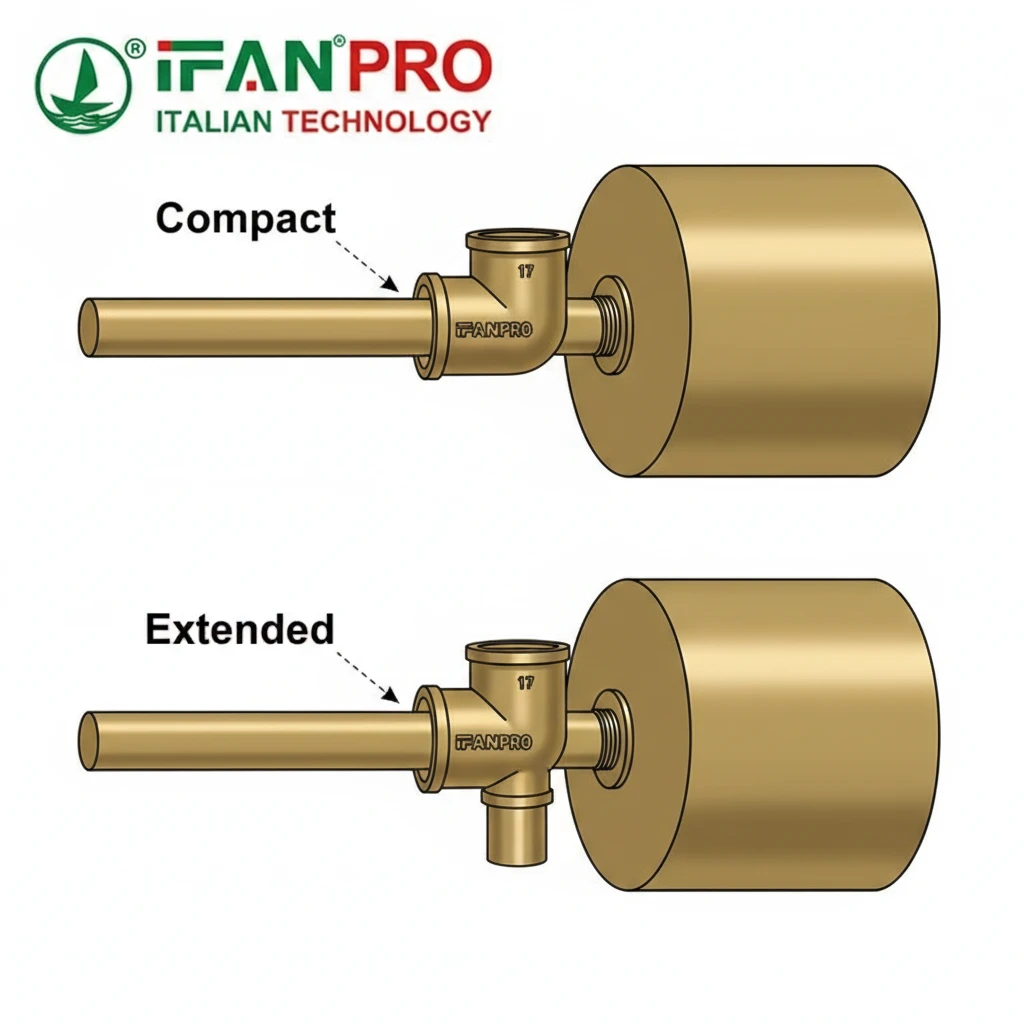

A street elbow saves space because its male end installs directly into a fitting, eliminating the need for a separate pipe nipple. This reduces the total length of the connection by the size of that nipple (often 1/2 to 1 inch), creating a tighter, more compact turn that fits where a regular elbow assembly would not.

Solving Real-World Space Problems

Imagine the water connections behind a wall-mounted toilet or inside a compact boiler. Every millimeter counts. A regular elbow requires enough space for its own body plus the length of a nipple sticking out of it before the pipe even starts to turn.

A street elbow changes this. Its male thread starts the turn immediately as it screws in. This creates a much tighter centerline. The turn happens closer to the connection point.

Visualizing the Space Savings

Let’s say you need to connect a pipe coming from a wall to a water heater inlet that is close to the wall. The pipe needs to make a 90-degree turn quickly.

- With a Regular Elbow: You would need a nipple from the wall, then the elbow, then the pipe to the heater. This pushes the entire pipe run further out from the wall.

- With a Street Elbow: The male end screws directly into the heater inlet. The turn begins right at the inlet, allowing the pipe to run straight back to the wall in a much shorter distance.

This is crucial in:

- Manufactured Housing and RVs: Where plumbing chases are extremely narrow.

- Industrial Control Panels: For gauge and instrument connections.

- Residential Kitchen/Bath Remodels: Where maximizing under-sink or behind-appliance space is key.

Choosing a street elbow can be the difference between a clean, feasible installation and a need to redesign the layout.

In What Scenarios is a Regular Female-by-Female Elbow More Appropriate?

The street elbow is useful, but the regular elbow is still the most common fitting for good reason. Each has its place.

A regular female-by-female elbow is more appropriate when you are connecting two lengths of pipe or two male-ended fittings. It is the standard, versatile choice for extending pipe runs, creating branches, or in any situation where the connection points are not a male thread and a pipe, but two of the same type.

The Standard for Pipe-to-Pipe Connections

The regular elbow’s strength is its simplicity and universality. It is designed to be installed between two pieces of pipe. Both of its ends are the same, so you don’t need to think about orientation when picking it up. You just need two pipes with male threads.

Common Use Cases for Regular Elbows

Here are specific scenarios where a regular elbow is the better or necessary choice:

1. Connecting Two Pieces of Pipe: This is the most basic use. If you have two threaded pipes that need to meet at a 90° or 45° angle, you put a regular elbow between them.

2. Creating a Branch with a Tee: When using a tee fitting, all three outlets are typically female. To turn the flow direction from one of these outlets, you use a regular elbow.

3. When Using a Union or Coupling: If you need a disconnect point in your line, you will use a union (which has female threads). To change direction after a union, a regular elbow is used.

4. For Structural or Aesthetic Symmetry: Sometimes, the plumbing is exposed, like in some industrial settings. Using all regular fittings (elbows, tees) creates a uniform, symmetrical look, as all connections are the same type.

The table below helps decide which fitting to use:

| Scenario | Recommended Fitting | Reason |

|---|---|---|

| Connecting a pipe to a water heater outlet (male) | Street Elbow | Male end screws directly into heater; space-saving. |

| Connecting two threaded pipes in the middle of a run | Regular Elbow | Standard connection for two male pipe ends. |

| Making a turn after a female-threaded valve | Regular Elbow | Requires a nipple, but is the correct adapter for the valve’s female port. |

| Turning a line that comes out of a female-threaded tee | Regular Elbow | The tee’s port is female, so the elbow must connect via a nipple or male pipe. |

In short, if both sides of your connection are the same, use a regular elbow. If one side is a male port and the other is a pipe, a street elbow is often the cleaner solution.

Can Street Elbows Simplify Connections to Valves and Gauges?

Yes, absolutely. Valves and gauges are where the street elbow’s design proves most useful.

Street elbows simplify connections to valves and gauges by providing a direct 90-degree turn right at the device’s port. This eliminates the need for a separate nipple and elbow combination, making the installation cleaner, more rigid, and less prone to leaks from over-tightening multiple fittings in a cramped space.

The Problem with Standard Connections

Many small valves, gauges, and pressure switches have female inlet or outlet ports. To pipe into them and make a turn, the traditional way is: screw a nipple into the port, then screw a regular elbow onto the nipple, then connect the pipe to the elbow.

This method has issues in tight spaces:

- Multiple Wrenches: You need to hold the valve, tighten the nipple, then tighten the elbow, often in a confined area.

- Stress Alignment: Getting the elbow to end up in the exact right orientation can require over-tightening or using extra turns of tape, which can weaken the joint.

- Increased Leverage: The nipple acts as a lever. If the pipe is bumped, force transfers directly to the valve’s internal threads, which can be fragile.

How the Street Elbow Provides a Solution

The street elbow fixes these problems. Its male end screws straight into the valve’s female port. In one step, you achieve a secure connection and the correct turn direction.

Benefits for Valve/Gauge Connections:

- Direct & Rigid: The connection is short and direct, reducing stress on the valve threads.

- Easy Alignment: You can orient the street elbow’s female end precisely where you need it as you tighten it into the valve, often within one full turn.

- Cleaner Look: The installation looks professional and intentional, not like an assembly of several small parts.

A Common Practical Example

Consider installing a pressure gauge on an air compressor line. The gauge port is female. You want the gauge to face forward, but the pipe comes from the side.

- Old Method: Nipple + Regular Elbow + Pipe. Three pieces, four threaded joints.

- Better Method: Street Elbow + Pipe. Two pieces, two threaded joints. The gauge is more securely mounted, and the whole assembly is shorter and stronger.

This simplicity is why street elbows are heavily used in instrumentation, hydraulic lines, and gas piping, where reliability and compactness are critical.

Заключение

Choose a street elbow for direct, space-saving turns into ports. Use a regular elbow for standard pipe-to-pipe connections. For reliable brass fittings in both types, choose ИФАН for quality and correct specifications.

Последние комментарии