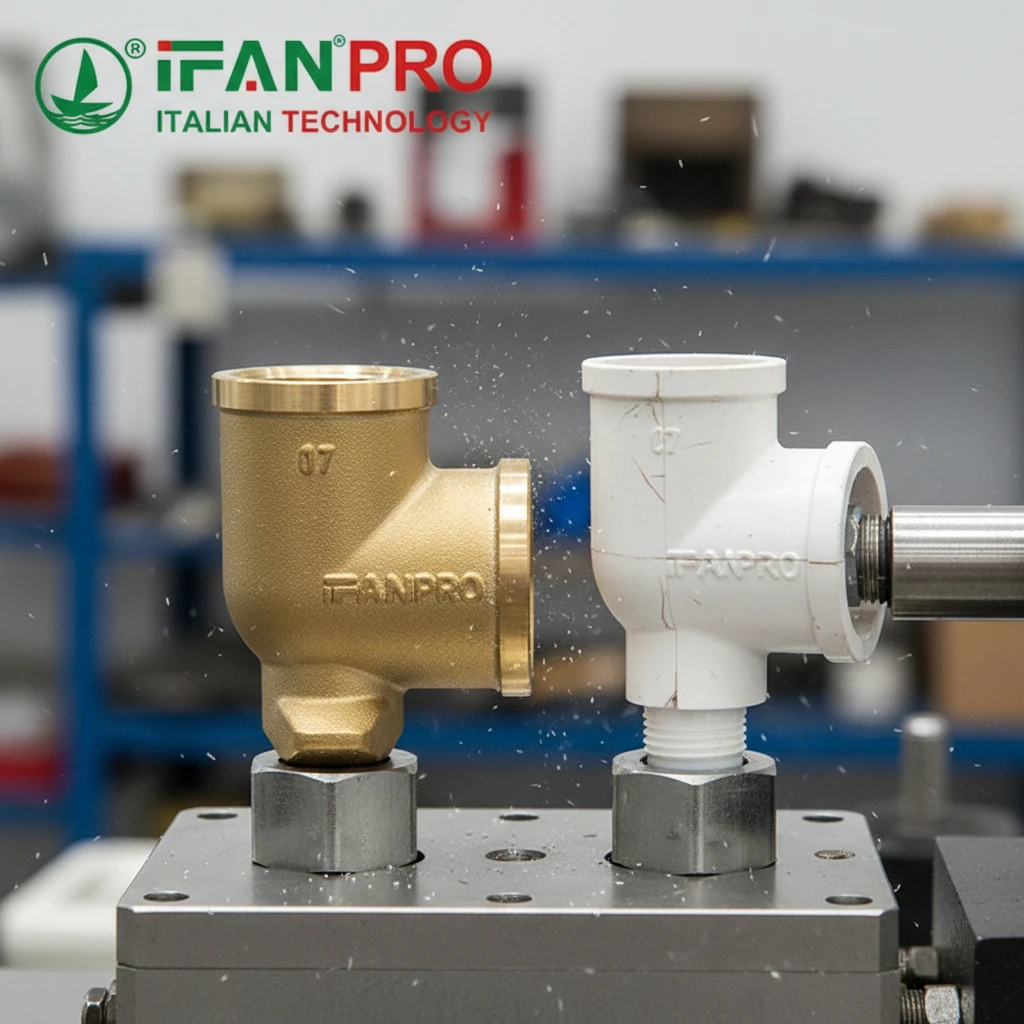

A client’s plastic air line fitting once shattered from a pressure surge, causing a shutdown. That moment cemented my respect for choosing the right material, like brass, for demanding jobs.

Yes, brass elbows are generally very suitable for standard compressed air systems. They offer an excellent balance of strength, corrosion resistance, and machinability. Brass effectively handles pressure surges, resists vibration better than many plastics, and is reliable for most industrial air applications within its specified pressure and temperature ratings.

However, “suitable” depends entirely on your system’s specific conditions. Let’s examine where brass excels and where you need to be cautious.

How Does the Strength and Ductility of Brass Handle Compressed Air Pulses?

Compressed air isn’t steady; it pulses with every compressor cycle. I’ve seen rigid materials crack under this repeated stress.

The strength and ductility of brass allow it to handle compressed air pulses very well. Its inherent ductility (ability to deform slightly without breaking) lets it absorb the energy of pressure spikes and vibrations, preventing the brittle fractures common in less malleable materials. This makes brass fittings highly resistant to fatigue failure from constant pulsing.

Understanding the Stress of Pulsation

Compressor systems do not deliver air at a perfectly constant pressure. Instead, they create pulses or waves of higher pressure. These pulses act like tiny, repeated hammer blows on the inside of your piping. A material that is very hard but brittle (like some cheap cast metals) might handle the steady pressure but crack over time from these cyclical impacts.

This is where brass’s material properties become a major asset. Brass is an alloy of copper and zinc, and this combination gives it a unique set of characteristics perfect for this environment.

The Role of Ductility and Fatigue Resistance

Ductility is key. When a pressure pulse hits a brass fitting, the material can undergo a tiny amount of elastic deformation. It flexes minutely and then returns to its original shape. This flexibility absorbs the shock, so the energy doesn’t concentrate in one spot to cause a crack. A brittle material cannot do this; it simply resists until it fails.

Fatigue strength is equally important. This refers to a material’s ability to withstand a very high number of stress cycles. Because brass is good at distributing stress and flexing elastically, it has a high fatigue limit. This means it can endure the millions of pressure pulses generated over years of compressor operation without developing cracks.

Comparison with Common Alternatives

The table below shows how brass compares to other common fitting materials under pulsating conditions:

| Материал | Response to Pressure Pulses & Vibration | Key Reason |

|---|---|---|

| Brass | Excellent | High ductility and good fatigue strength absorb cyclic stress. |

| Steel | Good (but can rust) | Very strong, but less ductile than brass; rust can create weak points. |

| Plastic (Nylon/PVC) | Poor to Fair | Can become brittle over time; prone to cracking from repeated impact/vibration. |

| Aluminum | Good | Lightweight and decent ductility, but threads can wear or gall more easily. |

In short, brass acts as a shock absorber in your air system. Its slight “give” is not a weakness but its greatest strength in this application, protecting your system from the hidden wear and tear of pulsation.

What Are the Risks of Using Brass in Systems with Lubricated Air?

Many compressors add oil to the air for lubrication. This common practice introduces a specific risk factor for brass components.

The primary risk of using brass in lubricated air systems is “dezincification,” a form of corrosion where the zinc in the brass alloy is selectively leached out by certain chemicals or acidic conditions. Compressor oil, especially if it breaks down or mixes with moisture, can create acidic byproducts that accelerate this process, potentially weakening the fitting over a long period.

The Science Behind Dezincification

Brass is not a simple element; it’s an alloy. Think of it like a cake made from copper and zinc flour. Dezincification is like water washing away only the zinc flour, leaving behind a porous, weak, and spongy copper structure. This process happens in the presence of specific agents, often chlorides or acids.

In a compressed air system, several factors can create these agents:

- Compressor Oil: Some oils can oxidize and form acidic compounds over time.

- Moisture: All compressed air contains some water vapor. When this moisture mixes with oil and heat, it can create a mildly corrosive environment.

- External Contaminants: In some workshop environments, airborne chemicals might enter the system.

Identifying and Mitigating the Risk

The good news is that this risk is manageable and often slow-acting. You are unlikely to see a sudden failure. Instead, dezincification causes a gradual loss of strength and, in advanced stages, can lead to pinhole leaks or fitting failure under pressure.

Here are practical steps to manage this risk:

1. Choose the Right Brass Alloy: Not all brass is the same. For critical applications or where lubricated air is present, specify dezincification-resistant (DZR) brass or “marine-grade” brass. These alloys have a small amount of arsenic or other elements added, which acts as a barrier to prevent the zinc from leaching out.

2. Maintain Air Treatment: Use proper filters, dryers, and oil separators in your compressed air line. The cleaner and drier your air, the lower the risk for all components, including brass fittings.

3. Conduct Regular Inspections: As part of routine maintenance, check brass fittings in lubricated systems. Signs of trouble include a reddish, pink, or porous appearance on the surface of the fitting, which indicates the zinc is gone, leaving only copper.

When is the Risk Highest?

The risk increases with:

- High system temperatures.

- Poor air quality (wet, oily, contaminated).

- Use of non-DZR brass fittings in critical, high-pressure lines.

For most general industrial applications with basic filtration, standard brass fittings from a quality manufacturer like IFAN perform reliably for years. For sensitive or high-reliability systems, opting for DZR brass is a wise, low-cost insurance policy.

Why Might Brass Be Preferred Over Plastic in High-Vibration Air Lines?

Vibration is a silent killer in pneumatic systems. I’ve replaced countless cracked plastic fittings on machinery, while the brass ones nearby remained solid.

Brass is strongly preferred over plastic in high-vibration areas because of its superior mechanical strength, fatigue resistance, and mass. Brass fittings are less likely to loosen, crack, or fail under constant shaking or flexing. They maintain a secure seal where plastic fittings can become brittle, fracture, or have their threads wear out from micro-movement.

The Problem with Plastic Under Stress

Plastic fittings, often made from nylon or PVC, are lightweight and inexpensive. However, they have fundamental weaknesses in dynamic environments:

- Creep: Plastic can slowly deform under constant pressure (a process called creep). In a vibrating line, this can cause fittings to gradually loosen.

- Brittleness: Many plastics become more brittle with age, temperature cycles, and exposure to UV light. A sudden impact or constant flexing from vibration can cause them to crack without warning.

- Thread Wear: The plastic threads on a fitting or adapter can wear down if there is any movement against a metal port. This wear creates leaks.

How Brass Solves Vibration Problems

Brass addresses each of these vulnerabilities:

1. Mechanical Strength and Thread Integrity: Brass threads are hard and durable. Once tightened onto a metal port, they are far less likely to wear down or strip. The metal-on-metal connection, when properly torqued, resists loosening from vibration due to higher friction and material strength.

2. Fatigue Resistance: As discussed earlier, brass handles repeated stress cycles (like constant vibration) extremely well. It flexes elastically without accumulating damage.

3. Mass and Damping: The simple weight of a brass fitting adds a slight damping effect, reducing the amplitude of vibration transmitted through that point in the line.

Practical Application Guide

Consider this table to decide where to use brass over plastic:

| Location / Condition | Recommended Fitting Material | Reason |

|---|---|---|

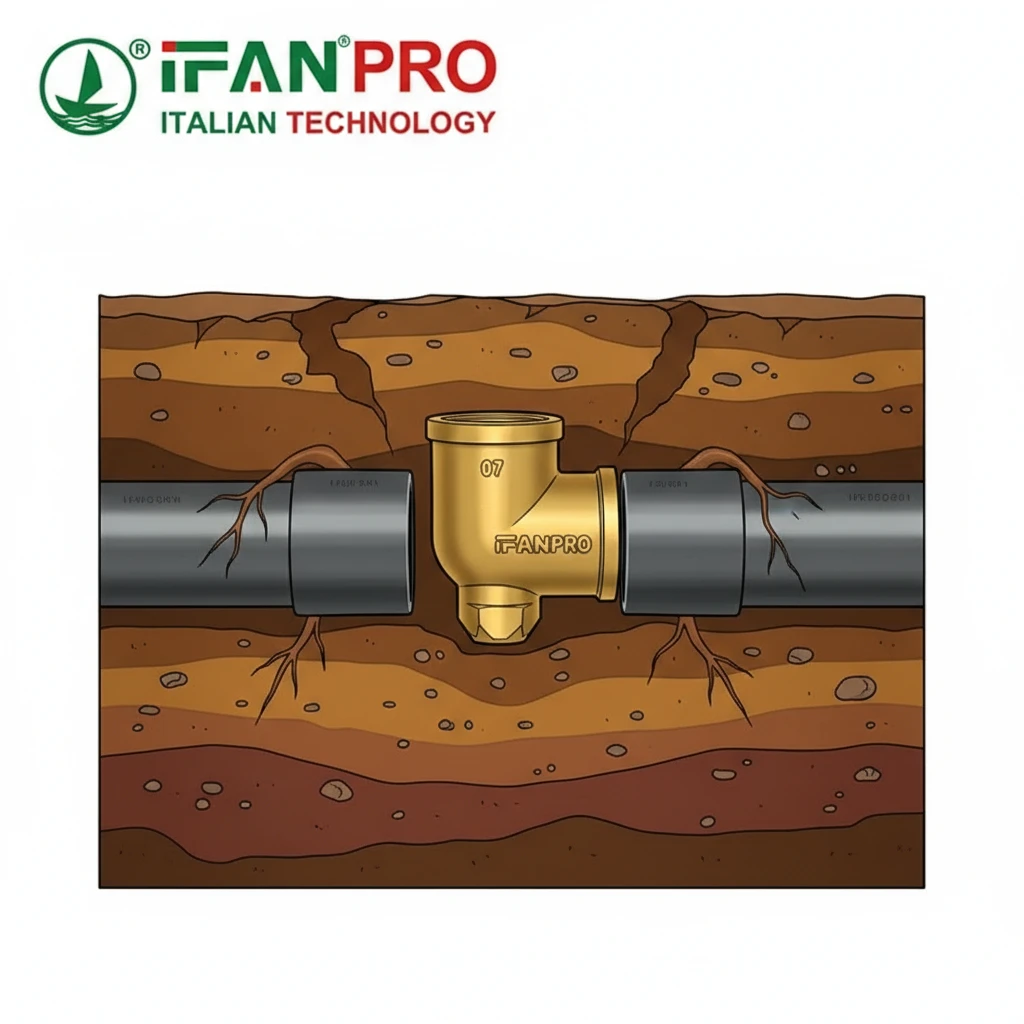

| On mobile equipment, trucks, or vibrating machinery | Brass | Withstands constant shaking and impact. |

| Stationary plant air lines, away from motors | Plastic or Brass | Plastic is often sufficient for stable lines. |

| At compressor discharge or near pulsation dampeners | Brass | Handles the highest pressure spikes and vibrations. |

| For drop lines to tools that are frequently moved/yanked | Brass | Resists cracking from accidental bending or impact. |

| Low-pressure, low-vibration workshop air | Пластик | Cost-effective and acceptable for light duty. |

In essence, brass is the choice for “mission-critical” air connections and any area where reliability under motion is non-negotiable. The slightly higher upfront cost prevents costly downtime, air leaks, and potential safety hazards from failed plastic fittings.

Are There Pressure and Temperature Limits for Brass in Compressed Air Service?

Yes, absolutely. Brass is not indestructible. Exceeding its limits is the fastest way to turn a reliable fitting into a dangerous projectile.

Brass fittings for compressed air have specific pressure and temperature limits, typically set by industry standards like SAE J514 or ISO 7241. Standard brass elbows are commonly rated for working pressures up to 300 PSI (20 BAR) or more, and temperatures from -20°F to 250°F (-30°C to 120°C). You must always check the manufacturer’s rating for the specific fitting.

Understanding Pressure Ratings (PSI/WP)

The pressure rating on a fitting is not a suggestion; it is its maximum safe working pressure. This rating includes a built-in safety factor (often 4:1) over the pressure that would cause burst failure.

- Do not confuse system pressure with compressor pressure. Your compressor might cut out at 150 PSI, but a pressure spike (water hammer) during valve closure can momentarily double that pressure. Always choose fittings rated significantly higher than your compressor’s cut-out pressure.

- Rating depends on size and type. Smaller diameter fittings often have higher pressure ratings than larger ones. A straight adapter may have a different rating than an elbow or tee due to stress concentrations.

Understanding Temperature Limits

Temperature affects brass strength. The two limits matter:

- Low-Temperature Limit: Brass becomes more brittle in extremely cold conditions. If your system is in an unheated environment that drops below the fitting’s rated minimum, impact failure becomes a risk.

- High-Temperature Limit: At elevated temperatures, brass loses tensile strength. If your air discharge is very hot (above 200°F/93°C), or if the line is near a heat source, the fitting’s pressure capability drops.

A Guide to Safe Operation

Follow these rules to stay within safe limits:

1. Know Your System’s Real Numbers:

- What is your compressor’s maximum output pressure?

- What is the highest temperature the air line will experience?

- Add a safety margin of at least 50% to these numbers when selecting fittings.

2. Decode the Fitting Markings:

Look for stamps on the fitting. Reputable manufacturers like IFAN clearly mark the pressure rating (e.g., “300 PSI WP”).

3. Standard Ratings Reference Table:

This table provides a general guideline for standard forged brass fittings. Always verify with your supplier.

| Fitting Type (Standard Forged Brass) | Typical Max Working Pressure | Typical Temperature Range | Key Consideration |

|---|---|---|---|

| Elbows, Tees, Straight Adapters | 300 PSI (20 BAR) | -20°F to 250°F (-30°C to 120°C) | The most common rating for industrial air. |

| Needle Valves, Flow Controls | Often 200-250 PSI | Similar range | Internal mechanisms may have a lower rating. |

| High-Pressure / Hydraulic Brass | Up to 10,000 PSI | Varies | Made from different alloys/processes; do not assume. |

The Golden Rule: If you are unsure, or if your system operates above 200 PSI or 200°F, consult directly with your fittings supplier. Using an under-rated fitting in a compressed air system is a serious safety risk.

Заключение

Brass elbows are a robust, reliable choice for most compressed air systems, especially where vibration and pressure pulses are concerns. For optimal performance, always select fittings with clear pressure ratings. For a full range of DZR brass and high-pressure-rated pneumatic fittings, consider the durable solutions from ИФАН.

Последние комментарии