Factory direct sales offer the best value for PVC pipe threaded couplings. Skip the middleman markup and get professional-grade components at wholesale prices.

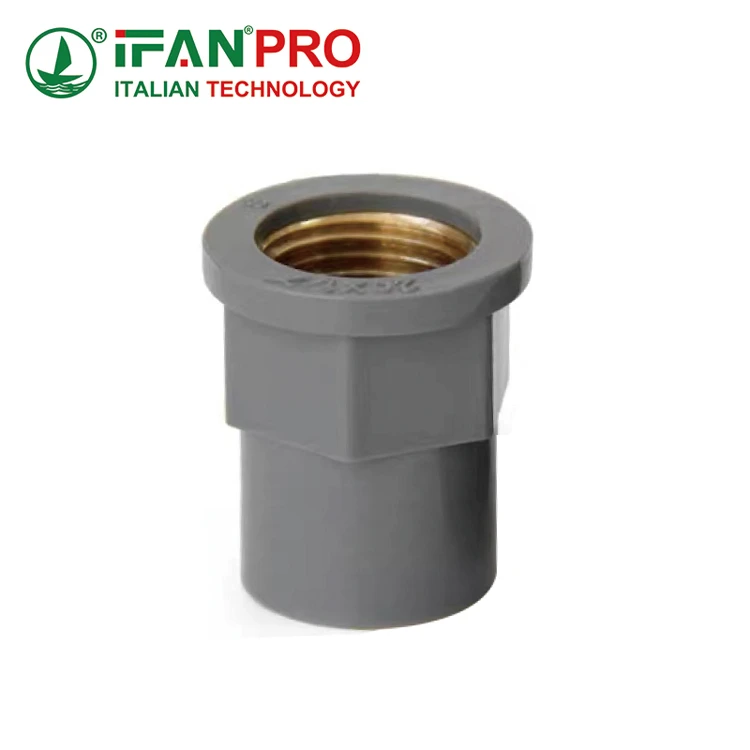

What Are PVC Pipe Threaded Couplings?

Threaded couplings connect two pipes with matching threads. These fittings create secure, leak-proof joints in plumbing systems. The internal threads grip pipe ends tightly, forming reliable connections.

PVC material resists corrosion and chemical damage. It handles temperature fluctuations better than metal alternatives. Installation requires no special tools or welding equipment.

Benefits of Factory Direct Purchasing

Cost Savings

Direct sales eliminate distributor markups. You pay manufacturing costs plus minimal profit margins. Bulk orders unlock additional discounts.

Quality Assurance

Factory oversight ensures consistent manufacturing standards. Each coupling undergoes quality testing before shipment. Direct communication resolves issues quickly.

Customization Options

Factories accommodate special requirements easily. Custom thread patterns, sizes, and materials are available. Small modification runs cost less than expected.

Key Specifications to Consider

Thread Types: NPT, BSP, and metric threads serve different applications. NPT threads work best in North American systems. BSP threads suit European and Asian markets.

Pressure Ratings: Standard couplings handle 200-600 PSI safely. High-pressure versions support up to 1000 PSI. Match ratings to your system requirements.

Size Range: Common sizes span 1/2 inch to 12 inches. Larger diameters require special manufacturing processes. Confirm availability before ordering.

Wall Thickness: Schedule 40 and Schedule 80 options provide different strength levels. Schedule 80 offers superior durability for demanding applications.

Manufacturing Process Overview

Quality begins with premium PVC resin selection. Injection molding creates precise thread patterns. Computer-controlled machines ensure dimensional accuracy.

Heat treatment strengthens the final product. Surface finishing removes imperfections. Each piece undergoes pressure testing before packaging.

Installation Best Practices

Clean pipe ends remove debris and old sealant. Apply thread sealant or tape clockwise on male threads. Hand-tighten first, then use wrenches carefully.

Over-tightening cracks PVC threads easily. Stop when resistance increases significantly. Test connections at operating pressure before final installation.

Common Applications

Residential Plumbing: Water supply lines, drain systems, and irrigation networks rely on threaded couplings. Easy installation suits DIY projects.

Industrial Systems: Chemical processing, water treatment, and manufacturing facilities use heavy-duty versions. Corrosion resistance extends service life.

Agricultural Irrigation: Farm irrigation systems demand reliable connections. UV-resistant formulations prevent degradation from sun exposure.

Quality Standards and Certifications

Reputable factories maintain ISO 9001 certification. ASTM D2466 standards govern PVC fitting specifications. NSF approval ensures drinking water safety.

Third-party testing validates pressure ratings. Material certifications confirm chemical composition. Documentation supports warranty claims.

Ordering Process Simplified

Contact factories with your specifications directly. Request samples for testing and approval. Negotiate pricing based on quantity requirements.

Production timelines vary by complexity and order size. Standard items ship within 2-3 weeks. Custom products may require 4-6 weeks.

Cost Factors That Matter

Raw material prices fluctuate with oil markets. Complex geometries increase manufacturing costs. Rush orders carry premium charges.

Shipping methods affect total delivered costs. Sea freight suits large orders economically. Air freight serves urgent requirements quickly.

Maintenance and Longevity

PVC couplings require minimal maintenance. Visual inspections catch early problems. Replace fittings showing stress cracks immediately.

Proper installation extends service life significantly. Avoid temperature extremes when possible. Chemical compatibility prevents premature failure.

Why Choose Factory Direct Sales

Direct relationships provide technical support access. Engineering teams assist with complex applications. Custom solutions develop faster through direct communication.

Quality issues resolve quickly without intermediaries. Warranty claims process efficiently. Long-term partnerships offer pricing stability.

Factory direct sales maximize your investment value while ensuring reliable performance. Professional-grade PVC pipe threaded couplings support critical applications across industries.

Connect with manufacturers directly for competitive pricing and expert guidance. Quality components delivered on schedule keep projects moving forward successfully.

Recent Comments