I once had a client ask me this exact question after buying a simple manual PVC valve. They later realized they needed remote control. The answer is crucial for planning your system.

Yes, a PVC valve can be controlled either manually or automatically. The control method is determined by the type of valve body and the presence of an actuator. Most standard PVC valves (like ball, gate, or check valves) are designed to be manually operated but can be easily fitted with an automatic actuator for on/off or modulating control, offering great flexibility.

The choice between manual and automatic isn’t just about convenience; it affects your entire system’s efficiency and cost. Let’s break down the key factors that guide this decision.

What Determines Manual Versus Automatic Control for a PVC Valve?

Many people think the valve body itself decides this. From my experience at IFAN, the truth is more about the accessories you add.

The control method for a PVC valve is determined by its design and the presence of an add-on device called an actuator. A manual valve is operated by a hand lever, gear, or wheel. An automatic valve replaces or supplements this manual operator with an actuator—an electric, pneumatic, or hydraulic motor that opens and closes the valve based on a signal.

The Core Components: Valve Body vs. Actuator

To understand control, you need to see the valve as two main parts. First, there is the valve body. This is the PVC part with the internal mechanism (like a ball or a gate) that stops or allows flow. Second, there is the operator. This is what turns that mechanism.

For manual control, the operator is a simple handle or handwheel you turn by hand. For automatic control, the operator is an actuator. The valve body is often the same for both methods. This means the fundamental decision isn’t “which valve to buy,” but “how do I want to operate it?”

Key Factors Influencing the Choice

Several practical factors push a project toward one method over the other:

- System Accessibility: If the valve is in a hard-to-reach place, like a high ceiling or an underground pit, automatic control is safer and more efficient. No one needs to climb a ladder to turn a valve.

- Operation Frequency: If you need to open or close the valve multiple times a day, automation saves huge amounts of labor and time. A manual valve is fine for a shut-off that is used once a year.

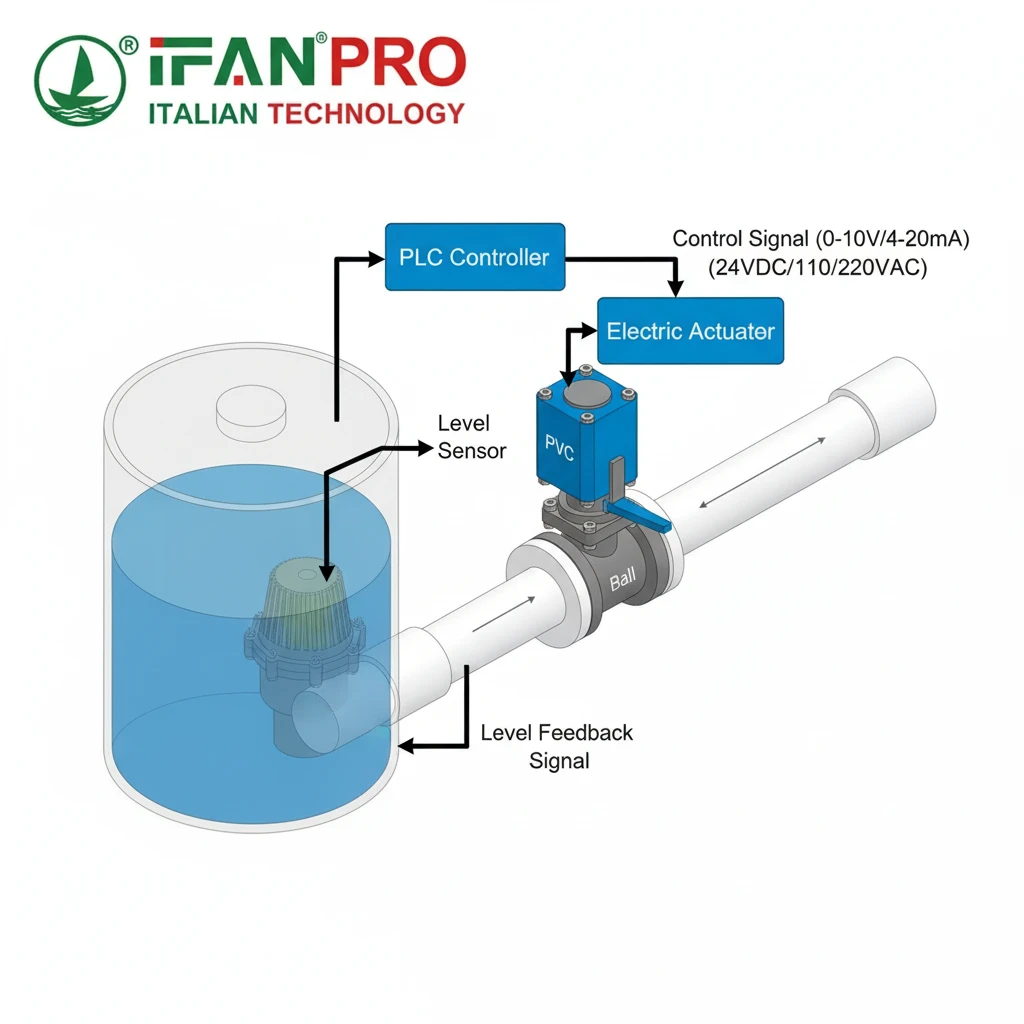

- Process Requirements: Automatic control is essential if the valve needs to react to a sensor. For example, a valve might need to close automatically if a tank gets too full (triggered by a level sensor) or open if pressure drops (triggered by a pressure switch).

- Cost Consideration: A manual valve has a lower upfront cost. An automatic system (valve + actuator + controls) costs more initially but saves money in labor and prevents errors in the long run for frequent or critical applications.

Decision-Making Table: Manual vs. Automatic

This table helps you decide based on common project needs.

| Project Requirement | Recommended Control Method | Why? |

|---|---|---|

| Emergency shut-off valve, rarely used. | Manual | Low cost and simplicity are perfect for seldom-used valves. |

| Valve for daily process control in an industrial line. | Automatic | Removes human error and saves significant operator time. |

| Valve located in a remote or hazardous area. | Automatic | Improves safety; operators can control it from a safe distance. |

| Irrigation system on a timer. | Automatic | The system can run on a pre-set schedule without human intervention. |

| Budget is very tight, and operation is simple. | Manual | Keeps the initial project cost as low as possible. |

Understanding these factors helps you make the right choice from the start, avoiding costly changes or inefficient operations later.

Can You Convert a Manual PVC Valve to Automatic Control Later?

This is one of the most common questions we get. Clients buy manual valves and then their needs grow.

Yes, you can almost always convert a manual PVC valve to automatic control later. This is done by removing the manual handle or handwheel and mounting a compatible automatic actuator onto the valve’s stem. This adaptability is a major advantage of standard PVC valve designs like ball valves and butterfly valves.

The Conversion Process Explained

The possibility of conversion comes from standardized valve design. The part of the valve you turn—the stem—is usually built to a common shape and size (like ISO 5211 mounting pad). This standardization allows different “operators” (a handle or an actuator) to be attached.

The conversion process is straightforward for a technician:

- Shut down the system and relieve pressure.

- Remove the existing manual handle or handwheel.

- Align the automatic actuator with the valve stem.

- Mount the actuator using a coupling kit or direct mounting bracket.

- Connect the power and control wires (for electric) or air lines (for pneumatic) to the actuator.

Critical Checkpoints Before Conversion

However, “can you” doesn’t always mean “should you without checking.” Before converting, you must verify a few key things:

- Valve Type and Stem Compatibility: Standard quarter-turn valves (ball, butterfly) are the easiest to convert. Multi-turn valves (like gate valves) require a specific type of actuator and are less commonly automated. The valve stem must be the correct shape and length.

- Torque Requirement: The actuator must be strong enough to turn the valve. The force needed is called torque. A valve that is sticky or used in high-pressure water needs more torque. You must select an actuator with a torque rating higher than the valve’s requirement.

- Mounting Interface: Check if the top of your valve has a standard mounting pattern (like ISO 5211). If not, you may need a special adapter bracket. Most modern industrial PVC valves have this.

Cost-Benefit of Retrofit vs. New Purchase

Sometimes, buying a new automated valve is better than converting an old one. Consider this:

- Retrofit (Add actuator to existing valve):

- Pros: Saves the cost of a new valve body. Good for recent, high-quality manual valves.

- Cons: The old valve body might be worn, which could cause the new actuator to fail. The total project might look less neat.

- Replace (Buy a new automated valve package):

- Pros: You get a guaranteed compatible system (valve + actuator) from one supplier. It often comes with a new warranty. The installation is cleaner.

- Cons: Higher upfront material cost.

Our Advice at IFAN: If your manual valve is new, in good condition, and of a standard type, conversion is a smart and economical choice. It’s the flexibility that makes PVC valve systems so popular.

How Do You Select the Right Actuator for Automatic PVC Valve Control?

Choosing the wrong actuator is a major pain point. I’ve seen undersized actuators burn out and oversized ones waste money. The selection is a science.

You select the right actuator by matching three key specs: 1) the required torque (turning force) of the valve, 2) the valve’s operation type (quarter-turn or multi-turn), and 3) your available power source (electricity or compressed air). Getting these matches right ensures reliable and long-lasting automatic control.

Step 1: Determine the Valve’s Torque Requirement

This is the most important step. Torque is the rotational force needed to open or close the valve. If the actuator is too weak, it will stall and fail. The required torque depends on:

- Valve Size: Larger valves generally need more torque.

- Valve Type: A butterfly valve often needs less torque than a ball valve of the same size.

- Operating Pressure: Higher system pressure creates more force against the valve disc, requiring more torque to move it.

- Media: The fluid type (water, slurry) affects friction.

How to find the torque: The best way is to check the valve manufacturer’s data sheet. It will list the “maximum operating torque.” If that’s not available, use an actuator manufacturer’s torque calculation chart based on valve size, type, and pressure.

Step 2: Choose the Actuator Type (Electric vs. Pneumatic)

This choice depends on what’s available in your facility and what you need the actuator to do.

| Feature | Electric Actuator | Pneumatic (Air) Actuator |

|---|---|---|

| Power Source | Electricity (common voltages: 24VAC, 110VAC, 220VAC) | Clean, dry compressed air (typically 4-7 bar). |

| Best For | Locations with easy electrical access, precise control, and no compressed air. | Hazardous or explosive environments, fast operation, and where air is readily available. |

| Управление | Excellent for complex signals (modulating control with 4-20mA or 0-10V). | Typically used for simple on/off (using a solenoid valve). Modulating is more complex. |

| Speed | Can be slow to fast, adjustable. | Very fast cycling. |

| Maintenance | Generally lower. | Requires clean, dry air; filters/dryers are needed. |

Step 3: Match the Operation (Quarter-Turn vs. Multi-Turn)

- Quarter-Turn Actuators: These rotate 90 degrees (a quarter turn) to open or close valves like ball valves and butterfly valves. This is the most common type for PVC systems.

- Multi-Turn Actuators: These rotate many times (like turning a steering wheel) to operate gate valves or globe valves. They are less common on PVC pipes but are used in specific applications.

Step 4: Consider Control Features

What signal will tell the actuator to move?

- On/Off: Simple signal (like a switch or relay closure).

- Modulating/Proportional: The actuator moves the valve to any position between open and closed based on an analog signal (like 4-20mA). This is for flow control.

- Fail-Safe: Should the valve close or open if power/air fails? This requires an actuator with a spring-return mechanism.

Selecting the right actuator is about careful matching. When in doubt, consult with your valve supplier (like IFAN). Providing them with your valve model, size, and pressure will allow them to recommend the perfect actuator match.

What Are the Key Requirements for Automatic Control of PVC Valves?

Automatic control is more than just adding an actuator. I’ve seen projects fail because they ignored the support system.

The key requirements for automatic PVC valve control are: 1) a compatible and robust valve body, 2) a correctly sized actuator, 3) a reliable control signal source (like a timer, PLC, or sensor), and 4) proper installation with protection against water hammer and environmental damage. Missing any one can lead to system failure.

Requirement 1: A Suitable Valve Body

Not every manual valve is ideal for automation. The valve body must be:

- Mechanically Sound: It must turn smoothly. A stiff, gritty-feeling valve will demand too much torque and burn out an actuator.

- Pressure-Rated: It must withstand not just working pressure, but also potential pressure surges from quick opening/closing.

- Standardized: It should have a standard stem top (ISO mount) for easy actuator attachment. Cheap, non-standard valves may need expensive adapters or cannot be automated at all.

Requirement 2: A Proper Support System (The “Brain” and “Nerves”)

The actuator is the “muscle.” You also need a “brain” and “nerves.”

- Control Source: This is the command. It could be a simple timer, a push-button station, a Programmable Logic Controller (PLC), or a sensor (like a float switch for level or a flow meter).

- Wiring/Piping: For electric actuators, you need correct gauge wires, conduits for protection, and possibly a local junction box. For pneumatic actuators, you need clean, dry air lines with filters and regulators.

- Power Supply: Ensure stable, correct voltage for electric actuators. For pneumatic, ensure sufficient air volume and pressure.

Requirement 3: Protection Against Physical Stress

Automation introduces new stresses:

- Water Hammer: Fast-closing automatic valves can cause dangerous pressure surges (water hammer). You may need to select actuators with adjustable closing speeds or install surge protectors in the pipeline.

- Environmental Protection: Outdoor actuators need weatherproof (NEMA 4X) or explosion-proof enclosures. The actuator must be rated for the ambient temperature and humidity.

System Integration Checklist

Use this table as a pre-installation checklist for your automatic PVC valve system.

| Requirement Category | Specific Item to Check | Why It’s Important |

|---|---|---|

| Valve & Actuator | Valve torque vs. actuator torque rating. | Prevents actuator overload and failure. |

| Valve & Actuator | Mounting interface compatibility (e.g., ISO 5211). | Ensures the actuator fits and mounts securely. |

| Control System | Type of control signal matches actuator input. | The actuator must understand the command (e.g., on/off vs. 4-20mA). |

| Control System | Proper fuse or circuit breaker for electric actuators. | Protects against electrical shorts and overloads. |

| Installation | Pipe is supported near the valve. | Prevents stress on the valve body from pipe weight/vibration. |

| Installation | Actuator is accessible for manual override (if needed). | Allows manual operation during power failure or maintenance. |

| Safety | Considered fail-safe position (open/closed/stop). | Defines what happens in a power/air loss for process safety. |

By ensuring all these requirements are met, you move from a risky experiment to a reliable, long-term automated solution. At IFAN, we help clients plan this entire system, not just sell them parts.

Заключение

Choosing between manual and automatic PVC valve control depends on your needs, but the ability to upgrade offers great flexibility. For reliable PVC valves and perfectly matched automation solutions, trust ИФАН to provide the right components and expert support.

Последние комментарии