I recently visited a site where a poorly chosen manifold fitting failed, causing a costly system shutdown. This moment cemented my belief in selecting the right component, like a brass cross, for critical HVAC distribution points.

Yes, brass cross fittings are highly suitable and commonly used for heating and cooling manifolds. They are ideal because brass withstands repeated temperature cycles without degrading, and the cross design provides a compact, central point to efficiently distribute multiple fluid lines from a single source within a confined manifold assembly.

Let’s examine why brass cross fittings are a top choice for HVAC professionals and manifold builders.

Why is Brass Ideal for the Temperature Cycles in HVAC Manifold Systems?

HVAC systems constantly cycle between hot and cold. I’ve seen plastic fittings crack and other metals corrode under this stress, but brass consistently endures.

Brass is ideal for HVAC temperature cycles because it has excellent thermal conductivity, which helps prevent localized hot spots, and it expands and contracts uniformly with temperature changes. This prevents stress fractures. Its natural resistance to corrosion from water and common antifreeze solutions also ensures long-term reliability in wet, cycling environments.

The Challenge of Thermal Cycling

HVAC manifolds are at the heart of system control, constantly managing the flow of hot water for heating and chilled water for cooling. This means the materials used must handle repeated heating and cooling without failing. This process is called thermal cycling, and it can cause many materials to weaken, crack, or corrode over time.

Brass performs exceptionally well here for several key reasons. First, brass is a metal alloy primarily made of copper and zinc. This gives it a natural ability to transfer heat quickly and evenly. When hot water flows through a brass fitting, the heat spreads out across the entire component. This prevents one area from becoming much hotter than another, which is a common cause of material fatigue and failure.

Material Strength and Flexibility

Second, brass has a good balance of strength and malleability. It is strong enough to hold pressure but can also flex slightly. When the temperature changes, all materials expand when hot and contract when cold. Brass does this in a very predictable and even way. Because it expands uniformly, it does not create high internal stresses that can lead to cracks. This is a major advantage over some plastics, which can become brittle with heat cycles, or over cast iron, which is more brittle.

Resistance to Corrosion

Third, and very importantly, brass is highly resistant to corrosion from water and standard HVAC fluids like glycol mixes. Corrosion is a chemical reaction that eats away at metal. In a manifold, you have water, oxygen, and sometimes different minerals or chemicals. Brass forms a protective surface layer that slows down this reaction significantly. This means the fitting won’t rust or develop pinhole leaks from the inside out, which is a critical failure point in systems using plain steel.

Comparison of Manifold Fitting Materials

The table below shows how brass compares to other common materials in an HVAC cycling environment.

| Материал | Performance in Thermal Cycling | Main Risk in HVAC Manifolds |

|---|---|---|

| Brass | Excellent | Very low risk of cracking or corrosion; most reliable. |

| Stainless Steel | Very Good | Can be susceptible to certain types of corrosion in chlorinated water. |

| Plastic (PPSU/PVDF) | Good | Can creep or deform under constant heat and pressure over time. |

| Malleable Iron | Fair | Prone to rust if the coating is damaged; can crack under shock. |

For a system builder, using brass means you are installing a component that is designed to last as long as the system itself. You avoid callbacks for leaks and repairs, saving time and protecting your reputation. The initial cost is often higher than plastic, but the total cost of ownership is lower due to its durability.

How Does a Cross Fitting Function as a Compact Distribution Point in Manifolds?

Space inside mechanical rooms is always tight. A brass cross fitting lets me design a clean, efficient manifold in a much smaller footprint than using multiple tees and elbows.

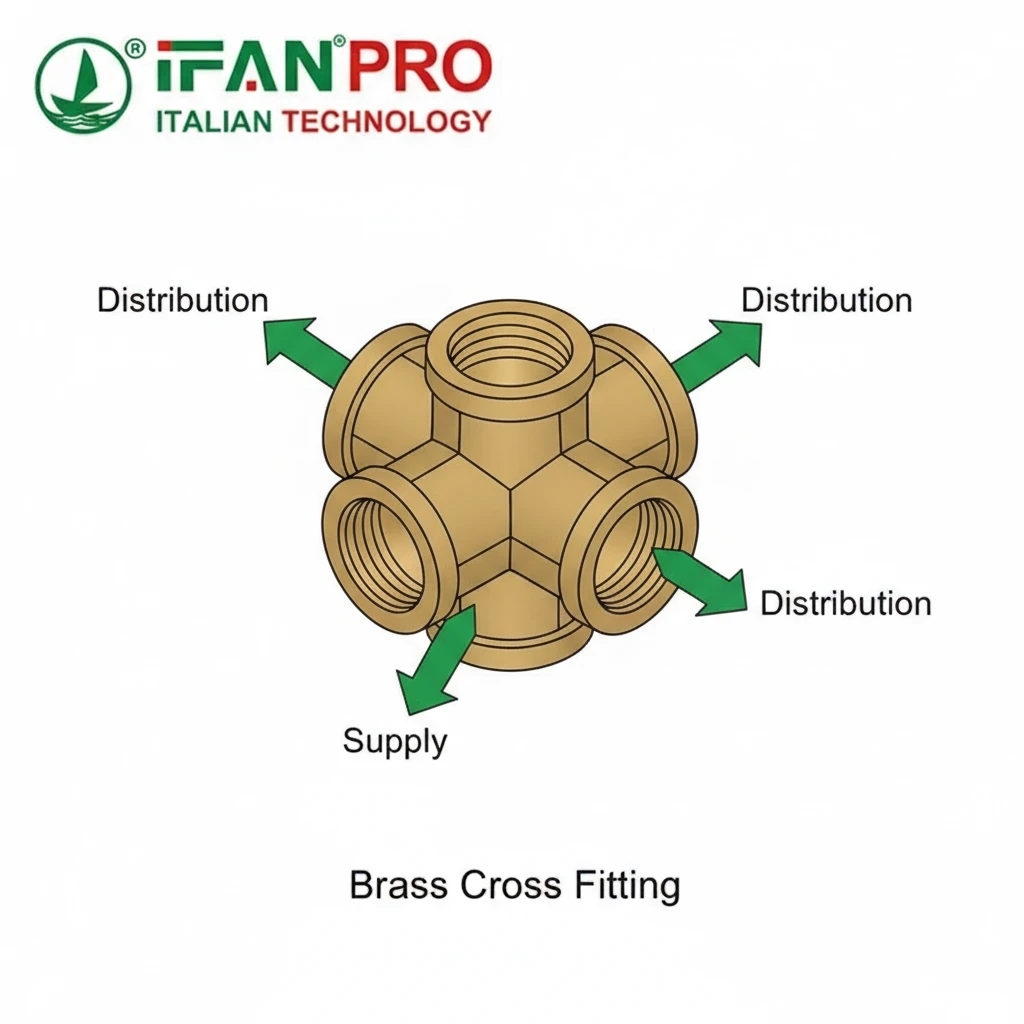

A cross fitting functions as a compact distribution point by providing four equal outlets arranged at 90-degree angles from a central hub. This allows one main supply line to be split into three distribution lines (or vice-versa) in a single, space-saving component, simplifying manifold design and reducing potential leak points compared to assembling the same function with multiple separate fittings.

The Anatomy of a Distribution Hub

To understand its function, picture a standard “plus” sign (+) or the letter “X”. A cross fitting has one inlet on one side and three outlets on the other three sides. In a heating or cooling manifold, the primary goal is to take water from a single source, like a boiler or chiller pump, and send it evenly to several different zones or circuits in a building.

Without a cross, you would need to use a combination of tees (T-shapes) and elbows, connected with short pieces of pipe. This assembly would take up more space, require more joints, and look more complicated. Each joint is a potential place for a leak to develop. The cross fitting consolidates this entire distribution function into one single, clean piece.

Benefits in Manifold Design

The compact nature of the cross is its biggest advantage for builders. Manifolds are often mounted on walls or placed in tight utility closets. Using a cross fitting reduces the overall length and width of the assembled manifold block. This makes the installation neater and often allows it to fit where a larger assembly would not.

Furthermore, using a single cross improves hydraulic efficiency. The internal water path is more direct and streamlined compared to a circuitous route made of several fittings. This can help maintain better flow and more consistent pressure to each branch line. For system performance, this means more balanced heating or cooling across all zones.

Manifold Assembly Comparison

The table below contrasts two ways to build a 4-zone distribution point.

| Design Aspect | Using a Single Brass Cross | Using Multiple Tees & Elbows |

|---|---|---|

| Number of Fittings | 1 | 3 or more |

| Number of Solder/Joint Points | 4 | 6 or more |

| Overall Assembly Size | Compact, minimal | Larger, more spread out |

| Assembly Complexity | Simple, one step | Complex, multiple alignments |

| Potential Leak Points | Lower | Higher |

From an installation perspective, a cross is simpler. You align one fitting instead of three. You solder or thread four connections instead of six or more. This saves labor time and reduces the chance of making an error during assembly. For maintenance, a manifold built with crosses is also easier to understand and service because the flow paths are clearer and more logical.

Can it Handle Both Hot and Cold Water Within the Same Assembly?

Clients often ask if they need separate systems. A properly specified brass cross simplifies dual-temperature systems, as I’ve used them in many combo heating/cooling installations.

Yes, a standard brass cross fitting can easily handle both hot and cold water within the same assembly. Brass maintains its strength and corrosion resistance across the typical temperature range of HVAC systems (from near-freezing chilled water up to high-temperature heating water). This makes it a versatile, universal component for mixed-service and changeover manifolds.

Understanding the Operating Range

A common requirement in modern buildings is a four-pipe system or a changeover system that provides both heating and cooling through the same terminal units (like fan coils). The manifold is the central switchboard that directs either hot or cold water to these units. Therefore, the fittings in this manifold must be able to see both extremes of temperature, sometimes in rapid succession.

Brass is perfectly suited for this role. Its mechanical properties do not significantly change within the standard HVAC operating range. Whether the water inside is 45°F (7°C) from a chiller or 180°F (82°C) from a boiler, the brass fitting performs reliably. It will not become brittle in the cold or soften and deform under sustained heat like some plastics might.

Material Stability is Key

The key factor here is material stability. Brass does not undergo any phase changes or significant weakening within these temperatures. Its excellent thermal conductivity, which we discussed earlier, also helps in this mixed-service environment. It allows the fitting to quickly adapt to temperature changes without holding onto thermal stress. This rapid equalization is good for the longevity of the fitting and the seals within any attached valves.

Addressing Condensation Concerns

One important consideration in mixed systems is condensation. When chilled water runs through pipes in a warm, humid room, moisture from the air can condense on the outside of the pipes and fittings. This is called “sweating.” If a fitting corrodes easily, this constant moisture will cause it to rust.

This is another area where brass shines. Its high corrosion resistance means that occasional condensation on the outside of the fitting will not cause it to rust or degrade. For extra protection in very humid environments, the manifold can be insulated, but the brass itself is not a weak point.

Temperature Range Suitability

| System Type | Typical Fluid Temperature | Brass Cross Suitability |

|---|---|---|

| Chilled Water Cooling | 40°F – 55°F (4°C – 13°C) | Excellent. No risk of brittleness. |

| Standard Hydronic Heating | 120°F – 180°F (49°C – 82°C) | Excellent. Maintains full strength. |

| High-Temp Heating | Up to 220°F (104°C) | Excellent. Standard brass handles this range. |

| Mixed / Changeover Systems | Alternating between above ranges | Ideal. Designed for this exact duty cycle. |

Using a single type of fitting—brass crosses—for the entire manifold, regardless of the water temperature, simplifies inventory for builders and reduces the risk of installing the wrong component. It provides a future-proof design, allowing system settings to be changed without worrying about the integrity of the distribution block.

What are the Installation Benefits for Manifold Builders Using Brass Crosses?

Time is money on the job site. I consistently find that prefabricating manifold sections with brass crosses cuts total installation time significantly.

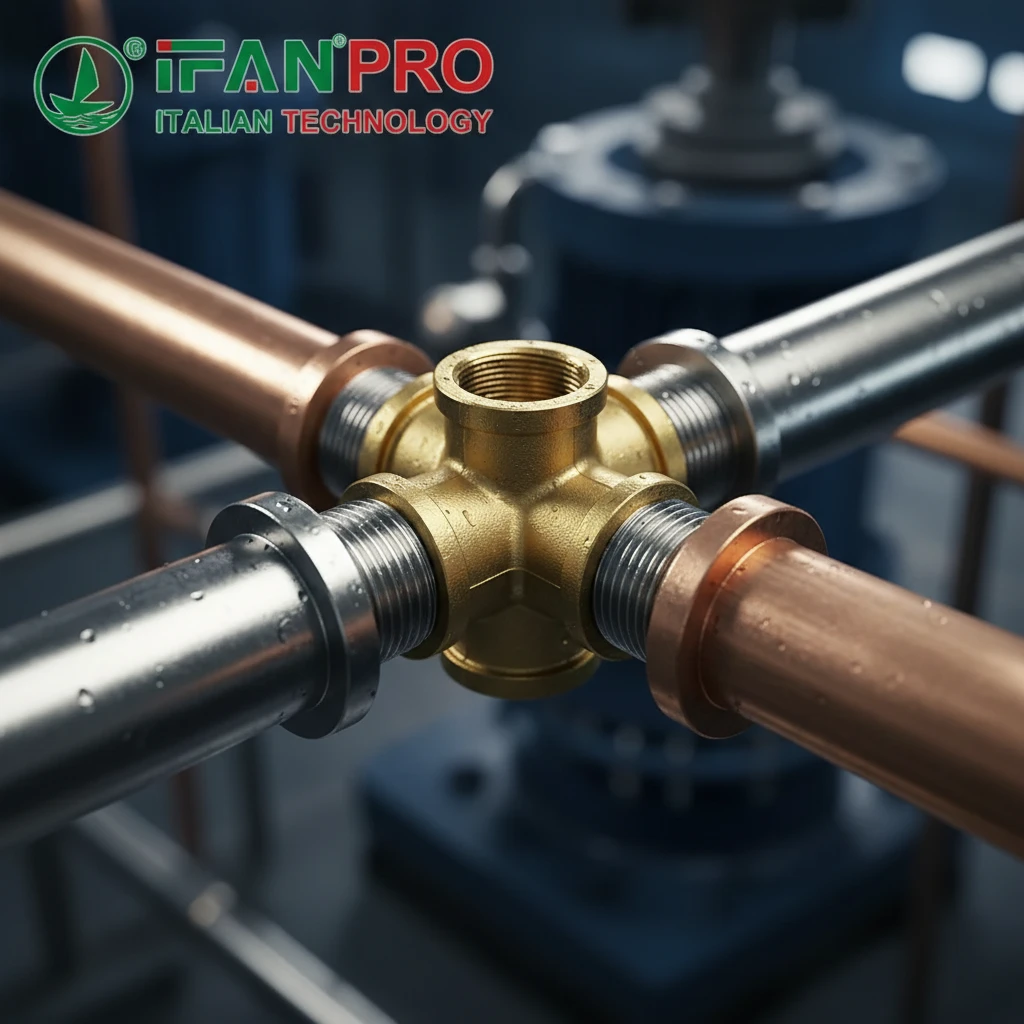

The main installation benefits for builders are speed, consistency, and reliability. Brass crosses allow for clean, repeatable manifold layouts. They are easy to solder or thread, providing strong, leak-free joints on the first try. This reduces assembly time, minimizes errors, and results in a professional-looking, durable product that installers can trust.

Streamlining the Fabrication Process

For a professional who builds manifolds regularly, efficiency and predictability are crucial. Brass cross fittings directly contribute to both. Their symmetrical, standardized design means that once a builder creates a jig or template for a specific manifold layout, they can reproduce it perfectly every time. This is much harder to do when cobbling together a layout from multiple different elbows and tees.

The installation benefits start with preparation. Brass is a joy to work with for both soldering and threading. For soldered joints, brass cleans easily and accepts flux and solder uniformly, creating a smooth, strong capillary joint. The metal heats evenly, which prevents cold solder joints—a common defect that leads to leaks. For threaded systems, brass machines cleanly and allows for precise engagement without galling or seizing, which can happen with steel.

Reducing Errors and Callbacks

Every joint in a plumbing system is a potential failure point. A significant advantage of using a brass cross is that it reduces the total number of joints. As shown in the earlier table, one cross replaces multiple tees and elbows. Fewer joints mean less time spent assembling and, most importantly, a statistically lower chance of having a leak. This directly translates to fewer costly and embarrassing callbacks to fix leaks after the system is pressurized.

Furthermore, the robust nature of the soldered or threaded joint on brass gives the installer confidence. They know that once the joint is properly made, it is permanent and reliable. This allows them to pressure-test the manifold and move on to the next task without worry.

Comparison of Builder Workflow

| Task | Using Brass Crosses | Using Multiple Fittings |

|---|---|---|

| Layout Planning | Simple, standardized. | Complex, requires more measurement. |

| Fitting Prep | Clean/solder 1 fitting. | Clean/solder 3+ fittings. |

| Alignment During Assembly | Easy (one center point). | Difficult (multiple points to align). |

| Pressure Test Confidence | High (fewer joints). | Lower (more potential leak points). |

| Professional Appearance | Clean, symmetrical, expert look. | Busy, cluttered, amateur look. |

Finally, the finished product simply looks more professional. A manifold built with brass crosses is neat, symmetrical, and clearly shows a high level of craftsmanship. This builds trust with the building owner or general contractor. It signals that attention to detail was paid in the mechanical room, which suggests the entire system was installed with care. For the builder, this enhances their reputation and can lead to more business through referrals.

Заключение

Brass cross fittings are a durable, versatile, and installer-friendly solution for efficient HVAC manifolds. For reliable, high-quality brass cross fittings and manifold components, choose ИФАН for your next project.

Последние комментарии