I once had a client facing constant leaks in a harsh water environment. We switched the failing components to brass adapters, and the problems stopped. This experience solidified my trust in this classic material.

You should choose brass for adapters because it offers an unmatched balance of strength, corrosion resistance, and machinability. It naturally withstands wet, high-pressure conditions, resists dezincification and cracking, and maintains reliable performance for decades, making it a cost-effective long-term solution for critical connections.

Let’s explore the specific properties that make brass the top choice for durable and corrosion-resistant adapters.

What Makes Brass Ideal for Wet and High-Pressure Plumbing Environments?

Wet and high-pressure systems test every component. I’ve seen inferior materials fail here, but brass consistently holds strong.

Brass is ideal for wet and high-pressure environments because it is a strong, non-sparking metal that resists water corrosion and can handle significant system pressure without deforming. Its excellent machinability allows for precise threading and sealing surfaces, ensuring leak-proof connections that last.

The Strength to Handle Pressure

Plumbing systems, especially in commercial or industrial settings, operate under constant pressure. Adapters are connection points that must be as strong as the pipes themselves. Brass provides this necessary strength. It is a malleable yet tough alloy, meaning it can withstand high internal water pressure without cracking or splitting. This durability is crucial for preventing catastrophic failures and leaks.

Furthermore, brass adapters maintain their shape and seal under repeated pressure cycles. Unlike some plastics that can creep or deform over time, brass provides a stable, reliable connection that you can install and forget.

Perfect for Wet Conditions

Water is the primary enemy of many metals, but not brass. Its natural resistance to corrosion from water, including hot water, is a key advantage. Additionally, brass is resistant to “water hammer,” the sudden pressure surges that can occur when valves close quickly. The material’s density and strength help absorb these shocks, protecting the wider system.

Superior Machining for Perfect Seals

Perhaps one of brass’s greatest practical benefits is how easy it is to machine. This allows manufacturers to create adapters with perfectly cut, sharp threads and smooth sealing faces. These precise manufacturing traits are what enable plumbers to create a perfect, leak-free seal with thread tape or compound. A poorly machined adapter will leak no matter how carefully it’s installed; brass’s machinability virtually eliminates this problem.

| Недвижимость | Why It Matters for Wet/High-Pressure Environments |

|---|---|

| High Strength | Withstands internal system pressure without bursting or deforming. |

| Устойчивость к коррозии | Does not rust or degrade when constantly exposed to water. |

| Excellent Machinability | Allows for precise threads and faces for guaranteed leak-free seals. |

| Malleability | Can absorb some pressure shock (water hammer) without failing. |

How Does Brass Naturally Resist Corrosion Compared to Other Metals?

Corrosion is a silent system killer. In my audits, I find corroded fittings are the root cause of most leaks in old systems using lesser metals.

Brass naturally resists corrosion because it forms a protective patina layer on its surface when exposed to air and water. This layer acts as a shield, preventing further oxidation. Unlike iron that rusts or steel that can pit, brass corrodes very slowly and uniformly, maintaining its structural integrity much longer.

The Protective Patina

The secret to brass’s corrosion resistance lies in its copper content. When brass is exposed to oxygen and moisture, it undergoes a controlled oxidation process. Instead of flaking away like rust, it forms a thin, adherent layer called a patina. This patina, often a greenish or brownish film, is stable and tightly bonded to the underlying metal. It effectively seals the surface, dramatically slowing down any further corrosion. This is a self-protecting mechanism that metals like plain steel do not possess.

Resistance to Specific Corrosion Types

Brass excels at resisting several common and destructive types of corrosion that plague other metals in plumbing:

- Galvanic Corrosion: This occurs when two dissimilar metals are in contact in an electrolyte (like water). While brass can be involved in galvanic couples, choosing the right brass alloy and using dielectric unions can manage this risk effectively. It is far less prone than, for example, aluminum.

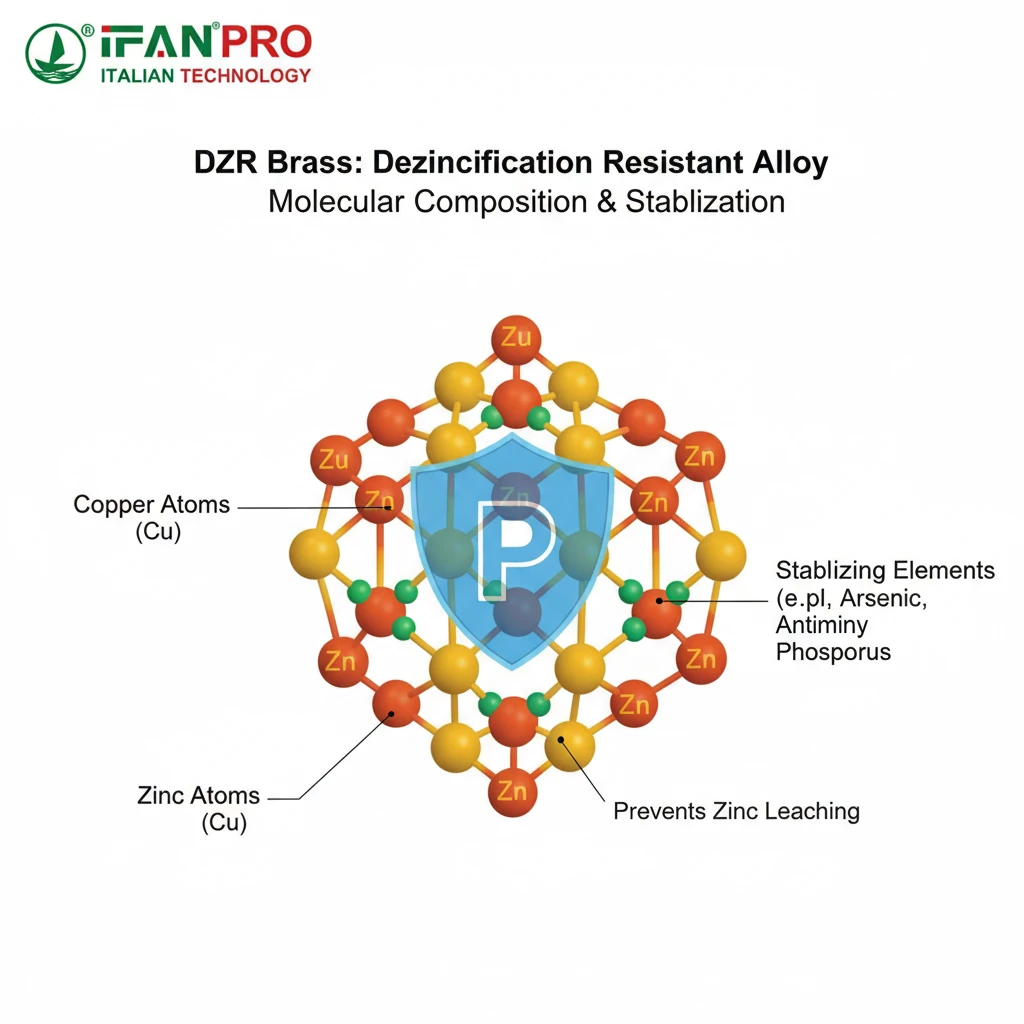

- Dezincification: This is a potential issue for brass, where zinc leaches out, leaving a porous, weak copper structure. However, modern dezincification-resistant (DZR or DR) brass alloys are specifically formulated to prevent this, making them ideal for potable water systems.

- Stress Corrosion Cracking: Some metals crack under combined stress and corrosive environments. Certain brass alloys are susceptible, but again, proper alloy selection (like using Admiralty brass) mitigates this risk for most plumbing applications.

Comparison with Common Plumbing Metals

| Metal | Corrosion Mechanism | Result in Plumbing |

|---|---|---|

| Carbon Steel | Rusts (iron oxide). Forms flaky, expansive scale that weakens the metal and blocks pipes. | Poor; requires coatings/galvanization. |

| Copper | Forms a protective green patina (verdigris). Corrodes in acidic water. | Very Good, but can be costly and soft. |

| Brass | Forms a stable, protective patina. Resists corrosion from water and many chemicals. | Excellent, especially with modern DZR alloys. |

| Stainless Steel | Forms a passive chromium oxide layer. Highly resistant but can pit in chloride-rich water. | Excellent, but more expensive and harder to machine. |

Why is Brass Known for Its Long-Term Durability and Reliability?

Clients want to install a system once. I recommend brass for critical connections because history has proven its decades of reliable service.

Brass is known for long-term durability and reliability because it combines metal strength with corrosion resistance, suffers minimal fatigue from thermal cycles, and maintains its sealing properties over time. A properly installed brass fitting often outlasts the building system it serves.

The Combination of Key Properties

Durability isn’t just about one thing; it’s about how multiple properties work together over time. Brass offers this synergy:

- Inherent Strength: It doesn’t become brittle with age like old plastic or crack from minor impacts.

- Corrosion Resistance: As discussed, its slow, uniform corrosion preserves wall thickness and strength for decades.

- Thermal Stability: Brass handles thermal expansion and contraction from hot/cold water cycles very well. It doesn’t fatigue and crack from these constant changes as readily as some materials.

This combination means a brass adapter maintains its shape, its seal, and its function under the daily stresses of a plumbing system for an exceptionally long time.

Reliability in Sealing

The reliability of a fitting comes down to its ability to not leak. Brass’s machinability ensures perfect initial threads. Its resistance to deformation ensures those threads don’t warp under pressure. Its corrosion resistance ensures the threads don’t degrade into a leaking mess over 20 years. This long-term sealing reliability is why brass is specified in so many commercial and institutional buildings where access for repairs is difficult and costly.

A Proven Track Record

There is perhaps no stronger argument than proven performance. Brass has been used in plumbing for over a century. Many buildings still have original brass fittings and valves in service after 50, 70, or even 100 years. This historical evidence provides a level of confidence that newer materials cannot yet match. When you choose brass, you are choosing a solution with a documented, successful history of long-term performance.

Are There Specific Brass Alloys Used for Superior Corrosion Resistance?

Not all brass is the same. Specifying the wrong alloy for a job is a common mistake I help clients avoid in their sourcing.

Yes, specific brass alloys are engineered for superior corrosion resistance. Dezincification-Resistant (DZR/DR) brass, like the UNS C37700 or C38500 series, is critical for potable water. Naval brass and Admiralty brass offer enhanced resistance to saltwater corrosion, making them ideal for marine applications.

Understanding Alloy Composition

Brass is an alloy primarily of copper (Cu) and zinc (Zn). By changing the percentages and adding small amounts of other elements, manufacturers can dramatically alter its properties. This is why alloy specification is so important for corrosion resistance.

Key Alloys and Their Applications

| Alloy Name (Common Examples) | Key Composition | Best For | Corrosion Resistance Feature |

|---|---|---|---|

| DZR Brass (DR Brass) | CuZn with added As, Sb, or P. | Potable Water Systems, heating systems. | Specifically resists dezincification, the main failure mode in water. |

| Naval Brass | CuZn with ~1% Sn. | Marine hardware, pump shafts, valve stems. | Tin addition greatly improves resistance to saltwater corrosion. |

| Admiralty Brass | CuZn with ~1% Sn and trace As/Sb. | Condenser tubes, heat exchangers. | Superior resistance to both corrosion and biofouling in water. |

| Free-Cutting Brass (C36000) | High Zn with Pb for machinability. | General fittings, valves, fixtures. | Good general corrosion resistance; easiest to machine. Not for potable water. |

How to Choose the Right Alloy

For most residential and commercial plumbing applications involving drinking water, Dezincification-Resistant (DZR) brass is the mandatory and correct choice. It is often certified to standards like EN 1254 (in Europe) or NSF/ANSI 61 for drinking water. Always check the material specification on supplier documentation.

For applications in coastal areas, on boats, or in any environment exposed to salt spray or brackish water, Naval Brass or Admiralty Brass should be specified. The small addition of tin is what provides the extra defense against aggressive salts.

The common “free-cutting brass” (C36000) is excellent for machining and is fine for decorative or non-critical mechanical parts, but its lead content makes it unsuitable for potable water contact. Knowing this difference is crucial for safety and compliance.

Заключение

For adapters that last, resist corrosion, and ensure reliable connections, brass is the proven choice. For a full range of certified, high-performance brass fittings and adapters, trust ИФАН to supply the right alloy for your specific application.

Последние комментарии