What Makes PPR Female Thread Sockets Essential for Modern Plumbing?

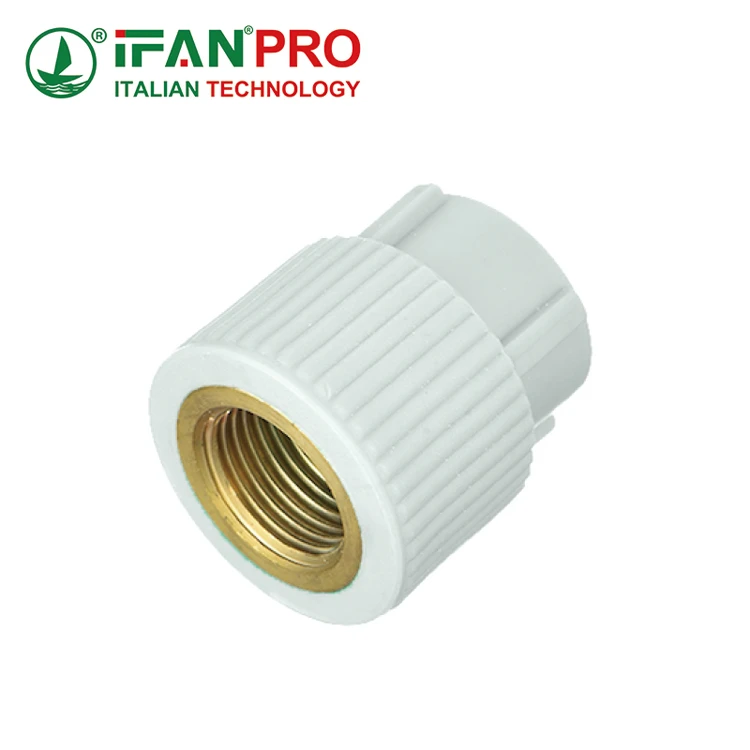

PPR female thread sockets revolutionize plumbing connections. These versatile fittings combine the durability of polypropylene random copolymer with threaded metal inserts. Professional plumbers choose them for residential and commercial projects.

The female thread design accepts male-threaded pipes and fittings seamlessly. This creates leak-proof connections that withstand high pressure and temperature variations.

Key Features of Premium PPR Female Thread Sockets

Superior Material Composition

High-quality PPR material offers exceptional chemical resistance. It withstands acidic and alkaline substances without degradation. The random copolymer structure provides enhanced impact strength at low temperatures.

Precision Threading

Machine-cut threads ensure perfect alignment with standard pipe fittings. The brass or stainless steel inserts resist corrosion effectively. Thread pitch meets international standards for universal compatibility.

Temperature Resistance

Operating range spans from -10°C to 95°C continuously. Short-term exposure to 110°C causes no structural damage. This thermal stability suits both hot and cold water applications.

Installation Advantages of Direct-Selling PPR Sockets

Cost-Effective Solution

Direct factory pricing eliminates middleman markups. Bulk purchasing options reduce per-unit costs significantly. Long-term durability minimizes replacement expenses.

Easy Installation Process

Heat fusion welding creates permanent connections. No special tools required beyond standard PPR welding equipment. Installation time reduces by 40% compared to traditional threaded joints.

Maintenance-Free Operation

Smooth internal surfaces prevent mineral buildup. No periodic tightening needed like mechanical fittings. Service life exceeds 50 years under normal conditions.

Technical Specifications and Standards

Pressure Ratings

- PN10: Suitable for low-pressure residential systems

- PN16: Standard for commercial applications

- PN20: High-pressure industrial installations

- PN25: Heavy-duty commercial and industrial use

Диапазон размеров

Available from 20mm to 110mm diameters. Common sizes include 25mm, 32mm, and 50mm for residential use. Industrial applications utilize larger diameters up to 110mm.

Compliance Standards

Meets ISO 15874 international standards. Certified under NSF/ANSI 14 for potable water systems. European EN 15874 compliance ensures quality consistency.

Applications Across Industries

Сантехника для жилых помещений

Hot and cold water distribution systems benefit from PPR reliability. Bathroom and kitchen installations use female thread connections for fixtures. Central heating systems require high-temperature performance.

Коммерческие здания

Office complexes demand leak-proof connections for reliability. Hotels and restaurants need food-grade certified materials. Shopping centers require long-lasting, maintenance-free solutions.

Industrial Facilities

Chemical processing plants utilize corrosion-resistant properties. Food and beverage industries need hygienic, non-toxic materials. HVAC systems benefit from thermal stability and pressure resistance.

Quality Control and Manufacturing Excellence

Production Standards

Modern extrusion equipment ensures consistent wall thickness. Computer-controlled threading machines guarantee precision cuts. Multi-stage quality testing validates each batch before shipping.

Raw Material Selection

Virgin PPR resin provides optimal performance characteristics. Metal inserts undergo corrosion resistance testing. Color additives meet food-grade safety requirements.

Factory Direct Benefits

Elimination of distribution delays ensures faster delivery. Custom sizing options accommodate unique project requirements. Technical support directly from manufacturing experts.

Installation Best Practices

Preparation Steps

Clean pipe ends thoroughly before welding. Check thread compatibility with mating components. Ensure proper heating tool calibration for consistent results.

Welding Technique

Heat both socket and pipe simultaneously. Insert pipe fully into heated socket quickly. Allow cooling period without movement for strong bond formation.

System Testing

Pressure test completed installations before commissioning. Check all connections for proper alignment and sealing. Document installation details for maintenance records.

Comparison with Alternative Connection Methods

Versus Traditional Threaded Fittings

PPR sockets eliminate thread cutting and sealing compounds. No risk of over-tightening damage to pipes. Thermal expansion compatibility prevents joint failure.

Versus Copper Fittings

Lower material costs reduce project budgets significantly. No soldering skills required for installation teams. Corrosion resistance exceeds copper performance in aggressive water conditions.

Versus PVC Solutions

Higher temperature rating suits hot water applications. Impact resistance prevents cracking during installation. Chemical compatibility covers broader range of fluids.

Selecting the Right PPR Female Thread Socket

Project Requirements Assessment

Water temperature determines pressure rating selection. Flow rates influence diameter sizing decisions. Chemical compatibility affects material grade choice.

Supplier Evaluation Criteria

Manufacturing certifications verify quality standards compliance. Direct factory relationships ensure competitive pricing. Technical support availability assists installation teams.

Long-term Cost Considerations

Initial investment compares favorably with alternatives. Maintenance costs approach zero over service life. Replacement frequency minimizes significantly with quality products.

Why Choose Direct Factory Sourcing?

Competitive Pricing Structure

Manufacturer direct pricing eliminates distributor margins. Volume discounts reward larger project commitments. Transparent cost structure builds trust with customers.

Custom Manufacturing Capabilities

Special sizes accommodate unique project requirements. Modified thread patterns match specific equipment needs. Custom colors identify different system functions.

Technical Expertise Access

Engineering support optimizes system design efficiency. Installation training ensures proper implementation techniques. Troubleshooting assistance resolves field challenges quickly.

Conclusion: Invest in Quality PPR Solutions

High-quality PPR female thread sockets deliver exceptional value for modern plumbing systems. Direct factory sourcing provides cost advantages without compromising quality standards.

Professional installers trust these connections for critical applications. Long service life and maintenance-free operation justify the investment decision.

Partner with experienced manufacturers for reliable supply chains. Quality certifications ensure compliance with international standards. Technical support maximizes installation success rates.

Contact qualified PPR socket suppliers today. Discuss your project requirements with manufacturing experts. Secure competitive pricing through direct factory relationships.

Последние комментарии