Many clients ask me which PEX type is the “best.” The truth is, the choice between PEX-A and PEX-B isn’t about good versus bad, but about the right tool for the specific job.

The main difference between PEX-A and PEX-B lies in their manufacturing process. PEX-A is made using the Engel method, creating a more flexible pipe with superior freeze resistance due to its cross-linked molecular structure. PEX-B uses the Silane method, resulting in a stiffer, more cost-effective pipe known for its high burst pressure resistance.

Both types have their place in plumbing, and the best choice depends on your project’s specific needs. Let’s break down these differences step by step.

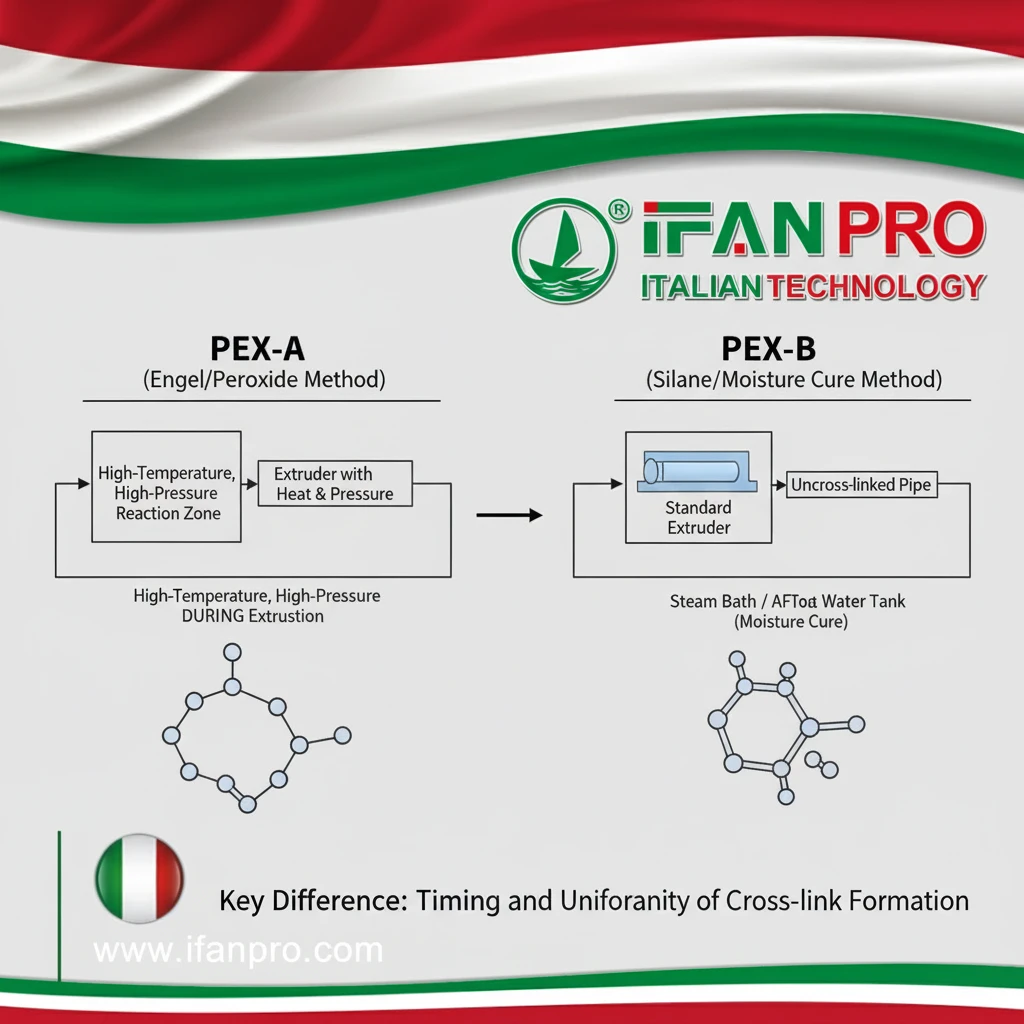

How Do Manufacturing Processes Differ for PEX-A and PEX-B Pipes?

The creation method isn’t just a technical detail—it defines the pipe’s very nature. I explain this to clients to help them understand why two types of PEX can behave so differently.

PEX-A pipes are manufactured using the Peroxide (Engel) method, where cross-linking happens during extrusion under high heat and pressure. PEX-B pipes are made using the Silane (Moisture Cure) method, where cross-linking occurs after extrusion, when the pipe is placed in a hot water or steam bath. This core process difference affects flexibility, memory, and long-term performance.

The Science Behind PEX-A: Peroxide Cross-Linking

The Engel method for creating PEX-A is a “hot” process. Manufacturers mix high-density polyethylene with organic peroxides. As the material is extruded into a pipe shape, it is subjected to very high temperatures and pressures. This environment causes the peroxide to decompose, creating free radicals that directly form bonds (cross-links) between the polymer chains right then and there.

Think of it like cooking a cake where all the ingredients mix and bake simultaneously. Because the cross-linking is immediate and uniform throughout the material, it creates a more flexible and elastic final product. This process gives PEX-A its signature “memory”—its ability to return to its original shape after being stretched—and a higher degree of cross-linking, typically around 80-90%.

The Science Behind PEX-B: Silane Cross-Linking

The Silane method for PEX-B is a “cooler,” two-step process. First, polyethylene is mixed with a silane compound and extruded into pipe at a lower temperature. At this stage, the pipe is not fully cross-linked; it’s known as a “pre-polymer.” Next, the pipe is placed in a hot water or steam bath. This moisture triggers a chemical reaction in the silane, creating the bridges (cross-links) between the polymer chains.

This is more like shaping dough and then putting it in the oven to set. The cross-linking happens from the outside in, which can sometimes lead to a slightly less uniform structure compared to PEX-A. The cross-linking density is typically around 70-80%.

Comparing the Two Methods

The table below summarizes how these processes lead to different material properties.

| Manufacturing Aspect | PEX-A (Engel Method) | PEX-B (Silane Method) |

|---|---|---|

| Cross-Linking Process | During extrusion (Hot). | After extrusion in a bath (Moisture Cure). |

| Typical Cross-Link Density | Higher (~80-90%). | Slightly lower (~70-80%). |

| Key Characteristic | Superior flexibility and elastic memory. | Higher burst pressure resistance, more rigid. |

| Production Cost | Generally higher. | Generally lower. |

This fundamental difference in “how they are made” is the root cause of all the practical differences you see on the job site—from how they feel in your hands to how they perform under stress.

Which PEX Type Offers Better Flexibility and Freeze Resistance?

In cold climates, this is the most critical question. I’ve seen both types perform, but one has a clear physical advantage in extreme situations.

PEX-A offers better flexibility and freeze resistance. Its molecular structure allows it to expand significantly more without rupturing, meaning it can often recover from a freeze event. PEX-B is stiffer and, while strong, is more likely to rupture if the water inside freezes solid because it has less capacity to expand.

Flexibility: Handling and Installation Ease

When you pick up a coil of PEX-A, you immediately notice it’s much more pliable. It uncoils easily and can be bent by hand into tight radii without kinking. This makes installation faster, reduces the number of fittings needed for turns, and is a major advantage in tight spaces like retrofit projects.

PEX-B, in contrast, is much stiffer. It often requires a bending spring or heat gun to make sharp turns without kinking. This stiffness can be an advantage for long, straight runs where you want the pipe to hold its position neatly, but it generally requires more fittings and effort during installation.

The Freeze Resistance Advantage

Freeze resistance is where PEX-A’s properties truly shine. Its high degree of cross-linking and elastic memory give it a remarkable ability to expand.

- PEX-A Performance: When water freezes inside PEX-A, the pipe can expand to accommodate the ice formation. It acts like a balloon stretching. Once the ice thaws, the pipe’s “memory” property allows it to contract back to near its original size, often without any damage. It’s not freeze-proof, but it is highly freeze-resistant.

- PEX-B Performance: PEX-B is very strong under steady pressure (high burst strength), but it is less elastic. When frozen, it has less capacity to expand. The immense pressure from the expanding ice is more likely to cause a brittle rupture or a split at a fitting connection.

For climates with harsh winters, or for installations in vulnerable areas like attics or exterior walls, PEX-A provides a much greater safety margin against costly freeze damage.

Performance Summary Table

| Недвижимость | PEX-A | PEX-B | Practical Implication |

|---|---|---|---|

| Гибкость | Excellent. Easy to bend by hand. | Good, but stiff. Often needs tools to bend. | PEX-A allows faster, fitting-saving installs. |

| Kink Resistance | High. If kinked, can often be repaired with heat. | Moderate. A kink may require cutting out the section. | PEX-A is more forgiving during installation. |

| Freeze Expansion Capacity | Very High. Can expand and contract back. | Lower. More prone to bursting if frozen. | PEX-A is the safer choice for freeze-prone areas. |

| Burst Pressure (at room temp) | High (e.g., 500+ psi at 73°F). | Very High (e.g., 600+ psi at 73°F). | PEX-B excels in high-temperature, high-pressure tests. |

Therefore, if your primary concerns are ease of installation and maximum protection against freezing, PEX-A is the superior choice.

When Should You Use Oxygen-Barrier Versus Standard PEX Pipes?

Mixing up these two types is a common and costly mistake. I always ask clients about their heating system first to guide them correctly.

Use oxygen-barrier PEX (often identified by a red, orange, or blue layer) exclusively for closed-loop hydronic heating and radiant floor heating systems. Use standard, non-barrier PEX for all potable water plumbing applications, such as domestic hot and cold water supply lines.

The Problem of Oxygen Diffusion

This choice has nothing to do with A or B types; both PEX-A and PEX-B come in barrier and non-barrier versions. The issue is oxygen permeation.

All standard plastic pipes allow tiny amounts of oxygen from the air to slowly diffuse through the pipe wall and into the water. For drinking water, this is irrelevant. However, in a closed-loop heating system filled with water and anti-freeze (glycol), this oxygen is a disaster waiting to happen.

Oxygen in the system leads to rapid corrosion of ferrous (iron-based) components in the boiler, circulators, pumps, and valves. This corrosion causes sludge, reduces efficiency, leads to noise, and ultimately results in premature and expensive system failure.

Identifying and Using Barrier PEX

Oxygen-barrier PEX has a thin, extra layer of polymer (like EVOH) laminated to the outside of the pipe. This layer is a near-impenetrable shield that reduces oxygen diffusion to acceptable levels for heating systems.

- How to Identify It: Look for the printed markings. Barrier PEX will clearly say “Oxygen Barrier,” “OB,” “AX,” or “for Hydronic Heating.” It is usually red for hot supply lines, blue for cold returns, but always check the label.

- Correct Application: Only use it in heating loops. It connects the boiler to the manifolds and the manifolds to the floor tubing or radiators. The fluid in this loop never mixes with your tap water.

Identifying and Using Standard PEX

Standard, non-barrier PEX is for your home’s drinking and bathing water. Using barrier PEX here is unnecessary and a waste of money, as the oxygen barrier layer offers no benefit for potable water.

- How to Identify It: It will be marked as “Potable Water,” “NSF 61,” “NSF pw,” or simply have no oxygen barrier designation.

- Correct Application: Use it for all your domestic cold and hot water lines running from your main to your sinks, showers, and toilets.

Application Guide Table

| System Type | Recommended PEX Type | Why? |

|---|---|---|

| Hydronic Radiant Floor Heating | Oxygen-Barrier PEX (A or B) | Protects expensive metal components from corrosion. |

| Baseboard/ Radiator Heating Loops | Oxygen-Barrier PEX (A or B) | Protects the boiler, pump, and valves from oxidation damage. |

| Domestic Hot & Cold Water Supply | Standard, Non-Barrier PEX (A or B) | Oxygen diffusion is not a concern for drinking water. Cost-effective. |

| Snow Melt Systems | Oxygen-Barrier PEX (A or B) | A closed-loop heating system, same rules apply. |

The Rule of Thumb: Always check the pipe print line. Never use a pipe marked for plumbing in your heating system, and don’t pay extra for barrier pipe on your standard water lines.

How Do You Choose Between PEX-A and PEX-B for Specific Applications?

There is no universal winner. My recommendation always starts with asking about the project’s climate, budget, and installer’s skill.

Choose PEX-A for projects where maximum flexibility, superior freeze resistance, and easier repairs are top priorities. Choose PEX-B for projects with a strict budget, long straight runs, or where high-temperature/high-pressure ratings are the main concern and freeze risk is minimal.

Decision Factor 1: Climate and Freeze Risk

This is the most decisive factor. If the installation is in a cold climate, an unheated basement, an attic, or an exterior wall, the freeze resistance of PEX-A makes it the wiser, safer investment. The potential cost of repairing a burst pipe far outweighs the initial material savings of PEX-B.

For interior, climate-controlled spaces in mild climates, the freeze resistance advantage is less critical, opening the door to other factors.

Decision Factor 2: Installation Complexity and Labor Cost

Consider the layout of the plumbing system.

- For complex retrofits with tight bends: The hand-bendability of PEX-A saves significant time and fittings. It’s the installer’s favorite for tricky jobs.

- For new construction with long, straight trunk lines:** The stiffness of PEX-B can be an asset, as it hangs neatly and requires fewer support clips. If labor rates are high, the lower material cost of PEX-B can impact the total project bid.

Decision Factor 3: Fitting Systems and Repairs

This is a crucial, often overlooked, difference.

- PEX-A is almost exclusively used with expansion fittings. You use a special tool to expand the pipe and a PEX-A ring, then insert the fitting. As the pipe shrinks back, it creates a powerful, reliable seal. A major benefit is that you can repair a fitting by reheating the pipe and ring with a special tool to release it.

- PEX-B is commonly used with crimp or clamp (cinch) fittings. You slide a metal ring over the pipe, insert the fitting, and use a tool to compress the ring. This creates a strong, permanent seal but is not serviceable—to change a fitting, you must cut it out.

Application-Based Recommendation Guide

| Project Scenario | Recommended Choice | Primary Reasons |

|---|---|---|

| Whole-house repipe in a cold climate | PEX-A | Superior freeze protection for the entire system, flexible for retrofits. |

| Hydronic radiant floor heating tubing | PEX-A | Best flexibility for snaking through floor joists, excellent long-term reliability under heat. |

| New construction, warm climate, tight budget | PEX-B | Cost-effective for long straight runs, high burst strength is adequate. |

| DIY project by a homeowner | PEX-B with clamp tools | Lower tool cost ($50-100 for clamp tool vs. $300+ for expansion tool). Simpler to learn. |

| Commercial project requiring UL listings for high temps | Verify with spec sheet | PEX-B often has higher pressure ratings at elevated temps (e.g., 100 psi at 180°F), but check specific product listings. |

Ultimately, both are excellent, durable materials that outperform metal in many ways. The choice comes down to matching the pipe’s inherent strengths to your project’s specific demands.

Заключение

PEX-A offers top-tier flexibility and freeze resistance, while PEX-B provides excellent strength at a lower cost. For a reliable supply of both PEX-A and PEX-B pipes and all necessary fitting systems, trust ИФАН to deliver certified quality for any application. Contact us for your project-specific needs.

Последние комментарии