Table of contents

隐藏

1. Introduction: The Critical Role of Custom Brass Ball Valves in Industrial Systems

- Explain the importance of ball valves in controlling fluid flow, pressure, and direction in pipelines.

- Highlight challenges in standard valves (mismatched specs, limited materials) and the rise of custom solutions for precision engineering.

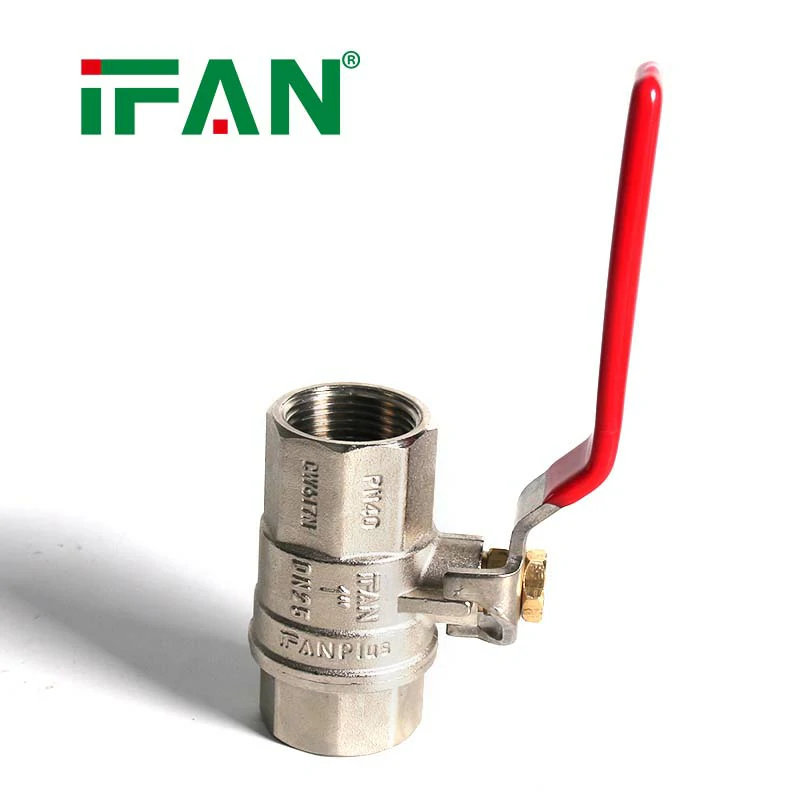

- Introduce Valve 81067 as a flagship brass ball valve designed for OEM/ODM needs, ideal for industries like oil & gas, plumbing, and manufacturing.

2. What Makes Brass Ball Valve 81067 a Hot Choice for Customization?

- Premium Brass Construction:

- Corrosion-resistant lead-free brass (e.g., C37700, CZ121) for durability in water, gas, and low-viscosity fluid applications.

- High tensile strength (up to 600 PSI) and temperature resistance (-20°C to 180°C) for harsh environments.

- Precision Engineering Features:

- Full-port design for minimal pressure drop and optimal flow efficiency.

- Double-seated Teflon/VITON® seals for bubble-tight shutoff and chemical compatibility.

- Lever, gear, or electric actuator options for manual or automated operation.

- Model 81067 Core Specs:

- Sizes: 1/2″ to 4″ (NPT, BSP, or custom threads).

- End connections: Threaded, flanged, socket weld, or butt weld (tailored to project needs).

3. Customization Options: How to Tailor Valve 81067 to Your Needs

- Material & Finish Customization:

- Brass alloys (naval brass, red brass) for saltwater or high-temperature use.

- Surface treatments: Nickel plating, chrome plating, or passivation for enhanced corrosion resistance.

- Functional Design Tweaks:

- Anti-static devices for explosive environments.

- Drain ports or extended stems for underground/remote installations.

- Custom pressure/temperature ratings to meet ASME, EN, or ISO standards.

- Branding & Packaging:

- Laser-engraved logos, serialized numbering, or custom color-coding for easy identification.

- Bulk packaging with anti-rust film or industry-specific certifications (e.g., CE, NSF, WRAS).

4. Ideal Applications: Where Custom Brass Ball Valve 81067 Shines

- Industrial Processes:

- Oil refineries (control of crude oil, lubricants).

- Chemical plants (corrosive media like sulfuric acid).

- Water treatment (potable water systems, wastewater recycling).

- Commercial & Residential Use:

- HVAC systems (hot/cold water regulation).

- Fire protection (quick-acting shutoff in sprinkler lines).

- Plumbing fixtures (high-traffic commercial buildings).

- Case Example: A Middle Eastern construction firm reduced leakage by 40% by specifying Valve 81067 with custom flange connections for a high-rise project.

5. Why Choose Our Factory for Custom Brass Ball Valve 81067?

- Direct Factory Pricing:

- Eliminate distributor markups: Competitive rates for orders as low as 500 units (MOQ flexible for prototypes).

- End-to-End Customization Process:

- Consultation: Engineers review blueprints/specs (CAD, PDF, or sample).

- Rapid Prototyping: 3D-printed samples in 72 hours; physical prototypes with T0 tooling in 2 weeks.

- Quality Assurance: 100% pressure testing (air/water), material certification (PMI reports), and ISO 9001:2015 compliance.

- Global Logistics:

- DDP shipping via DHL/FedEx (7-10 days) or sea freight (20-30 days).

- Export documentation handled: CO, Form E, or ATA Carnet as needed.

6. How to Purchase: A Step-by-Step Guide for Buyers

- Step 1: Define Your Requirements:

- List critical specs: size, pressure rating, fluid type, and end connections.

- Download our Customization Checklist (link to PDF resource on your site).

- Step 2: Request a Quote:

- Submit RFQ via Contact Form with drawings/specs.

- Get a detailed quote in 24 hours, including tooling costs (if applicable).

- Step 3: Prototype & Approval:

- Test prototypes for fit/function; iterate designs at no extra cost (up to 3 revisions).

- Step 4: Production & Delivery:

- Mass production timeline: 4-6 weeks after final approval.

- Track orders via dedicated customer portal (real-time updates on casting, machining, and QC).

7. Common Questions About Custom Brass Ball Valves

- Q: Can Valve 81067 handle gaseous media?

- A: Yes—rated for air, natural gas, and LPG with appropriate seal materials (e.g., NBR for gas).

- Q: What’s the lead time for fully custom designs?

- A: 8-10 weeks from design approval (including tooling and testing).

- Q: Do you offer after-sales support?

- A: 2-year warranty; 24/7 technical support for installation and maintenance.

8. Ready to Optimize Your System with a Tailored Solution?

- Recap key benefits: corrosion resistance, customizable specs, factory-direct efficiency, and global compliance.

- Call to Action:

- Explore Valve 81067 Details: Visit Product Page for specs, CAD drawings, and certification downloads.

- Start Your Custom Project: Submit an RFQ today or chat with our engineers via live chat (available 9 AM–6 PM UTC+8).

- Stay Informed: Subscribe to our newsletter for case studies, industry insights, and exclusive discounts.

Conclusion: Custom Brass Ball Valve 81067—Engineered for Your Unique Needs

Position your factory as a partner in solving complex fluid control challenges, not just a supplier. Emphasize precision, speed, and reliability to convert buyers seeking tailored industrial solutions.

Recent Comments