СМИ

Главная " СМИ

30 лет истории бренда

100+ агентов по всему миру

Немецкое технологическое оборудование

Десять серий закупок по принципу "одного окна

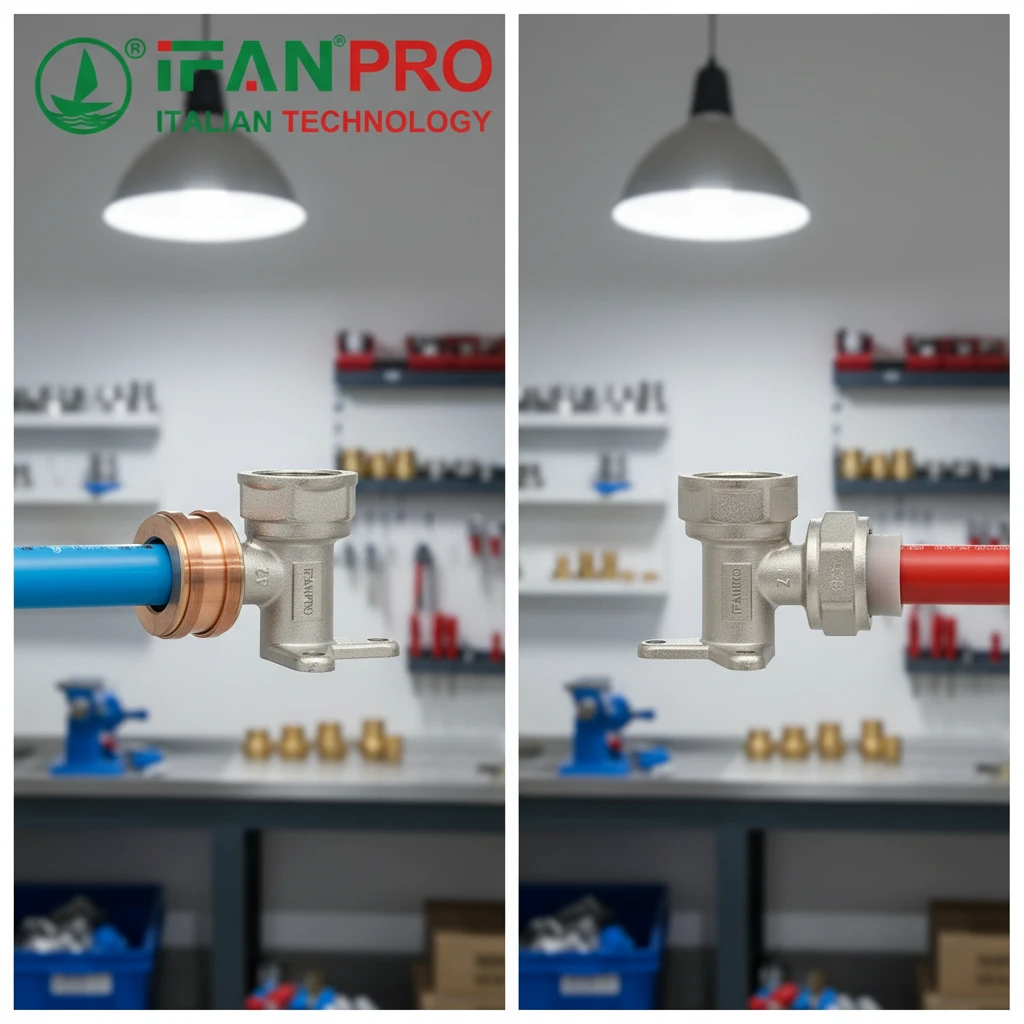

How to Install a PEX Female Seated Elbow for Stable Pipe Turns?

I once saw a poorly seated PEX elbow cause a leak that ruined a finished wall. That costly mistake taught me that correct installation is

Why Choose a Seated Elbow with Female Threads for PEX-to-Fixture Connections?

I’ve watched plumbers struggle with a tangle of pipes and brackets inside a vanity. This messy scene shows exactly why the seated elbow is a

Can the Seated Design Prevent Stress on PEX Female Threaded Joints?

I’ve seen too many failed PEX connections where the pipe tore right at the thread. This common failure led us to champion a smarter solution:

Does This Elbow Ensure a Leak-Proof Seal at the Female Connection Point?

I’ve seen too many projects delayed by a single dripping connection. The promise of a leak-proof seal is what every installer relies on from the

How Does the Seat Provide Extra Support in PEX Plumbing Systems?

I once inspected a PEX installation where a loose pipe shook violently with every faucet turn. The problem wasn’t the fittings—it was the missing support.

Are Female Seated Elbows Ideal for Connecting PEX to Shower Valves?

After years of seeing plumbers struggle with awkward shower valve connections, I can confidently say the right fitting changes everything. The female seated elbow is

Can This Fitting Withstand Thermal Cycling in PEX Hot Water Lines?

I’ve seen too many callbacks for leaks where a hot water line meets a rigid fitting. This common failure is exactly why the right connection

Why Use a Female Seated Elbow Instead of a Standard PEX Bend?

I once saw a sink faucet wobble and leak because the connection underneath was weak. That moment proved why choosing the right fitting matters more

How to Ensure Proper Alignment with a PEX Female Seated Elbow?

I once saw a misaligned PEX elbow cause a persistent leak months after installation. That headache taught me that perfect alignment isn’t just careful—it’s critical.

Is the Seated Design Compatible with Different PEX Installation Methods?

I once saw an installer struggle for an hour because a fitting wouldn’t work with his tool. That moment proved that true compatibility is everything

What Are the Emerging Trends in Global Pipe Fitting Materials?

Last year, a client demanded a pipe material that didn’t exist five years ago. This moment showed me the industry is changing faster than ever.

How to Build a Resilient Supply Chain for Plumbing Projects?

I once saw a multi-million dollar project stall for weeks because one factory shut down. That moment taught me that true supply chain resilience is