I’ve seen metal support systems fail completely in coastal projects, turning into rusted, weak structures. This frustrating experience pushed us to find and rely on a better solution: PVC clips.

Yes, PVC (Polyvinyl Chloride) clips are highly corrosion-resistant, making them an ideal choice for humid environments. Unlike metals, PVC is an inert plastic that does not oxidize or react chemically with moisture, salts, or common airborne pollutants, ensuring long-term stability and reliability without rust or degradation.

If you manage projects in bathrooms, food processing plants, coastal areas, or any damp location, understanding why PVC outperforms metal is crucial. Let’s break down the reasons and the standards that guarantee their performance.

How Does PVC Material Resist Corrosion in High-Humidity Environments?

When a client’s stainless steel clips started showing rust spots in a steamy laundry room, the switch to PVC became the obvious, permanent fix.

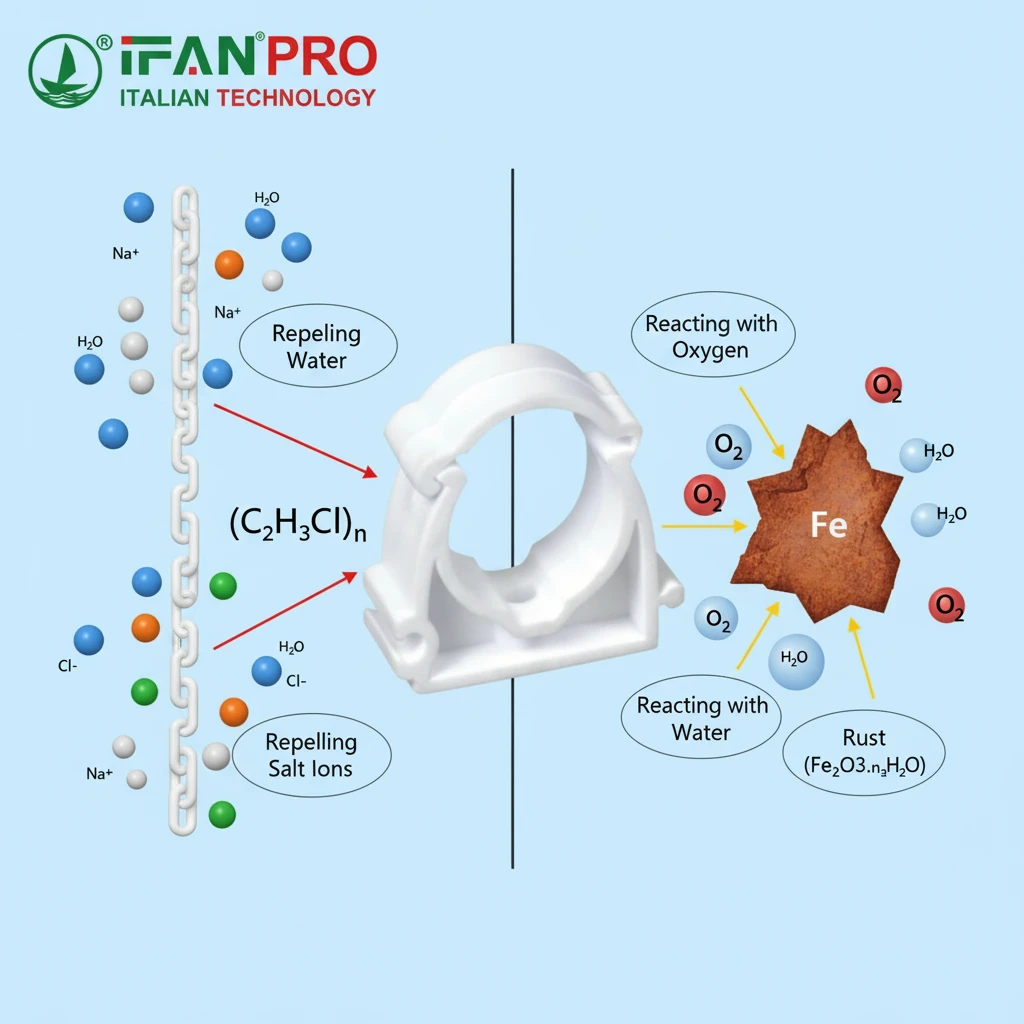

PVC resists corrosion in humid environments because it is a non-conductive, chemically inert thermoplastic. Water and water vapor cannot initiate an electrochemical reaction (like rusting) on its surface. It is also immune to galvanic corrosion and highly resistant to a wide range of acids, alkalis, and salts commonly found in damp industrial or marine atmospheres.

The Science of Non-Reactivity

To understand PVC’s resistance, we must first understand corrosion. Corrosion in metals is typically an electrochemical process where the metal reacts with oxygen in the presence of water (electrolyte), forming oxides (rust). PVC avoids this problem entirely.

- No Electrochemical Process: PVC is an excellent electrical insulator. Since it does not conduct electricity, the electrochemical cell required for corrosion cannot form on its surface. Moisture simply sits on it or rolls off, causing no chemical change to the material itself.

- Chemical Inertness: The molecular structure of PVC is very stable. It does not easily react with water, salts, mild acids, or alkalis. This makes it perfect for environments with:

- Splashing saltwater (coastal areas)

- High condensation (indoor pools, HVAC systems)

- Chemical vapors (food processing, cleaning facilities)

Comparison of Material Reactions in Humidity

The table below shows how different clip materials behave in the same humid, salty environment over time.

| Материал | Reaction in High Humidity & Salt | Long-Term Result |

|---|---|---|

| PVC | No chemical reaction. Water beads up. Salts do not adhere chemically. | Maintains original strength and appearance. No degradation. |

| Galvanized Steel | Zinc coating slowly degrades, then the underlying steel rusts. | Coating fails, leading to severe rust, swelling, and loss of strength. |

| Stainless Steel (304) | Can suffer from pitting corrosion in chloride-rich (salty) environments. | Small, deep pits form, weakening the structure and leading to potential failure. |

| Nylon | Absorbs small amounts of moisture, which can slightly reduce stiffness. | Minimal physical change, but may become less rigid in constant dampness. |

Real-World Performance

In practice, this means PVC clips will not rust, stain, or weaken when exposed to constant moisture. They won’t leave ugly red streaks on walls or pipes. Their clamping force remains consistent year after year because the material itself doesn’t deteriorate. This reliability removes a major point of failure and maintenance from your piping support system, which is why we at IFAN consistently recommend them for challenging environments.

What Are the International Standards for PVC Clip Corrosion Resistance?

A client once asked for “corrosion-resistant clips,” but the vague term led to a failed installation. Now, we always point to specific international standards as the true measure of quality.

Key international standards for PVC clip corrosion resistance include ISO 9001 for quality management in manufacturing, ASTM G154 for UV and moisture resistance testing, and various national plumbing codes (like NSF/ANSI 14) that certify material safety and durability for specific applications, ensuring the product meets minimum performance benchmarks.

Why Standards Matter

Standards are not just certificates on a brochure; they are proof that a product has been tested independently and will perform as promised. For procurement managers, specifying clips that meet recognized standards is the best way to mitigate risk and ensure project compliance.

Key Standards Explained

Here are the most important standards to look for when evaluating PVC clips for humid or harsh environments:

- ISO 9001: This is a fundamental standard. It doesn’t test the clip itself, but certifies that the manufacturer has a robust Quality Management System. This means every batch of PVC compound and every production run follows strict, documented procedures to ensure consistency and traceability. You are less likely to get a substandard product from an ISO 9001-certified factory.

- ASTM Standards: The American Society for Testing and Materials (ASTM) provides specific test methods.

- ASTM G154: This standard tests for resistance to ultraviolet (UV) light and moisture condensation. Clips exposed outdoors need to pass this to ensure they won’t become brittle or fade quickly.

- ASTM D543: Evaluates resistance to chemical reagents, confirming PVC’s inertness.

- NSF/ANSI 14 & 61: Crucial for plumbing applications. NSF/ANSI 14 covers the physical performance of plastics piping system components. More importantly, NSF/ANSI 61 certifies that the product is safe for contact with drinking water, ensuring no harmful chemicals leach out—a critical consideration for any humid environment where condensation might form and drip.

Standards Compliance Table

This table helps you match the standard to the project requirement.

| Standard | Focus Area | Why It’s Important for Humid Environments |

|---|---|---|

| ISO 9001 | Manufacturing Quality | Ensures consistent, reliable production of every clip. |

| ASTM G154 | UV & Condensation Resistance | Guarantees performance for outdoor or sun-exposed damp areas. |

| NSF/ANSI 61 | Drinking Water Safety | Essential for indoor plumbing, food/beverage, and healthcare facilities. |

| UL 94 | Flammability Rating | Important for safety compliance in building codes. |

By insisting on products that meet these standards, you move from hoping a clip will work to knowing it has been designed and proven to work. At IFAN, our sourcing and audit process prioritizes factories that adhere to these international benchmarks, providing you with verified quality.

Why Is PVC Often Preferred Over Metal Clips in Humid Conditions?

After replacing a corroded metal support system in a seafood plant, the plant manager told me the constant maintenance was a “hidden tax.” PVC eliminated that cost completely.

PVC is preferred over metal in humid conditions because it is inherently corrosion-proof, electrically non-conductive (preventing galvanic corrosion with pipes), lighter, and easier to install. It also does not require costly secondary coatings or maintenance, providing a lower total lifetime cost compared to metals, which are always vulnerable to rust and degradation in damp settings.

Head-to-Head: The Direct Advantages

The choice between PVC and metal in a damp location is clear when you compare their fundamental properties. Let’s look at the specific reasons PVC is the superior choice.

1. Inherent vs. Applied Protection:

Metal clips rely on coatings (galvanization, powder coating) or alloy composition (stainless steel) to resist corrosion. These are applied protections. If the coating is scratched, chipped, or compromised during installation or service, the underlying metal is exposed and will rust. PVC’s resistance is inherent to the material itself. Even if you scratch it, the color and material are the same throughout, and its corrosion resistance remains intact.

2. Elimination of Galvanic Corrosion:

This is a major hidden problem. When two dissimilar metals (like a steel clip and a copper pipe) are in contact in the presence of an electrolyte (humidity/water), they create a battery. This causes accelerated corrosion of the more active metal (usually the steel clip). PVC is an insulator. It completely stops this electrochemical reaction, protecting both itself and the pipe it holds.

3. Weight and Installation Ease:

PVC clips are significantly lighter than metal ones. This makes them easier to handle, transport, and install, reducing labor time. They can also be easily cut or adjusted on-site with simple tools.

Total Cost of Ownership Analysis

The initial price of a PVC clip might be similar to a coated metal one, but the real financial story is told over years.

| Cost Factor | PVC Clips | Coated Metal Clips |

|---|---|---|

| Initial Purchase Price | Comparable or slightly lower. | Comparable or slightly higher. |

| Installation Labor | Lower (lighter, easier to cut/handle). | Higher (heavier, may require pre-drilling). |

| Preventive Maintenance | None required. No need for inspections or touch-up painting. | Regularly required. Coatings must be inspected and repaired. |

| Replacement Frequency | Very low; lasts decades without degradation. | High in harsh environments; rust leads to frequent replacement. |

| Risk of Pipe Damage | Very low (no rust staining, no galvanic corrosion). | High (rust stains pipes, galvanic corrosion can damage pipe). |

| Total 10-Year Cost | Very Low (mostly just initial cost). | Very High (initial + maintenance + replacement + risk). |

For engineers and project managers, choosing PVC is a risk-averse decision. It removes corrosion from the equation as a failure mode. It simplifies specification, as you don’t need to choose between zinc, stainless, or aluminum grades based on the specific chemical environment. One material—PVC—solves the problem universally for humidity, making design, procurement, and long-term facility management much simpler.

How Can Proper Installation Extend the Life of PVC Clips Outdoors?

We supplied clips for a large outdoor irrigation project. The ones installed correctly a decade ago are still fine, while a few that were over-tightened or poorly supported failed early.

Proper installation extends the life of outdoor PVC clips by ensuring they are not over-stressed, are correctly spaced to support the pipe weight, and are shielded from unnecessary direct UV exposure. Using the correct fasteners for the wall material and allowing for thermal expansion of the pipe are also critical steps to prevent mechanical failure long before any material degradation occurs.

The Installation Principle: Respect the Material

PVC is tough and chemical-resistant, but it is still a plastic. Its weaknesses are extreme mechanical stress and prolonged, direct UV degradation. Good installation practices work to minimize these factors.

Critical Installation Guidelines

Follow these steps to ensure your PVC clip system lasts as long as the material itself is designed to:

1. Correct Support Spacing:

This is the most important rule. Pipes sag if clips are too far apart. This sagging puts a constant bending stress on the clip’s “ears,” which can lead to creep (slow deformation over time) or cracking. Always follow the pipe manufacturer’s or engineering guidelines for maximum support spacing based on the pipe material, diameter, and fluid content.

2. Avoid Over-Tightening:

Use a hand screwdriver, not a powerful drill/driver on its highest torque setting. Overtightening the screw can:

- Crack the clip’s mounting hole.

- Put the clip body under so much hoop stress that it becomes brittle and prone to cracking later.

- Deform the pipe if it is also plastic. The clip should be snug and secure, not crushing the pipe.

3. Use Appropriate Fasteners and Backing:

The clip is only as strong as its attachment to the wall.

- For masonry/concrete: Use plastic anchors with stainless steel screws.

- For wood: Use standard corrosion-resistant screws.

- For metal studs: Use self-tapping metal screws.

- Never attach a clip to loose or crumbling substrate. Ensure the mounting surface is solid.

Installation Checklist Table

Use this quick guide during installation to avoid common pitfalls.

| Do’s | Don’ts |

|---|---|

| ✅ Follow official support spacing tables. | ❌ Guess the spacing between clips. |

| ✅ Use a hand tool to tighten screws firmly. | ❌ Use an impact driver at full power. |

| ✅ Ensure the mounting surface is solid and clean. | ❌ Mount clips to unsound plaster or rusty metal. |

| ✅ Allow a small gap for pipe thermal expansion (don’t pinch pipes tightly at every point). | ❌ Lock the pipe in place immovably over long runs. |

| ✅ Consider UV-resistant PVC or simple shading for clips in direct, all-day sun. | ❌ Assume standard grey PVC is ideal for 24/7 desert sun. |

4. Consider UV Exposure:

While PVC has UV stabilizers, continuous direct sunlight will eventually cause some surface chalking and embrittlement. For extreme outdoor applications, you can:

- Specify UV-resistant PVC formulations (often denoted for outdoor use).

- Simple installation planning, like running pipes and clips under a slight eave or shade structure, can dramatically extend their pristine lifespan.

In short, think of PVC clips as durable system components that need to be installed with sense. A good installation respects the clip’s design purpose, preventing mechanical failures and allowing its excellent corrosion resistance to deliver decades of reliable service.

Заключение

PVC clips are the reliable, cost-effective choice for damp and humid environments because they cannot corrode. For your next project, choose guaranteed quality with IFAN’s range of certified PVC pipe clips and supports.

Последние комментарии