I’ve seen a metal valve fail after just weeks of handling chlorine, causing a costly shutdown. That experience proved why material choice is critical, and PVC offers a smart solution where others fail.

PVC is ideal for chemical pump valves because it provides exceptional corrosion resistance to a wide range of acids, bases, and salts at a very low cost. Its inherent smoothness reduces clogging, and its lightweight nature allows for easy installation and maintenance in aggressive chemical environments.

Now, let’s explore the specific properties that make PVC valves a top choice for handling corrosive chemicals.

Which Chemicals and Corrosive Substances Can PVC Valves Effectively Handle?

Choosing the wrong valve material can lead to dangerous leaks and system failure. For this reason, I always advise clients to match the valve to the specific chemical.

PVC valves can effectively handle a broad range of corrosive substances, including many dilute and concentrated acids (like hydrochloric and sulfuric acid), bases (like sodium hydroxide), salts, and oxidizing agents. However, their non-reactive nature makes them unsuitable for strong solvents, certain concentrated oxidizing acids, and aromatic hydrocarbons, so you must always check a chemical compatibility chart.

Understanding PVC’s Chemical Resistance

Professionals choose PVC for chemical services primarily because of its outstanding corrosion resistance. Unlike metals, PVC does not rust or corrode in the traditional sense. The material’s polymer structure remains inert to many aggressive substances that would quickly destroy metal valves.

This impressive resistance stems from the strong carbon-chlorine bonds in the material. These stable bonds do not easily react with many corrosive chemicals. As a result, the valve body and internal parts won’t degrade, ensuring long-term integrity and preventing contamination of the process fluid.

Key Chemicals and Applications

From my experience, here are common chemical families where PVC valves perform reliably:

- Acids: PVC handles many inorganic acids very well. This category includes hydrochloric acid (HCl), sulfuric acid (H₂SO₄) at various concentrations, and phosphoric acid. Consequently, it is a standard choice for acid dosing systems and effluent treatment.

- Bases and Alkalis: Solutions of sodium hydroxide (caustic soda) and potassium hydroxide are also well-managed by PVC valves, making them perfect for pH adjustment applications.

- Salt Solutions: PVC is highly resistant to brine, seawater, and many other salt solutions that cause severe pitting and corrosion in stainless steel.

- Oxidizing Agents: It shows good resistance to chemicals like sodium hypochlorite (bleach) and hydrogen peroxide at moderate concentrations, which are common in water treatment and disinfection.

Chemical Compatibility Guide

It’s crucial to consult a detailed chart, but this table provides a quick reference for common substances.

| Chemical | PVC Compatibility (at 20°C) | Typical Concentration | Notes |

|---|---|---|---|

| Hydrochloric Acid | Excellent | Up to 37% | A primary application for PVC valves. |

| Sulfuric Acid | Excellent to Good | Up to 70% | Check specific grade for high concentrations. |

| Sodium Hydroxide | Excellent | Up to 50% | Standard for caustic transfer. |

| Sodium Hypochlorite | Good | Up to 15% | Common in bleach dosing systems. |

| Acetone | Poor | Any | PVC will soften and dissolve. Use alternative materials. |

| Toluene | Poor | Any | Aromatic hydrocarbons attack PVC. |

A Critical Warning: You must always verify compatibility for your exact chemical, concentration, and temperature. Importantly, PVC is not suitable for strong solvents (like ketones, aromatics), concentrated nitric acid, or certain esters.

How Does PVC Material Ensure Reliable Sealing in Chemical Pump Systems?

A leak in a chemical line is a serious safety hazard. Through my work, I’ve found that PVC’s material properties directly contribute to a tight seal.

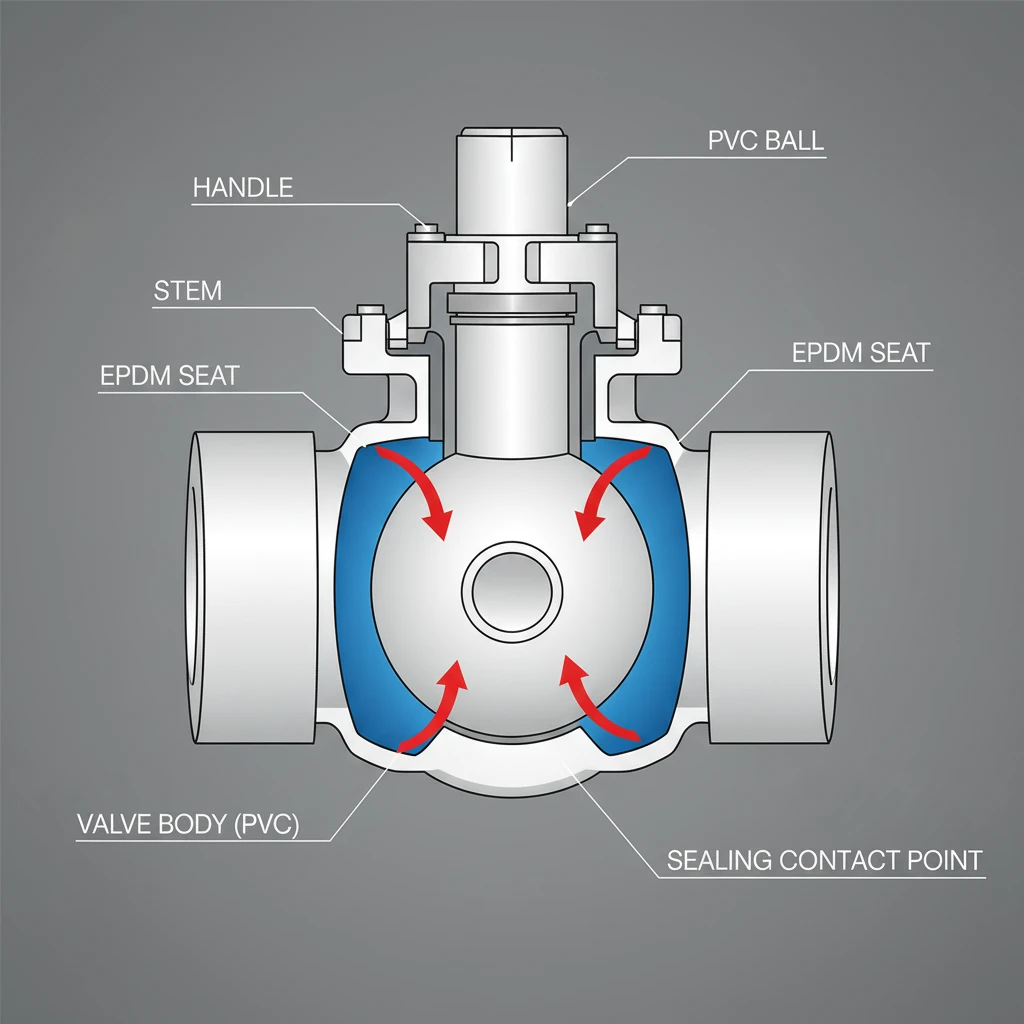

PVC material ensures reliable sealing through its machinability, which allows for the creation of very smooth, precise sealing surfaces on the valve seat and disc. Additionally, manufacturers use elastomeric seals (like EPDM or Viton) compatible with PVC bodies to create a tight, resilient closure that maintains integrity even after many cycles.

The Importance of Surface Finish

Reliable sealing in any valve depends on two main things: the precision of the sealing surfaces and the quality of the seal itself. PVC excels in the first area because manufacturers can easily machine it to a very smooth finish.

When a factory produces a PVC ball valve or diaphragm valve, they can make the sealing surfaces on the ball and seat (or the diaphragm) extremely smooth. This smoothness means that when the valve closes, there are no microscopic grooves or pits for fluid to escape through. Therefore, a tight, uniform contact is achieved across the entire sealing surface.

The Role of Elastomeric Seals

The second part of the seal comes from the elastomer (rubber) seats and seals used in PVC valves. Common choices include EPDM for general water and mild chemicals, and Viton (FKM) for a wider range of acids and solvents.

These elastomers compress when the valve closes. Their elastic nature allows them to conform perfectly to the machined PVC surface, filling any infinitesimal imperfections. This combination—a hard, smooth PVC surface and a soft, conforming elastomer—creates an excellent bubble-tight seal. Furthermore, these seals are designed for chemical resistance, so they won’t swell, crack, or degrade quickly, which maintains the seal’s effectiveness over time.

Valve Design for Optimal Sealing

Different PVC valve designs use this principle in specific ways:

- Ball Valves: A PVC ball with a precision-machined port rotates against resilient polymeric (e.g., PTFE) or elastomeric seats. Often, the pressure of the system helps push the ball against the downstream seat, enhancing the seal.

- Diaphragm Valves: A flexible, elastomeric diaphragm is pressed down by the valve stem onto a weir (a raised dam) in the PVC valve body. This action creates a very reliable seal that isolates the fluid entirely from the valve stem and bonnet, preventing any external leakage.

- Check Valves: A PVC or elastomer disc seals against a machined PVC seat to prevent backflow, relying on smooth surfaces and a good seal material.

The result is a sealing system that is both effective and durable in corrosive service, where metal-to-metal seals would gall or corrode shut.

What Are the Temperature and Pressure Limits for PVC Chemical Valves?

Exceeding the limits of a PVC valve is a common and costly mistake. Therefore, I always stress the importance of knowing these numbers before installation.

PVC chemical valves have clear temperature and pressure limits. Typically, the maximum continuous service temperature is around 60°C (140°F), and the maximum pressure rating drops as temperature rises. For instance, at room temperature (20°C), common Schedule 80 PVC valves can handle pressures up to 150 PSI, but this decreases significantly at higher temperatures.

Understanding the Temperature Limitation

PVC is a thermoplastic. This means it gets softer as it gets hotter. The maximum service temperature for standard PVC (uPVC) is about 60°C (140°F). Above this temperature, the material loses strength and can begin to deform under pressure.

This is the most critical limit for chemical applications. Many chemical processes or cleaning cycles involve hot fluids. It is essential to know the maximum fluid temperature, not just the ambient temperature. A common failure occurs when a steam condensate line or a hot wash cycle is connected to a PVC valve, causing it to warp or collapse.

Understanding the Pressure Limitation

The pressure rating of a PVC valve is not a single number. It is directly tied to the temperature. The material’s strength decreases as temperature increases. Therefore, the maximum safe working pressure is lower at higher temperatures.

For example, a valve rated for 150 PSI at 23°C (73°F) might only be rated for 75 PSI at 50°C (122°F). Manufacturers provide pressure-temperature rating charts for their products, and you must consult these for safe operation.

Key Factors Affecting Limits

Several factors define the exact limits for a specific PVC valve:

- PVC Schedule (Wall Thickness): Schedule 80 PVC has thicker walls than Schedule 40, giving it a higher pressure rating at the same temperature.

- Valve Design: A true union ball valve will have a different rating than a diaphragm valve due to differences in structure and stress points.

- Chemical Exposure: Some chemicals can weaken PVC over time, effectively lowering its temperature and pressure resistance. As a rule, always derate (use a lower rating) for aggressive chemicals.

Pressure-Temperature Rating Table (Example for Schedule 80 PVC)

This table shows the typical relationship. Always use the manufacturer’s official chart for your specific valve.

| Fluid Temperature | Maximum Working Pressure (Approx.) | Note |

|---|---|---|

| 20°C (68°F) | 150 PSI | Standard room temperature rating. |

| 30°C (86°F) | 130 PSI | Pressure rating begins to drop. |

| 40°C (104°F) | 110 PSI | Common limit for many cooled chemical processes. |

| 50°C (122°F) | 90 PSI | Close to the upper limit for safe operation. |

| 60°C (140°F) | 70 PSI | Absolute maximum temperature; pressure rating is much lower. |

Critical Safety Note: Never use PVC valves for compressed air or gas systems at their water pressure ratings. The energy stored in compressed gas can cause PVC to fail in a brittle and dangerous manner if damaged.

Why Choose PVC Over PPR or Metal for Specific Chemical Applications?

Selecting between PVC, PPR, and metal often comes down to cost versus performance. Typically, I guide clients to pick the most cost-effective material that safely does the job.

Choose PVC over PPR or metal when you need excellent corrosion resistance to specific acids and chlorides at a very low cost, and when temperature requirements are below 60°C. Choose PVC over metals for superior corrosion resistance without the high cost of exotic alloys. Conversely, choose PPR over PVC for higher temperature tolerance in non-corrosive hot water.

PVC vs. PPR: A Plastic vs. Plastic Choice

Both PVC and PPR are thermoplastics, but they serve different purposes.

- Temperature: This is the biggest difference. PPR can handle continuous hot water up to 70°C and short-term peaks higher, making it better for domestic hot water. In contrast, PVC is limited to 60°C, making it unsuitable for most hot water lines but fine for many chemical processes that run at ambient or cooled temperatures.

- Chemical Resistance: They have different chemical profiles. PVC is generally superior for a wider range of acids and oxidizing agents. Meanwhile, PPR has good chemical resistance but may not be the best choice for strong acids. As a result, PVC is often the default for industrial chemical transfer.

- Jointing: PPR uses heat fusion, creating monolithic joints. On the other hand, PVC uses solvent cement welding. Both are reliable, but fusion is considered slightly more robust for pressurized systems, while solvent welding is very common and effective for PVC.

Choose PVC for: Chemical transfer lines, acid waste drainage, bleach dosing, and room-temperature process lines where its specific chemical resistance is needed.

Choose PPR for: Hot and cold drinking water systems, industrial hot water circulation, and chemicals where its higher temperature rating is required.

PVC vs. Metal: The Corrosion Cost Equation

Comparing PVC to metals like stainless steel, cast iron, or bronze reveals its core advantage.

- Corrosion Resistance: PVC is vastly superior to standard metals like carbon steel or cast iron in corrosive environments. It even outperforms standard 304 stainless steel in applications involving chlorides (which cause pitting corrosion). To match PVC’s resistance, you often need expensive high-grade alloys (like Hastelloy or titanium).

- Cost: PVC valves and piping systems are significantly cheaper than metal systems, and dramatically cheaper than exotic alloy systems. Therefore, the installed cost difference can be enormous.

- Weight & Installation: PVC is very light, making handling and installation easier and faster than heavy metal pipe.

- Pressure/Temperature: Metals win here. Metal valves can handle much higher temperatures and pressures than PVC. So, if your process is hot or under very high pressure, PVC is not an option.

Choose PVC for: Handling corrosive acids, alkalis, and salts at low to moderate temperatures and pressures where metal would corrode quickly or be prohibitively expensive.

Choose Metal for: High-temperature processes, high-pressure systems, steam lines, or applications involving solvents that attack PVC.

Application Selection Guide

| Application | Recommended Material | Primary Reason |

|---|---|---|

| Hydrochloric Acid Transfer (Dilute) | PVC | Excellent corrosion resistance at very low cost. |

| Hot Water Circulation (70°C) | PPR | Higher temperature rating than PVC. |

| Chlorinated Salt Water (Seawater) | PVC | Superior resistance to pitting vs. standard stainless steel. |

| High-Pressure Steam Line | Metal (Steel) | PVC cannot handle the temperature or pressure. |

| Acetone or Solvent Transfer | Specialty Metal (e.g., SS316) | PVC is incompatible and would dissolve. |

Заключение

PVC valves offer unmatched cost-effective corrosion resistance for many chemicals at moderate temperatures. For reliable, certified PVC valves and fittings for your chemical applications, trust ИФАН as your supply partner.

Последние комментарии