I once rushed a PVC repair job, and the joint failed under pressure. That moment taught me that understanding how PVC glue works is the key to a permanent seal.

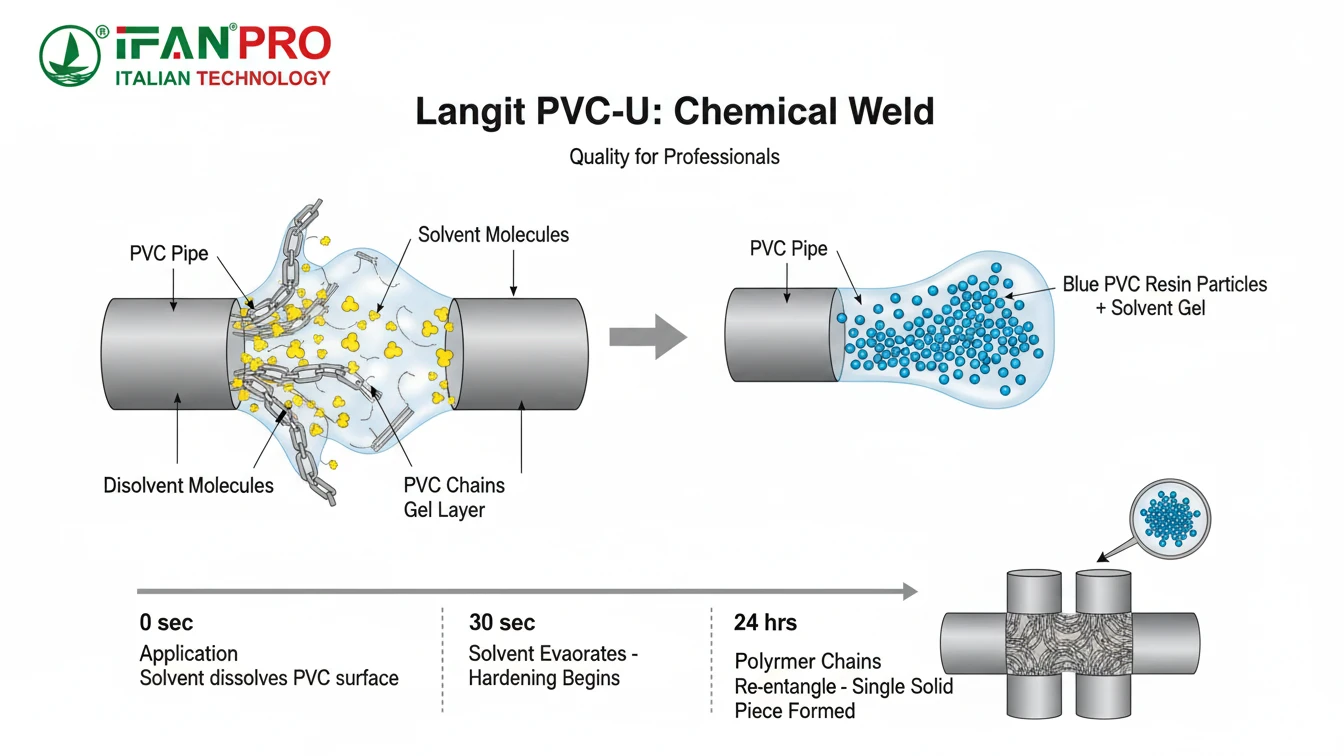

PVC glue, or cement, sets and cures quickly through a two-step process: first, powerful solvents melt the surface of the PVC, and second, the PVC resin in the cement then fuses the softened surfaces together into a single, solid piece of plastic as the solvents evaporate. This chemical welding creates a bond stronger than the original pipe.

So, let’s break down the science and factors behind this fast and strong bond to ensure your projects are successful.

What Chemical Reaction Causes PVC Glue to Dry and Bond So Fast?

Many people think PVC glue is just a sticky adhesive. This misunderstanding leads to weak joints. The truth is more like a chemical weld.

PVC cement creates a fast bond through a chemical welding process, not just adhesion. Strong solvents first dissolve the PVC surfaces, turning them into a gel. Then, the PVC resin in the cement mixes with this gel. As the solvents quickly evaporate, the PVC resin hardens, permanently fusing the pipes and fittings together into one homogenous piece.

It’s Not Glue, It’s Solvent Cement

First, you must know that “PVC glue” is not actually a glue. Glues work by sticking to surfaces. PVC cement works by melting and fusing the plastic. This is why it’s called “solvent welding.”

The process depends on two main ingredients: solvents and PVC resin.

The Role of Solvents

The solvents are the key to speed. They are very aggressive chemicals, like tetrahydrofuran (THF) or methyl ethyl ketone (MEK). When you apply the cement, these solvents instantly attack the surface of the PVC pipe and fitting.

- They break down the hard PVC plastic.

- They turn the surface into a soft, gel-like material.

- This allows the pipe and fitting materials to mix together.

Think of it like welding metal. You melt the edges of two metal pieces, and they flow together. The solvents do the same thing to plastic, but without heat.

The Role of PVC Resin

The cement also contains tiny particles of PVC resin. While the surfaces are soft and melted:

- These resin particles fill in the tiny gaps between the pipe and fitting.

- They mix thoroughly with the dissolved PVC from the pipe and fitting.

- This creates a thick mixture of PVC material in the joint.

The Setting and Curing Process

Now, for the fast part: evaporation and hardening.

- Setting (Fast): The solvents evaporate into the air very quickly. This starts within seconds. As they evaporate, the soft, gel-like mixture begins to harden. This is the “set.” The joint feels dry and can handle some light pressure quickly, often within 1-5 minutes.

- Curing (Slower): After the solvents are gone, the PVC resin and the fused plastic continue to harden and gain strength. This is the “cure.” During this time, the polymer chains re-form and entangle across the joint, creating a single, solid piece.

The Final Result: A Homogeneous Joint

The final joint has no distinct boundary between the pipe and the fitting. It is a seamless, monolithic piece of PVC. This is why a properly made solvent-welded joint is stronger than the pipe itself. The pipe will burst before the joint fails.

Key Takeaway: The speed comes from the rapid evaporation of powerful solvents, initiating the chemical fusion process almost immediately.

How Do Temperature and Humidity Affect PVC Cement Curing Time?

Ignoring the weather is a top reason for joint failure. Applying cement on a cold, damp day is very different from a warm, dry one.

Temperature and humidity dramatically affect curing time. Low temperatures slow down solvent evaporation and the chemical welding process, leading to a very long, weak cure. High humidity can cause moisture to contaminate the joint, preventing proper fusion and creating a brittle, failed connection.

The Impact of Temperature

Temperature is the most critical factor. It affects both the chemical reaction and the physical evaporation.

In Cold Conditions (Below 50°F / 10°C):

- Problem: The solvent evaporates very slowly.

- Result: The PVC surfaces do not melt and soften enough. The cement stays wet for a long time. The final joint will be weak because the chemical fusion never properly happens.

- What to do: You must warm the pipes and the cement can. Use a heat gun carefully (do not overheat) or store materials in a warm space before use.

In Hot Conditions (Above 90°F / 32°C):

- Problem: The solvent evaporates too quickly.

- Result: The cement may start to dry before you can fully assemble the joint. This leads to a “skin” forming, which blocks proper fusion. The joint may also appear stringy or rough.

- What to do: Work faster. Assemble the joint immediately after applying cement. Consider working in the shade.

The Impact of Humidity

High humidity, especially above 60%, poses a hidden threat: moisture contamination.

How Moisture Ruins a Joint:

- When you apply cement, moisture in the air can condense on the cold surface of the PVC pipe.

- This water gets trapped between the pipe and the cement.

- The solvents in the cement cannot dissolve PVC properly if water is present.

- The result is a poor fusion, leaving the joint weak and prone to cracking.

Practical Guidelines Table

Use this table as a quick guide for ideal application conditions:

| Condition | Effect on Cure | Risk | Practical Advice |

|---|---|---|---|

| Low Temp (<50°F/10°C) | Slows drastically | Weak, incomplete fusion | Warm pipes & cement. Use cold-weather formula cement. |

| Ideal Temp (60-80°F / 16-27°C) | Optimal speed & strength | Minimal | Standard application procedures apply. |

| High Temp (>90°F/32°C) | Accelerates too much | Skin-over, poor fusion | Work very quickly in the shade. Assemble immediately. |

| High Humidity (>60%) | Interferes with fusion | Moisture contamination, brittleness | Wipe pipes dry. Work indoors if possible. Use primer. |

Always read the manufacturer’s instructions on the can, as they provide the best temperature and humidity range for their specific product.

Why Do Some PVC Glues Set Faster Than Others on the Market?

Choosing the wrong cement can ruin your project timeline. Not all PVC cements are the same, and their speed is a deliberate design choice.

Some PVC glues set faster because they contain a higher percentage of more volatile (fast-evaporating) solvents and a lower viscosity (thinner formula). Manufacturers create different formulas—like “fast-set,” “medium-set,” and “heavy-duty”—to give professionals the right tool for specific jobs, such as small pipes in tight spaces or large-diameter pressure pipes.

Formula Design: The Recipe for Speed

Manufacturers change the “recipe” of their cement to control setting time. Here are the main factors:

1. Solvent Type and Amount:

- Fast-Set Cements: Use a high percentage of the most aggressive, fastest-evaporating solvents (e.g., THF). This causes rapid surface melting and drying.

- Medium-Set/All-Purpose Cements: Use a balanced blend of solvents for a reliable, workable set time suitable for most jobs.

- Heavy-Duty Cements: May use stronger solvents but often have a thicker consistency, which can slow the evaporation slightly for deeper fusion on large pipes.

2. Viscosity (Thickness):

- Thinner Cements: Flow and penetrate faster. The solvents reach the PVC material quickly and also evaporate faster. This leads to a quicker set.

- Thicker Cements: Are designed to stay in the joint longer, especially on large pipes or in vertical applications. They allow for a longer working time and deeper fusion but set more slowly.

3. Additives:

- PVC Resin Content: More resin can make the cement thicker and slightly slower to set, but it contributes to greater final strength and gap filling.

- Fillers and Colors: Some cements include fillers for extra bulk or blue/clear colors for inspection purposes. These can affect flow and set time.

Product Comparison Table

This table shows typical characteristics based on common product labeling:

| Product Type | Typical Set Time | Key Features | Best Use Case |

|---|---|---|---|

| Fast-Set Cement | 1-2 minutes | Very low viscosity, high volatile solvents. | Small diameter pipes (up to 2″), repairs, tight spaces where you need pressure quickly. |

| Medium-Set/All-Purpose | 2-5 minutes | Balanced formula, medium viscosity. | The most common choice for general plumbing, pipes from 1/2″ to 4″. Reliable and forgiving. |

| Heavy-Duty Cement | 5+ minutes | High viscosity, high resin/solids content. | Large diameter pipes (4″ and above), pressure pipes, or situations requiring superior gap filling. |

| Cold-Weather Cement | Adjusted for cold | Special solvents that evaporate in low temps. | Any outdoor or unheated space work where temperatures are below 50°F (10°C). |

Important Note: Faster is not always better. A fast-set cement on a large pipe can skin over before you complete assembly. Conversely, a slow-set cement on a small repair is inefficient. Matching the cement to the job is a mark of a professional.

How Can You Test if PVC Glue Has Fully Cured for Maximum Strength?

A joint that looks dry can still be dangerously weak. Putting a system under pressure too soon is a common and costly mistake.

You cannot reliably test a PVC joint for full cure without damaging it. Therefore, you must follow the manufacturer’s recommended cure times before applying pressure. For a visual check, look for a uniform, glossy weld bead and no softness when scraped with a fingernail. The only true test is time under recommended conditions.

Understanding Cure Time vs. Set Time

This is the most critical concept for strength:

- Set Time: This is when the solvents evaporate, and the joint is dry to the touch. It can handle its own weight. It is NOT ready for pressure.

- Cure Time: This is the time needed for the chemical fusion to complete and reach maximum strength. This can take several hours, even if the joint feels dry.

Steps for a Basic Visual and Tactile Check

While not a strength test, these checks can indicate a poor joint:

- Inspect the Weld Bead: Look for a continuous, uniform bead of cement around the joint. It should be glossy and smooth. A missing, cracked, or bubbly bead suggests improper application or contamination.

- The Fingernail Test: After the recommended initial cure time (e.g., 2 hours), gently try to scrape the weld bead with your fingernail. It should feel hard. If it is soft or gummy, the cure is not complete.

- Tap Test: Lightly tap the pipe and fitting with a plastic screwdriver handle. A fully cured joint will have a solid, consistent sound. A hollow or different sound at the joint may indicate a problem (but this requires experience).

Why There is No Instant “Pass/Fail” Test

You cannot bend or pressure test the joint without potentially causing micro-fractures in the still-curing plastic. The bond gains strength gradually as the polymer chains fully intertwine. Testing it early breaks these forming chains, creating a permanent weak point.

Recommended Safe Handling Times

The best practice is to follow the manufacturer’s chart religiously. Here is a general example for medium-set cement at 60-80°F:

| Time After Assembly | Joint Status | What You Can Do |

|---|---|---|

| 15-30 minutes | Set / Handled | Carefully move the assembled pipe. Do NOT pressurize. |

| 2 hours | Initial Cure | Light pressure (e.g., filling the system for a test). |

| 24 hours | Full Cure | Apply full operating pressure. This is the standard safe wait time. |

| 48 hours | Maximum Strength | The joint has reached its ultimate strength. |

The Ultimate “Test”: A Pressure Test

The definitive confirmation of a good joint is a successful hydrostatic pressure test. This is done after the recommended full cure time (usually 24 hours).

- Cap the system and fill it with water.

- Use a pump to raise the pressure to 1.5 times the system’s normal operating pressure (check local codes).

- Hold the pressure for a specified time (e.g., 30 minutes to 2 hours).

- If the pressure holds steady with no drops or visible leaks, all joints have passed the test.

For guaranteed reliable results, always use high-quality products from trusted manufacturers like IFAN, and follow their instructions precisely.

Conclusion

PVC glue works fast through chemical welding, but full strength requires patience and the right conditions. For strong, reliable joints every time, use IFAN’s professional-grade PVC cements and primers designed for consistent performance.

Recent Comments