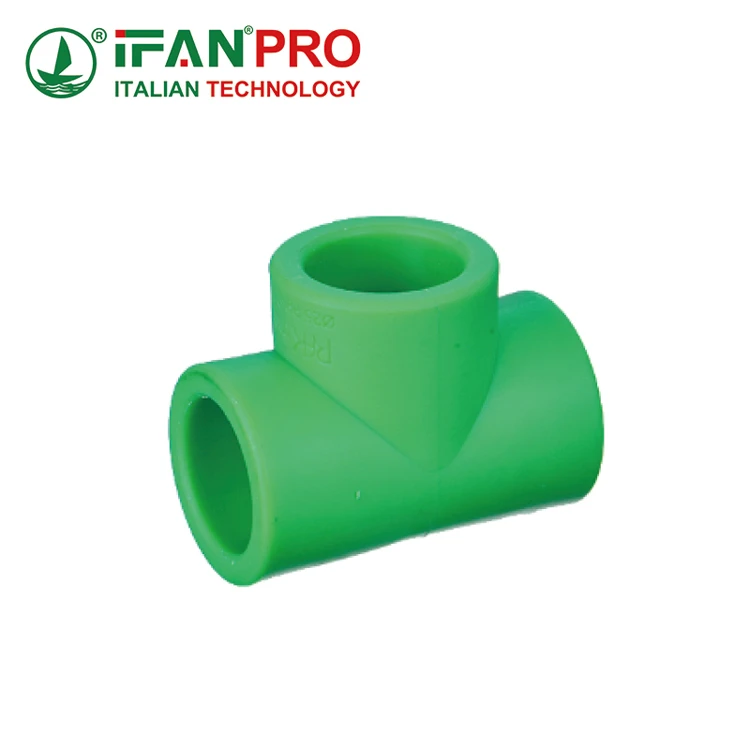

PPR tee fittings are essential components in modern plumbing systems. These versatile connectors enable three-way pipe connections with superior durability and reliability. When sourcing directly from manufacturers, you gain access to premium quality at competitive prices.

Why Choose Factory Direct PPR Tee Fittings?

Direct factory purchasing eliminates middleman costs. You receive authentic products with full traceability. Quality control happens at the source, ensuring consistent performance across every batch.

Factory direct sales provide several key advantages:

- Lower unit costs for bulk orders

- Customization options for specific project requirements

- Direct communication with engineering teams

- Faster lead times for standard sizes

- Comprehensive technical support

Understanding PPR Tee Fitting Applications

PPR tee fittings excel in both residential and commercial installations. Hot water systems benefit from their thermal resistance properties. Cold water applications appreciate their chemical stability and long service life.

Common installation scenarios include:

- Branch connections in main supply lines

- Water heater integration points

- Irrigation system distribution networks

- Industrial process piping layouts

- HVAC system connections

Quality Standards That Matter

Premium PPR tee fittings meet international certification requirements. ISO standards ensure dimensional accuracy and material consistency. Pressure ratings comply with regional plumbing codes worldwide.

Material composition directly impacts performance longevity. Virgin polypropylene random copolymer provides optimal strength characteristics. Stabilizer additives prevent UV degradation and thermal breakdown.

Size Options and Specifications

Standard PPR tee fittings range from 20mm to 110mm diameter connections. Equal tees maintain consistent pipe dimensions across all three outlets. Reducing tees accommodate different pipe sizes in single fittings.

Threading options include:

- Socket fusion connections for permanent joints

- Threaded male/female combinations

- Mixed connection types for versatile applications

- Custom threading specifications upon request

Installation Best Practices

Proper installation ensures optimal performance and longevity. Clean pipe ends before fusion welding. Maintain correct heating temperatures during socket connections. Allow adequate cooling time before system pressurization.

Professional installers recommend specific tools for PPR fitting assembly. Specialized heating equipment ensures consistent weld quality. Pipe cutters create clean, square end preparations.

Custom Manufacturing Capabilities

Factory direct suppliers offer extensive customization services. Non-standard dimensions accommodate unique project requirements. Special material grades handle extreme temperature or chemical conditions.

Custom options include:

- Modified outlet angles for space constraints

- Reinforced wall thickness for high-pressure applications

- Color coding for system identification

- Integrated mounting features for support systems

- Specialized end connections for hybrid installations

Quality Assurance and Testing

Rigorous testing protocols verify every production batch. Pressure testing exceeds standard operating requirements by significant safety margins. Dimensional inspections ensure precise fit-up with existing pipe systems.

Testing procedures include:

- Hydrostatic pressure validation

- Thermal cycling stress tests

- Chemical compatibility verification

- Long-term aging simulations

- Impact resistance evaluations

Cost-Effective Sourcing Strategies

Direct factory relationships reduce total project costs significantly. Volume pricing tiers provide economies of scale for larger installations. Long-term supply agreements stabilize pricing over extended project timelines.

Procurement advantages include:

- Transparent pricing without distributor markups

- Flexible payment terms for established customers

- Consolidated shipping for mixed product orders

- Technical documentation in multiple languages

- Warranty support directly from manufacturing source

Global Shipping and Logistics

Efficient logistics networks ensure timely delivery worldwide. Export documentation includes all necessary certifications for international projects. Packaging protects products during extended transportation cycles.

Shipping options accommodate various project schedules:

- Express shipping for urgent requirements

- Consolidated freight for cost optimization

- Direct container shipments for large orders

- Regional distribution center support

- Local pickup arrangements where applicable

Technical Support and Documentation

Comprehensive technical resources support successful installations. Detailed specification sheets provide all necessary design parameters. Installation guides ensure proper assembly procedures.

Available documentation includes:

- CAD drawings for system design integration

- Pressure-temperature rating charts

- Chemical compatibility matrices

- Installation procedure videos

- Troubleshooting guides for common issues

Экологические соображения

PPR materials offer excellent environmental profiles compared to traditional metal fittings. Recyclability supports sustainable construction practices. Lower transportation weights reduce carbon footprint for global projects.

Sustainability benefits include:

- 100% recyclable material composition

- Energy-efficient manufacturing processes

- Reduced installation labor requirements

- Minimal maintenance needs over service life

- No toxic substances in material formulation

Choosing the Right Supplier

Reliable suppliers demonstrate consistent quality and service excellence. Manufacturing certifications indicate adherence to international standards. Customer references provide insight into real-world performance.

Evaluation criteria should include:

- Production capacity for your volume requirements

- Quality management system certifications

- Technical support capabilities

- Delivery performance history

- Competitive pricing structure

Заключение

Direct sourcing of PPR tee fittings from qualified manufacturers provides optimal value for plumbing projects. Quality assurance, customization capabilities, and competitive pricing make factory direct purchasing the preferred approach for professional contractors and system designers.

Contact experienced PPR fitting manufacturers to discuss your specific project requirements. Professional consultation ensures optimal product selection for your unique application needs.

Последние комментарии