I once saw a batch of product ruined because a valve couldn’t maintain a steady flow. That moment proved to me that precision is not a luxury; it’s a necessity for modern industry.

Precise flow control with smart valves is crucial because it directly determines the quality, efficiency, and safety of industrial processes. It ensures consistent product quality, enables accurate batching, minimizes waste of resources, and protects expensive downstream equipment from damage. In short, it is the foundation of reliable and profitable automation.

Now, let’s examine the specific reasons why precision in flow control matters so much across different applications.

How Does Precise Control Improve Process Quality and Consistency?

Inconsistent flow leads to inconsistent products. I’ve worked with clients who struggled with quality variations until they focused on valve precision.

Precise control improves process quality and consistency by maintaining exact flow rates and mixture ratios. This ensures every product unit meets the same high standards, eliminates rejects caused by flow fluctuations, and provides reliable, repeatable results batch after batch. It turns a variable process into a stable one.

The Direct Link Between Flow and Quality

Think about any process where liquids or gases are mixed, heated, or cooled. The amount of each ingredient and the rate at which it is added must be exact. A smart valve with precise control acts like a perfect, automated hand on a tap.

For example, in food and beverage production, adding too much flavoring or too little catalyst in a chemical reaction will change the final product. Even a small, steady leak or an inaccurate flow rate over time can ruin an entire production run. Precise valves stop this from happening. They give operators total confidence that the process is running exactly as planned.

Understanding Process Stability

Additionally, many factors can disrupt flow. Upstream pressure might change, or the viscosity of a fluid might shift with temperature. A basic valve cannot respond to these changes. However, a smart valve continuously monitors the flow and makes instant, tiny adjustments. It uses feedback from flow meters to keep the rate constant, no matter what disturbances occur.

This stability is key for continuous processes. For instance, in coating or painting applications, an uneven flow means an uneven coating thickness. This leads to poor product performance and appearance. Therefore, precise valves ensure a smooth, uniform application from start to finish.

Key Benefits for Product Consistency

The main advantages include:

- Eliminating Variations: You get consistent results, so there are no more “good” batches and “bad” batches.

- Reducing Waste: You stop producing off-specification materials that people must throw away or rework.

- Increasing Customer Trust: Delivering consistently high-quality products builds a strong reputation.

The table below shows common problems caused by poor flow control and how precise valves solve them.

| Process | Problem with Imprecise Valves | Solution with Precise Smart Valves |

|---|---|---|

| Chemical Mixing | Incorrect ratios create unstable or ineffective compounds. | Accurate dosing ensures perfect chemical reactions every time. |

| Food Production | Varying amounts of ingredients affect taste, texture, and safety. | Consistent flow guarantees uniform flavor and composition. |

| Water Treatment | Improper chemical dosing fails to clean water properly. | Exact control delivers the right treatment dose for safe water. |

Ultimately, by ensuring consistency, precise flow control protects your brand and your profits.

Why is it Essential for Batching or Dosing Applications?

Mistakes in batching are costly. I recall a client who lost a full day’s production due to a dosing error a simple valve upgrade could have prevented.

Precise control is essential for batching and dosing because these applications require exact quantities to be delivered. Smart valves enable highly accurate repeatable shots of material, ensuring each batch has the correct formula, which is critical for product effectiveness, safety, and compliance with strict industry regulations.

The Need for Absolute Accuracy

Batching and dosing are not about “roughly right.” They are about “exactly right.” Adding 99.5 liters instead of 100 liters, or 10.2 grams instead of 10.0 grams, can be a major problem. For example, in pharmaceuticals, a wrong dose can make medicine ineffective or dangerous. In semiconductor manufacturing, a tiny error in chemical dosing can ruin millions of dollars worth of chips.

Smart valves are built for this task. They can be programmed to open and close with extreme speed and accuracy. Furthermore, they can deliver very small, precise amounts of fluid repeatedly. This level of control is impossible to achieve manually or with traditional valves.

How Smart Valves Achieve Precise Dosing

The process involves three key steps. First, the valve receives a command from the control system. Next, it opens for a precisely calculated amount of time. Finally, it closes sharply and completely. Advanced smart valves can even adjust their opening profile to account for changes in pressure, ensuring the same volume is delivered each cycle.

This repeatability is vital. Whether you are filling 10,000 bottles or adding catalyst to 100 batches of resin, every single action must be identical. Smart valves provide this mechanical consistency.

Applications Where Precision is Non-Negotiable

Let’s look at some critical examples:

- Water Treatment: Under-dosing disinfectant risks public health. Conversely, over-dosing wastes chemicals and can create harmful by-products.

- Food & Beverage: Incorrect dosing of additives, vitamins, or carbonation affects taste, nutritional value, and safety standards.

- Adhesive Dispensing: Too much adhesive is wasteful and messy. On the other hand, too little fails to bond parts together.

Comparing Dosing Methods

The choice of valve technology directly impacts accuracy.

| Dosing Method | Typical Accuracy | Best For |

|---|---|---|

| Manual Valve | Low (Varies with operator) | Non-critical applications, rough filling |

| Solenoid On/Off Valve | Medium | Simple, repetitive dosing where high accuracy isn’t critical |

| Precision Smart Control Valve | Very High (≥ 99%) | Critical batching, expensive ingredients, pharmaceutical dosing |

| Positive Displacement Pump | High | Very high-precision, low-flow viscous fluids |

In conclusion, for any operation where recipe integrity is paramount, investing in precise flow control for dosing is not an option—it is a fundamental requirement for quality and compliance.

How Does it Contribute to Resource Conservation and Sustainability?

Waste is lost profit. I’ve helped factories use precise valves to cut their raw material and energy costs significantly, turning an efficiency project into a major sustainability win.

Precise flow control contributes directly to resource conservation by eliminating overuse of water, chemicals, steam, and gas. It ensures only the exact amount needed is used, reducing waste and energy consumption. This lowers operational costs and minimizes the environmental footprint of the process, supporting key sustainability goals.

The Direct Path from Precision to Savings

In many plants, resources are wasted simply because control is not tight enough. For instance, a valve might allow a little too much steam into a heater, or a continuous trickle of water might be left running. Over a year, these small losses add up to huge amounts of wasted money and resources.

Smart valves stop this waste. By controlling flow exactly, they prevent overconsumption. For example, in a heating system, precise control of steam flow means you use just enough energy to reach the desired temperature—no more. This reduces fuel consumption at the boiler.

Key Areas for Resource Conservation

Precision helps in several ways:

- Water Management: In cooling systems or rinsing processes, precise valves can shut off completely or provide the minimum effective flow, drastically reducing water usage.

- Chemical Usage: In pH control or treatment processes, precise dosing adds chemicals only as needed, preventing both wasteful overuse and unsafe under-treatment.

- Gas and Steam: In combustion, heating, or inerting applications, accurate flow control optimizes the air-to-fuel ratio or heat input, maximizing energy efficiency.

Quantifying the Savings

You can measure the financial and environmental impact. Let’s consider a simple example of a water rinse line.

| Scenario | Flow Rate | Operation Hours/Year | Annual Water Use | Cost (at $0.005/gal) |

|---|---|---|---|---|

| Traditional Valve (Constant Flow) | 10 GPM | 8,000 | 4.8 million gallons | $24,000 |

| Smart Valve (Precise, Reduced Flow) | 6 GPM | 8,000 | 2.88 million gallons | $14,400 |

| Savings with Precision Control | 1.92 million gallons | $9,600 |

This table shows how precision cuts resource use by 40% in this case, saving nearly 2 million gallons of water and $9,600 per year. For steam or natural gas, the cost savings are often even greater.

Supporting Sustainability Goals

Beyond cost, this has a direct positive environmental impact. Using less water conserves a vital resource. Similarly, using less chemical reduces the load on wastewater treatment. Moreover, using less fuel (gas, steam) lowers greenhouse gas emissions. Therefore, precise flow control makes a process leaner and greener. For companies committed to sustainability, it is one of the most effective and measurable actions they can take. In essence, it turns operational efficiency into an environmental benefit.

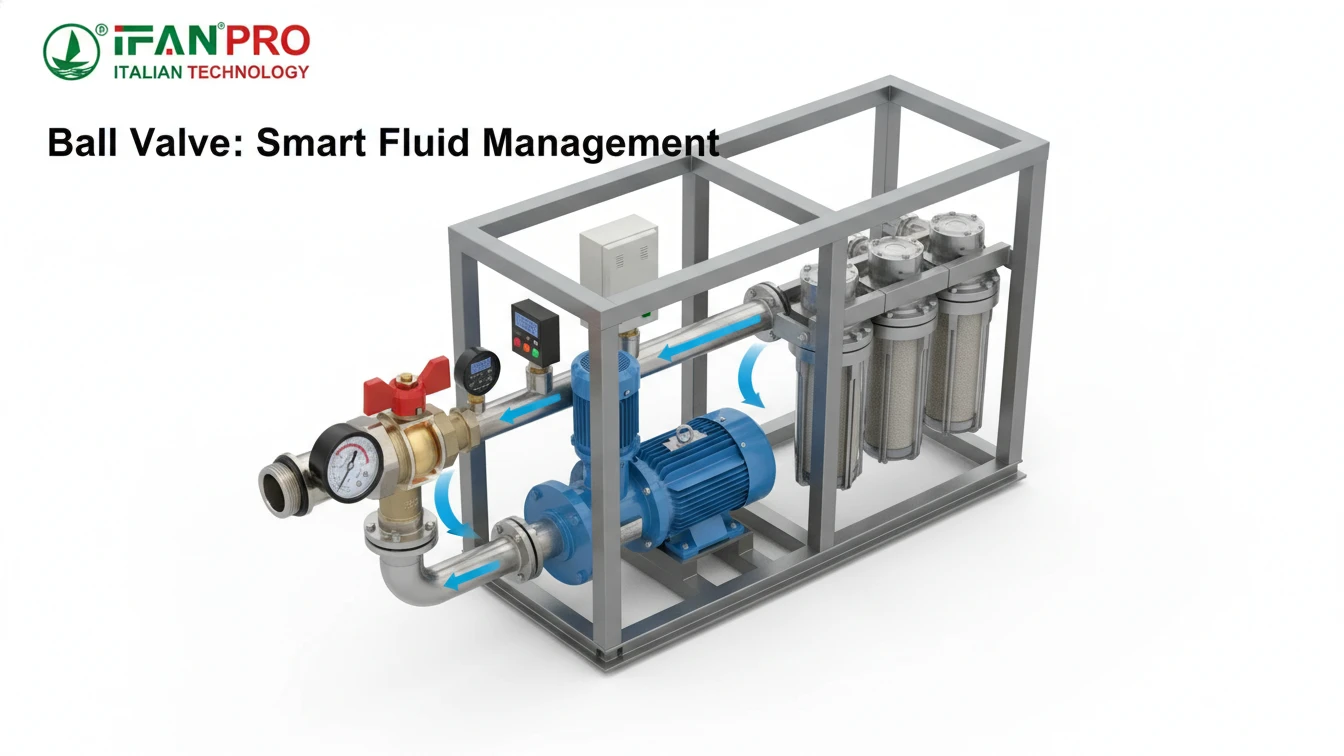

What Role Does it Play in Protecting Downstream Equipment?

Unexpected pressure surges can break things. I’ve seen pumps and sensors fail because an upstream valve slammed shut too quickly—a problem smart valves are designed to prevent.

Precise flow control plays a critical role in protecting downstream equipment by preventing damaging pressure surges (water hammer), avoiding over-pressurization, and ensuring stable operating conditions. This extends the lifespan of pumps, gauges, filters, and sensitive instruments, reducing downtime and maintenance costs.

The Danger of Pressure Surges

Downstream equipment is designed to handle specific pressure ranges. A sudden spike in pressure, known as water hammer, can burst pipes, damage pump seals, and break gauges. This often happens when a valve closes too quickly, stopping the flow of liquid abruptly. The energy in the moving liquid has nowhere to go, creating a shock wave through the system.

Smart valves protect against this. Engineers can program them to close (and open) at a controlled, gradual speed. This gentle ramp-up or ramp-down of flow eliminates the sudden shock, safely dissipating the energy. Consequently, this single feature can prevent thousands of dollars in equipment damage and process shutdowns.

Ensuring Stable Operating Conditions

Many pieces of equipment need steady flow to work properly. For example, a filter works best at its designed flow rate. Too high a flow can tear the filter media or force contaminants through. Conversely, too low a flow might be ineffective. A precise control valve maintains the ideal, stable flow for the downstream filter, maximizing its efficiency and life.

Similarly, flow meters and other sensors provide accurate readings only when the flow is stable. Erratic flow caused by poor valve control leads to noisy, unreliable data, which can cause the entire control system to make poor decisions.

How Precision Prevents Different Types of Damage

Let’s break down the protection benefits:

1. Protection for Pumps:

Running a pump against a closed or nearly closed valve (dead-heading) causes extreme stress, overheating, and rapid wear. However, a smart control valve can integrate with the pump control to ensure a minimum safe flow is always maintained, protecting the pump.

2. Protection for Heat Exchangers:

A sudden drop in coolant flow can cause a heat exchanger to overheat rapidly, leading to tube damage or failure. Therefore, precise, reliable flow control ensures the cooling medium is always present at the required rate.

3. Protection for Delicate Instruments:

Analytical probes and sensors can be fouled or damaged by sudden fluid surges. A gentle, controlled flow preserves their accuracy and longevity.

Equipment Protection Summary Table

| Downstream Equipment | Risk from Poor Flow Control | How Precise Smart Valves Help |

|---|---|---|

| Pumps & Seals | Cavitation, dead-heading, seal blow-out. | Ensures smooth flow transitions, prevents sudden pressure drops/spikes. |

| Piping & Joints | Water hammer, vibration, fatigue failure. | Provides soft start/stop functions to eliminate shock waves. |

| Filters & Membranes | Blinding, tearing, inefficient operation. | Maintains optimal, stable flow rate for maximum filter life. |

| Sensors & Meters | Erratic readings, physical damage from surge. | Creates a stable flow environment for accurate measurement. |

In summary, by acting as a gentle and precise gatekeeper, a smart valve does more than control flow—it safeguards your entire downstream investment.

Заключение

Precise smart valve control is essential for quality, efficiency, and protection in modern industry. For reliable and precise flow control solutions, explore the IFAN Smart Control Valve Series for your application needs.

Последние комментарии