I once saw a composite system fail at the valve connection. That single point of mismatch caused leaks and corrosion, proving that the valve is the system’s most critical link.

The 121UC valve outperforms standard valves because it is engineered as an integral component of the composite pipe system, not just an add-on. It specifically matches the pipe’s thermal expansion, uses compatible materials to prevent corrosion, and is designed to maintain the continuous oxygen barrier, eliminating the weak points that standard valves create.

This specialized design solves the unique challenges of multilayer composite systems. Let’s examine exactly how it achieves this superior performance.

How Are Its Thermal Expansion Characteristics Matched to the Composite Pipe?

A mismatched valve can stress the entire system. We’ve seen standard valves cause joint failures after just a few heating cycles.

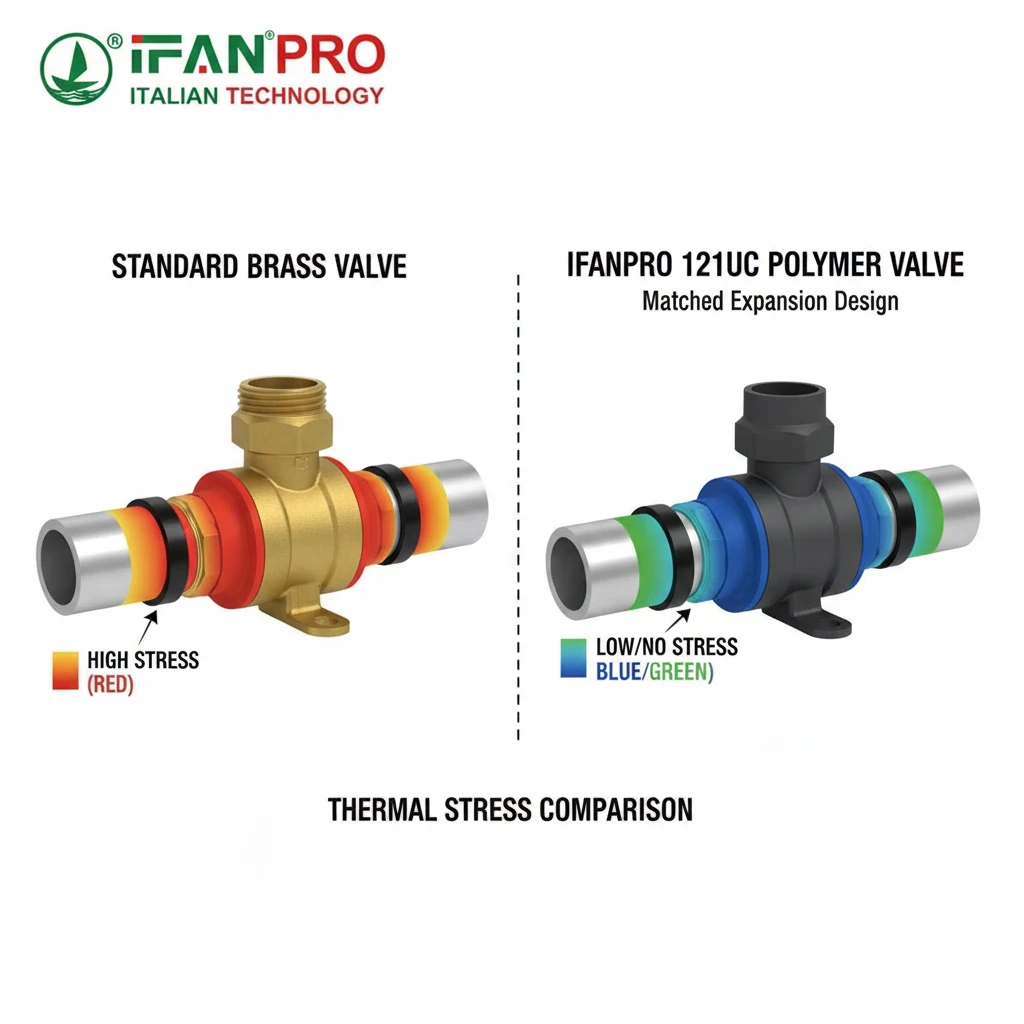

The 121UC valve’s thermal expansion characteristics are matched to the composite pipe by being manufactured from the same polymer family (like PP-R or PEX) as the pipe’s inner and outer layers. This ensures that when the system heats and cools, the valve and pipe expand and contract at nearly the same rate, preventing stress, gaps, or leaks at the connection.

Understanding the “Thermal Movement” Problem

All materials expand when heated and contract when cooled. Different materials do this at different rates, called the Coefficient of Thermal Expansion (CTE). In a composite pipe system, the aluminum layer provides strength but expands much less than the plastic layers.

When you connect a standard valve—often made from brass or a different plastic—to this composite pipe, you create a problem. During heating, the pipe and the valve try to expand by different amounts. This creates pulling and pushing forces at the joint.

How the 121UC Valve Solves It

The 121UC valve is designed from the ground up to move with the pipe. First, its body is made from a polymer that is identical or very similar to the pipe’s plastic. Because they are from the same material family, their expansion rates are a close match.

Second, the valve’s connection method is crucial. It typically uses a heat-fusion or a compression system designed for that specific composite pipe. This creates a unified joint that can handle the movement as a single unit.

Think of it like a bridge. If the bridge and the road are made of the same material, they flex together with temperature changes. If the bridge is steel and the road is concrete, they flex differently, causing cracks at the connection point. The 121UC valve is like a bridge made from the same material as the road.

The Result of a Mismatch

If the expansion is not matched, two things happen:

- Stress Buildup: Constant pushing and pulling creates mechanical stress.

- Seal Failure: Over many heating/cooling cycles, this stress can crack the pipe, loosen fittings, or cause the seal to fail, leading to leaks.

The 121UC valve, by matching the expansion, makes the joint as reliable as the pipe itself.

Why Do Its Materials Prevent Galvanic Corrosion with the Aluminum Layer?

Galvanic corrosion is a silent system killer. We’ve found corroded fittings that looked fine from the outside but were failing inside.

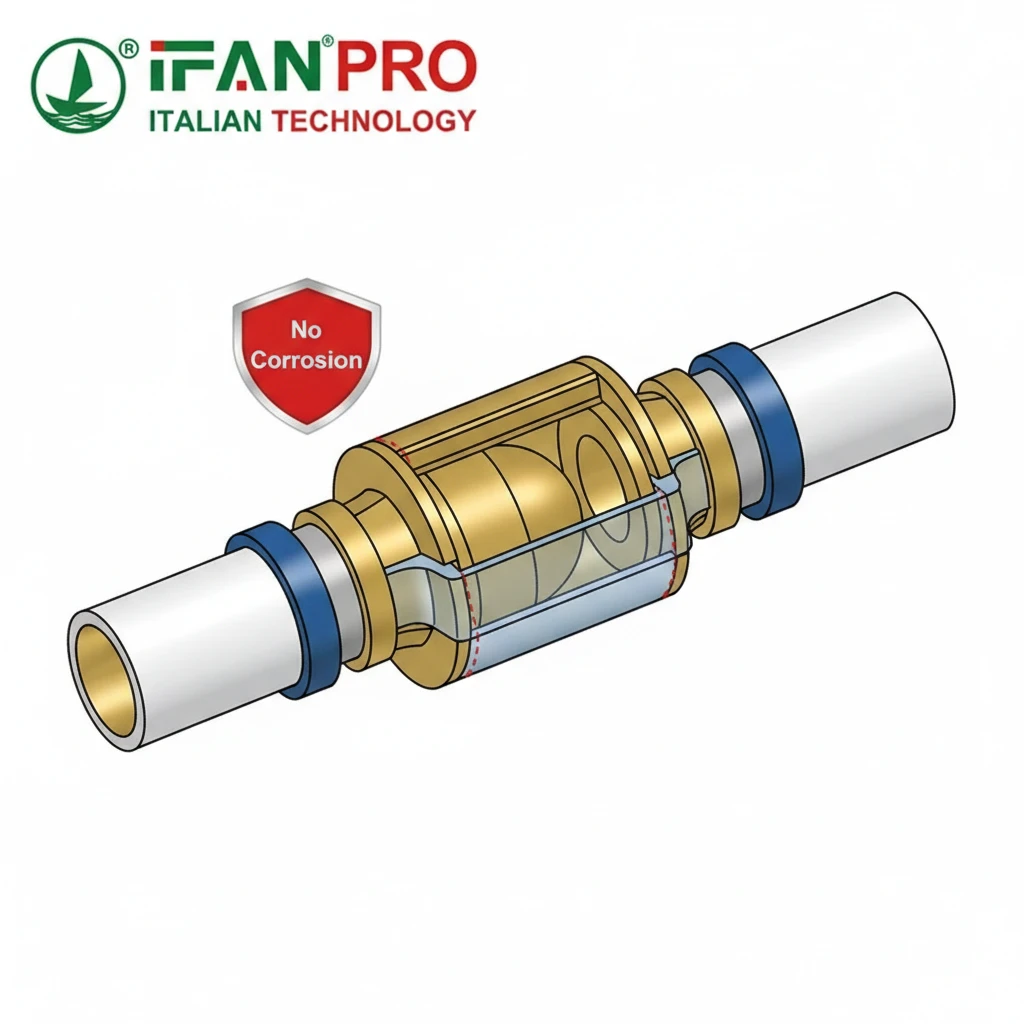

The 121UC valve’s materials prevent galvanic corrosion because they are either non-metallic (polymeric) or use a specially insulated metallic insert that is electrochemically isolated from the pipe’s aluminum layer. This breaks the electrical circuit needed for corrosive electro-chemical reactions to occur.

What is Galvanic Corrosion?

Galvanic corrosion is a chemical reaction that happens when two different metals are connected in the presence of an electrolyte (like water). It works like a tiny battery. One metal (the less “noble” one, like aluminum) becomes the anode and corrodes, sacrificing itself to protect the other metal.

In a composite pipe, the aluminum layer is vulnerable. If a standard brass valve touches this aluminum directly through the water or a metal fitting, it creates a perfect environment for galvanic corrosion. The aluminum layer slowly degrades, weakening the pipe’s structure and integrity.

The 121UC Design Solution

The 121UC valve addresses this in one of two smart ways:

1. The All-Polymer Valve Body: Many 121UC valves have a body made entirely of high-performance plastic. No metal touches the water stream or the pipe’s aluminum layer. This completely eliminates the possibility of metal-to-metal galvanic corrosion.

2. The Insulated Metal Insert Design: Some designs include a metallic part (like a brass stem) for strength. However, this metal is fully encapsulated or “plastic-jacketed.” The plastic body of the valve sits between the metal insert and the pipe’s aluminum, providing a permanent insulating barrier. The electrical circuit is never completed.

Material Compatibility in Practice

It’s not just about the valve body. Every component is considered. The sealing rings (often EPDM) and any retaining clips are also non-metallic and inert. This holistic material selection ensures long-term chemical stability within the system.

| Component in Standard Valve | Corrosion Risk with Aluminum Pipe | 121UC Valve Solution |

|---|---|---|

| Valve Body (e.g., Brass) | High – Direct galvanic couple. | Uses a polymer body or insulated insert. |

| Internal Stem/Metal Parts | High – Contact with water stream. | Encapsulated or made from coated, compatible alloys. |

| Seals & Gaskets | Can hold electrolyte, enabling corrosion. | Made from inert, non-conductive polymers like EPDM. |

By systematically removing the conditions for galvanic corrosion, the 121UC valve protects the most critical part of the composite pipe: its aluminum core.

How Does Its Design Maintain Oxygen Barrier Continuity at the Connection?

The oxygen barrier is what protects the entire heating system from corrosion. A leak here has costly consequences.

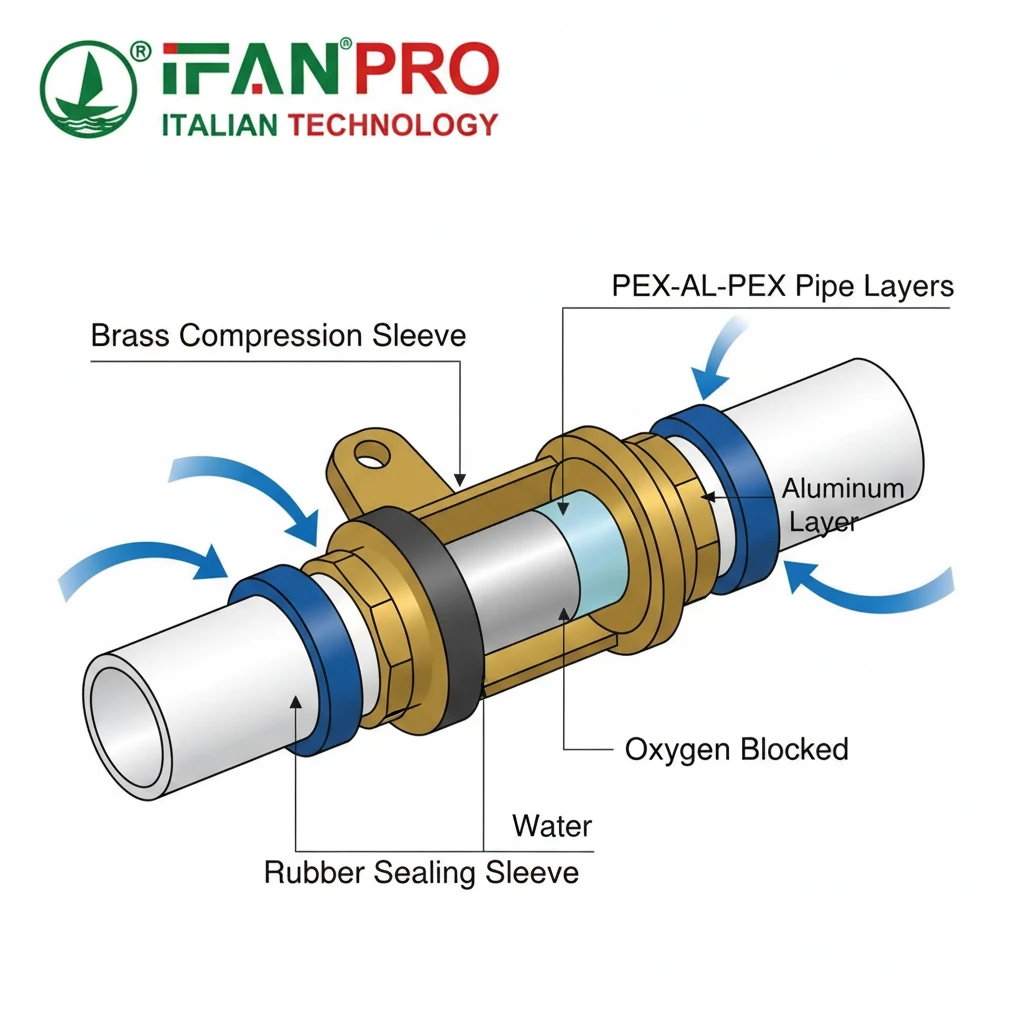

The 121UC valve maintains oxygen barrier continuity through a specially designed compression sleeve or fusion zone that fully encapsulates the pipe’s end, including the trimmed aluminum layer. This creates a hermetic seal that restores the complete diffusion barrier right up to the valve mechanism, preventing oxygen from entering the water circuit.

The Role of the Oxygen Barrier

Composite pipes for heating systems have an aluminum layer that acts as an oxygen barrier. Oxygen in the water causes rapid corrosion of ferrous components in the system like radiators, pumps, and boilers. The aluminum layer is excellent at blocking oxygen diffusion—but only if it’s continuous.

The problem arises at connections. When you cut the pipe to install a valve, you expose the raw edge of the aluminum layer. A standard valve fitting simply clamps around the outside of the pipe. Microscopic gaps can allow oxygen to seep in through this exposed edge, defeating the purpose of the barrier.

The 121UC Connection Method

The 121UC valve uses a connection technology designed specifically for this challenge. The process typically involves a precision tool.

- Preparation: The pipe end is trimmed square. A special tool is used to slightly expand the end of the pipe.

- Encapsulation: The valve has a built-in sealing sleeve. When the prepared pipe is inserted into the valve and the fitting is tightened (or fused), this sleeve deforms and flows.

- Creating Continuity: The sealing material presses tightly against the inside of the pipe’s polymer layer and around the cut edge of the aluminum, completely encapsulating it. This forms a new, seamless plastic layer over the exposed aluminum edge.

The result is a connection where the oxygen barrier is not just clamped, but reconstituted. The path for oxygen diffusion is completely blocked.

Why This Matters for System Longevity

Even small amounts of oxygen ingress over years can cause significant damage. Sludge builds up in radiators, pumps seize, and heat exchangers fail. By ensuring every valve connection maintains the barrier, the 121UC design protects the entire system’s investment, not just the pipe.

What Performance Gaps Appear When Using a Standard Valve in a 121UC System?

Using the wrong valve risks the whole system. We’ve been called to fix the expensive results of this common mistake.

Using a standard valve in a 121UC system creates critical performance gaps: it introduces a point of differential thermal stress, risks galvanic corrosion of the aluminum layer, breaches the oxygen diffusion barrier, and often fails to provide a mechanically secure, long-term connection designed for the composite pipe’s unique structure.

A Summary of the Failure Points

A standard valve is a generic component. A 121UC system is a precision-engineered assembly. Mixing them creates multiple mismatches that lead to system degradation.

Let’s break down the specific gaps:

1. The Thermal Stress Gap: The standard valve (brass or generic plastic) expands differently than the composite pipe. This constant stress cycling weakens the connection over time, leading to a higher risk of leaks, especially under varying temperatures.

2. The Corrosion Gap: As discussed, metal parts in a standard valve can create a galvanic cell with the aluminum layer. This leads to the hidden, progressive corrosion of the pipe’s core, potentially causing premature pipe failure without external warning signs.

3. The Oxygen Barrier Gap: A standard compression fitting does not encapsulate the cut aluminum edge. Oxygen can permeate through microscopic paths at this junction, leading to systemic corrosion of boilers, pumps, and radiators, reducing efficiency and causing breakdowns.

4. The Mechanical Connection Gap: The connection profile of a standard valve is not optimized for the specific dimensions and material behavior of the composite pipe. This can lead to poor grip, seal relaxation over time, or even cracking of the pipe under stress.

Real-World Consequences and Costs

These gaps don’t just cause a single leak. They lead to systemic failure. The costs are not just in repairs, but in energy inefficiency and component replacement.

| Performance Aspect | With Standard Valve | With 121UC Valve | Consequence of the Gap |

|---|---|---|---|

| Long-Term Seal Integrity | Compromised by thermal cycling stress. | Maintained by matched expansion. | Risk of leaks, water damage. |

| Pipe Core Integrity | Aluminum layer vulnerable to corrosion. | Aluminum layer fully protected. | Hidden pipe degradation, burst risk. |

| System Water Purity | Oxygen ingress leads to system corrosion. | Oxygen barrier remains continuous. | Sludge, pump/boiler failure, low efficiency. |

| Total System Lifetime | Significantly reduced (may be 10-15 years). | Matches the pipe’s lifespan (50+ years). | Early, costly full system replacement. |

In short, using a standard valve negates the key engineered benefits of the composite 121UC system, turning a premium installation into a vulnerable one.

Заключение

The 121UC valve is essential for composite system performance, sealing thermal, corrosive, and oxygen barriers. For guaranteed compatibility, always pair your system with IFAN’s engineered 121UC valves.

Последние комментарии