In chemical processing plants and water treatment facilities, PP-R pipes consistently demonstrate exceptional performance where metal alternatives fail. The fundamental difference lies in the material science: while metals undergo electrochemical degradation, PP-R maintains structural integrity through its inert polymer composition.

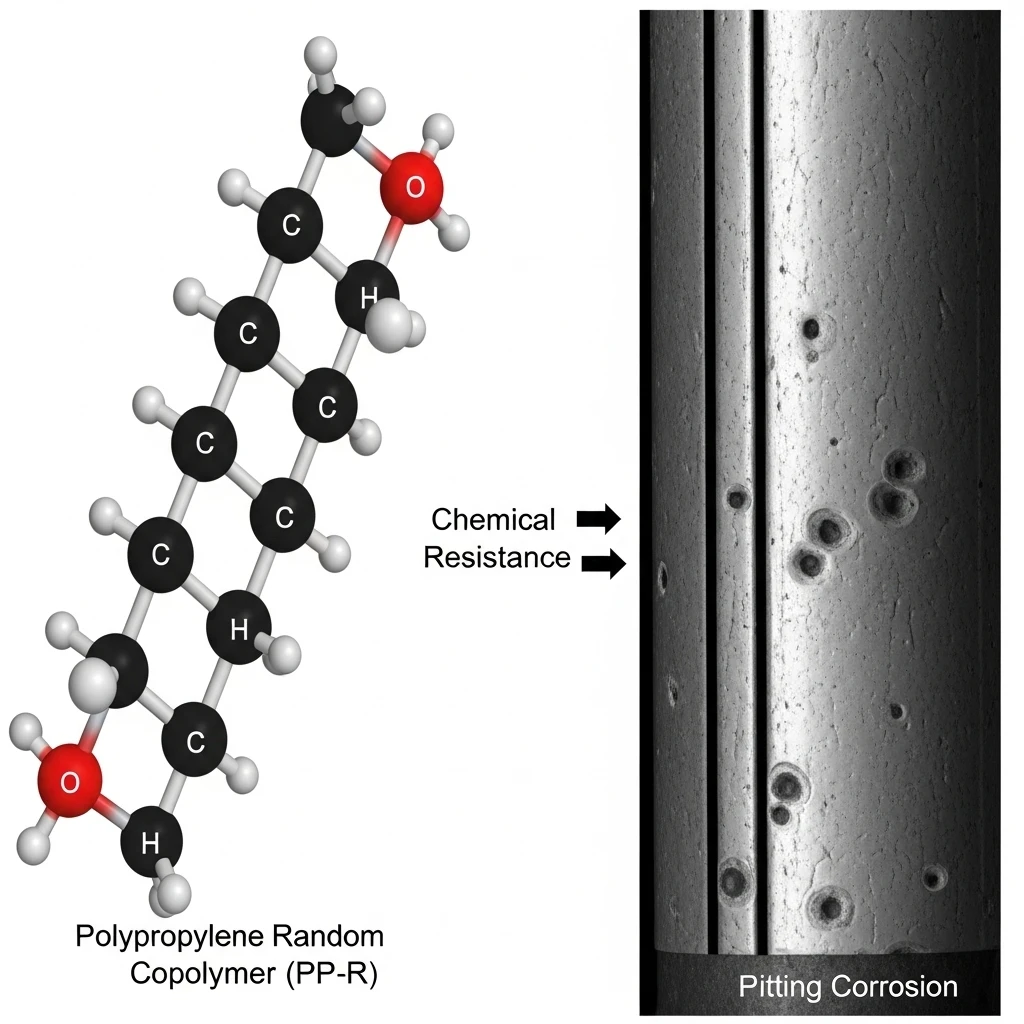

PP-R pipes offer complete corrosion resistance due to their polypropylene random copolymer structure, which prevents the electrochemical reactions that deteriorate metal pipes. This inherent property eliminates rust, scale accumulation, and chemical degradation, ensuring long-term water quality preservation and extended system lifespan without the maintenance demands of metallic alternatives.

Understanding the technical basis for PP-R’s corrosion resistance enables better material selection decisions. The following sections explore the specific characteristics that make these pipes ideal for demanding applications where corrosion resistance is paramount.

What Chemical Properties Make PP-R Pipes Completely Corrosion-Resistant?

Comparative testing across various environments reveals why PP-R maintains performance while metal pipes deteriorate. The answer lies in molecular structure and chemical composition.

PP-R’s corrosion immunity stems from its saturated carbon-carbon bonds that resist oxidation, absence of metallic elements vulnerable to electrochemical reactions, and non-polar surface that prevents ionic bonding. These fundamental characteristics create a material inherently protected against the corrosion mechanisms that plague metal piping systems.

Molecular Structure Advantages

The corrosion resistance begins at the molecular level. PP-R consists of long-chain polymers with stable covalent bonds that don’t participate in electron transfer processes. Unlike metals, these polymers contain no free electrons to drive galvanic corrosion, making them immune to the electrochemical degradation that shortens metal pipe lifespan.

Material homogeneity further enhances performance. While metal pipes often have heterogeneous microstructures with vulnerable grain boundaries, PP-R’s uniform composition provides consistent resistance throughout the material. This eliminates the localized corrosion that creates pitting and premature failures in metallic systems.

Comprehensive Chemical Resistance

PP-R demonstrates exceptional performance across diverse chemical environments:

| Chemical Exposure | PP-R Performance | Metal Pipe Vulnerability | Practical Impact |

|---|---|---|---|

| Chlorinated Water | No degradation | Pitting and crevice corrosion | 5x longer service life |

| Acidic Conditions (pH 2-5) | Full resistance | Rapid wall thinning | No protective lining required |

| Alkaline Solutions (pH 9-12) | Maintains integrity | Surface etching and general corrosion | Consistent flow characteristics |

| High Mineral Content | No scale adhesion | Progressive flow reduction | Stable system pressure |

How Does PP-R Prevent Rust and Scale Buildup in Plumbing Systems?

Documented case studies show PP-R systems maintaining original flow capacity decades after installation, while metallic alternatives require progressive pump pressure increases to compensate for internal constriction from corrosion products.

PP-R prevents rust through its non-metallic composition containing no iron to oxidize, while resisting scale through a smooth surface that provides no nucleation sites for mineral crystals. This dual protection maintains consistent internal diameter and hydraulic efficiency throughout the system’s service life.

Rust Prevention Mechanism

The rust prevention approach is fundamentally different from metallic systems. Since PP-R contains no iron, the oxidation process that creates rust in ferrous pipes cannot initiate. This eliminates the gradual wall thinning and structural weakening that plagues steel pipes in oxygenated water environments.

Unlike metal pipes that require protective coatings, cathodic protection, or chemical inhibitors, PP-R’s protection is intrinsic to the material. These secondary protection systems often fail over time in metallic pipes, while PP-R maintains its corrosion resistance permanently without maintenance or monitoring.

Scale Resistance Properties

Scale prevention operates through multiple physical mechanisms. The material’s low surface energy prevents strong adhesion of mineral crystals to the pipe wall. While water hardness may cause mineral precipitation, the crystals cannot form the tenacious bonds that create permanent scale deposits in metal pipes.

Thermal properties further enhance scale resistance. PP-R’s lower thermal conductivity reduces the temperature gradient at the pipe wall that typically drives scale formation in metallic hot water systems. This characteristic proves particularly valuable in applications with high water temperatures where scale accumulation typically accelerates.

Why Won’t PP-R Pipes Corrode Like Metal Pipes in Water Systems?

Long-term performance data from municipal water systems demonstrates PP-R’s superiority, with installations maintaining integrity after decades of service while metallic alternatives require replacement due to corrosion-induced failures.

PP-R pipes cannot experience metallic corrosion because they lack the necessary components for electrochemical reactions: no metallic atoms to oxidize, no electrical conductivity to support galvanic cells, and no crystalline structure vulnerable to chemical attack. This fundamental difference in material science prevents the corrosion mechanisms that inevitably degrade metal pipes.

Electrochemical Immunity

Corrosion processes require specific conditions that PP-R cannot support. Metallic corrosion involves anodic reactions where metal atoms lose electrons and dissolve, and cathodic reactions where those electrons are consumed. PP-R contains no metallic atoms to participate in these reactions, making it fundamentally immune to electrochemical corrosion regardless of water chemistry.

Galvanic corrosion presents another concern eliminated by PP-R’s properties. When dissimilar metals connect in water, the more active metal corrodes rapidly. PP-R’s non-conductive nature prevents this corrosion mechanism, allowing connection to various system components without requiring dielectric isolation.

Chemical Degradation Resistance

PP-R resists chemical attack through its stable polymer structure. While metals corrode through oxidation or reaction with specific ions, PP-R’s covalent bonds resist breaking under normal water system conditions. The material maintains performance across extreme pH levels and resists oxidation from strong disinfectants.

Environmental stress cracking resistance further differentiates PP-R from many plastics. The random copolymer structure withstands simultaneous chemical exposure and mechanical stress, a common failure combination in plumbing systems that causes many plastics to fail prematurely.

How Does PP-R’s Corrosion Resistance Improve Water Quality and Pipe Longevity?

Water quality monitoring demonstrates significantly lower metal content in PP-R systems compared to metallic alternatives, with particular benefits in sensitive applications like healthcare facilities, laboratories, and food processing plants.

PP-R’s corrosion resistance preserves water quality by eliminating metal ion leaching and corrosion product contamination, while extending system longevity by maintaining structural integrity and hydraulic performance. This dual benefit ensures consistent water purity and reliable operation throughout the pipe’s 50-year design life.

Water Quality Protection

The water quality benefits begin with eliminating metallic contamination. Copper, iron, and lead pipes continuously leach ions into drinking water, particularly in aggressive water conditions. PP-R releases no metallic elements, maintaining water purity and eliminating concerns about heavy metal contamination.

Corrosion product contamination is equally important. The discoloration, turbidity, and particulate matter common in aging metal systems cannot occur with PP-R. This maintains aesthetic water quality and prevents the staining of fixtures and appliances that plagues metallic systems.

Longevity Enhancement

Service life advantages stem from maintained integrity. Unlike metal pipes that experience progressive wall thinning from corrosion, PP-R maintains its original dimensions throughout its service life. This preserves pressure rating and structural integrity indefinitely when operated within design parameters.

Localized failure modes common in metal systems are eliminated. Pitting corrosion, which creates small perforations while the majority of the pipe appears sound, cannot occur in PP-R. This prevents the unexpected leaks and catastrophic failures that often disrupt operations in aging metallic plumbing.

System Performance Benefits

The corrosion resistance translates into measurable advantages:

| Performance Aspect | Metal Pipe Limitations | PP-R Pipe Advantages | Operational Impact |

|---|---|---|---|

| Flow Capacity | Decreases over time | Maintains original performance | Consistent pressure and flow |

| Maintenance Frequency | Regular corrosion monitoring | Minimal inspection requirements | Reduced operational costs |

| Water Purity | Degrades with system age | Consistent throughout lifespan | Better compliance with standards |

| System Reliability | Unpredictable failures | Predictable long-term performance | Reduced emergency repairs |

Заключение

PP-R pipes provide complete corrosion resistance through their inert chemical structure, preventing the rust, scale, and deterioration that compromise metallic piping systems. This inherent characteristic ensures maintained water quality, extended system longevity, and reduced lifetime costs. For applications demanding corrosion resistance and water purity, PP-R represents the optimal choice, eliminating the progressive performance degradation and unexpected failures characteristic of metal pipes in water systems. IFAN’s expertise in PP-R technology ensures solutions that maximize these benefits through proper material selection and system design.

Последние комментарии