I once had a client’s irrigation project fail because a cheap, uncertified PVC cement dissolved under pressure. That moment proved why standards matter.

Yes, a PVC glue meets international ASTM standards only if it is specifically formulated, tested, and certified to pass the rigorous performance and safety tests set by ASTM International. You cannot assume compliance; you must verify it by checking for the relevant ASTM standard codes (like D2564) on the product’s technical data sheet or certification mark.

Let’s break down exactly what these standards mean for your project’s safety and success.

What Are the Specific Requirements of ASTM Standards for PVC Cement?

Many glues claim to “meet” standards, but only certified products prove it. The specifics separate reliable products from the rest.

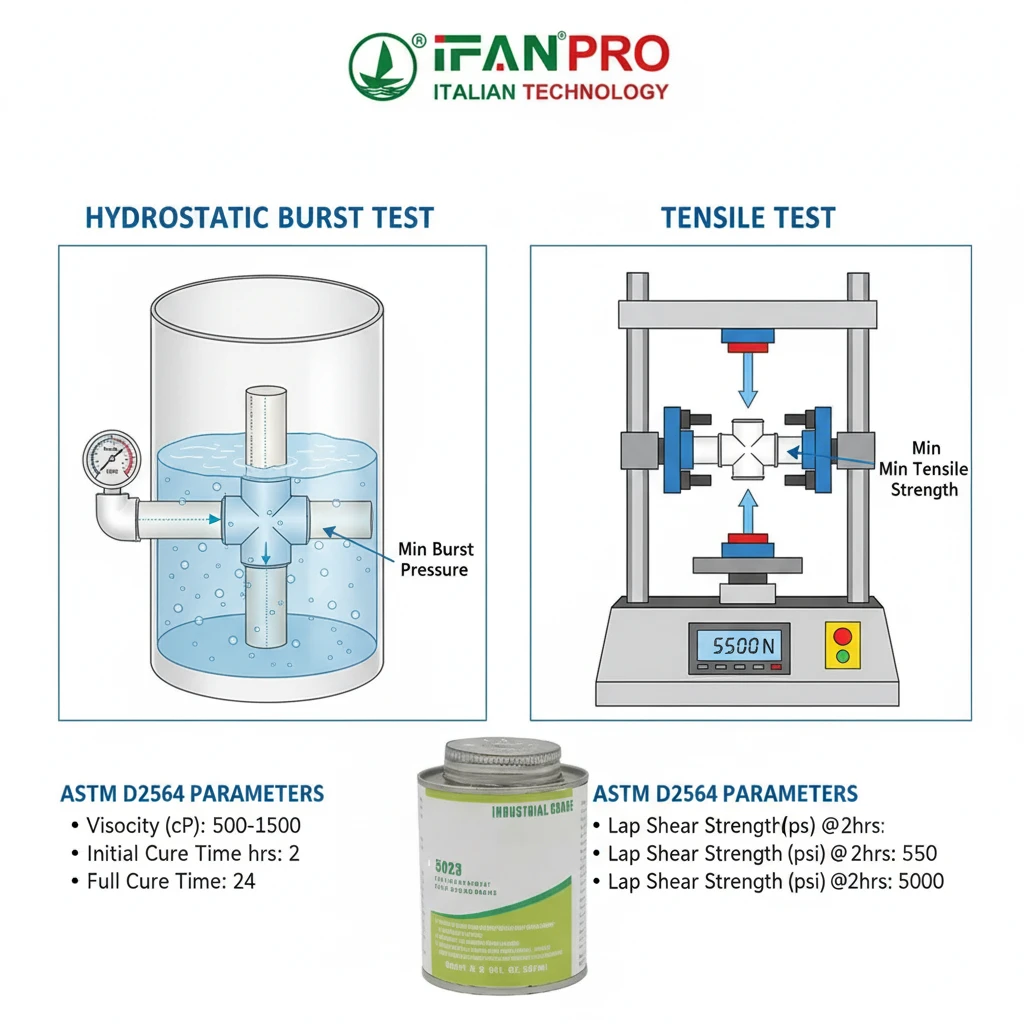

ASTM standards for PVC cement, primarily ASTM D2564 for PVC pipes and fittings, set specific requirements for joint strength, cure time, viscosity, and pressure resistance. The standard dictates precise laboratory tests that the cement must pass, such as achieving a minimum hydrostatic burst pressure and tensile strength within set timeframes, ensuring the glued joint performs as a unified system.

The Core Performance Benchmarks

Think of ASTM D2564 as a detailed recipe and quality check for PVC cement. It doesn’t just say the glue should work; it defines how well it must work under measurable conditions.

First, the standard sets rules for joint strength. The bond created by the cement must be stronger than the PVC pipe itself. This is tested by subjecting cemented joints to high internal water pressure until they burst (hydrostatic burst test) or by pulling them apart (tensile test). The cement must ensure the joint fails in the pipe wall, not at the glued seam.

Second, it regulates cure time. The cement must set fast enough for practical installation but also reach full strength within a specified period. This balances job site efficiency with long-term reliability. For example, a cement might need to withstand handling in minutes but achieve full pressure rating in hours.

Material and Consistency Specifications

Furthermore, the standard covers viscosity. The glue must be thick enough to fill the gap between the pipe and fitting without dripping, but fluid enough to be applied easily. This is crucial for creating a complete, void-free seal.

Another critical aspect is chemical composition and safety. While primarily a performance standard, D2564 implies the use of appropriate solvents and resins. Related standards and certifications (like NSF/ANSI 61 for potable water) govern the safety of these chemicals to ensure they don’t leach harmful substances.

Key ASTM D2564 Requirement Summary

| Недвижимость | Requirement | Why It Matters |

|---|---|---|

| Hydrostatic Burst Strength | The joint must withstand minimum pressure levels, often exceeding the pipe’s rated pressure. | Guarantees the joint won’t fail under normal or surge pressure conditions. |

| Tensile Strength | The bonded joint must meet a minimum pull-apart force. | Ensures the joint can withstand axial stresses and pulling forces. |

| Set Time & Cure Time | Defined stages for initial set and full strength development. | Allows for correct installation scheduling and prevents early pressure testing failures. |

| Viscosity | Must be within a specified range for proper application. | Ensures easy application and complete gap filling for a perfect seal. |

In short, ASTM D2564 provides a complete, verifiable blueprint for what makes a PVC cement trustworthy. A product claiming compliance must have passed these tests in a certified laboratory.

Why Is ASTM Certification Critical for PVC Glue Performance and Safety?

Choosing uncertified glue is a major gamble. I’ve seen the consequences: leaks, system failures, and costly rework.

ASTM certification is critical because it provides independent, scientific proof that the PVC glue will perform as expected under stress and over time. It validates the manufacturer’s claims for pressure rating, temperature resistance, and long-term durability, directly ensuring system safety, preventing leaks, and protecting your project investment from catastrophic failure.

The Guarantee of Predictable Performance

Without ASTM certification, you are relying solely on the manufacturer’s word. Certification moves the claim from marketing to fact-based assurance.

The most important reason is system integrity and safety. A plumbing or irrigation system operates under constant pressure. A weak joint can burst, causing water damage, service interruption, and in industrial settings, even safety hazards. ASTM testing, especially the hydrostatic burst test, simulates years of pressure stress in a short time. Using certified glue means your joints have a proven strength reserve.

Next, consider long-term durability and aging. PVC systems are designed to last decades. Certified cements are tested to ensure the chemical bond remains stable and does not degrade when exposed to water, soil chemicals, and temperature cycles over time. An uncertified glue might form an initially strong bond that becomes brittle and fails after a few years.

Protecting Health and Project Viability

For potable water applications, safety is twofold. While ASTM D2564 focuses on performance, using a certified cement is often a prerequisite for the overall system to achieve health safety certifications like NSF/ANSI 61. A certified glue uses ingredients that, when properly cured, do not contaminate drinking water.

From a project management and financial standpoint, certification is a risk mitigation tool. It reduces the risk of:

- Costly Leaks and Repairs: Fixing a failed joint behind a wall or underground is far more expensive than the glue itself.

- Project Delays: Failures during pressure testing or after installation halt projects.

- Liability Issues: In commercial projects, using non-compliant materials can violate building codes and insurance terms.

The Risk of Non-Certified Products

| Potential Risk | Consequence | How ASTM Certification Mitigates It |

|---|---|---|

| Insufficient Bond Strength | Joint failure under pressure, causing leaks or bursts. | Mandatory burst and tensile tests prove joint strength exceeds pipe strength. |

| Slow or Improper Curing | Joints fail during pressure testing or early service. | Set and cure time standards ensure reliable installation windows. |

| Material Degradation | Bond becomes brittle and fails after a few years. | Testing implies long-term stability of the chemical formulation. |

| Non-Compliance | Project fails inspection, violating codes and contracts. | Provides documented proof of compliance with industry specifications. |

Simply put, ASTM certification is not just a stamp; it’s your insurance policy for the entire piping system’s performance and longevity.

How Can You Test PVC Adhesive Compliance With ASTM International Standards?

You don’t need a lab to be a savvy buyer. Knowing how to verify compliance protects you from misleading claims.

You can test PVC adhesive compliance by first checking the product’s official Technical Data Sheet (TDS) for references to specific ASTM standards like D2564. Then, look for a valid certification mark or report from an independent third-party laboratory (like NSF, UL, or CSA) that confirms the product was tested and passed the full ASTM protocol, not just parts of it.

Step 1: Scrutinize the Product Documentation

As an end-user, you cannot perform the formal ASTM tests yourself, as they require specialized equipment and controlled conditions. However, you can perform due diligence by examining the evidence.

The first and most critical step is to review the Technical Data Sheet (TDS). This is a legally binding document from the manufacturer. Do not rely on general packaging or website claims. A compliant product will explicitly list the ASTM standards it meets. Look for clear statements like “Conforms to ASTM D2564” or “Meets the requirements of ASTM F656.” Be wary of vague language like “designed to meet” or “comparable to.”

Step 2: Verify Third-Party Certification

The gold standard of proof is independent third-party certification. This means a recognized laboratory has tested samples from production batches and verified compliance. Look for marks from:

- NSF International (especially NSF-pw for potable water)

- Underwriters Laboratories (UL)

- Canadian Standards Association (CSA)

These marks are usually printed on the product container or shown on the manufacturer’s website with a certificate number you can often verify online.

Step 3: Ask the Right Questions

If documentation is unclear, contact the supplier or manufacturer directly. Ask precise questions:

- “Can you provide the ASTM D2564 compliance certificate from an accredited third-party lab?”

- “Is this product certified for potable water (NSF/ANSI 61) in addition to ASTM D2564?”

- “What is the specific hydrostatic pressure rating of the cemented joint as per the test report?”

Compliance Verification Checklist

| Action Item | What to Look For | Red Flag |

|---|---|---|

| Read the TDS | Explicit mention of “ASTM D2564” or other relevant standards. | Phrases like “meets or exceeds” without a listed standard. |

| Check the Container | Third-party certification marks (NSF, UL, CSA). | No certification marks, only the manufacturer’s own logo. |

| Request Certificates | A test report from an independent lab with a date and batch number. | Refusal to provide documentation or only offering a generic “statement of compliance.” |

| Confirm Scope | Certification covers the exact product type (e.g., PVC Class, temperature rating). | A single certificate claimed to cover an entire product line without specific testing. |

Remember, the responsibility for proving compliance lies with the manufacturer. Your job is to demand and verify that proof before making a purchase.

Which Certified PVC Glue Should You Choose for Different Piping Applications?

Using the wrong type of certified glue is like using the wrong tool—it might work poorly or fail. Matching the product to the application is key.

You should choose a certified PVC glue based on the pipe type (PVC, CPVC), size, application (pressure or drain), and environment (indoor, underground, potable water). For example, use a standard ASTM D2564-certified PVC cement for schedule 40/80 pressure pipes, a NSF-certified version for drinking water, and a heavy-bodied cement for large-diameter pipes or vertical applications to prevent sagging.

Matching Glue to Pipe Material and System Type

All certified cements are not the same. Their formulations are optimized for different jobs.

First, distinguish between PVC and CPVC. These are different plastics with different chemical compositions. You must use a cement specifically formulated and certified for each material. Using a PVC cement on CPVC pipe (which handles hotter water) will result in a weak, unreliable joint. Look for certifications like ASTM F493 for CPVC cement.

Next, consider the system purpose. Is it for:

- Pressure Systems (water supply, irrigation): Requires cement certified to pressure standards like ASTM D2564. This is non-negotiable.

- DWV Systems (Drain, Waste, Vent): While still important, the pressure requirements are lower. Specific drain/waste cements are available, but using a pressure-rated cement is often a safer, more universal choice.

Considering Environmental and Practical Factors

The operating environment dictates special requirements:

- Potable Water: The cement must have additional NSF/ANSI 61 certification to ensure it does not contaminate drinking water. Never use a non-NSF cement on pipes carrying drinking water.

- Underground or Wet Conditions: Look for cements labeled as “all conditions” or “wet conditions” that can bond effectively even if the pipe surface is slightly damp.

- Large Diameter Pipes or Vertical Runs: Use a heavy-bodied or high-viscosity cement. It won’t drip or sag, ensuring an even application and complete socket fill on big pipes or overhead joints.

PVC Glue Selection Guide Table

| Application Scenario | Pipe Type | Key Standards/Certifications Needed | Recommended IFAN Product Type |

|---|---|---|---|

| Residential Potable Water Supply | PVC Schedule 40 | ASTM D2564, NSF/ANSI 61 | IFAN Standard PVC Cement (NSF Certified) |

| Hot & Cold Water Supply (up to 200°F/93°C) | CPVC | ASTM F493, NSF/ANSI 61 | IFAN CPVC Cement |

| Underground Irrigation & Pressure Mains | PVC Schedule 40/80 | ASTM D2564, All-Weather Formula | IFAN Heavy-Bodied PVC Cement |

| Industrial Pressure Process Pipes | PVC Schedule 80 | ASTM D2564, High Pressure Rating | IFAN High-Strength PVC Cement |

| Drain, Waste & Vent (DWV) Systems | PVC DWV | Local Plumbing Code Compliance | IFAN Universal PVC Cement |

Finally, always follow the manufacturer’s instructions on the can for primer use (if required), application temperature, and cure times, even with a certified product. Proper surface preparation and technique are part of achieving the certified performance.

Заключение

Choosing the right ASTM-certified PVC glue ensures safety, durability, and compliance. For reliable, application-specific solutions, trust IFAN’s range of certified PVC and CPVC cements.

Последние комментарии