A client once faced a huge problem: manually operating a large valve in a remote, hard-to-reach location was costly and slow. This pushed us to find a reliable automation solution.

Yes, large PVC valves can be fully automated for remote control. By adding an electric or pneumatic actuator and a control system, you can open, close, or modulate the valve from a control room or even a smartphone. This upgrade solves major issues with manual operation in hard-to-reach or dangerous locations.

This transformation is simpler than you might think. Let’s break down exactly how it works and what you need to make it happen.

Which Automation Accessories Are Compatible with Large PVC Valves?

Compatibility is the first hurdle. We’ve seen projects stall because the chosen parts simply didn’t fit together.

The key compatible automation accessories for large PVC valves are mounting kits (brackets and couplings) that connect the valve to the actuator, limit switches to signal open/close positions, solenoid valves for pneumatic systems, and positioners for precise flow control. Ensuring the mounting kit matches both the valve’s ISO standard mounting pad and the actuator is crucial.

Understanding the Core Connection Kit

Automating a valve isn’t just about sticking a motor on it. You need a set of parts to make them work as one unit. The most critical accessory is the mounting kit. This is a bracket and a coupling that physically connects the actuator to the valve stem.

- The Bracket bolts onto the valve’s top, which is called the mounting pad. Most industrial PVC valves follow an ISO standard for this pad size. You must check that your valve’s pad (e.g., ISO 5211) matches the bracket.

- The Coupling links the rotating shaft of the actuator to the valve stem. It must fit the exact dimensions of both to transfer torque properly without slipping or causing damage.

Essential Control and Feedback Devices

Once the actuator is mounted, you need accessories to control it and monitor its status.

- Limit Switches: These are small sensors inside or on the actuator. They tell the control system when the valve has reached the fully open or fully closed position. This stops the motor at the right point, preventing damage from over-torque.

- Solenoid Valves: For pneumatic (air-powered) actuators, a solenoid valve is the switch. It controls the flow of compressed air into the actuator to make it move open or closed. You choose it based on your air pressure and voltage (e.g., 24V DC, 110V AC).

- Positioners: If you need the valve to stop at any position (not just fully open or closed), you need a positioner. It receives a control signal (like 4-20mA) and precisely moves the valve to the exact required opening percentage for flow modulation.

Compatibility Checklist Table

Use this table to verify part compatibility before purchasing.

| Accessory | Its Purpose | Key Compatibility Check |

|---|---|---|

| Mounting Kit | Connects actuator to valve. | Valve mounting pad standard (ISO 5211 F05/F07/F10) must match kit and actuator interface. |

| Limit Switches | Sends open/close position signals. | Must be compatible with the actuator model and your control system’s voltage. |

| Solenoid Valve | Directs air to pneumatic actuator. | Air pressure rating and coil voltage must match your plant’s supplies. |

| Positioner | Allows precise partial valve opening. | Must match the actuator type (electric/pneumatic) and control signal (e.g., 4-20mA). |

Choosing the right accessories from the start prevents mechanical failure and control issues, ensuring a smooth and reliable automated system.

How to Select the Right Actuator for Automated PVC Valve Control?

Selecting the wrong actuator is a common and expensive mistake. We help clients avoid this by focusing on a few key specs.

Select the right actuator by determining the required torque (to turn the valve), the operating speed, the power source available (electricity or compressed air), and the necessary safety features. The valve size, type (ball, butterfly), and operating pressure determine the torque, which is the most critical factor.

The Critical Factor: Torque

The actuator’s main job is to produce enough rotational force, called torque, to turn the valve. Too little torque, and the valve won’t move. Too much, and you risk breaking the valve stem.

- Break Torque: This is the highest torque needed to start moving the valve from a fully closed or open position. It is always higher than the torque needed to keep it moving.

- Running Torque: This is the torque needed to keep the valve rotating.

You can get this torque requirement from the valve manufacturer’s datasheet. If it’s not available, an experienced supplier like IFAN can calculate it based on valve size, type, and pressure.

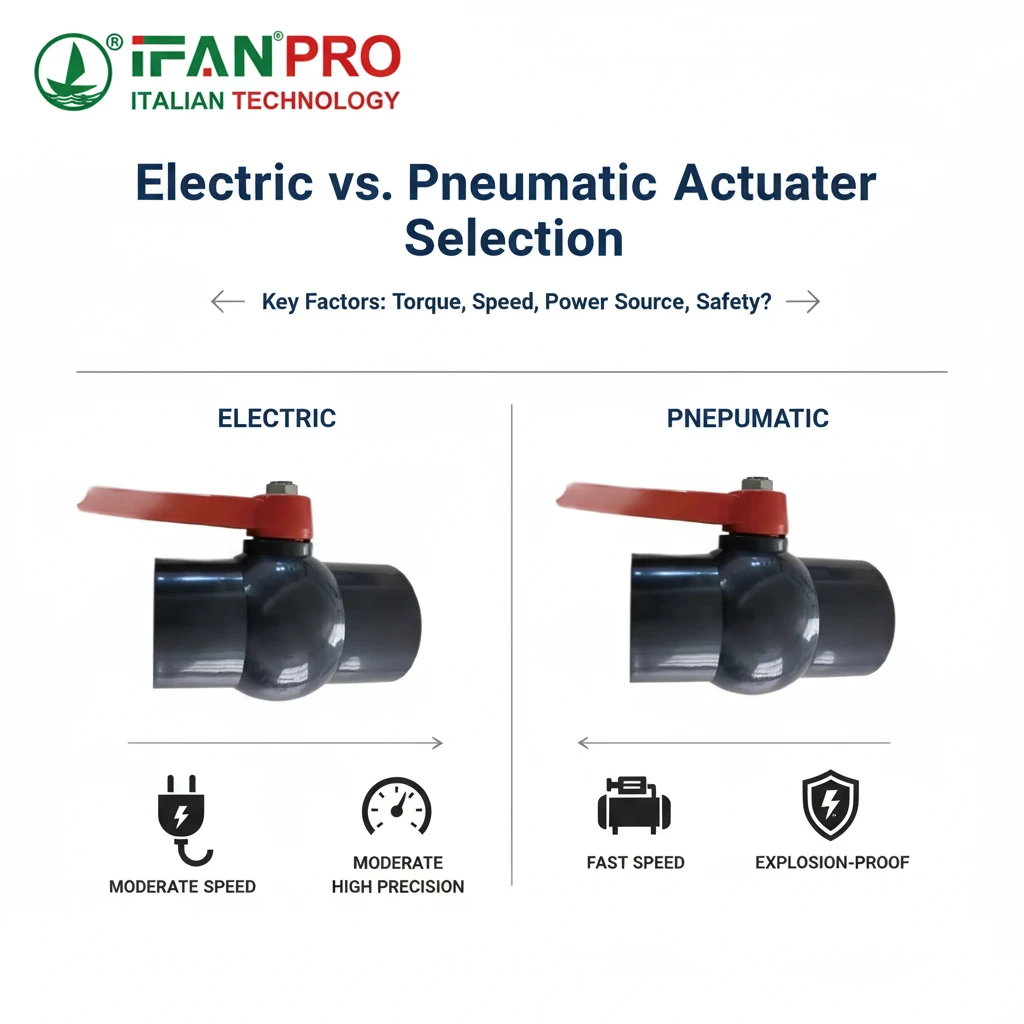

Electric vs. Pneumatic: Choosing the Power Source

Next, decide between an electric or pneumatic (air) actuator.

Electric Actuators:

- Pros: Easier to install (need only power and control cables). More precise control. Quieter operation. Suitable for locations without an air supply.

- Cons: Can be slower. Risk of overheating if stuck. Generally less powerful for very large valves.

- Best for: Standard on/off or modulating control where compressed air is not available.

Pneumatic Actuators:

- Pros: Very fast operation. Explosion-proof by design (safe in hazardous areas). Can produce very high torque. Simple, strong mechanism.

- Cons: Require a clean, dry compressed air supply and air lines. Less precise for modulation without a positioner.

- Best for: Large valves, fast shut-off applications, or hazardous environments.

Other Key Selection Criteria

- Operating Speed: How fast do you need the valve to open/close? Pneumatic actuators are much faster.

- Fail-Safe Mode: What should the valve do if power or air fails? Spring-return actuators automatically go to a safe position (open or closed). This is crucial for safety.

- Protection Rating: The actuator housing must be suitable for its environment (e.g., IP67 for water resistance, NEMA 4X for outdoor/corrosive areas).

Actuator Selection Guide Table

| Valve Scenario | Recommended Actuator Type | Key Reason | Special Consideration |

|---|---|---|---|

| 8″ PVC Ball Valve, On/Off, non-hazardous area | Electric | Simple wiring, adequate power. | Select torque 30% above valve requirement. |

| 12″ PVC Butterfly Valve, Fast Emergency Shut-off | Pneumatic (Double-Acting) | Very fast operation, high torque. | Requires air supply; add a solenoid valve. |

| Process Control Valve requiring precise flow | Electric or Pneumatic with Positioner | For precise modulation. | A control signal (4-20mA) and positioner are mandatory. |

| Valve in a wet or dusty environment | Electric with IP67/IP68 Rating | Protects internal electronics. | Ensure mounting kit also has good sealing. |

By systematically checking these factors, you can choose an actuator that is reliable, safe, and perfectly matched to your valve.

What Control Systems Enable Remote Operation of Automated PVC Valves?

The actuator is the muscle, but the control system is the brain. A good brain makes everything work together smoothly.

Common control systems for remote PVC valve operation include simple Push-Button Stations, Programmable Logic Controllers (PLCs), and Distributed Control Systems (DCS). For basic remote on/off, a push-button station with relays works. For complex logic or integration with other equipment, a PLC or DCS connected via networks like Ethernet/IP or Modbus is required.

Level 1: Basic Local & Remote Control

The simplest system uses a Push-Button Station and relays. Imagine a box with “OPEN” and “CLOSE” buttons. You wire this station to the actuator’s control wires. Pressing the button sends power to the actuator motor or solenoid valve.

- How it enables remote control: You can place this button station up to hundreds of meters away from the actual valve, using control cables. This is “remote” in the sense that the operator doesn’t have to be at the valve.

- Best for: Simple, standalone applications with few valves. It offers no automation logic or computer interface.

Level 2: Automated & Programmable Control

For true automation, you need a Programmable Logic Controller (PLC). A PLC is a rugged industrial computer.

- How it works: You program the PLC with logic (e.g., “If Tank A is full, close Valve 1 and open Valve 2”). The PLC receives signals from sensors (like limit switches, pressure sensors) and sends commands to the actuators.

- How it enables remote control: The PLC can be connected to a Human-Machine Interface (HMI) touchscreen locally, or more importantly, to a Supervisory Control and Data Acquisition (SCADA) system over a factory network (Ethernet, Profibus, Modbus). This allows operators in a control room to see all valve statuses and operate them with a click. It also allows for scheduling, alarms, and data logging.

Level 3: Large-Scale Integrated Control

For a whole plant or very complex processes, a Distributed Control System (DCS) is used. It’s like a more powerful, integrated network of controllers managing thousands of points, including valves.

- How it enables remote control: It provides a centralized, high-level interface for operators to monitor and control the entire process from multiple workstations. Valve control is just one function within this large system.

Communication Protocols: The Language of Control

The control system and the actuators/valves need to “talk” the same language. These are called communication protocols.

| Protocol | Best For | Key Advantage |

|---|---|---|

| Hard-Wired Signals | Simple on/off control. | Low cost, very reliable, easy to troubleshoot. |

| Modbus RTU/TCP | Connecting many devices to a PLC/SCADA. | Very common, widely supported, works over long distances. |

| Ethernet/IP, Profinet | High-speed, modern factory networks. | Very fast, can handle large amounts of data, integrates with IT networks. |

| 4-20mA Analog Signal | Precise positioning (modulation). | Sends a varying signal to a positioner to set the valve’s exact opening. |

Choosing the right control system depends on your need for automation, integration, and scale. For most industrial applications wanting remote control, a PLC-based system is the standard, flexible solution.

What Are the Key Steps to Install an Automated PVC Valve System?

A poor installation can ruin the best equipment. Following a clear, step-by-step plan is the key to success.

The key installation steps are: 1) Pre-assembly and testing of the actuator and valve on the bench, 2) Secure mechanical mounting of the assembled unit into the pipeline, 3) Correct wiring or piping of power and control signals, and 4) Thorough commissioning and tuning of limits and controls before final operation.

Step 1: Pre-Assembly and Bench Testing (Most Important)

Never install the valve and actuator separately in the pipe. Always assemble them first on the workbench.

- Mount the Actuator: Use the correct mounting kit to attach the actuator to the valve. Follow the manufacturer’s torque specifications for bolts. Connect the coupling carefully.

- Manual Test: Use the actuator’s manual override (usually a handwheel) to operate the valve fully. Feel for smooth operation. This checks for any mechanical binding before it’s in a hard-to-reach spot.

- Connect & Dry-Run: Temporarily connect power/air and control wires to the actuator. Test its open/close cycles. Verify that limit switches activate correctly. This “bench testing” finds and fixes most problems easily.

Step 2: Mechanical Installation into Pipeline

Now install the pre-assembled unit into your pipe system.

- Support the Pipeline: Large PVC pipes can sag. Install proper pipe supports before and after the valve. The valve should not bear the weight of the pipe.

- Use Proper Flanges/Gaskets: Follow the valve manufacturer’s instructions for flange bolts. Tighten them in a criss-cross pattern to avoid uneven pressure that can crack the PVC body.

- Align Carefully: Ensure the valve is not twisted or under stress from pipe misalignment. This prevents leaks and high operating torque.

Step 3: Electrical/Pneumatic Connections

This step powers the system and connects it to the brain.

- For Electric Actuators: Run conduit and cables as per electrical codes. Ensure proper grounding. Connect power wires to the correct terminals. Connect control wires from your PLC or push-button station to the control terminals.

- For Pneumatic Actuators: Run clean, dry air lines. Install a filter-regulator-lubricator (FRL) unit if needed. Connect the air lines to the solenoid valve, and from the solenoid to the actuator ports.

- Safety: Always follow lock-out/tag-out procedures. Ensure all power and air is off during connection.

Step 4: Commissioning and Tuning

This final step makes the system smart and safe.

- Set Limit Switches: Manually cycle the valve. Adjust the limit switch cams or sensors so they trigger exactly when the valve is fully open and fully closed. This protects the valve and actuator.

- Configure Controls: In your PLC or control system, program the correct logic. Test each command (open, close, stop).

- Test Fail-Safe: If you have a spring-return actuator, simulate a power/air failure to confirm the valve moves to its safe position.

- Final Check: Do a complete operational test under no pressure, then under low pressure, and finally under full system pressure. Check for leaks and smooth operation.

Installation Checklist Table

| Phase | Task | Why It’s Important |

|---|---|---|

| Preparation | Verify torque, voltage, air pressure. | Ensures all parts are correctly specified. |

| Bench Assembly | Mount actuator, test manually and electrically. | Finds mechanical issues in a safe, accessible environment. |

| Pipe Installation | Support pipe, align valve, tighten flanges evenly. | Prevents PVC cracking and reduces stress on the valve. |

| Connection | Wire/power according to codes, connect control signals. | Ensures safe and reliable power/control. |

| Commissioning | Set limits, program logic, test fail-safe, pressure test. | Makes the system intelligent, safe, and ready for reliable service. |

Following these steps methodically prevents callbacks, ensures safety, and delivers a system that works reliably for years.

Заключение

Automating large PVC valves is a straightforward process that brings major efficiency and safety benefits. For reliable PVC valves and compatible automation kits, partner with ИФАН for expert support and quality components.

Последние комментарии