I once saw a DIY project fail because someone used the wrong glue on a CPVC pipe. The joint never set right and started leaking within a week. This taught me that not all plastic pipe glues are the same.

No, one PVC glue cannot work on all types of plastic pipe. Different plastics, like PVC, CPVC, and ABS, have different chemical compositions. A glue or cement that works perfectly on one type may not create a strong bond on another, and it can even damage the pipe, leading to leaks and system failure.

If you try to use the wrong glue, you risk the integrity of your entire plumbing system. Let’s look at why this happens and how to make the right choice.

What are the Main Plastic Pipe Materials That Require Different Adhesives?

When you walk into a hardware store, you see many kinds of plastic pipes. It is easy to think they are all the same, but they are not.

The main plastic pipe materials that need different adhesives are PVC (Polyvinyl Chloride), CPVC (Chlorinated Polyvinyl Chloride), and ABS (Acrylonitrile Butadiene Styrene). Each plastic has a unique chemical makeup, so manufacturers make specific cements designed to chemically weld each one.

Understanding the Different Plastics

First, you need to know what you are working with. The most common plastic pipes in home and industrial use are PVC, CPVC, and ABS.

PVC is the white or cream-colored pipe you often see for drain lines, irrigation, and non-pressure applications. CPVC is a light yellow or off-white pipe. It is similar to PVC but is specially treated with chlorine to handle higher temperatures. This makes it common for hot and cold water supply lines inside homes. ABS is a black pipe that is used mainly for drain, waste, and vent (DWV) systems.

Why They Need Different Glues

These materials are not the same. Think of them like different types of wood. You would not use the same strong glue for a piece of soft pine as you would for a piece of hard oak. The same logic applies here.

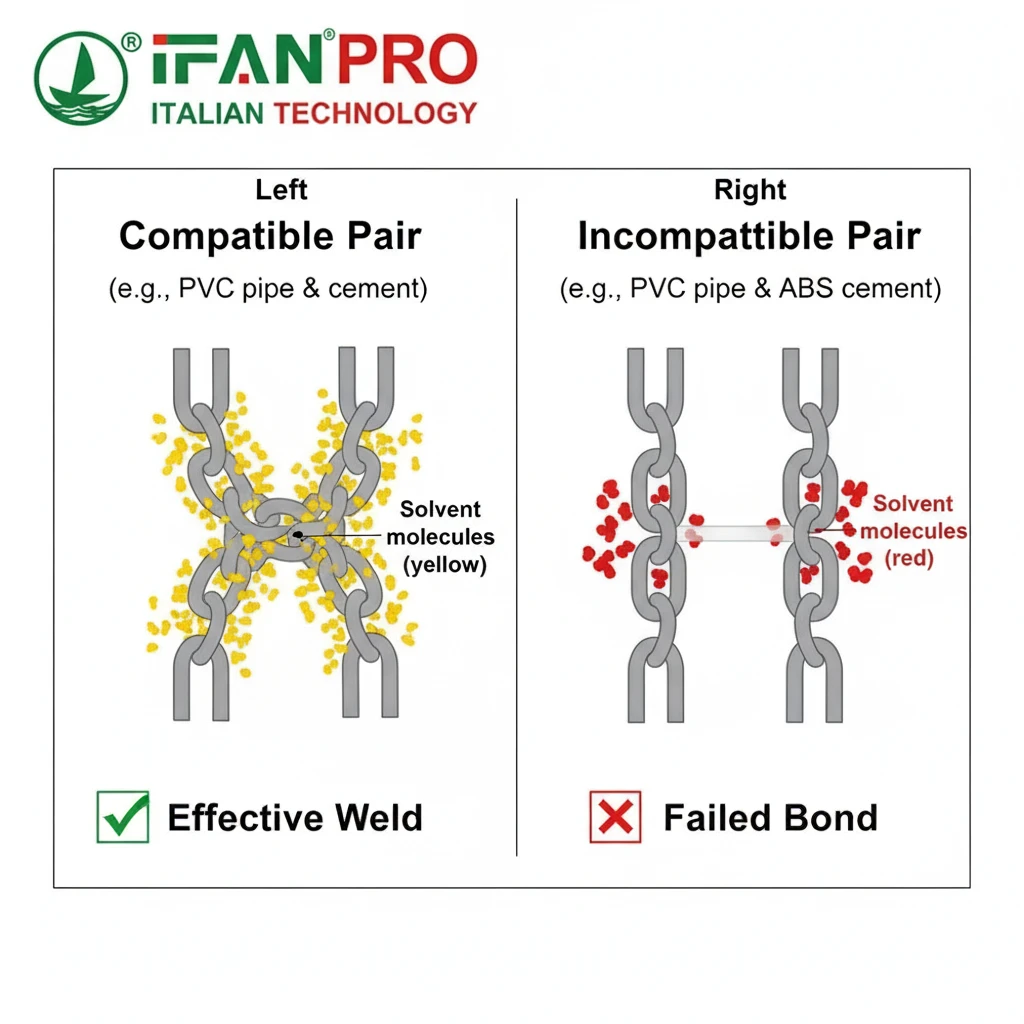

The glue for plastic pipes is not really a glue. It is a solvent cement. It works by chemically melting the surface of the plastic. When you push the pipe and fitting together, the melted surfaces mix. As the solvent evaporates, the plastics re-harden into a single, solid piece. This process is called solvent welding.

Because PVC, CPVC, and ABS have different chemical formulas, they need different solvents to melt them properly. A PVC cement has a solvent mixture designed for standard PVC resin. A CPVC cement has a stronger, different solvent blend to work on the chlorinated material. ABS cement is formulated for ABS plastic.

Quick Reference Guide

The table below shows the key differences:

| Pipe Material | Common Color | Primary Uses | Key Property |

|---|---|---|---|

| PVC | White, Gray | Drainage, Irrigation, Cold Water | Rigid, cost-effective |

| CPVC | Light Yellow, Cream | Hot & Cold Potable Water Supply | Heat resistant |

| ABS | Black | Drain, Waste, Vent (DWV) Systems | Tough, impact resistant |

Using the wrong cement is like using the wrong key. It will not work correctly. For example, using a standard PVC cement on CPVC might not create a full chemical weld because the solvents are not strong enough to melt the CPVC surface completely. This makes a weak joint that can fail under pressure or over time.

Why Does Chemical Compatibility Matter When Choosing Pipe Glue or Cement?

Choosing glue based only on color or a guess can lead to big problems. Chemical compatibility is the most important rule.

Chemical compatibility matters because the cement must soften the pipe’s surface to create a weld. If the chemicals are not compatible, they will not melt the plastic correctly. This results in a weak bond that can crack or leak immediately or fail months later under stress.

The Science of a Strong Joint

The goal is to create a permanent, leak-proof connection. A mechanical joint can come loose, but a proper solvent weld makes the pipe and fitting one piece.

For this to happen, the solvents in the cement must be compatible with the plastic’s chemistry. When you apply the right cement, it dissolves a thin layer of the plastic. You then quickly join the pieces. The dissolved plastics from the pipe and fitting mix together. As the solvent evaporates, this mixture hardens into a new, solid material that holds everything together.

What Happens with Incompatible Chemicals?

If the chemicals are not compatible, several bad things can happen:

- No Bond: The solvent might not soften the plastic at all. The cement will just sit there like a sticky coating. When you push the pipe in, it will not weld. The joint may hold for a short while from friction, but it will fail easily.

- Weak Bond: The solvent might soften the surface a little, but not enough. This creates a shallow, weak weld. The joint might pass a simple test but will crack under temperature changes or water pressure.

- Damage: In the worst case, the wrong chemical can actually attack the plastic. It can make the pipe material brittle or cause it to craze (create tiny cracks). This damage weakens the pipe itself, not just the joint, and can lead to catastrophic failure.

Think of it like this: water is compatible with salt; it dissolves it. But water is not compatible with oil; they separate. You need the right “liquid” to dissolve your specific “solid.”

Real-World Impact of Incompatibility

In our work at IFAN, we have seen clients face costly callbacks because of this issue. A plumber might use a general-purpose “plastic glue” on a CPVC water line to save time. The joint may hold during initial testing. However, when hot water runs through the pipe, the thermal expansion stresses the weak joint. A slow leak develops inside the wall, causing mold and water damage that costs thousands to repair. This problem was entirely preventable by using the correct CPVC cement.

What are the Risks of Using Incorrect Glue on Plastic Plumbing Pipes?

The risk is much higher than just a simple leak. Using the wrong glue can compromise your safety and cause major damage.

The risks of using incorrect glue include immediate joint failure, slow leaks that cause hidden water damage, toxic chemical leaching into drinking water, and reduced pressure rating of the entire system. This leads to expensive repairs, health hazards, and potential property damage.

Risk 1: Joint Failure and Leaks

This is the most obvious risk. A joint that is not properly welded will leak. This can happen right away when you pressurize the system, or it can happen slowly over time. A slow leak is often worse because it can go unnoticed for months, rotting wood, promoting mold growth, and damaging drywall and insulation. The repair cost for the water damage can be many times more than the cost of the original plumbing job.

Risk 2: Chemical Contamination

This is a serious health risk, especially for drinking water lines (potable water). Solvent cements contain strong chemicals. When used correctly on the right pipe, these chemicals fully evaporate and cure. If used on the wrong pipe, the chemical reaction may not complete. This means unreacted solvents can stay trapped in the joint. Over time, these chemicals can leach into your drinking water. Always use cements that are certified for potable water (like NSF-PW) on any pipe that carries water for drinking or cooking.

Risk 3: Reduced System Strength and Pressure Rating

A plumbing system is rated to handle a certain amount of water pressure. A perfect solvent weld restores the joint to nearly the full strength of the pipe itself. A bad weld is the weakest point in the system. Under high pressure or a pressure surge (water hammer), this weak point can blow apart or crack. This can cause a sudden flood. Even if it does not burst, the system’s overall safe pressure rating is now lower than designed.

Summary of Potential Consequences

The table below outlines the key risks:

| Type of Risk | Short-Term Consequence | Long-Term Consequence |

|---|---|---|

| Mechanical Failure | Joint leaks or separates during pressure test. | Slow leak causes hidden structural damage and mold. |

| Chemical Contamination | Water may have a strong chemical smell or taste. | Health risks from long-term ingestion of leached solvents. |

| System Weakness | Joint may crack under minor stress. | Catastrophic pipe failure or burst during pressure spikes. |

In short, the few dollars and minutes you might save by using the wrong glue are not worth it. The potential consequences are too severe. Always take the time to identify your pipe and use the cement made for it.

How Do You Select the Right Cement for Your Specific Plastic Pipe Type?

The process is simple if you follow clear steps. Do not guess; always check.

You select the right cement by first identifying the pipe material (check the printing on the side), then choosing a cement labeled specifically for that material, and finally ensuring the cement is rated for your application (e.g., potable water, pressure). Always follow the manufacturer’s instructions on the can for the best results.

Step-by-Step Selection Guide

Selecting the right product is easy when you know what to look for. Here is a simple guide to follow for every project.

Step 1: Identify the Pipe.

Look for printed markings on the side of the pipe. This is the most reliable method. The printing will say something like “PVC 1120,” “CPVC 4120,” or “ABS DWV.” The pipe color is a good clue, but always check the printing, as colors can fade or be non-standard.

Step 2: Read the Cement Label.

Go to the store and look at the cans of cement. The front label will clearly say “PVC Cement,” “CPVC Cement,” or “ABS Cement.” Some are “All-Purpose” or “Multi-Purpose,” but you must check the fine print to see which materials they list. When in doubt, choose the dedicated, specific product.

Step 3: Check for Applicator Ratings.

Consider your project’s needs:

- Potable Water: If the pipe will carry drinking water, the cement must be certified for potable water (look for NSF-PW or similar on the label).

- Pressure vs. Drainage: For pressurized water lines, use a cement rated for pressure. For drain lines, a standard cement is usually fine.

- Set Time: Cements come in “regular,” “fast-set,” and “slow-set” varieties. Fast-set is good for small repairs where you need water back on quickly. Slow-set is better for large projects or hot weather, as it gives you more working time.

Pro Tips from the Field

Based on IFAN’s experience helping clients, here is some practical advice:

- Never Mix and Match: Do not use PVC cement on CPVC or ABS, and do not use ABS cement on PVC. They are not interchangeable.

- Prime When Required: For PVC and CPVC, using a primer (the purple or clear liquid) before the cement is a required step for pressure systems. It pre-softens the plastic for a deeper, stronger weld. While some “no-primer” cements exist, following the local plumbing code (which often requires primer) is the safest practice.

- Buy from Reputable Brands: Quality varies. A reputable cement from a known pipe manufacturer ensures chemical compatibility and reliable performance.

- Match the Manufacturer: For critical applications, using the cement brand recommended by the pipe manufacturer is the best way to guarantee a perfect weld and often maintains the pipe’s warranty.

Cement Selection Checklist

Use this table as a quick guide:

| Your Pipe Material | Look for Cement Labeled As: | Potable Water Safe? | Primer Usually Needed? |

|---|---|---|---|

| PVC | PVC Cement | Yes, if marked NSF-PW | Yes, for pressure applications |

| CPVC | CPVC Cement | Yes, if marked NSF-PW | Yes |

| ABS | ABS Cement | No (not used for potable water) | No |

By following these steps, you ensure a safe, strong, and long-lasting plumbing system. The right cement is a small detail that makes a huge difference.

Conclusion

Using the correct solvent cement is critical for a safe and lasting plumbing system. For reliable PVC, CPVC pipes, and the right matching cements, trust IFAN to supply certified, compatible materials for your project.

Recent Comments