We received an urgent call from a water treatment plant manager. Their main line valve failed, causing a costly shutdown. This incident highlights why understanding the true durability of large-diameter PVC ball valves is critical for any large-scale project.

Large-diameter PVC ball valves are highly durable for specific applications, with lifespans often exceeding 20 years when selected and installed correctly. Their durability depends on material quality, pressure rating, correct installation, and chemical compatibility. Unlike metal valves, they won’t corrode, making them a long-lasting, cost-effective choice for many industrial and municipal systems.

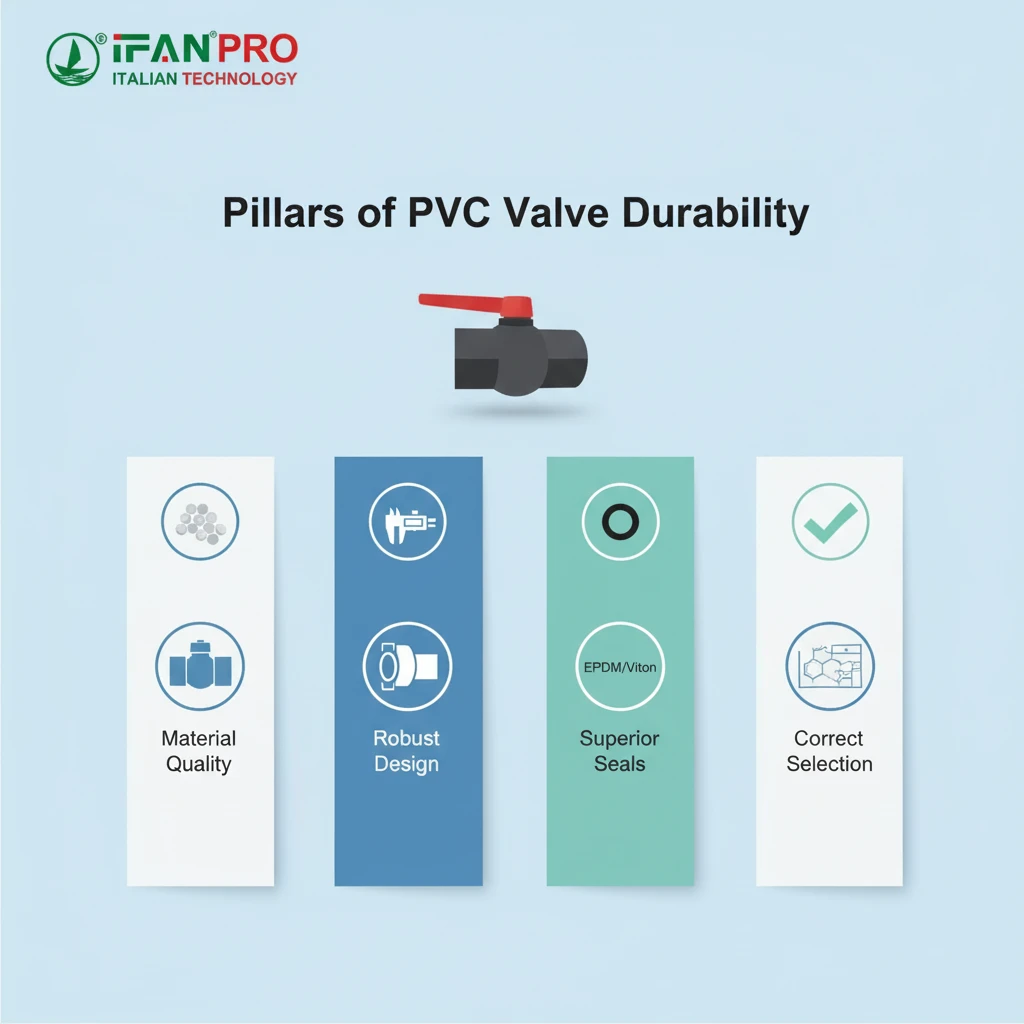

Let’s break down exactly what makes these valves durable and how you can ensure you get a reliable product for your project.

What Factors Determine the Durability of Large-Diameter PVC Ball Valves?

A client once complained about a valve cracking within a year. The problem wasn’t the valve’s design—it was the wrong material grade for their chemical process.

The durability of large-diameter PVC ball valves is determined by four main factors: the quality of the PVC compound (like uPVC or CPVC), the precision of the valve’s design and wall thickness, the quality of internal seals and the ball, and the correct matching of the valve to the fluid’s chemical properties and operating temperature. Proper installation is also a critical durability factor.

Material Quality is the Foundation

The type of PVC used is the most important factor. Not all PVC is the same.

- uPVC (Unplasticized PVC): This is the most common and rigid type. It has excellent chemical resistance and strength. It’s perfect for cold water and many aggressive chemicals at ambient temperatures.

- CPVC (Chlorinated PVC): This material is similar to uPVC but can handle much higher temperatures—often up to 200°F (93°C). If your process involves hot fluids, CPVC is the durable choice.

A valve made from low-grade, recycled PVC compound will be brittle and prone to cracking under stress or temperature changes. High-quality valves use virgin, certified PVC compounds.

Design and Manufacturing Precision

For large-diameter valves, design is crucial. The valve body must have a uniform wall thickness that is calculated to handle the pressure. Thin spots are weak points. The ball must be perfectly round and smoothly coated (often with chrome or nickel plating) to ensure a tight seal and easy operation. The stem must be robust and properly integrated to prevent blow-out under high pressure.

The Critical Role of Seals

The seals, or seats, are what make the valve shut off completely. They are usually made from EPDM, Viton, or Teflon.

- EPDM: Good for water and mild chemicals.

- Viton: Excellent for oils, fuels, and aggressive chemicals.

- Teflon (PTFE): Has the broadest chemical resistance and handles higher temperatures.

A durable valve pairs the right seat material with your specific fluid. Using an EPDM seat with oil will cause it to swell and fail quickly.

Chemical and Thermal Compatibility

PVC is not universal. A valve that is durable in a water line may quickly fail in a line carrying a strong solvent. You must check chemical resistance charts. Similarly, operating at a temperature above the valve’s rating will soften the PVC, drastically reducing its pressure-bearing capacity and lifespan.

Installation: The Final Durability Factor

Even the best valve can fail if installed poorly. Large-diameter PVC valves need proper support to avoid stress on the pipe connections. They must not be forced into alignment. The use of correct gaskets and following torque specifications for flange bolts is essential to prevent leaks and cracks.

Key Durability Factors Summary Table

| Factor | Why It Matters | What to Look For |

|---|---|---|

| PVC Type | Determines basic strength and temperature limit. | Specify uPVC for cold, CPVC for hot fluids. |

| Wall Thickness | Handles internal pressure and external loads. | Consistent, heavy-wall design per diameter. |

| Seal Material | Creates the leak-proof shutoff. | Match to your fluid (EPDM, Viton, PTFE). |

| Chemical Compatibility | Prevents degradation from the inside. | Consult manufacturer’s chemical resistance chart. |

| Installation Support | Prevents physical stress and cracking. | Use proper hangers and avoid pipe strain. |

How Does the Pressure Rating Affect Large-Diameter PVC Ball Valve Service Life?

A municipal project chose valves with a pressure rating that was too low. The result was constant leaks and premature replacements after just a few years of service.

The pressure rating (PN or Class) directly determines a valve’s service life. Operating a valve at or near its maximum rated pressure for long periods puts constant stress on the body and seals, leading to fatigue and early failure. For a long life, experts recommend selecting a valve with a pressure rating at least 1.5 times higher than your system’s normal operating pressure.

Understanding Pressure Ratings

The pressure rating (like PN16 or Class 150) is not a random number. It is the maximum continuous pressure the valve is designed to handle safely at a specified temperature (usually 20°C or 68°F). It includes a safety factor. However, treating this rating as a target operating pressure is a mistake.

Think of it like a bridge. A bridge with a 10-ton limit will survive for decades if only 5-ton trucks use it. But if 9.5-ton trucks are constantly crossing, the structure will wear out much faster. The same principle applies to valves.

Pressure, Fatigue, and Lifespan

Constant high pressure causes material fatigue. In PVC, this can lead to:

- Seat Deformation: The seals are under constant high force, causing them to compress and lose their ability to spring back. This leads to leaks around the ball.

- Body Stress: The valve body endures constant hoop stress. Over time, this can contribute to slow crack growth, especially if there are any imperfections in the material.

- Stem Stress: The stem mechanism is under higher torque, leading to potential wear and making the valve harder to operate.

Furthermore, all systems experience pressure surges or “water hammer.” A surge can momentarily spike to several times the normal operating pressure. A valve rated just at your normal pressure could be damaged by these surges. A valve with a higher rating has the headroom to absorb these shocks without harm.

Choosing the Right Rating for Long Life

For a durable, long-lasting installation, follow this simple rule: Derate. Always choose a valve whose rated pressure is significantly higher than your normal system pressure.

Recommended Pressure Selection Guide

| Your System’s Steady Operating Pressure | Minimum Recommended Valve Pressure Rating | Reason |

|---|---|---|

| 80 PSI | 125 PSI (PN10) | Provides a safe margin for small surges. |

| 115 PSI | 150 PSI (PN16) | Good standard practice for water systems. |

| 150 PSI | 200 PSI (PN16/PN20) | Essential for systems with frequent pump starts/stops. |

| 200 PSI | 250 PSI+ (PN25) | Required for industrial processes or high-head applications. |

This conservative approach is the single most effective way to extend the service life of your large-diameter PVC ball valves. It is a small upfront cost that prevents major downtime and replacement expenses later.

Which Applications Are Most Suitable for Durable Large-Diameter PVC Ball Valves?

We helped a mining company replace heavy, corroded iron valves with PVC. Their maintenance costs dropped by 60% because the new valves were perfectly suited to handling slurry and process water.

Large-diameter PVC ball valves are most suitable for applications involving corrosive fluids, ultrapure water, and abrasive slurries where metal valves would corrode or contaminate the flow. Their best uses are in water treatment plants, irrigation systems, chemical processing (with compatible fluids), mining operations, and aquaculture. They are not suitable for compressed air/gas systems or high-temperature steam lines.

The Ideal Use Cases for PVC Valves

PVC valves excel in environments that are hostile to metals. Their non-corrosive nature is their biggest advantage.

1. Water and Wastewater Treatment:

This is a prime application. From intake to filtration to discharge, plants handle water with chlorine, alum, ferric chloride, and other treatment chemicals that rapidly rust metal valves. Large-diameter PVC valves are durable here because they are immune to this corrosion. They are used for flow diversion, tank isolation, and filter control.

2. Chemical Processing and Handling:

For many acids, bases, and salt solutions, PVC offers excellent resistance. They are common in plants manufacturing fertilizers, textiles, and pharmaceuticals for handling a wide range of process fluids. Always verify chemical compatibility first.

3. Irrigation and Agricultural Systems:

Large-scale farm and golf course irrigation systems use huge amounts of water, often with dissolved fertilizers. PVC valves are lightweight, easy to install in the field, and resist corrosion from both water and fertilizers.

4. Mining and Mineral Processing:

This industry uses large amounts of water and abrasive slurries (mixtures of water and fine solids). Metal valves wear out quickly from abrasion. Durable PVC valves, especially with full-port designs that minimize flow restriction, last much longer in these slurry lines.

5. Aquaculture and Fish Farming:

In saltwater or brackish water environments, metal valves fail within months due to salt corrosion. PVC valves are completely resistant, making them a durable and safe choice for flow control in ponds, tanks, and raceways.

Applications to Avoid

Knowing where not to use PVC valves is just as important for ensuring durability and safety.

- Compressed Air or Gas Systems: PVC can become brittle and shatter if it fails under pressure, creating dangerous projectiles. Use metals specifically rated for compressed gas.

- High-Temperature Steam Lines: Even CPVC has limits. Steam systems require metal valves.

- Systems with High UV Exposure: Sunlight degrades PVC. If used outdoors, valves must be painted or specifically manufactured from UV-stabilized PVC.

- Fire Protection Systems: These are governed by strict codes that almost always require metal (like iron or steel) components.

Application Suitability Table

| Application | Why PVC is a Durable Choice | Important Considerations |

|---|---|---|

| Potable Water Mains | No corrosion, no rust contamination. | Must have NSF/ANSI 61 certification. |

| Chemical Transfer | Resists a wide range of corrosive acids/bases. | MUST match valve material & seals to specific chemical. |

| Slurry & Waste Lines | Resists abrasive wear better than many metals. | Specify full-port (full-bore) design to prevent clogging. |

| Saltwater Intake | Completely immune to saltwater corrosion. | Ensure all metal components (stem, ball) are also corrosion-resistant. |

| Industrial Cooling Water | Handles treated water without scaling or corrosion. | Verify temperature rating for closed-loop systems. |

How Can You Verify the Durability Standards of Large-Diameter PVC Ball Valves?

A distributor once offered us valves at a price that seemed too good to be true. They were—the valves lacked any certification and failed pressure tests in our lab.

You can verify the durability standards of large-diameter PVC ball valves by demanding and checking official product certifications, reviewing detailed technical data sheets, and requesting third-party test reports. Look for marks like NSF, ISO 9001, and relevant pressure standard certifications (e.g., EN 12266, ASTM F1970). Reputable manufacturers provide all this documentation openly.

Step 1: Demand Official Certifications

Certifications are your first line of defense. They prove an independent organization has tested the valve or the manufacturer’s process.

- NSF/ANSI 61: For potable water applications, this is non-negotiable. It certifies the valve does not leach harmful contaminants into drinking water.

- ISO 9001: This certifies the manufacturer’s quality management system. It means their production process is controlled and consistent, which is key for durable products.

- CE Marking (for EU): Indicates the product meets EU safety, health, and environmental requirements.

Step 2: Scrutinize the Technical Data Sheet (TDS)

A detailed TDS is a sign of a professional manufacturer. It should contain:

- Material Specifications: Exact PVC type (e.g., uPVC to ISO 15493), seal material grade.

- Pressure Rating: Clear PN or Class rating at a specified temperature.

- Temperature Range: Minimum and maximum continuous service temperatures.

- Test Pressures: Both the shell test pressure (higher, tests the body) and the seat test pressure.

- Standards Met: Such as ISO 16135 (for industrial valves) or ASTM F1970.

Step 3: Request Third-Party Test Reports

For critical projects, don’t just take the datasheet’s word for it. Ask the supplier for copies of recent third-party lab test reports. These reports show actual performance data against the claimed standards, such as pressure cycling tests (opening/closing under pressure) and burst pressure tests.

Step 4: Evaluate the Manufacturer’s Reputation and Support

Durability isn’t just about the product; it’s about the source.

- Experience: How long have they been making large-diameter valves?

- Technical Support: Can they help you select the right valve and provide chemical compatibility guidance?

- Warranty: What warranty do they offer? A confident manufacturer stands behind their product’s durability.

Key Verification Checklist Table

| What to Verify | Where to Find It | What it Confirms |

|---|---|---|

| Potable Water Safety | NSF/ANSI 61 Certificate | Valve is safe for drinking water and won’t leach toxins. |

| Manufacturing Quality | ISO 9001 Certificate | Production process is reliable and consistent. |

| Pressure Integrity | TDS listing EN 12266 or ASTM F1970 | Valve meets international pressure test standards. |

| Material Authenticity | TDS with exact PVC grade (e.g., uPVC ISO 15493) | Valve is made from high-grade, virgin material. |

| Performance Proof | Third-party lab test report | Actual valves have been tested successfully. |

Заключение

For durable, large-diameter PVC ball valves that meet strict standards, partner with a trusted source. ИФАН supplies certified, heavy-duty PVC valves built for long-term performance in demanding applications. Contact us for valves you can rely on.

Последние комментарии