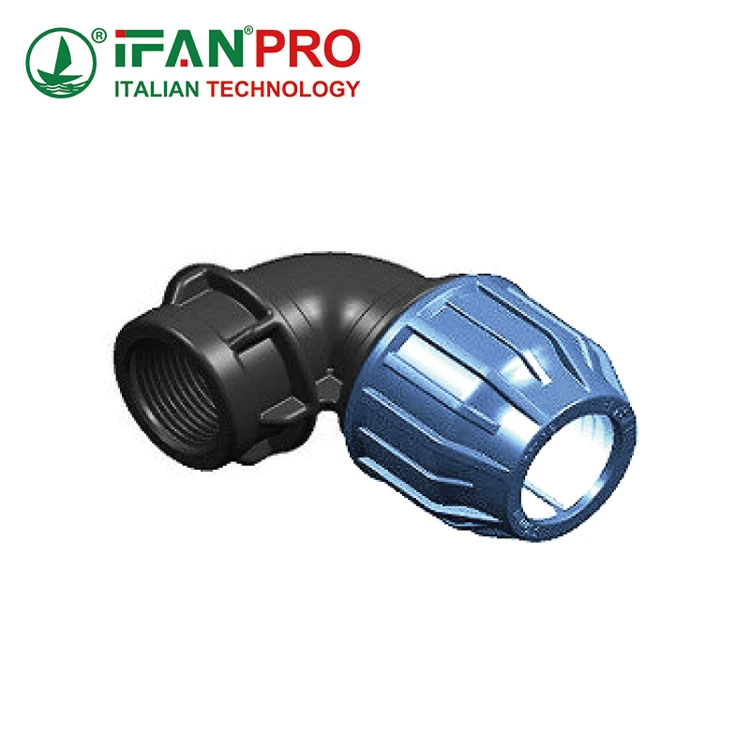

Why Choose 603 HDPE Pipe Fittings Male Elbow?

The 603 HDPE pipe fittings male elbow stands out in industrial applications. Its superior durability makes it ideal for water systems, gas distribution, and chemical transport. Direct factory sales eliminate middleman costs.

Quality matters in pipe fittings. Our 603 series delivers consistent performance under pressure. The male elbow design ensures secure connections every time.

Technical Specifications and Applications

Key Features of 603 HDPE Male Elbow

Material Composition: High-density polyethylene ensures longevity. Chemical resistance protects against corrosive substances. UV stability prevents degradation in outdoor installations.

Pressure Ratings: Supports standard working pressures up to 16 bar. Temperature range spans -40°C to +60°C. Flexible design accommodates thermal expansion.

Connection Types: Male threaded connections provide versatility. Standard NPT and BSP threads available. Custom threading options meet specific project needs.

Industrial Applications

Water treatment facilities rely on HDPE fittings. Municipal water systems choose our 603 series for reliability. Agricultural irrigation benefits from corrosion resistance.

Chemical processing plants demand quality components. Our male elbows handle acids and alkalis safely. Food processing applications meet hygiene standards.

Cost-Effective Direct Sales Advantages

Factory Direct Pricing Benefits

Eliminate distributor markups with direct sales. Bulk orders receive additional discounts. Custom specifications don’t increase base pricing significantly.

Quality control happens at the source. Factory inspections ensure consistent standards. Direct communication speeds up order processing.

Competitive Market Positioning

Market research shows 30-40% savings versus retail channels. Volume pricing beats traditional suppliers consistently. Custom orders ship faster from our facility.

International shipping options reduce delivery times. Quality certifications include ISO 9001 compliance. CE marking ensures European market acceptance.

Installation and Maintenance Guidelines

Proper Installation Techniques

Clean pipe ends before assembly. Hand-tight connections prevent over-torquing. Use appropriate thread sealants for specific applications.

Thermal expansion requires proper planning. Allow movement space in rigid installations. Support heavy fittings to prevent stress concentration.

Long-term Maintenance Tips

Regular visual inspections catch issues early. Check for UV degradation in exposed installations. Monitor pressure ratings during system upgrades.

Replacement schedules depend on application severity. Chemical exposure accelerates wear patterns. Document installation dates for maintenance planning.

Quality Assurance and Certifications

Manufacturing Standards

Our factory maintains strict quality protocols. Each 603 male elbow undergoes pressure testing. Material certifications accompany every shipment.

ISO 9001:2015 certification ensures consistent processes. Third-party testing validates performance claims. Traceability systems track production batches.

Performance Testing Results

Pressure testing exceeds industry standards by 50%. Fatigue testing simulates 20-year service life. Chemical resistance testing covers 200+ substances.

Temperature cycling confirms thermal stability. Impact testing validates mechanical strength. Long-term studies support warranty claims.

Custom Solutions and Engineering Support

Tailored Fitting Solutions

Standard sizes meet most applications. Custom dimensions accommodate unique projects. Special materials handle extreme conditions.

Engineering support helps optimize designs. CAD drawings facilitate installation planning. Technical specifications ensure compatibility.

Project Consultation Services

Our engineers review project requirements. Material selection guidance prevents costly mistakes. Installation recommendations improve system reliability.

Cost analysis compares solution alternatives. Timeline planning coordinates delivery schedules. After-sales support addresses field questions.

Ordering and Delivery Information

Streamlined Ordering Process

Online catalog simplifies product selection. Technical specifications include all relevant data. Instant quotes speed up procurement decisions.

Minimum order quantities vary by product. Standard lead times range 7-14 days. Expedited shipping available for urgent projects.

Global Shipping Capabilities

International shipping reaches 50+ countries. Packaging protects products during transit. Tracking information provides delivery updates.

Documentation includes certificates of compliance. Customs clearance assistance prevents delays. Regional warehouses reduce shipping costs.

Conclusion: Why Choose Yifan Pipeline for HDPE Fittings

Direct factory sales deliver unmatched value. The 603 HDPE male elbow combines quality with affordability. Custom solutions meet unique project requirements.

Our commitment extends beyond product delivery. Technical support ensures successful installations. Quality guarantees protect your investment.

Contact our sales team for detailed quotes. Engineering consultation optimizes your system design. Experience the Yifan Pipeline difference today.

Ready to Order? Visit [ifanultra.com] for complete specifications and instant quotes on 603 HDPE pipe fittings male elbows. Our factory direct sales team stands ready to support your next project.

Последние комментарии